Documente Academic

Documente Profesional

Documente Cultură

Handouts Specs

Încărcat de

Eugene Miras0 evaluări0% au considerat acest document util (0 voturi)

14 vizualizări2 paginiTitlu original

handouts specs

Drepturi de autor

© © All Rights Reserved

Formate disponibile

DOCX, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

14 vizualizări2 paginiHandouts Specs

Încărcat de

Eugene MirasDrepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 2

CHAPTER 9 - Soldering shall be done slowly with well heated iron in order to

thoroughly heat the seam and sweat the solder completely

ROOFING MATERIALS through the full length of the seam.

9. Non-soldered joint of Roof Accessories

A. CORRUGATED METAL ROOFING - Two adjoining edges of lock seam shall be bent 90 degrees. One

bent strip shall be at least 1.5 cm wide and the connecting piece

9A-1 MATERIAL REQUIREMENTS shall have a bent strip twice in width which shall be bent down

over the upturned narrower strip and pressed together.

1. CORRUGATED GALVANIZED IRON 10. Water leak test

A. Corrugated galvanized iron (G.I) sheets shall be cold-rolled - The water spray system shall have nozzle which will deliver

meeting ASTM-153 and with spelter coating of zinc not less pressure of 2 kg/cm^2 and for a duration directed by the

than 0.381 kg/m2 supervising Architect or Engineer.

B. Roofing sheets shall be 0.50 mm thick.

C. Sheets shall weigh not less than 4.14 kg/m2

B. PRE-PAINTED METAL SHEET

ROOF ACCESSORIES

A. Strap fasteners – shall be 0.50 mm thick by 2.5 cm 9B-1 MATERIAL REQUIREMENTS

B. Rivets and washers 1. Gutters, valleys, flashings, hip & ridge roll shall be fabricated from

1. Shall be galvanized mild iron and shall not be less than gauge 24 ( 0.6 mm ) thick cold rolled plain galvanized iron sheets

5 mm diameter and 10 mm length. specially tempered steel.

C. Washers shall not be less than 1.5 mm thick and 20mm in 2. Fastening hardware shall be of galvanized iron straps and rivets

outside diameter. are of .50 mm thick x gauge 26 and standard G.I rivets.

D. Soldering lead – shall have a composition of 50 percent lead. 3. Base metal thickness shall correspond to the ff.

E. Fabricated metal roof accessories .40 mm thick – gauge 28

Gutters and downspouts – 0.60 thick. .50 mm thick – gauge 26

Wire basket strainers – gauge 14, galvanized, .60 mm thick – gauge 24

aluminum. .80 mm thick – gauge 22

If stainless steel is specified for gutter and

flashing – use gauge 24, 0.60mm thick, 120 cm x - End lap. Provide 15 cm. minimum end lap.

240 cm. - Anchorage. Pre-painted steel roofing sheets shall be fastened to

the wood purlins with standard length G.I straps and rivets.

CONSTRUCTION REQUIREMENTS for steel frame up to 4.5 mm thick, use self-drilling screw no. 12

A. PREPARATORY WORK by 3.5 cm long hexagonal head with neoprene washer.

1. The centerline of the purlins at end laps shall be 15 cm from the C. CLAY ROOF TILES

bottom line of end laps

B. Installation of corrugated G.I sheet MATERIAL REQUIREMENTS

1. Installation of corrugated G.I sheets with end lap shall start the

lower part of the roof and proceed towards the direction of A. Clay Roof Tiles – shall manufactured from red clay specie, molded

monsoon wind providing a side laps of 2-1/2 corrugations. to custom tile patterns.

C. Installation of Roofing Accessories B. Sheating

1. Ridge, hip and valley roll - Corrugated G.I sub-roofing shall be 0.5 mm thick long span.

- Ridge & hip rolls shall lap at least 25 cm. over roof sheets and Plywood sheating when used instead of G.I shall be 12 mm thick

together shall be riveted at every second corrugation. marine plywood treated with two piles of felt paper asphalt

- Valleys shall lap at least 45 cm. each way under the roofing impregnated.

sheets.

2. Flashing CONSTRUCTION REQUIREMENTS

- Shall be from 0.50 mm thick plain G.I sheet and shall be installed

along intersections of roofs with concrete or masonry walls in 1. For clay tiles on concrete roof slab provide and install pressure

accordance with the details shown on plans. treated lumber 25 mm x 50 mm or metal strips properly aligned,

- Parallel to sheet corrugation shall lap at least two corrugations. level squared and firm.

Across sheet corrugations shall lap at least 25 cm. and the edge of 2. Apply waterproofing on slab surface to control moisture by cold

flashing turned down at each corrugation. process.

3. Counter flashing 3. Laying of tiles shall at the lower layer from right to left. See to it

- Counter flashing sheets of gauge no. 24 plain G.I sheet shall be that the left anchorage of tile is placed near or close to hip truss

built into preformed wedge-shape groove of concrete or masonry as much as possible.

wall. 4. Continue to the next layer of clay roof tiles following the same

4. Reglets procedure.

- Shall be located not less than 20 cm or more than 40 cm above 5. After all clay tiles are laid out , mark the clay roof tiles at hips and

roofing. valleys which are to be cut suing straight edge or strings as guide.

5. Gutter 6. Where tiles join a hip stringer, provide waterproof elastic cement.

- Gutters, from gauge 24 plain G.I sheets, shall be fabricated to the Cement hi roll and ridge in lap and fasten with nails or tie wires as

shape and dimensions indicated on the plans. specified.

6. Downspout 7. Fill voids at hip starters and ridge ends with mortar, color to

- Downspouts if not embedded in concrete post or walls shall be match the tile.

secured to adjoining wall with metal strap spaced not more than 8. Remove all debris and clean roof area ready for service.

1.0 meter apart.

7. Roof Ventilators

- Shall be firmly secured to the roof structure by means of rivets.

Roof ventilators installed on the roof at places other than the

ridge shall be provided with adequate flashing around intersection

with roofing to ensure watertight joints.

8. Soldered joints

Roof Drainage

CONSTRUCTION REQUIREMENTS (B) STEEL WINDOWS

Drainage

1. The contractor shall provide, fit or install all necessary drains with MATERIAL REQUIREMENTS

strainers where so shown or indicated on plans and or where the

supervising engineer directs. 1. All materials shall be hot rolled, new billet steel frame, heavy

2. Each drain with strainers shall fit the size of the corresponding section with depth of at least 33 mm and web thickness of at least

downspouts or conductor over which is to be installed and in 3 mm.

accordance with the following schedule. 2. Frame members shall be of equal leg design section only at points

Drain and over flow pipes where called for in the plans, and continuous angle finish as

1. Concrete roof gutters or any other work which catches drains or indicated on drawings.

collect rain water shall be provided with adequate drain or A. Heavy duty side hinged Ventilator

overflow, pipes, one inch in diameter pipe spaced at 2.00 meters 1. Frame and ventilator members shall be specially designed

on centers and or as specified. zee section not less than 33 mm in depth and not less than 3

MEASUREMENT AND PAYMENT mm in thickness, with weathering baffles rolled integrally to

1. All roof drains with strainers actually installed shall be measured provide continuous double contact between frame and side

and determined by the number of pieces or units ready for service hinged ventilator members.

as provided in the bill of quantities accepted to the satisfaction of B. Projected ventilators

the supervising architect or engineer. 1. All members shall be hot rolled new billet steel. Window frames

and ventilator sections shall be special angle shape not less than

Chapter 10 33 mm deep from front to back and shall not be less than 3 mm in

thickness.

STEEL DOORS AND WINDOWS C. Awning Ventilators

(A) STEEL DORRS This is a series of ventilators operating simultaneously. Frame

ventilator and muntin members shall be hot rolled new billet steel

MATERIAL REQUIREMENTS

sections not less than 33 mm deep, specially designed for steel

All door cladding plates or panels shall be formed from gauge 20

cold-rolled, quality steel. Frames shall be formed from gauge 16 cold-rolled windows.

steel. The materials used shall conform with the specifications requirements

CONSTRUCTION REQUIREMENTS

of ASTM-A505.

A. Fabrication and welds

A. TUBULAR DOOR (Casement / sliding)

1. Corners of frame and ventilator shall be mitered and

1. Hollow steel doors shall be custombuilt size and details as

electrically butt welded with exposed welds ground smooth.

indicated on the plans and or shop drawing.

2. Cladding of doors shall be flush or louver type. Doors shall be 44 B. Residential casement, heavy duty side hinge window

mm thick, side hinged or overhead hung, as called for on the 1. Roto type

plans. a. Each ventilator shall be hung on two heavy hot rolled

3. Flush doors shall be constructed from two outer steel sheet not steel hinges of the extensive type, welded to both

less than gauge 20, with edges welded and finished flush. frame and ventilator.

B. Steel Louvers 2. Simplex Type

1. Louvers shall be machine pressed conforming to the size and - Hinges shall be of the extension friction type with bronze friction

design indicated on the plans with removable louver pane formed washers and rust proofed steel scorn nuts.

to fit the metal sub-frame of openings. - Hinge designed shall provide ferrous to non-ferrous contacts

C. Anchors and Fasteners between all movable surfaces.

1. Anchors shall be steel zinc coated or painted with rust inhibitive C. Projected window ventilators

paint of sizes, and design according to manufacturer’s standard.

- Each ventilator shall be balanced on two heavy steel arms riveted

CONSTRUCTION REQUIREMENTS

to vent and frame. Rivet holes in arms to be bronze bushed.

A. Fabrication D. Awning window ventilators

1. Corner joints of frames shall be mitered and welded conforming - Each awning window indicated on the plans shall be of the awning

to the manufacturer’s standard manual for metal doors. type window in which the ventilators operate simultaneously and

2. All contact edges shall be closed tight. Welds on exposed surface re-controlled manually. Each projecting panel shall be balanced on

shall be grinded smooth and neat in appearance. two heavy steel supporting arms.

B. Shop Finish E. Installation

1. After fabrication, grease and dirt shall be removed by a hot - All steel window shall set plumb and true to line in openings. The

alkali solution the rinsed with hot water. joints between window frame and masonry shall be carefully

2. After cleaning, all parts shall be immersed in hot or cold caulked.

phosphate solution and rinsed with a diluted solution of - Contact between windows or doors and adjacent steel including

chronic acid. mullions shall be sealed with mastic furnished and applied by the

C. Wall Anchors

contractor.

1. A minimum of three anchors shall be provided for each jamb.

- Windows shall be designed for glazing from the outside with

Anchors shall be located opposite the top bottom hinges and

midway between top and bottom anchors. spring wire glazing clips and glazing putty.

2. Anchors for fastening frames to masonry shall be adjustable, - Mullions and anchors shall be o manufacturer’s standard design.

corrugated and or perforated and shall be embedded not less Vertical mullions, anchors and blots for attaching shall be

than 20 cm into the masonry. furnished where required.

- Adequate anchorage shall be provided to ensure firm installation.

D. Hardware F. Shop Painting

Side bronze butts for side hung doors and overhead pocket - All windows shall be given a coating of gray metallic paint applied

hardware for track and roller types, and lockets shall be suitable to all surfaces base for prevention of corrosion.

for the service required and subject to the approval of the - Prior to application of paint primer the steel sections shall be

supervising architect or engineer. cleaned of rust, oil, grease and other foreign matter.

S-ar putea să vă placă și

- Sample Building SpecificationsDocument3 paginiSample Building SpecificationsJan Alexis Monsalud85% (20)

- Two Storey General SpecificationsDocument7 paginiTwo Storey General SpecificationsJayson Hernandez75% (32)

- General Notes For ConstructionDocument7 paginiGeneral Notes For Constructionjonilyn florentino100% (1)

- The Impact of Social Networking Sites To The Academic Performance of The College Students of Lyceum of The Philippines - LagunaDocument15 paginiThe Impact of Social Networking Sites To The Academic Performance of The College Students of Lyceum of The Philippines - LagunaAasvogel Felodese Carnivora64% (14)

- Outline Specifications (One 1 Storey Residential)Document5 paginiOutline Specifications (One 1 Storey Residential)mark manalang100% (1)

- Technical Specifications CanopyDocument5 paginiTechnical Specifications CanopyNaman SharmaÎncă nu există evaluări

- 5 Stance Pit Latrine BOQDocument12 pagini5 Stance Pit Latrine BOQMwesigwa Daniel100% (2)

- Drill Bit Classifier 2004 PDFDocument15 paginiDrill Bit Classifier 2004 PDFgustavoemir0% (2)

- UntitledDocument17 paginiUntitledSedat100% (1)

- Welding and Heat Treatment Requirements For Equipment and PipingDocument34 paginiWelding and Heat Treatment Requirements For Equipment and Pipingonur gunesÎncă nu există evaluări

- Estimation and Specificatn - ppt.20.2.18Document22 paginiEstimation and Specificatn - ppt.20.2.18aparna baburaj100% (1)

- General Specification (Building) 30-01-21 198-380Document183 paginiGeneral Specification (Building) 30-01-21 198-380shujaÎncă nu există evaluări

- Technical Specifications 45990Document4 paginiTechnical Specifications 45990Ravi RajÎncă nu există evaluări

- Sample SpecificationDocument13 paginiSample SpecificationNo OneÎncă nu există evaluări

- S9-Specification For GabionDocument3 paginiS9-Specification For Gabionwongtianhui100% (1)

- Interior Furnishing Work of New Circle Office in Bank'S Own Building at Plot No. 4, PSP, Saket Nagar, Near Aiims BhopalDocument37 paginiInterior Furnishing Work of New Circle Office in Bank'S Own Building at Plot No. 4, PSP, Saket Nagar, Near Aiims BhopalSAI ASSOCIATEÎncă nu există evaluări

- Checklist For C Class Masonry BuildingDocument4 paginiChecklist For C Class Masonry BuildingAbhay SuwalÎncă nu există evaluări

- Roof and Roofing MaterialsDocument29 paginiRoof and Roofing MaterialsChristian BeninÎncă nu există evaluări

- Different Types of RoofingDocument163 paginiDifferent Types of RoofingPrethish KumarÎncă nu există evaluări

- SECTION 02822 Chain Link Fences and Gates Part 1 - GeneralDocument4 paginiSECTION 02822 Chain Link Fences and Gates Part 1 - GeneralEmad KhanÎncă nu există evaluări

- Castrol India Ltd. Bill of Quantities For Civil & Interior WorksDocument48 paginiCastrol India Ltd. Bill of Quantities For Civil & Interior WorksSarinÎncă nu există evaluări

- Proposed Three Bedroom ResidentialDocument5 paginiProposed Three Bedroom ResidentialMel FÎncă nu există evaluări

- SPECS2020Document3 paginiSPECS2020nadzimar maquilingÎncă nu există evaluări

- Cable TraysDocument6 paginiCable TrayssallammohamedÎncă nu există evaluări

- Sample Specification From Monoxivent Corrosion Composites: SECTION 15800Document4 paginiSample Specification From Monoxivent Corrosion Composites: SECTION 15800Ahmed NabilÎncă nu există evaluări

- Specification of Toilet BlockDocument2 paginiSpecification of Toilet BlockKuldeep ChakerwartiÎncă nu există evaluări

- Specification For General Construction: A. Intent and Application of The Provision of This SectionDocument7 paginiSpecification For General Construction: A. Intent and Application of The Provision of This SectionJanice SubidoÎncă nu există evaluări

- Bid PDFDocument4 paginiBid PDFAr Shubham KumarÎncă nu există evaluări

- SP-S-05 - Rev - 4 - FENCINGDocument16 paginiSP-S-05 - Rev - 4 - FENCINGJahanzeb MaharÎncă nu există evaluări

- Container SpecificationDocument4 paginiContainer SpecificationDesign TeamÎncă nu există evaluări

- General Specifications AlbalateDocument8 paginiGeneral Specifications Albalatejhnrynalbalate95xÎncă nu există evaluări

- General SpecificationsDocument6 paginiGeneral SpecificationsMaire Joy E. AzañaÎncă nu există evaluări

- Material SpecificationsDocument3 paginiMaterial SpecificationsJonathan SilayaÎncă nu există evaluări

- Cement Plaster On Metal LathDocument7 paginiCement Plaster On Metal LathwalidÎncă nu există evaluări

- Material General Specifications For OboDocument4 paginiMaterial General Specifications For OboTyron CustodioÎncă nu există evaluări

- Rough Carpentry Section 6100Document3 paginiRough Carpentry Section 6100apsARCHITECTÎncă nu există evaluări

- Right-Of-Way Fence and Gate: SECTION 02822Document5 paginiRight-Of-Way Fence and Gate: SECTION 02822Jordy PerezÎncă nu există evaluări

- Two Storey General SpecificationsDocument7 paginiTwo Storey General SpecificationsJoseph MalabananÎncă nu există evaluări

- Wearing CoatDocument5 paginiWearing Coatnandi_scrÎncă nu există evaluări

- Technical Specifications: Duct Work and Outlets GeneralDocument16 paginiTechnical Specifications: Duct Work and Outlets GeneralNedunuri.Madhav MurthyÎncă nu există evaluări

- Canara Bank Estimate Boq PDFDocument23 paginiCanara Bank Estimate Boq PDFSai SrimanthÎncă nu există evaluări

- SarfDocument51 paginiSarfSantosh ThakurÎncă nu există evaluări

- Building SpecificationsDocument5 paginiBuilding Specificationsjologscresencia100% (1)

- Section 12 - RoofingDocument14 paginiSection 12 - RoofingShing Faat WongÎncă nu există evaluări

- Fittings of Sanitary AppliancesDocument16 paginiFittings of Sanitary AppliancesrajendraÎncă nu există evaluări

- Duct and PVC in ConcreteDocument6 paginiDuct and PVC in ConcreteAli AimranÎncă nu există evaluări

- BOQ-Acoustic Work at IIIDEM 31.01.2020Document10 paginiBOQ-Acoustic Work at IIIDEM 31.01.2020Kirti BaliÎncă nu există evaluări

- Section - 2800: Expansion /sepration / Isolation Joints 2800.1 GeneralDocument5 paginiSection - 2800: Expansion /sepration / Isolation Joints 2800.1 Generalkartick adhikaryÎncă nu există evaluări

- ARKI ALE Structural NotesDocument5 paginiARKI ALE Structural Notesiloilocity100% (1)

- House EstimateDocument46 paginiHouse EstimatesheikÎncă nu există evaluări

- ConstructionDocument8 paginiConstructionGaspar Lig-ang TolomiaÎncă nu există evaluări

- 2700 Wearings Coat and AppurtenancesDocument5 pagini2700 Wearings Coat and Appurtenancesdhamu_i4uÎncă nu există evaluări

- Type FP - Push-Up Service Door: Stainless Steel - Full Weatherstrip - Face of Wall MountedDocument2 paginiType FP - Push-Up Service Door: Stainless Steel - Full Weatherstrip - Face of Wall MountedSergio Romero GonzalezÎncă nu există evaluări

- TECH SPECS For Cabin For Jail - FINALDocument8 paginiTECH SPECS For Cabin For Jail - FINALmanzarsamanposÎncă nu există evaluări

- General SpecificationDocument5 paginiGeneral SpecificationAlvin King I. MacaalayÎncă nu există evaluări

- 09 Zeta Hafif Celik Galvenizli Celik Yapi Teknik Sartname - Tr.enDocument2 pagini09 Zeta Hafif Celik Galvenizli Celik Yapi Teknik Sartname - Tr.enVengatesh HariÎncă nu există evaluări

- General Specifications Musngi Residence - As Per SiteDocument8 paginiGeneral Specifications Musngi Residence - As Per SiteJanine Palec100% (1)

- Pages From BS7430-2011-A1-2015Document2 paginiPages From BS7430-2011-A1-2015Nouh RaslanÎncă nu există evaluări

- Plumbing Sample Make List & Techinal SpecificationsDocument49 paginiPlumbing Sample Make List & Techinal SpecificationsrohanbagadiyaÎncă nu există evaluări

- Btech5 Specs DigestDocument9 paginiBtech5 Specs DigestKaren Dela TorreÎncă nu există evaluări

- To Collection $Document2 paginiTo Collection $Koh YhÎncă nu există evaluări

- A Guide to Making Your Own Fishing-Rod and TackleDe la EverandA Guide to Making Your Own Fishing-Rod and TackleEvaluare: 5 din 5 stele5/5 (1)

- How to Make Electrical Machines: Containing Full Directions for Making Electrical Machines, Induction Coils, Dynamos, and Many Novel Toys to Be Worked by ElectricityDe la EverandHow to Make Electrical Machines: Containing Full Directions for Making Electrical Machines, Induction Coils, Dynamos, and Many Novel Toys to Be Worked by ElectricityÎncă nu există evaluări

- Earthquakes and Earthquake Prediction: Andrei GabrielovDocument37 paginiEarthquakes and Earthquake Prediction: Andrei GabrielovEugene MirasÎncă nu există evaluări

- When To IrrigateDocument2 paginiWhen To IrrigateEugene MirasÎncă nu există evaluări

- Richelene B. Labrador Bsce Va: ActivityDocument10 paginiRichelene B. Labrador Bsce Va: ActivityEugene MirasÎncă nu există evaluări

- Activity Days: A B C DDocument2 paginiActivity Days: A B C DEugene MirasÎncă nu există evaluări

- Eto Ang TrussDocument10 paginiEto Ang TrussEugene MirasÎncă nu există evaluări

- CPM ProjectDocument10 paginiCPM ProjectEugene MirasÎncă nu există evaluări

- OK CHAPTER 4 E. Socio Economic AspectsDocument2 paginiOK CHAPTER 4 E. Socio Economic AspectsEugene MirasÎncă nu există evaluări

- Seismic Waves Are Waves of Energy That Travel Through The Earth's Layers, and Are A Result ofDocument2 paginiSeismic Waves Are Waves of Energy That Travel Through The Earth's Layers, and Are A Result ofEugene MirasÎncă nu există evaluări

- Earthquake Engineering HandoutsDocument1 paginăEarthquake Engineering HandoutsEugene MirasÎncă nu există evaluări

- What Is The Magnitude of An Earthquake and How Is It Measured?Document4 paginiWhat Is The Magnitude of An Earthquake and How Is It Measured?Eugene MirasÎncă nu există evaluări

- What Is The Magnitude of An Earthquake and How Is It Measured?Document4 paginiWhat Is The Magnitude of An Earthquake and How Is It Measured?Eugene MirasÎncă nu există evaluări

- FTB PDFDocument1 paginăFTB PDFEugene MirasÎncă nu există evaluări

- The Magnitude Just Depends On The EarthquakeDocument1 paginăThe Magnitude Just Depends On The EarthquakeEugene MirasÎncă nu există evaluări

- Ramon Magsaysay Technological University Iba, Zambales College of Engineering and ArchitectureDocument4 paginiRamon Magsaysay Technological University Iba, Zambales College of Engineering and ArchitectureEugene MirasÎncă nu există evaluări

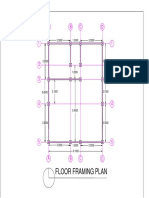

- Roof Framing Plan PDFDocument1 paginăRoof Framing Plan PDFEugene MirasÎncă nu există evaluări

- Appendix B Organizational Chart (Construction Period)Document3 paginiAppendix B Organizational Chart (Construction Period)Eugene MirasÎncă nu există evaluări

- OK CHAPTER 4 C. Technical - AspectDocument17 paginiOK CHAPTER 4 C. Technical - AspectEugene MirasÎncă nu există evaluări

- Definition of TermsDocument2 paginiDefinition of TermsEugene MirasÎncă nu există evaluări

- Table 1 Total Male and Female As of 2015: Republic of The Philipines Province of Zambales Municipality of BotolanDocument1 paginăTable 1 Total Male and Female As of 2015: Republic of The Philipines Province of Zambales Municipality of BotolanEugene MirasÎncă nu există evaluări

- Ramon Magsaysay Technological University Iba, Zambales College of Engineering and ArchitectureDocument4 paginiRamon Magsaysay Technological University Iba, Zambales College of Engineering and ArchitectureEugene MirasÎncă nu există evaluări

- Floor Framing PDFDocument1 paginăFloor Framing PDFEugene MirasÎncă nu există evaluări

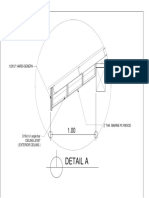

- Roof 3 PDFDocument1 paginăRoof 3 PDFEugene MirasÎncă nu există evaluări

- Acronyms: Ramon Magsaysay Technological University Iba, Zambales College of Engineering and ArchitectureDocument1 paginăAcronyms: Ramon Magsaysay Technological University Iba, Zambales College of Engineering and ArchitectureEugene MirasÎncă nu există evaluări

- Guide Lowpres PDFDocument78 paginiGuide Lowpres PDFjsenadÎncă nu există evaluări

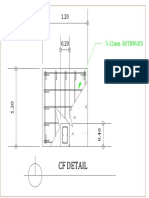

- CF PDFDocument1 paginăCF PDFEugene MirasÎncă nu există evaluări

- Chapter 9Document6 paginiChapter 9Eugene MirasÎncă nu există evaluări

- Sports and EntertainmentDocument1 paginăSports and EntertainmentEugene MirasÎncă nu există evaluări

- Member'S Data Form (MDF) : HQP-PFF-039Document2 paginiMember'S Data Form (MDF) : HQP-PFF-039Eugene MirasÎncă nu există evaluări

- Sports and EntertainmentDocument1 paginăSports and EntertainmentEugene MirasÎncă nu există evaluări

- CV Old NicDocument4 paginiCV Old NicTensonÎncă nu există evaluări

- Lesson Plan Wid Awt Method 2Document7 paginiLesson Plan Wid Awt Method 2Yan LianÎncă nu există evaluări

- Why Do Kashmiris Need Self-Determination?: UncategorizedDocument16 paginiWhy Do Kashmiris Need Self-Determination?: UncategorizedFarooq SiddiqiÎncă nu există evaluări

- January 11, 2019 Grade 1Document3 paginiJanuary 11, 2019 Grade 1Eda Concepcion PalenÎncă nu există evaluări

- El Nino 3Document8 paginiEl Nino 3nisAfiqahÎncă nu există evaluări

- Tema & Htri by Bert BoxmaDocument5 paginiTema & Htri by Bert Boxmabloodterry2284Încă nu există evaluări

- UV-Visible Systems - Operational Qualification - Col23 PDFDocument10 paginiUV-Visible Systems - Operational Qualification - Col23 PDFIsabelle PlourdeÎncă nu există evaluări

- KPI's Troubleshooting GuideDocument27 paginiKPI's Troubleshooting GuideMohamed SayedÎncă nu există evaluări

- Lahainaluna High School Cafeteria: Lahaina, Maui, HawaiiDocument42 paginiLahainaluna High School Cafeteria: Lahaina, Maui, HawaiiKeerthy MoniÎncă nu există evaluări

- General Information Exhibition Guide Lines - 3P 2022Document6 paginiGeneral Information Exhibition Guide Lines - 3P 2022muhammad khanÎncă nu există evaluări

- Police Cranston School Committee Member Stole PTO FundsDocument1 paginăPolice Cranston School Committee Member Stole PTO FundsashaydelineÎncă nu există evaluări

- Management Glossary - Musa KamawiDocument50 paginiManagement Glossary - Musa KamawiKazi Nazrul IslamÎncă nu există evaluări

- RSM222.f22.CourseOutline v3 2022-09-05Document9 paginiRSM222.f22.CourseOutline v3 2022-09-05Kirsten WangÎncă nu există evaluări

- Micro Fibra Sintetica at 06-MapeiDocument2 paginiMicro Fibra Sintetica at 06-MapeiSergio GonzalezÎncă nu există evaluări

- Easy NoFap EbookDocument37 paginiEasy NoFap Ebookசரஸ்வதி சுவாமிநாதன்Încă nu există evaluări

- Cambridge IGCSE Physics 0625 Complete Notes PDocument5 paginiCambridge IGCSE Physics 0625 Complete Notes PYamikani ManthandoÎncă nu există evaluări

- EPA NCP Technical Notebook PDFDocument191 paginiEPA NCP Technical Notebook PDFlavrikÎncă nu există evaluări

- ATA212001Document3 paginiATA212001Tarek DeghedyÎncă nu există evaluări

- E Commerce and Its Influence in Changing in Purchasing Behavior of Modern ConsumersDocument13 paginiE Commerce and Its Influence in Changing in Purchasing Behavior of Modern ConsumersRichard VillanuevaÎncă nu există evaluări

- Auburn Bsci ThesisDocument5 paginiAuburn Bsci Thesisafksaplhfowdff100% (1)

- Stitch2421 1 Kit PDFDocument8 paginiStitch2421 1 Kit PDFJoshua Robertson100% (1)

- COSO DefinEDDocument21 paginiCOSO DefinEDRefdy AnugrahÎncă nu există evaluări

- No Experience ResumeDocument2 paginiNo Experience ResumeNatalia PantojaÎncă nu există evaluări

- Rotc Reviewer FinalsDocument11 paginiRotc Reviewer FinalsAngel Atienza100% (1)

- Lecture 5: Triangulation Adjustment Triangulation: in This Lecture We Focus On The Second MethodDocument5 paginiLecture 5: Triangulation Adjustment Triangulation: in This Lecture We Focus On The Second MethodXogr BargarayÎncă nu există evaluări

- Part 1. Question 1-7. Complete The Notes Below. Write NO MORE THAN THREE WORDS AND/OR A NUMBER For Each AnswerDocument13 paginiPart 1. Question 1-7. Complete The Notes Below. Write NO MORE THAN THREE WORDS AND/OR A NUMBER For Each Answerahmad amdaÎncă nu există evaluări