Documente Academic

Documente Profesional

Documente Cultură

Importance of Bond and Water-Cement Ratio in RCC

Încărcat de

amitkap00rDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Importance of Bond and Water-Cement Ratio in RCC

Încărcat de

amitkap00rDrepturi de autor:

Formate disponibile

Lateral Strain

------------------- = A Constant

Linear strain

The Constant is known as poisson’s Ratio and denoted by 1 / m or µ .

Importance of bond in RCC -

One of the most important assumptions in the behavior of reinforced concrete structures is that

there is proper bond between concrete and reinforcing bars. When steel bars are embedded in

concrete, the concrete after setting adheres to the surface of the bars and thus resist any force

that tends to pull or push this rod. The intensity of this adhesive force is called bond stress.

Thus the term bond is used to describe the means by which slip between steel and concrete is

prevented. The bond stresses are the longitudinal shearing stresses acting on the surface

between the steel and concrete.

The bond between steel and concrete comprise of three resistance –

i. Pure adhesive resistance.

ii. Frictional resistance.

iii. Mechanical resistance.

*************************************

Q. 27 – Give in brief the current specification for –

i. Reinforced Cement Concrete. [ LDCE 1992 ]

Ans.- Specification for Reinforced Cement Concrete –

1. Cement to be used for RCC as per ISI Specification.

2. Water used for RCC work shall be free from curtly, vegetable or organic matters, oils acids

and alkaline substance in solution or suspension and impurities and shall be fit for drinking,

No sea or brackish water shall be used.

3. Aggregate to be with in the limit for combined fine course.

4. Proportion of water to be as per specification 701.

5. The maximum permissible slump for ordinary RCC 100 mm and if vibrator is used shall not

exceed 40 mm.

6. Mixing of concrete to be as for as possible mechanical batch mixer.

7. Transport of concrete to quick to prevent segregation of the ingredients. These should be

continuing flow in chute.

8. Reinforcement shall have concrete cover -

i. At ends not less than 25 mm or twice the dia of the bar.

ii. For longitudinal reinforcement bar in a column not less then 40 mm, nor less then the dia

of bar.

iii. For longitudinal reinforcement bar in a beam not less than 25 mm, nor less then 12 mm,

nor less then the dia of the bar.

iv. For tensile compressive shear or other reinforcement in a slab not less then 12 mm, nor

less then the dia of the bar.

v. For any other reinforcement not less than 12 mm or less than the dia of such

reinforcement.

9. Interior of the form work shall be treated with an approved composition.

10. Cleaning of rods and shuttering by air pressure if possible or even washing before

concreting.

11. Placing of concrete -

i. To be placed early and within 30 minutes.

ii. Construction joints to be as per drawing.

Strength of Materials, Structural Design & Drawings 25

iii. Before concrete is resumed the surface of construction joint to be thoroughly cleaned by

wire brush and excess water drained out before next layer is laid a layer of 15 mm

mortar of 1 : 2 mortar to be laid.

iv. Compaction – By rodding tamping or vibrator to get dense concrete. Compaction to be

stopped when air bubbles eases to brake in the surface.

v. When working in extreme temperature – While placing concrete the temperature should

be at least 4.50C and the temperature of the concrete after having been placed and

compacted is maintained above 20C . In hot weather temperature of wet concrete should

not exceed 380C while placing.

vi. Curing - The concrete to be covered with a layer of soaking canvas Hessian and kept

wet for 14 days continuously or such longer period as prescribed by Engineer.

vii. Form work not be removed unless the concrete reaches a strength of at least twice the

stress to which the concrete may be subjected at the time of striking.

********************************

Q. 28 – What advantage can be derived by making a beam continuous ? [ LDCE 1997 ]

Ans.- A Beam is said to be continuous when it rests on at least three supports. The main

advantage of continuous Beam are as under –

i. The monolithic pouring of concrete to form a monolithic continuous member of a rigid

frame is fully utilized in continuous beams in reducing the maximum bending moments,

without in most cases, affecting the shear force.

ii. The shear force remains unaffected.

iii. The fiber stress is reduced to half.

iv. Continuous beam when loaded will deflect with convexity upwards over the intermediate

supports and with concavity upwards over the mid of the spans.

v. The intermediate supports of a continuous beam are always subjected to some bending

moment. The end supports if simply supported will not be subjected to any bending

moment. But the end supports if fixed will be subjected to fixing moments and the slope

of the beam at the fixed ends will be zero.

vi. Sometimes a continuous beam is simply supported on its one or both the end supports.

In such a case the fixing moment on the simply supported is Zero.

vii. Sometimes a continuous beam is simply supported curve on one or both the end

supports. We know that the fixing moment on a simply supported end is zero. Therefore

in such a case the simply supported ends are released by applying equal and opposite

moments and their effects are carried over on the opposite joints. It may also noted that

no moment is carried over from the opposite joint to the simply supported end.

***********************************

Q. 29 – Write Short notes on –

i. Water Cement Ratio. [ LDCE 1987, 89, 92, 2008 LGS 1987,91,98 ]

Importance of Water Cement ratio in concrete. [ LGS 2008 ]

ii. Prestressed Concrete. [ LGS 1987, 1998 ]

iii. Advantage of Prestressed Concrete. [ LDCE 1989 ]

iv. Cover in RCC. [ LGS 1993, 98 ]

Ans. –

Water Cement Ratio –

Strength of Materials, Structural Design & Drawings 26

The ratio of the volume of water to volume of cement used in concrete mix is termed as water

cement ratio. As a result of experiments it is observed that for a given proportion of ingredients

in a concrete mix, there is almost a fixed amount of water, which gives maximum strength of

concrete. In case the water used is less, the resultant concrete will be comparatively dry, difficult

to place in position and may pose problems in compaction. Moreover with less water complete

setting of cement can not be ensured and hence the strength of concrete get reduced

appreciably. On the other hand, in case the water is more it would result in formation of

excessive voids and honey combing in the set concrete, there by reducing its density, strength

and durability. Thus water cement ratio serves as a yard stick for obtaining concrete of desired

strength. The lower the ratio, the greater is the strength of the mix. A rich mix of concrete gives

higher strength than a lean mix, not because of more cement but it is on account of the fact that

concrete can be used with a lower water cement ratio.

Prestressed Concrete –

With the introduction of prestressing it has become possible to avoid the formation of cracks in

tension concrete and to use high strength steel most economical.

The essence of prestressing a concrete member in the induction of sufficient compressive

stress in concrete prior to the member being subjected to loads in the zones, which will be

tensile when the loads are applied. Thus when the prestressed concrete member is subjected to

external loads. The already induced compressive stress in concrete will neutralize the tensile

stress developed in the member on loading. Hence the resultant stresses in concrete in tensile

zone will be eliminated altogether or get reduced to a great extent. Thus in a prestressed

concrete member the entire cross section of the member becomes effective for resisting

bending and at the same time the danger of cracking when the member is loaded is minimized

or even avoided.

Advantage of Prestressed Concrete –

i. By the method of prestressing it is possible take full advantage of high compressive

strength of concrete and high tensile strength of the steel used. Hence the combination

of the two materials results in most economical sections.

ii. On account of its higher strength it can be safely recommended for structures having

longer spans and subjected to heavy loads and those subjected to impact and vibration.

iii. Since it is possible to eliminate the formation of cracks in prestressed concrete

members, they have increased resistance to atmospheric and other chemical action and

hence they prove more durable.

iv. Prestressed concrete members are, thinner in section and hence these are a great

reduction of the self weight of the structure, which ultimately effects economy in the cost

of foundation.

Cover in RCC -

Reinforcement shall have concrete cover as follows:

i. For each end of a reinforcing bar, not less than 25 mm, nor less then twice the diameter

of the bar.

ii. For a longitudinal reinforcing bar in a column, not less than 40 mm, nor less than the

diameter of the bar.

iii. For a longitudinal reinforcing bar in a beam, not less than 25 mm, nor less than the

diameter of the bar.

iv. For tensile, compressive, shear or other reinforcement in a slab, not less than 12 mm,

nor less than the diameter of the reinforcement.

v. For any other reinforcement, not less than 12 mm, nor less than the diameter of such

reinforcement.

Strength of Materials, Structural Design & Drawings 27

****************************************

Q. 30 – A Beam A B 10 meter long is simply supported at 2m and 1 m from A and B

respectively. The beam carries a uniformly distributed load of 200 kg per meter and

concentrated loads of 1500 kg and 2000 kg at A & B respectively.

Draw the shear force and bending moment diagrams and also calculate the maximum

bending moment. [ LGS 1998 ]

Ans.- Taking moments about C

RD x 7 = (2000 x 8 ) + (200 x 8 x 4) – (1500 x 2) – (200 x 2 x 1)

= 16000 + 6400 – 3000 - 400 = 22400 – 3400 = 19000

RD = 19000 / 7 = 2714.29 kg.

And RC = ( 2000 + 1500 + 200 x 10 ) – 2714.29 = 5500 – 2714.29 = 2785.71 kg.

Shear Force –

The shear force diagram is drawn in fig. And values are Tabulated hear

FA = + 1500Kg, FC = +1500 + 400 – 2785.71= + 1900 – 2785.71 = - 885.71 Kg,

FD = - 885.71 + 200 x 7 – 2714.29 = - 3600 + 1400 = - 2200 Kg, FB = - 2000 kg.

Bending Moment –

The Bending Moment Diagram is drawn in fig. And the values are tabulated hear

MA = 0 , MC = - (1500 x 2) – ( 200 x 2 x 1 ) = - 3000 – 400 = -3400 kgm ,

MD = - ( 2000 x 1 ) – (200 x 1 x 0.50 ) = - 2000 – 100 = - 2100 kgm. MB = 0

Maximum Bending Moment –

X / 885.71 = (7 – x) / 514.29 , 514.29 x = 7 x 885.71 – 885.71 x ,

514.29 x + 885.71 x = 6199.97 , 1400 x = 6199.97 , x = 6199.97 / 1400 = 4.43 m.

MM = - ( 1500 x 6.43 ) + ( 2785.71 x 4.43 ) – ( 200 x 6.43 x 6.43 / 2 )

= - 9645 + 12340.70 – 4134.49 = - 13779.49 + 12340.70 = + 1438.79 kgm.

***************************************

Strength of Materials, Structural Design & Drawings 28

Q. 31 - A retaining wall 5 m height is shown in the sketch. Density of the back fill is 1.9 T / m3 its

angle of shear resistance is 30o and cohesion is zero. Work out the resultant earth

pressure on the wall and its point of application. [ LDCE 1996 ]

Ans.- W H2 1 – sin f

Earth pressure on the Wall P = --------- X ---------------

2 1 + sin f

Where H = Total height in meters = 5 m. , W = Density of earth = 1.9 T / m3

+ surcharge load on earth = 2.5 T / m3 , Total W = 1.9 + 2.5 = 4.4 T / m3.

f = angle of shear resistance = 300

4.4 x 52 1 – sin 300 4.4 x 52 1 – 0.50

P = ------------ X ------------------ = ------------ x ----------------- ,

2 1 + sin 300 2 1 + 0.50

= 2.2 x 25 x 0.33 = 18.34 T.

Point of application of P at H / 3 = 5 / 3 = 1.67 m from Bottom.

Now that the weight of Dam per unit length w = r x ( a + b ) / 2 x H ,

Where a = 0.50 m. b = 2.00 m. H = 5.00 m. r = specific wt of Dam = 2400 kg / m3

W = 2400 x ( 0.50 + 2.00 ) / 2 x 5 = 15000 kg / m. = 15 T / m.

And the horizontal distance between the center of gravity of Dam and the point where the

resultant R cuts the base

X = P / w x H / 3 = 18.34 / 15 x 5 / 3 = 2.04 m.

The distance of center of gravity from the toe of the dam

Y = [ a2 + ab + b2 ] / 3 ( a + b ) = [ 0.502 + 0.50 x 2.00 + 2.002 ] / 3 ( 0.50 + 2.00 ) = 0.70 m.

The distance between the toe of the dam and the point the resultant R cuts the base –

D = Y + X = 2.04 + 0.70 = 2.74 m.

Since the point the resultant cuts the base at outer of dam hence dam is unstable.

**********************************************

Strength of Materials, Structural Design & Drawings 29

Q.32.- Draw the Shear force and Bending movement diagrams in the following cases duly

indicating the values at various critical locations. [ WCR LDCE 2005 ]

a)

b)

Ans.- a) Taking moment about A

RB x 10 = ( 3 x 8 ) + 1.5 x 4 x 4/2 = 24 + 12 = 36, RB = 36 / 10 = 3.6 T .

And RA = ( 3 + 1.5 x 4 ) – 3.6 = 9 – 3.6 = 5.4 t.

Shear Force –

The shear force diagram is drawn in fig. And values are Tabulated hear

FA = - 5.4T, FC = 3.6 - 3 = + 0.6T, FD = + 3.6T, FB = + 3.6 T

Bending Moment –

The Bending Moment Diagram is drawn in fig. And the values are tabulated hear

MA = 0 , MC = ( 3.6 x 6 ) – ( 3 x 4 ) = 21.6 – 12 = 9.6 Tm., MD = 3.6 x 2 = 7.2 Tm., MB = 0

Maximum Bending Moment –

X / 5.4 = (4 – x) / 0.6 , 0.6 x = 21.6 – 5.4 x , 0.6 x + 5.4 x = 21.6 , 6 x = 21.6 ,

x = 21.6 / 6 = 3.6 m.

Strength of Materials, Structural Design & Drawings 30

MM = ( 3.6 x 6.4 ) – ( 3 x 4.4 ) – ( 0.4 x 1.5 x 0.4 / 2 ) = 23.04 – 13.20 – 0.12 = 23.04 – 13.32 =

9.72 Tm.

b) Shear Force –

The shear force diagram is drawn in fig. And values are Tabulated hear

FA = - (3 + 1.5 x 1.5 )T= - 5.25 T, FB = -( 5.25 – 3 ) – 2.25 T, FC = - 2.25T, FD = 0.

Bending Moment –

The Bending Moment Diagram is drawn in fig. And the values are tabulated hear

MD = 0 , MC = 1.5 x 1.5 x 1.5 / 2 = 1.69Tm, MB = 1.5 x 1.5 x 1.75 = 3.94 Tm., MA = 2 x 3 +

1.5 x 1.5 x 3.75 = 14.44Tm.

*********************************************

Q.33.- Design a simply supported RCC slab to carry 6000 N /m2 inclusive of its own weight on

an effective span of 4 m. The maximum stresses in concrete and steel are not to exceed

c = 5.00 N / mm2 , zt = 140 N / mm2, m = 18.

Ans.- N = mc / t + mc = 18 x 5 / 140 + 18 x 5 = 90 / 140 + 90 = 90 / 230 = 0.39.

j = ( 1 – N / 3 ) = 1 – 0.39 / 3 = 0.87, Q = ½ Ncj = ½ x 0.39 x 50 x 0.87 = 8.48.

Span = 4 m. D = span / 32 = 4 / 32 = 0.125 m. = 12.5 cm.

Effective span = 4 + 0.125 = 4.125 m. and effective depth = 12.5 – 0.25 = 12.25 cm.

Weight on slab = 6000 N /m2 , = 600 kg / m2 , including self weight

Bending Moment – BM = wl2/ 8 = 600 x 4.1252 / 8 = 1276.17 kgm = 127617 kgcm.

BM = MR = Qbd2 , d = Ö MR / Qb = Ö 127617 / 8.48 x 100 = 12.26 cm.

Hence slab depth can be used = 12.5 cm.

At = MR / tjd = 127617 / 1400 x 0.87 x 12.26 = 127617 / 14932.68 = 8.55 cm2.

[ t = 140 140 N / mm2 = 1400 kg / cm2 , c = 5.00 N / mm2 = 50 kg / cm2 , ]

10 mm f bar used at C / C P = 100 x 0.78 / 8.55 = 9.12 cm. Say 9 cm. C / C.

********************************

Strength of Materials, Structural Design & Drawings 31

Q.34.- What is meant by balanced design in RCC.

Ans.- Balanced reinforced concrete sections are designed on the assumption that the

maximum stresses in concrete and steel reach their permissible stresses at the same time both

the materials are stressed to their fullest allowable stress at one end the same time as such

section is called balanced or critical or economic. The neutral axis of this section is called critical

neutral axis and may be denoted by xc, critical NA is calculated as follow –

scbc xc

--------- = ---------

sst / m d – xc

scbc = Permissible stress in concrete in bending compression.

sst / m = Permissible stress in steel in tension / modular ratio.

***************************

Q.35.- What items will you check before casting of a RCC slab of a building? [ LGS 2007 ]

Ans.- Following items to be checked before casting of a RCC slab of a building –

i. Adequate quantity of material of material of approved quality available at site.

ii. The form work props are in order.

iii. The reinforcement is as per approved drawing and spacers for cover is provided.

iv. Concrete is mixed in a mechanical mixture.

v. Least time less between mixing of laying of concrete.

vi. Foreign material such as wood shaving etc. are removed from form work before lay

concrete.

vii. Water cement ratio is controlled.

viii. Cement added to the correct proportion.

ix. Compaction mechanically.

x. Provide opening / cavities wherever indicated.

xi. Laying to be done continuously. If unavailable take necessary precautions.

*****************************

Q. 36 - Design an RCC lintel across an opening of 3 m clear span in brick wall 35 cms. Thick, 6

m high above the lintel level. Assume reasonable values for permissible stresses in

concrete and steel.

Draw neat sketches (not to scale) showing the construction details of the above lintel

adequate for field execution. [ LDCE 1986 ]

Strength of Materials, Structural Design & Drawings 32

Ans.- Let bearing of lintel = 20 cm. = 0.20 m. , Clear span of lintel = 3.00 m. Given

Width of lintel b = 0.35 m. Wall thickness ,

Depth of Lintel D = Span / 10 = 3.00 / 10 = 0.30 m. , Take Cover 3 cm = 0.03 m.

Effective depth of lintel d = 0.30 – 0.03 = 0.27 m.

Effective span – which is less –

i. C/C to distance of support = 3.00 + 0.20 = 3.20 m.

ii. Clear span + effective depth = 3.00 + 0.27 = 3.27 m.

Hence effective span = 3.20 m.

Let Triangle masonry angle = 600 [ For law quality brick masonry ]

[ Since Brick masonry quality not given in question for good masonry triangle angle will be given

as 450 ]

Height of Triangle = 3.20 / 2 x tan 600 = 1.60 x 1.732 = 2.77 m.

Masonry height above lintel 6.00 m. more than 2.77 m.

Hence Triangle masonry weight can be taken – ½ x 3.20 x 3.20 sin 60 x 0.35 x1920,

i. Weight of masonry - ½ x 3.20 x 3.20 x 0.866 x 0.35 x1920 = 2979.59 kg. Say – 2980 kg.

ii. Self weight of Lintel – 0.35 x 0.30 x 2500 = 262.50 kg / meter, Say 263 kg / meter.

Note – Density of RCC = 2500 kg / m3, Density of Brick Masonry = 1920 kg / m3,

BM due to masonry height - BM = WL / 6 = 2980 x 3.20 / 6 x 100 = 158933.33 kg cm.

BM due to self weight of Lintel – wl2 / 8 = 263 x 3.202 / 8 x 100 = 33664 kg cm.

Total Maximum BM = 158933 + 33664 = 192597 kg cm.

BM = MR = Qbd2 , d = √ MR / Qb = √ 192597 / 8.48 x 0.35 = 25.47 cm. Say – 26 cm.[ Q = 8.48 ]

Area of Reinforcement Steel – At = MR / tjd = 192597 / 1400 x 25.47 x 0.87 = 6.20 cm2 .

Use 16 mm Φ Bar – Nos of Bar = 6.20 / 2.0096 = 3.085. Say 4 Nos of Bars.

**************************************

Q.37 - Design a double reinforced RCC roof slab for a room of size 16’ x 16’. [ LDCE 1984 ]

Strength of Materials, Structural Design & Drawings 33

Ans.- Let thickness of slab = 14 cm. Effective depth of slab d = 14 – 2 = 12 cm.

Effective width lx = 4.80 + 0.12 = 4.92 m. Effective length ly = 4.80 + 0.12 = 4.92 m.

r = ly / lx = 4.92 / 4.92 = 1,

Weight on slab - i) Self weight of slab = 0.14 x 2500 x 1 x 1 = 350 kg.

ii) Weight of finishing = 50 kg. iii) Live load = 300 kg.

Total load = 350 + 50 + 300 = 700 kg.

Wx = r4 / 1 + r4 x w = 14 / 1 + 14 x 700 = ½ x 700 = 350 kg.

Wy = W – Wx = 700 – 350 = 350 kg.

Mx = My = Wx lx2 / 8 x 100 = 350 x 4.922 / 8 x 100 = 105903 kg cm.

Maximum BM = 105903 kg cm.

Effective depth of slab d = √ M / Qb = √ 105903 / 8.48 x 100 = 11.17 cm. [ Q = 8.48 ]

Total depth of slab = 11.17 + 1.5 + 1.0/2 = 13.17 cm. Say – 14 cm.

Effective depth 14 – 2 = 12 cm.

Area of Reinforcement Steel – At = MR / tjd = 105903 / 1400 x 12 x 0.87 = 7.25 cm2 .

[ t = 1400 , j = 0.87 ]

10 mm dia bar c / c distance Px = 100 x 0.785 / 7.25 = 10 82 cm. say 10 cm. c / c .

Atx = Aty = 7.25 cm2 . Py = 100 x 0.785 / 7.25 = 10 82 cm. say 10 cm. c / c

*************************************

Q.38.- Design a RCC column and footing to carry a load of 100 tones. Soil at 8 ft. depth has a

safe bearing capacity of 15 tones per M2. propose the quality of concrete, footing and

illustrate by a dimensional sketch. [ LDCE 1989 ]

Ans.- Weight on column = 100 tones.

Self weight of column foundation = 20% of weight on column = 20 / 100 x 100 = 20 tones.

Total weight on column = 100 + 20 = 120 Tones.

Bearing capacity of soil at 8’ ( 2.40 m. ) depth = 15 Tones /m2.

Hence depth of column foundation will be taken = 2.40 m.

Area of foundation bed A = Total Load / bearing capacity = 120 / 15 = 8 m2.

Size of footing a = √ 8 = 2.828 m. Say 2.90 m.

P1 = Load / Area = 100 / 8 = 12.5 T/ m2 = 12500 kg / m2.

Let size of column b = 45 cm.

i ) Force = P1 ( a2 – b2 ) = 12500 x ( 2.902 – 0.452 ) = 102625 kg. Let foundation depth d,

Force = 4 bd x Bearing capacity of soil , 102625 = 4 x 45 x d x 15 ,

d = 102625 / 4 x 45 x 15 = 38 cm.

ii ) M = p’ x a/8 x ( a – b )2 x 100 = 12500 x 2.90 / 8 ( 2.90 – 0.45 )2 x 100 = 2719882 kg cm.

MR = Qb1d2, b1 = b + 1/8 ( a – b ) = 45 + 1/8 ( 290 –45 ) = 75.62 cm. Say 76 cm.

Proposed Mix M150 – 1 : 2 : 4, For M150 Q = 8.48 and t = 1400 kg / cm2.

d = √ MR / Qb1 = √ 2719882 / 8.48 x 76 = 64.96 cm.

Depth of footing - D = d + cover = 64.96 + 7.5 = 72.46 cm. Say – 75 cm.

At = M / tjd = 2719882 / 1400 x 0.87 x 64.96 = 34.376 cm2.

Proposed 16 mm Φ bar in column footing – Nos of bar = 34.376 / 2.01 = 17.10 say 18 Nos. @

at 2.90 – 0.10 / 18 = 0.15 cm. C / C.

Reinforcement in column 0.8% of column section = 0.8 / 100 x 452 = 16.20 cm2.

Provide 16 mm Φ bar in column , Nos of bar = 16.20 / 2.01 = 8.05 bars. Say 8 bars

Lateral ties –Diameter of ties shall not be less than –

i. 1/ 4 x Dia of longitudinal bars = 16 / 4 = 4 mm.

Strength of Materials, Structural Design & Drawings 34

ii. 5 mm.

Provide 8 mm dia ties.

Pitch of ties - Pitch of ties shall not exceed –

i. Least lateral dimension of column – 450 mm.

ii. 16 x Diameter of longitudinal bars = 16 x 16 = 256 mm.

iii. 48 x diameter of ties = 48 x 8 = 384 mm.

Provide 8 mm dia tie @ 180 mm C / C.

***********************************

Q.39 - A retaining wall 6 m high has smooth vertical back. The backfill has a horizontal surface

in level with the top of wall . There is a uniformly distributed surcharge load of 3.6 t / m2

intensity over the backfill. The density of back fill is 1.8 t / m2 its angle of shear resistance

is 30o and rise cohesion is zero.

Determine the magnitude and point of application of active pressure per meter length of

the wall. [ LDCE 2000 ]

Ans.- Given Surcharge = 3.6 t / m2 , Weight of Soil W1 = 1.8 t / m3

Depth of Soil h1 = 6.00 m. , Angle of shear resistance = 300

Resultant Lateral pressure per meter length of the retaining wall .

The pressure diagram on the retaining wall is shown in fig.

P1 - Total pressure due to soil. , P2 - Total pressure due to surcharge.

We know that the pressure BC

1 – Sin ø 1 – Sin 300

= W1 h1 x -------------- = 1.8 x 6 x ---------------- = 3.6 t / m2

1 + Sin ø 1 + Sin 300

Strength of Materials, Structural Design & Drawings 35

And Pressure DB

1 – Sin 300

= 3.6 x ------------------ = 1.2 t / m2

1 + Sin 300

Total pressure due to soil –

P1 = Area of Triangle ABC x length of wall = ½ x 3.6 x 6 x 1 = 10.8 t.

P2 = Area of rectangle ABCD x length of wall = 1.2 x 6 x 1 = 7.2 t.

Total pressure P = P1 + P2 = 10.8 + 7.2 = 18 T. Ans.

Point of application of the resultant pressure –

Let Y = Height of the point of application from the bottom of the wall.

Taking moments of all pressures about D and equating the same –

P x Y = [ pressure ABC x 6 / 3 ] + [ Pressure ABDE x 6 / 2 ]

18 x y = [ 10.8 x 2 ] + [ 7.2 x 3 ] = 21.60 + 21.60 = 43.20 m

Y = 43.60 / 18 = 2.40 m. Ans.

****************************************************

Q. 40. - Draw a realistic dimensioned sketch of -

RCC ‘T’ beam, showing its reinforcement in a longitudinal section, cross section and a

sectional plan. [ LDCE 1996 ]

Ans. – L Section of the T Beam

Strength of Materials, Structural Design & Drawings 36

Cross Section of Slab with T Beam

**************************************************

Q. 41.- Draw the Shear force and Bending movement diagram with values. [ LDCE 2007 ]

Ans.-

Strength of Materials, Structural Design & Drawings 37

Shear Force –

The shear force diagram is drawn in fig. And values are Tabulated hear

FA = - ( 2 + 2 x 1 ) = - 4 T. FB = - 2 T, FC = - 2 T.

Bending Moment –

The Bending Moment Diagram is drawn in fig. And the values are tabulated hear

MA = - [ ( 2 x 4 ) + 1 x 2 x 2 / 2 = - [ 8 + 2 ] = - 10 T M. MB = - ( 2 x 2 ) = - 4 TM. MC = 0,

****************************

Q. 42. - Draw the typical reinforcement details in the following RCC Beam. [ LDCE 2007]

Ans.-

*********************

Q. 43. - Write short notes on the following :

i. Draw and explain the ‘Stress- Strain’ curve of mild steel. Also mark the corresponding

points in the graph to represent the yield stress & ultimate strength. Which stress is

taken in our design calculations and why? [ LDCE 2003, 2006 ]

Draw and explain the ‘Stress- Strain’ curve of mild steel. [ LDCE 2008 ]

ii. Yeild stress and ultimate stress. [ LDCE 2007, 2008 ]

iii. Yeild stress. [ LDECE 2012 ]

iv. In what ways a riveted joint can fail. [ LDCE 2008 ]

Ans.- ( I ) Stress- Strain’ curve of mild steel –

Strength of Materials, Structural Design & Drawings 38

The stress level at which a metal or other material ceases to behave elastically. The stress

divided by the strain is no longer constant. The point at which this occurs is known as the yield

point.

Common metals like steel, brass, aluminum behave in a predetermined fashion when subjected

to external force. When a metal rod is pulled gradually, its length increase the stress and strain

graph, when drawn will appear as shown below –

It can be seen that from A to B the graph is a straight line which means that the elongation to

force applied.

Beyond the point B the metal yield and elongation is much more than the force applied then at

Point c there is ultimate failure. The Point B denotes yield strength and point C denotes ultimate

strength.

Safe stress or Working stress or Ultimate stress is taken in our design calculations because

stress up to which a structure can work safely without permanent set well within elastic limit.

( ii ) Yeild stress and ultimate stress - As above.

( iii ) Failure of a Riveted Joint –

The Riveted joint may fail in any of the following manners :-

i. Tearing of the plate between rivet holes :- The strength of the plate is reduced by rivet

holes and plate may tear off along the line of the rivet holes.

ii. Shearing of rivet :- The rivet s fail by shearing if the shearing stress exceeds their

shearing strength.

iii. Bearing of plate or rivet :- The plate or rivet is crushed if the compressive stress exceeds

the bearing strength of the plate or the rivet.

iv. Edge cracking :- The plate will crack at the back of a rivet if it is placed very near to the

edge of the plate.

***************************************

Strength of Materials, Structural Design & Drawings 39

Q.44. - Draw a typical reinforcement diagram ( cross section ) of one way continuous roof ( 5 x 6

m span ) Slab simply supported on brick walls. [ LGS 2003 ]

Ans.- Typical reinforcement diagram ( cross section ) of one way continuous roof ( 5 x 6

m span ) Slab simply supported on brick walls-

*******************************

Q.45.- ( a ) As an AEN what precautions you will take while casting of an RCC slab of room.

( b ) Show the details of reinforcement of an over hanging canopy with a sketch.

[ LGS 2007 ]

Ans.- ( a ) Following precautions you will take while casting of a RCC slab of a room –

xii. Adequate quantity of material of material of approved quality available at site.

xiii. The form work props are in order.

xiv. The reinforcement is as per approved drawing and spacers for cover is provided.

xv. Concrete is mixed in a mechanical mixture.

xvi. Least time less between mixing of laying of concrete.

xvii. Foreign material such as wood shaving etc. are removed from form work before lay

concrete.

xviii. Water cement ratio is controlled.

xix. Cement added to the correct proportion.

xx. Compaction mechanically.

xxi. Provide opening / cavities wherever indicated.

xxii. Laying to be done continuously. If unavailable take necessary precautions.

( b ) Details of reinforcement of an over hanging canopy -

Strength of Materials, Structural Design & Drawings 40

************************

Q.46.- Draw the Shear force diagram for following beam. [ LDCE 2008 ]

Ans.- Taking moment about A

RB x 8 = ( 4000 x 6 ) + 2000 x 4 x 4/2 = 24000 + 16000 = 40000, RB = 40000 / 8 = 5000 N.

And RA = ( 4000 + 2000 x 4 ) – 5000 = 12000 – 5000 = 7000 N.

Shear Force –

The shear force diagram is drawn in fig. And values are Tabulated hear

FA = - 7000N, FC = 5000 - 4000 = + 1000 N, FD = + 5000 N, FB = + 5000N.

Bending Moment –

The Bending Moment Diagram is drawn in fig. And the values are tabulated hear

MA = 0 , MC = ( 5000 x 4 ) – ( 4000 x 2 ) = 20000 – 8000 = 12000 Nm., MD = 5000 x 2 = 10000

Nm., MB = 0

Maximum Bending Moment –

X / 7000 = (4 – x) / 1000 , 1000 x = 28000 – 7000 x , 1000 x + 7000 x = 28000 , 8000 x =

28000 , x = 28000 / 8000 = 3.5 m.

MM = ( 5000 x 4.5 ) – ( 4000 x 2.5 ) – ( 0.5 x 2000 x 0.5 / 2 ) = 22500 – 10000 – 250 = 22500

– 10250 = 12250 Nm.

Strength of Materials, Structural Design & Drawings 41

***************************

Q. 47.- Draw bending moment and shear force diagram for a beam having live loads as

indicated below. Assume dead load of the beam as 0.25 t / m. Also show the typical

arrangement of main and distribution reinforcements for this beam.

( WCR LDCE 2012 )

Ans.- RA + RB = 3.00 + 0.25 x 6.00 + 1 x 4.5 + 1.50

= 3.00 + 1.50 + 4.50 + 1.50 = 10.50 T

Taking Moment about A –

RB x 4.50 = 1.50 x 6.00 + 0.25 x 6.00 x 3.00 + 1 x 4.50 x 2.25 + 3.00 x 1.50 – 2.00 ( - 2 T Due

to anticlockwise couple )

RB x 4.50 = 9.00 + 4.50 + 10.125 + 4.50 – 2.00 = 26.125 T

RB = 26.125 / 4.50 = 5.80 T

RA = 10.50 – 5.80 = 4.70 T

Strength of Materials, Structural Design & Drawings 42

Shear Force – The S. F. Diagram is shown in fig and the values are Tabulated hear –

FA = + 4.70 T,

FD = 4.70 – 0.25 x 1.50 – 1 x 1.50 = 4.70 – 0.375 – 1.50 = 4.70 – 1.875 = + 2.825 T

FB = - 0.175 – 1 x 3.00 – 0.75 x 3.00 = - 0.175 – 3.00 – 0.75 = 3.925 T

FC = 1.875 – 0.25 x 1.50 = 1.875 -0.375 = + 1.50 T

Bending Moment – The B.M. Diagram is shown in fig and the values are Tabulated hear –

MA = 0, MC = 0,

MD = 4.70 x 1.50 – 0.25 x 1.50 x 0.75 – 1 x 1.50 x 0.75

= 7.05 – 0.28 – 1.125 = 7.05 – 1.405 = 5.645 Tm.

At D the B.M. will suddenly decrease from 5.645 to 2 Tm because of anti clock wise couple as

shown in fig. 5.645 – 2.00 = 3.845 Tm.

MB = 4,70 x 4.50 – 3.00 x 3.00 – 1 x 4.50 x 2.5 – 0.25 x 4.50 x 2.25 – 2.00

= 21.15 – 9.00 – 10.125 – 2.53 – 2.00 = 21.15 – 23.655 = - 2.505 Tm.

******************************

Q. 48 - Draw the bending moment diagram for the following beam indicating values at critical

locations. [ LDCE 2012 ]

Ans.- Taking moments about A

RB x 6 = ( 4 x 6 x 3 ) + ( 8 x 4 ) + ( 8 x 2 ) = 72 + 32 + 16 = 120

RB = 120 / 6 = 20 T

And RA = ( 8 + 8 + 4 x 6 ) – 20 = 40 – 20 = 20 T.

Strength of Materials, Structural Design & Drawings 43

Bending Moment Diagram

Bending Moment –

The Bending Moment Diagram is drawn in fig. And the values are tabulated hear

MA = 0 , MC = ( 20 x 2) – ( 4 x 2 x 1 ) = 40 – 8 = 32 Tm ,

MD = ( 20 x 4 ) – ( 4 x 4 x 2 ) – ( 8 x 2 ) = 80 – 32 – 16 = 80 - 48 = 32 Tm. MB = 0

Maximum Bending Moment –

Since RA = RB Hence Maximum Bending Moment at Center.

MM = ( 20 x 3 ) - ( 4 x 3 x 1.5 ) – ( 8 x 1 ) = 60 – 18 – 8 = 34 Tm.

*************************************

Q.49.- Draw shear force diagram for the following beam showing values. [ LDCE 2012 ]

Ans.- Shear force - The S. F. Diagram is shown in fig and the values are Tabulated hear –

FC = 0 T, FB = 1 x 1.5 = 1.5 T, and 1.5 + 1 = 2.5 T, FA = ( 1 x 3 ) + 1 = 4 T.

Shear Force Diagram

****************************************

Strength of Materials, Structural Design & Drawings 44

Q. 50. - In what manner prestressed concrete technology is economical and superior to RCC

structure ? Explain with the help of a typical bending moment or stress diagram.

[ LDCE 2012 ]

Ans.- Prestressed concrete technology is economical and superior to RCC structure of the

following reasons –

1. A Prestressed concrete member is a member of concrete in which internal stresses are

introduced in a planned manner so that the stresses resulting from the superimposed

loads are counteracted to a desired degree.

2. Concrete has a high compressive strength compared to its very low tensile strength.

3. In RCC members due to the low tensile resistance of concrete a large quantity of steel

reinforcement is provided so that the entire tensile resistance is taken as offered by the

reinforcement.

4. Concrete will also offer a tensile resistance along with the steel reinforcement and in this

process will develop minute tensile stress.

5. Under the usual superimposed working loads the concrete present in the tension zone of

a reinforced concrete member will develop cracks not being able to can from to the

strains taking place in the steel.

6. A reinforced concrete member has other weaknesses too.

7. The dimensions of the member may also have to be determined from diagonal tensile

stress considerations.

8. In the case of beams where large shear forces exist the beam sizes have got to be large

to limit the diagonal tensile stresses under certain limits.

9. In the concrete member is also found to develop cracks even the absence of loads due

to the shrinkage of concrete in the hardening stage.

10. Prestressed concrete member are thinner in section & therefore not heavy.

In a Prestressed concrete member all the above defects and weaknesses are made up due to

under example –

A simply supported prestressed by a tendon provided through its centroidal longitudinal axis. Let

the beam be subjected to an external load system. Let P be the prestressing force supplied by

the tendon. Due to this prestressing force the compressive stress induced in concrete fa = P / A

where A is the sectional area of the member. If due to the dead load and external loads. The

bending moment at a section is M than the extreme at the section due bending moment alone.

Fb = ± M / Z Where Z is the section modulus of the beam section.

F = fa ± fb = P / A ± M / Z

Stress at the extreme top edge = P / A + M / Z

Stress at the extreme Bottom edge = P / A - M / Z

The amount of prestressing force we can reduce the tension at bottom or eliminate entire

tension or introduce compression throughout the section of a beam so that it can resist

considerably greater bending moment than ordinary reinforced concrete beam.

*******************************

Strength of Materials, Structural Design & Drawings 45

Q. 51. - What steps are involved in designing a retaining wall? Also indicate various forces to be

considered with help of a diagram. [ LDCE 2012 ]

Ans. - Steps involved in designing a retaining wall –

1. Design constants – For M15 and Fe 415, σcbc = 5 N / mm2, m = 18.66, σst = 230 N / mm2,

x = 0.29d, z = 0.90d, Mr = 0.65 bd2, pt = 0.32.

2. Trial dimensions of wall -

i. The length of the base is between 0.4 to 0.7 times the height of the wall.

ii. Toe to base ratio is 1 : 4.

iii. The thickness of base slab shall be more than thickness of the stem at the bottom.

iv. The minimum thickness of the stem shall be 200 mm.

3. Earth pressure on wall –

From Rankine’s theory of earth pressure –

WH2 ( 1 – sin F )

P = -------(--------------)

2 ( 1 + sin F )

Where – P = total pressure on wall acting at H / 3 from the base. H = total height in meters.

W = weight of density of earth in kN / m3 . F = angle of repose of earth.

4. Bending moment & Thickness of stem -

Bending moment M = P x H / 3

Thickness of stem - M = Mr = 0.65 bd2

5. Steel - M

Ast = ------

σst z

6. Distribution Steel – 0.12 % of Ag Where Ag = Cross section area of stem at center.

7. Stability of retaining Wall -

Factor of safety for overturning – Moment due to load of wall

------------------------------------- ≥ 1.5

Moment due to force P

Factor of safety for Sliding - Total load of wall x µ

----------------------------- ≥ 1.5

Force P

Where - µ = coefficient of friction between base and the ground below.

8. Check for shear - V

v = -------

bd

For concrete M15 and pt = 0.31 and c = 0.22 N /mm2

Strength of Materials, Structural Design & Drawings 46

If c > v no shear reinforcement is required.

9. Development length - F σs

Ld = ------------

4 bd

**************************************

Strength of Materials, Structural Design & Drawings 47

S-ar putea să vă placă și

- 9.1 Formwork Notes-1Document4 pagini9.1 Formwork Notes-1RahulSinghRajput100% (1)

- Types of Formwork (Shuttering) For ConcreteDocument29 paginiTypes of Formwork (Shuttering) For Concretesaima BatoolÎncă nu există evaluări

- Circular TanksDocument8 paginiCircular TanksMohamed Ehab100% (1)

- Choice of Foundation For BrigdesDocument15 paginiChoice of Foundation For BrigdesSamuel AntobamÎncă nu există evaluări

- Lecture Notes on Reinforced Concrete DesignDe la EverandLecture Notes on Reinforced Concrete DesignÎncă nu există evaluări

- Architectural 5 - Building TechDocument14 paginiArchitectural 5 - Building Techdice tengayÎncă nu există evaluări

- Introduction To RCDDocument41 paginiIntroduction To RCDChristian James Ingco100% (1)

- Non Engineered Reinforced Concrete BuildingDocument11 paginiNon Engineered Reinforced Concrete Buildingmath_0222Încă nu există evaluări

- CE2404 QB PDFDocument20 paginiCE2404 QB PDFresha bhatiaÎncă nu există evaluări

- Important Questions PDFDocument20 paginiImportant Questions PDFresha bhatiaÎncă nu există evaluări

- Design of Composite BridgeDocument10 paginiDesign of Composite BridgeHarold Jackson MtyanaÎncă nu există evaluări

- CEB 711 - Structural Design II: Semester 2, 2020 2Document32 paginiCEB 711 - Structural Design II: Semester 2, 2020 2Asnil PrakashÎncă nu există evaluări

- 150 Interview Qs For Fresh CIVIL EngineersDocument18 pagini150 Interview Qs For Fresh CIVIL EngineersKashif Khan100% (2)

- Questions and Answers For Bridge EngineerDocument7 paginiQuestions and Answers For Bridge Engineeralfaza3Încă nu există evaluări

- Introduction To Reinforced ConcreteDocument65 paginiIntroduction To Reinforced ConcreteIsmail FarajpourÎncă nu există evaluări

- Introduction To Reinforced ConcreteDocument54 paginiIntroduction To Reinforced ConcreteHussain Al AmerÎncă nu există evaluări

- Advanced Construction Methods in R.C.C: Prestessed ConcreteDocument12 paginiAdvanced Construction Methods in R.C.C: Prestessed Concretepoosa annupriyaÎncă nu există evaluări

- Rehabilitation Techniques: Assignment ONDocument10 paginiRehabilitation Techniques: Assignment ONEldho CaÎncă nu există evaluări

- Cantilever DesignDocument8 paginiCantilever DesignJun CrisostomoÎncă nu există evaluări

- National Conference On Recent Advances in Science and Engineering NCRASE-2019Document22 paginiNational Conference On Recent Advances in Science and Engineering NCRASE-2019som dutt thanviÎncă nu există evaluări

- Simplified Reinforced Concrete Design 1Document87 paginiSimplified Reinforced Concrete Design 1Josua Biadno MenisÎncă nu există evaluări

- Building Construction ReportDocument15 paginiBuilding Construction ReportDevendra SharmaÎncă nu există evaluări

- BT Searc Search SearchDocument13 paginiBT Searc Search Searchdice tengayÎncă nu există evaluări

- RCC and PSCDocument50 paginiRCC and PSCradhakrishnangÎncă nu există evaluări

- Reinforced Concrete Design FundamentalsDocument49 paginiReinforced Concrete Design FundamentalsMichael SuanÎncă nu există evaluări

- 3 - Durability of Reinforced Concrete StructureDocument24 pagini3 - Durability of Reinforced Concrete StructureyakaÎncă nu există evaluări

- Canal LiningDocument10 paginiCanal LiningShahid RøckzzÎncă nu există evaluări

- Analysis and Designe of Water TanksDocument28 paginiAnalysis and Designe of Water TanksJuan Agustin DiazÎncă nu există evaluări

- Types of VibratorsDocument13 paginiTypes of VibratorsM Baqir IsmailÎncă nu există evaluări

- 150 Civil Interview QuestionsDocument18 pagini150 Civil Interview QuestionsWei LeeÎncă nu există evaluări

- Introduction To Advanced R.C.C Roofing.: Group - 1Document15 paginiIntroduction To Advanced R.C.C Roofing.: Group - 1Nidhi MehtaÎncă nu există evaluări

- Civil Engineering Interview QuestionsDocument7 paginiCivil Engineering Interview QuestionsAdjei BaldanÎncă nu există evaluări

- RCC Short NotesDocument5 paginiRCC Short Notesashok pradhanÎncă nu există evaluări

- Bs5400 DesignDocument10 paginiBs5400 DesignMahesh Pokhrel67% (3)

- 150 Civil Engineer Interview Questions Asked in Top CompaniesDocument15 pagini150 Civil Engineer Interview Questions Asked in Top CompaniesApon khanÎncă nu există evaluări

- What Are The Steps Involved in The Concreting ProcessDocument7 paginiWhat Are The Steps Involved in The Concreting ProcessMohammed RafeeqÎncă nu există evaluări

- Mix Design of Concrete and Properties of Green ConcreteDocument32 paginiMix Design of Concrete and Properties of Green ConcreteShuvanjan Dahal100% (9)

- Reinforced Concrete Design GuideDocument46 paginiReinforced Concrete Design GuideJohn Cedrick JulatonÎncă nu există evaluări

- DPSC Mod 1 IntroductionDocument12 paginiDPSC Mod 1 IntroductionKajalÎncă nu există evaluări

- Module 8 SAHITA ConcreteDocument11 paginiModule 8 SAHITA ConcreteHarrybfnÎncă nu există evaluări

- Engineering Interview QuestionDocument174 paginiEngineering Interview QuestionKharisma Jayatra100% (1)

- Interview Question Bank on Standard Brick Sizes, Concrete Admixtures, and Reinforcement CodesDocument6 paginiInterview Question Bank on Standard Brick Sizes, Concrete Admixtures, and Reinforcement CodesT SeriesÎncă nu există evaluări

- Congested ReinforcementDocument2 paginiCongested ReinforcementCT0011100% (1)

- A RC Filler Slab With Non-Autoclaved Cellular Concrete Blocks For Sustainable ConstructionDocument8 paginiA RC Filler Slab With Non-Autoclaved Cellular Concrete Blocks For Sustainable ConstructionShailendra Mark EkkaÎncă nu există evaluări

- Concrete CanvasDocument20 paginiConcrete CanvasJet Espejon JavierÎncă nu există evaluări

- Quality Assurance For ConcreteDocument4 paginiQuality Assurance For ConcretePreethi SekarÎncă nu există evaluări

- Civil Engineering Interview QuestionsDocument12 paginiCivil Engineering Interview Questionsjadgug100% (1)

- Water StopperDocument6 paginiWater StopperMF YousufÎncă nu există evaluări

- Appendix 2 Concrete OverlaysDocument29 paginiAppendix 2 Concrete Overlaysproteor_srlÎncă nu există evaluări

- REPORT ON EXPANSION JOINTSDocument19 paginiREPORT ON EXPANSION JOINTSAr Dinesh GaikwadÎncă nu există evaluări

- IDE-Lec8-Canal LiningDocument65 paginiIDE-Lec8-Canal LiningAhmed RazaÎncă nu există evaluări

- Pre-stressed Concrete Structures: Advantages, Limitations, and Need for High Strength MaterialsDocument11 paginiPre-stressed Concrete Structures: Advantages, Limitations, and Need for High Strength MaterialsAlbinPSunnyÎncă nu există evaluări

- Two Mark QuestionsDocument9 paginiTwo Mark QuestionsNitin SureshÎncă nu există evaluări

- Folded plate structures: thin-walled building shellsDocument4 paginiFolded plate structures: thin-walled building shellsSonal Sharma50% (2)

- RCDA - 02 - Reinforced Concrete V1Document19 paginiRCDA - 02 - Reinforced Concrete V1Victor MirandaÎncă nu există evaluări

- General Construction Practice Methods R.rajkUMARDocument43 paginiGeneral Construction Practice Methods R.rajkUMARGurupriyaÎncă nu există evaluări

- RCD - Chapter 1Document22 paginiRCD - Chapter 1James KarlÎncă nu există evaluări

- EstimationDocument51 paginiEstimationAVINASH TINKUÎncă nu există evaluări

- Reinforced Concrete Buildings: Behavior and DesignDe la EverandReinforced Concrete Buildings: Behavior and DesignEvaluare: 5 din 5 stele5/5 (1)

- Question Paper For Junior Engineer Pway in S W RailwayDocument26 paginiQuestion Paper For Junior Engineer Pway in S W Railwayamitkap00rÎncă nu există evaluări

- IndexDocument1 paginăIndexamitkap00rÎncă nu există evaluări

- Question Bank of PWay Engineering For TMO TRACK MACHINEDocument28 paginiQuestion Bank of PWay Engineering For TMO TRACK MACHINEamitkap00rÎncă nu există evaluări

- Railway Syllabus of LDCE For Promotion To Group B in Civil Engineering Cadre 30% Quota LDCE - CM JHA AcademyDocument3 paginiRailway Syllabus of LDCE For Promotion To Group B in Civil Engineering Cadre 30% Quota LDCE - CM JHA Academyamitkap00rÎncă nu există evaluări

- Answer Key Jee 2 PDFDocument16 paginiAnswer Key Jee 2 PDFamitkap00rÎncă nu există evaluări

- General KnowledgeDocument36 paginiGeneral Knowledgeamitkap00rÎncă nu există evaluări

- Civil Engineering Objective Type QuestionsDocument15 paginiCivil Engineering Objective Type QuestionsJean Simon100% (7)

- 2021 - 09 - 06 RBCE - CE-I-CT Change of Base Year of Consumer Price Index of Industrial Workers (Labour Index)Document3 pagini2021 - 09 - 06 RBCE - CE-I-CT Change of Base Year of Consumer Price Index of Industrial Workers (Labour Index)amitkap00rÎncă nu există evaluări

- 2021 - 09 - 06 RBCE - CE-I-CT Change of Base Year of Consumer Price Index of Industrial Workers (Labour Index)Document3 pagini2021 - 09 - 06 RBCE - CE-I-CT Change of Base Year of Consumer Price Index of Industrial Workers (Labour Index)amitkap00rÎncă nu există evaluări

- Construction MaterialDocument9 paginiConstruction Materialamitkap00rÎncă nu există evaluări

- Strength of Materials, Structural Design & DrawingsDocument24 paginiStrength of Materials, Structural Design & Drawingsamitkap00rÎncă nu există evaluări

- JEE-Main-January-12-Shift2 2 PDFDocument43 paginiJEE-Main-January-12-Shift2 2 PDFamitkap00rÎncă nu există evaluări

- Management of Engineering StoresDocument4 paginiManagement of Engineering Storesamitkap00rÎncă nu există evaluări

- SURVEYINGDocument29 paginiSURVEYINGamitkap00rÎncă nu există evaluări

- Foundation & Construction EngineeringDocument20 paginiFoundation & Construction Engineeringamitkap00rÎncă nu există evaluări

- Hydraulics & HydrologyDocument4 paginiHydraulics & Hydrologyamitkap00rÎncă nu există evaluări

- CBIC GST: GST Goods and Services RatesDocument70 paginiCBIC GST: GST Goods and Services Ratesamitkap00rÎncă nu există evaluări

- Tax Information: Collecting CustomerDocument2 paginiTax Information: Collecting Customeramitkap00rÎncă nu există evaluări

- Better Burger, Chicken Confidential & Mach2 discountsDocument10 paginiBetter Burger, Chicken Confidential & Mach2 discountsamitkap00rÎncă nu există evaluări

- Annexure Classification of ServicesDocument20 paginiAnnexure Classification of Servicesamitkap00rÎncă nu există evaluări

- JEE-MAIN-2019-Answer 3 PDFDocument40 paginiJEE-MAIN-2019-Answer 3 PDFamitkap00rÎncă nu există evaluări

- Principles of Physical ChemistryDocument23 paginiPrinciples of Physical ChemistryShibu Kumard0% (1)

- ASR STN 8 CRDocument20 paginiASR STN 8 CRamitkap00rÎncă nu există evaluări

- 6508Document6 pagini6508amitkap00rÎncă nu există evaluări

- Gu'Idelines For Manufacture OF $ Gypsum Plaster in 1L Iechanized ' Pan System w?hmw6 !Document7 paginiGu'Idelines For Manufacture OF $ Gypsum Plaster in 1L Iechanized ' Pan System w?hmw6 !amitkap00rÎncă nu există evaluări

- Lowgradegypsum-Useinbuilding - ., - Industry-Codeofpractice 0 T ,' - VRM"RSDocument7 paginiLowgradegypsum-Useinbuilding - ., - Industry-Codeofpractice 0 T ,' - VRM"RSamitkap00rÎncă nu există evaluări

- 4139Document7 pagini4139amitkap00rÎncă nu există evaluări

- Preparationandusbof Ltm-E-Pozzolana Mixtureconcrete Inbuildingsandroads-Code Ofpractice (Document11 paginiPreparationandusbof Ltm-E-Pozzolana Mixtureconcrete Inbuildingsandroads-Code Ofpractice (amitkap00rÎncă nu există evaluări

- Reaffirmed 2002Document9 paginiReaffirmed 2002amitkap00rÎncă nu există evaluări

- Tutorial Chapter 9Document3 paginiTutorial Chapter 9Nurul MawaddahÎncă nu există evaluări

- P4. Fungsi Keadaan Dan Diferensial EksakDocument8 paginiP4. Fungsi Keadaan Dan Diferensial EksakAnis AnisaÎncă nu există evaluări

- Mechanics of MaterialsDocument0 paginiMechanics of Materialssatishkumarkolluru9809Încă nu există evaluări

- "2020" Seminar Information: FORD 6R140W - 6R80Document4 pagini"2020" Seminar Information: FORD 6R140W - 6R80Gina LópezÎncă nu există evaluări

- Stamping (Metalworking)Document5 paginiStamping (Metalworking)Odebiyi StephenÎncă nu există evaluări

- Manual Termostato Digitall t6812 FancoilDocument4 paginiManual Termostato Digitall t6812 FancoilaarroyofÎncă nu există evaluări

- Workshop Manual Freightliner M915a3Document20 paginiWorkshop Manual Freightliner M915a3jennifer100% (50)

- A330 RR Trent 700 Technical Training Manual Mechanical & Avionics Course - T1+T2 (LVL 2&3) APUDocument110 paginiA330 RR Trent 700 Technical Training Manual Mechanical & Avionics Course - T1+T2 (LVL 2&3) APULuiz Fernando MibachÎncă nu există evaluări

- Fired Heater ModelingDocument19 paginiFired Heater ModelingAhmed Elhady100% (1)

- Hydraulic Transmission, Installing: Información de ServicioDocument5 paginiHydraulic Transmission, Installing: Información de ServicioFútbol y másÎncă nu există evaluări

- Rotary ActuatorDocument4 paginiRotary ActuatorAnderson Luiz GambaroÎncă nu există evaluări

- Numerical Simulations of Interrupted and Conventional Microchannel Heat SinksDocument12 paginiNumerical Simulations of Interrupted and Conventional Microchannel Heat SinksAnkit LonareÎncă nu există evaluări

- Service Bulletin: - CorrectedDocument3 paginiService Bulletin: - CorrectedmichaeltibocheÎncă nu există evaluări

- BMW Z4 BrochureDocument8 paginiBMW Z4 BrochureNicolo GarciaÎncă nu există evaluări

- Austenitic Stainless Steel Tube, Pipe & Fittings-ZHEJIANG JIUSIN PIPE CO., LTDDocument3 paginiAustenitic Stainless Steel Tube, Pipe & Fittings-ZHEJIANG JIUSIN PIPE CO., LTDMichael VillaluzÎncă nu există evaluări

- AWWA Tapping SleevesDocument21 paginiAWWA Tapping SleevesdanilobossuÎncă nu există evaluări

- Pfaudler Din Be Reactors 1Document42 paginiPfaudler Din Be Reactors 1Nancy GarciaÎncă nu există evaluări

- Agma 908-B89-1999Document79 paginiAgma 908-B89-1999Alex OliveiraÎncă nu există evaluări

- Orrcon National Product CatalogueDocument84 paginiOrrcon National Product CatalogueEswaran RajamaniÎncă nu există evaluări

- F302Manual PDFDocument38 paginiF302Manual PDFPaulo Coimbra100% (1)

- 03 Nissan Maxima Engine ControlDocument738 pagini03 Nissan Maxima Engine ControlHaus El Muflih Aflaha100% (1)

- TURNING FIX (04-005) - Sheet - 1Document1 paginăTURNING FIX (04-005) - Sheet - 1daryosh hassanyÎncă nu există evaluări

- Baja Design Report PDFDocument9 paginiBaja Design Report PDFZubair HussainÎncă nu există evaluări

- Selecting, Operating, and Maintaining Electric Motors: Instructional Materials Service Texas A&M University 8795Document153 paginiSelecting, Operating, and Maintaining Electric Motors: Instructional Materials Service Texas A&M University 8795John Reantaso100% (1)

- FEMA Precast Concrete Design ExamplesDocument175 paginiFEMA Precast Concrete Design ExamplesFeras TemimiÎncă nu există evaluări

- Repair Parts Catalog: FOR Sunnen Vertical Honing MachineDocument48 paginiRepair Parts Catalog: FOR Sunnen Vertical Honing MachineLucas Isaias da Silva100% (1)

- Thermal Management of Electronics Using Phase ChangeDocument9 paginiThermal Management of Electronics Using Phase ChangeRaj kumarÎncă nu există evaluări

- Sensores RGDocument47 paginiSensores RGMauricioCerdaCastilloÎncă nu există evaluări

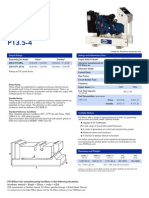

- FG Wilson P13.5-4 Generating Set Ratings and SpecsDocument4 paginiFG Wilson P13.5-4 Generating Set Ratings and Specsscribdledee100% (1)

- Cradle Operations ManualDocument33 paginiCradle Operations ManualArul Alvin InfantÎncă nu există evaluări