Documente Academic

Documente Profesional

Documente Cultură

ASME Sec VIII Div 1 Table UHT-56

Încărcat de

hieuDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

ASME Sec VIII Div 1 Table UHT-56

Încărcat de

hieuDrepturi de autor:

Formate disponibile

ASME BPVC.VIII.

1-2017 UHT-75 – UHT-79

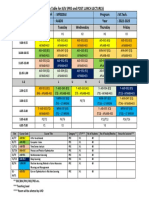

Table UHT-56

Postweld Heat Treatment Requirements for Materials in Table UHT-23

Nominal Thickness Holding Time

P‐No./ Requiring PWHT, hr/in. Minimum,

Spec. No. Grade or Type Gr. No. in. (mm) Notes PWHT Temp., °F (°C) (25 mm) hr

Plate Steels

SA-353 9Ni 11A/1 Over 2 (50) … 1,025−1,085 (550−585) 1 2

1

SA-517 Grade A 11B/1 Over 0.58 (15) (1) 1,000−1,100 (540−595) 1 /4

1

SA-517 Grade B 11B/4 Over 0.58 (15) (1) 1,000−1,100 (540−595) 1 /4

1

SA-517 Grade E 11B/2 Over 0.58 (15) (1) 1,000−1,100 (540−595) 1 /4

1

SA-517 Grade F 11B/3 Over 0.58 (15) (1) 1,000−1,100 (540−595) 1 /4

1

SA-517 Grade J 11B/6 Over 0.58 (15) (1) 1,000−1,100 (540−595) 1 /4

1

SA-517 Grade P 11B/8 Over 0.58 (15) (1) 1,000−1,100 (540−595) 1 /4

1 1

SA-533 Types B, D, Cl. 3 11A/4 Over 0.58 (15) … 1,000−1,050 (540−565) /2 /2

SA-543 Types B, C, Cl. 1 11A/5 … (2) 1,000−1,050 (540−565) 1 1

SA-543 Types B, C, Cl. 2 11B/10 … (2) 1,000−1,050 (540−565) 1 1

SA-543 Types B, C, Cl. 3 11A/5 … (2) 1,000−1,050 (540−565) 1 1

SA-553 Types I, II 11A/1 Over 2 (50) … 1,025−1,085 (550−585) 1 2

SA-645 Grade A 11A/2 Over 2 (50) … 1,025−1,085 (550−585) 1 2

SA-724 Grade A, B 1/4 None … NA NA NA

SA-724 Grade C 1/4 Over 11/2 (38) … 1,050−1,150 (565−620) 1 1

/2

Castings

1

SA-487 Class 4B 11A/3 Over 0.58 (15) … 1,000−1,050 (540−565) 1 /4

1

SA-487 Class 4E 11A/3 Over 0.58 (15) … 1,000−1,050 (540−565) 1 /4

1

SA-487 Class CA 6NM 6/4 Over 0.58 (15) … 1,050−1,150 (565−620) 1 /4

Pipes and Tubes

SA-333 Grade 8 11A/1 Over 2 (50) … 1,025−1,085 (550−585) 1 2

SA-334 Grade 8 11A/1 Over 2 (50) … 1,025−1,085 (550−585) 1 2

Forgings

SA-508 Grade 4N Cl. 1 11A/5 … (2) 1,000−1,050 (540−565) 1 1

SA-508 Grade 4N Cl. 2 11B/10 … (2) 1,000−1,050 (540−565) 1 1

SA-522 Type I 11A/1 Over 2 (50) … 1,025−1,085 (550−585) 1 2

1

SA-592 Grade A 11B/1 Over 0.58 (15) (1) 1,000−1,100 (540−595) 1 /4

1

SA-592 Grade E 11B/2 Over 0.58 (15) (1) 1,000−1,100 (540−595) 1 /4

1

SA-592 Grade F 11B/3 Over 0.58 (15) (1) 1,000−1,100 (540−595) 1 /4

GENERAL NOTE: NA = not applicable.

NOTES:

(1) See UHT-82(g).

(2) PWHT is neither required nor prohibited. Consideration should be given to the possibility of temper embrittlement. The cooling rate

from PWHT, when used, shall not be slower than that obtained by cooling in still air.

FABRICATION UHT-79 FORMING PRESSURE PARTS ð17Þ

UHT-75 GENERAL The selected thickness of material shall be such that the

The rules in the following paragraphs apply specifically forming processes will not reduce the thickness of the

to the fabrication of pressure vessels and vessel parts that material at any point below the minimum value required

are constructed of heat-treated steels covered by this Part by the rules.

and shall be used in conjunction with the general require- (a) Pieces that are formed after heat treatment at a

ments for Fabrication in Subsection A, and, when applic- temperature lower than the final tempering shall be heat

able, with the specific requirements for Fabrication in treated in accordance with Table UHT-56 when the ex-

Subsection B, Part UW. treme fiber elongation from forming exceeds 5% as deter-

mined by the equations in Table UG-79-1.

(b) Pieces that are formed at temperatures equal to or

higher than the original tempering shall be reheat treated

in accordance with the applicable material specification,

either before or after welding into the vessel.

243

S-ar putea să vă placă și

- Asme Ix QW MTDocument57 paginiAsme Ix QW MTharabiÎncă nu există evaluări

- Sponge Iron Products, Buy Sponge Iron Products From AlibabaDocument3 paginiSponge Iron Products, Buy Sponge Iron Products From AlibabasangonoteÎncă nu există evaluări

- Quality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaDocument5 paginiQuality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaPetromat Oil and Gas Equipment Pvt. Ltd.Încă nu există evaluări

- Welding SAF2205 Tubes To CS TubesheetDocument2 paginiWelding SAF2205 Tubes To CS Tubesheetmasterdol1983Încă nu există evaluări

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateDocument2 paginiWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateAmjad PathanÎncă nu există evaluări

- Bohler Welding Thermalpower - ENGDocument24 paginiBohler Welding Thermalpower - ENGghostinshellÎncă nu există evaluări

- Calculator For Welding Parameters - Rev1Document2 paginiCalculator For Welding Parameters - Rev1mehul2011Încă nu există evaluări

- WPS PQR FormulirDocument2 paginiWPS PQR FormulirAZaiÎncă nu există evaluări

- CR Mo Issues of Concern 6Document33 paginiCR Mo Issues of Concern 6Asad Bin Ala Qatari100% (1)

- Pagoda - Ebxl Xlpo Solar DC CableDocument4 paginiPagoda - Ebxl Xlpo Solar DC CableVishek MittalÎncă nu există evaluări

- Sponge Iron Industry Current Scenario SDocument2 paginiSponge Iron Industry Current Scenario Sapi-26041653100% (1)

- ASTM A36 DatasheetDocument4 paginiASTM A36 DatasheetRene D. ArrietaÎncă nu există evaluări

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 paginăQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarÎncă nu există evaluări

- Material Comparison Tables (ASTM KS, JIS, DIN, BS, NBN, NF, UNI)Document12 paginiMaterial Comparison Tables (ASTM KS, JIS, DIN, BS, NBN, NF, UNI)mihailspiridonÎncă nu există evaluări

- ReferenceDocument25 paginiReference이은지Încă nu există evaluări

- WPS - 008Document11 paginiWPS - 008MAT-LIONÎncă nu există evaluări

- Pressure Parts Weld ScheduleDocument5 paginiPressure Parts Weld SchedulesbmmlaÎncă nu există evaluări

- Review of Type IV Cracking of Weldments in 9Document64 paginiReview of Type IV Cracking of Weldments in 9Krishnan SanthanarajÎncă nu există evaluări

- Astm 4140 PDFDocument3 paginiAstm 4140 PDFRameshÎncă nu există evaluări

- Astm Nos. For Piping CommoditiesDocument1 paginăAstm Nos. For Piping CommoditiesHitesh MhatreÎncă nu există evaluări

- Condensate in HRSG PDFDocument15 paginiCondensate in HRSG PDFCoalhouse Walker JuniorÎncă nu există evaluări

- Kobelco - Kobe Steel PDFDocument6 paginiKobelco - Kobe Steel PDFbarukomkssÎncă nu există evaluări

- Hardfacing Wires: For Steel Mill RollsDocument16 paginiHardfacing Wires: For Steel Mill RollsRaviTeja BhamidiÎncă nu există evaluări

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Document6 paginiMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)attaullaÎncă nu există evaluări

- Wps No. 0 Rev. No. 19: Asme Section Ix Welding Procedure SpecificationDocument5 paginiWps No. 0 Rev. No. 19: Asme Section Ix Welding Procedure SpecificationAmit ChapagainÎncă nu există evaluări

- WPS - 006Document13 paginiWPS - 006MAT-LIONÎncă nu există evaluări

- Introduction To Combined Cycle Power Plants PDFDocument4 paginiIntroduction To Combined Cycle Power Plants PDFShamimAhammedÎncă nu există evaluări

- Test Certificate: T T T T %elon H.No. A B H.No. Size (MM) Hardness (BHN) Yield Strength UTS (Kg/mm2)Document1 paginăTest Certificate: T T T T %elon H.No. A B H.No. Size (MM) Hardness (BHN) Yield Strength UTS (Kg/mm2)yskushwah16Încă nu există evaluări

- Cleaner ProductionDocument5 paginiCleaner ProductionBECCA2908Încă nu există evaluări

- Welding Consumable GuideDocument26 paginiWelding Consumable Guidebrianpham007100% (1)

- Equivalent MaterialDocument1 paginăEquivalent Materialmuhammadf SardarÎncă nu există evaluări

- JTS Series High Speed Bevel Gear Screw Jack, Bevel Gear Driven Screw Jack, Bevel Gearbox Jack, Bevel Screw Jack Travel Speed, Screw Jack Bevel, Jack Screw Bevel Gearbox, Quick Lifting Screw JackDocument19 paginiJTS Series High Speed Bevel Gear Screw Jack, Bevel Gear Driven Screw Jack, Bevel Gearbox Jack, Bevel Screw Jack Travel Speed, Screw Jack Bevel, Jack Screw Bevel Gearbox, Quick Lifting Screw JackWarren LeeÎncă nu există evaluări

- ASTM A335 Pipe Specification1 PDFDocument8 paginiASTM A335 Pipe Specification1 PDFRoberto EliasÎncă nu există evaluări

- Trim Number Chart API ValveDocument2 paginiTrim Number Chart API ValveJuliusMaximus12Încă nu există evaluări

- SC20 Sample CoolerDocument3 paginiSC20 Sample CoolerjdanastasÎncă nu există evaluări

- Welding Electrodes For Petrochemical IndustryG PDFDocument44 paginiWelding Electrodes For Petrochemical IndustryG PDFerogonÎncă nu există evaluări

- Material Inspected This Visit Item Code Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoDocument3 paginiMaterial Inspected This Visit Item Code Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoRahul MoottolikandyÎncă nu există evaluări

- AWS Classifications of ElectrodesDocument2 paginiAWS Classifications of ElectrodesJorge SobrevillaÎncă nu există evaluări

- 06-Klitzke Sidwell Jensen Presentation Part 123Document89 pagini06-Klitzke Sidwell Jensen Presentation Part 123Nguyễn Thanh TùngÎncă nu există evaluări

- GRAFOIL Engineering Manual 2nd EdDocument117 paginiGRAFOIL Engineering Manual 2nd EdRino Nelson100% (1)

- Selection of Filler Metal For WeldingDocument21 paginiSelection of Filler Metal For WeldingRegu vlogsÎncă nu există evaluări

- WPS - 007Document11 paginiWPS - 007MAT-LIONÎncă nu există evaluări

- Common Abbreviations in The Valve IndustryDocument10 paginiCommon Abbreviations in The Valve IndustryNath BoyapatiÎncă nu există evaluări

- Q245R PDFDocument2 paginiQ245R PDFAnonymous 9zykaX6T100% (1)

- Selection of Materials For WeldingDocument1 paginăSelection of Materials For WeldingIshwarÎncă nu există evaluări

- 12 Valves SpecificationsDocument19 pagini12 Valves Specificationsshaliq28100% (1)

- 2.5 Vol-I, Part-Ii, SCC PDFDocument63 pagini2.5 Vol-I, Part-Ii, SCC PDFKoushik DeyÎncă nu există evaluări

- Esab 6013 PDFDocument1 paginăEsab 6013 PDFBijaya RaulaÎncă nu există evaluări

- Bill of Material - Globe Valve - Model 3000Document1 paginăBill of Material - Globe Valve - Model 3000RAVIKIRAN BARDEÎncă nu există evaluări

- Duplex Stainless Steel - Part 2 - TWIDocument6 paginiDuplex Stainless Steel - Part 2 - TWItuanÎncă nu există evaluări

- GTAW Welding of CP Titanium and Ti6Al4VDocument1 paginăGTAW Welding of CP Titanium and Ti6Al4VDeepak KumarÎncă nu există evaluări

- 5 Methods To Determine Preheat TemperatureDocument4 pagini5 Methods To Determine Preheat TemperatureMohamed AtefÎncă nu există evaluări

- Uht 75 Uht 79Document1 paginăUht 75 Uht 79ALI MESSAOUDIÎncă nu există evaluări

- CC Giacomini Bola FMDocument2 paginiCC Giacomini Bola FMMaisonÎncă nu există evaluări

- VolvoDocument20 paginiVolvoعبدالغني القباطي100% (1)

- Time Table - MFS - MTech - 2022-23 - WinterDocument1 paginăTime Table - MFS - MTech - 2022-23 - WinterRavindraSamriaÎncă nu există evaluări

- ASME Sec. IX - Welding Qual - 2013 - Material SA 335 P22Document1 paginăASME Sec. IX - Welding Qual - 2013 - Material SA 335 P22Et NeÎncă nu există evaluări

- Truss FlangeDocument1 paginăTruss Flangenaufalfadhlirahman4223600052Încă nu există evaluări

- s00-004 Index of Drawings 4Document1 paginăs00-004 Index of Drawings 4Sereyponleu KhunÎncă nu există evaluări

- 6 Cylinder Engines: Moving Forward in Every FieldDocument1 pagină6 Cylinder Engines: Moving Forward in Every FieldАлександрÎncă nu există evaluări

- Y7 Electromagnetic Yoke - Product Data Sheet PDFDocument2 paginiY7 Electromagnetic Yoke - Product Data Sheet PDFfaisal ekaÎncă nu există evaluări

- Metals 08 00404Document17 paginiMetals 08 00404urslÎncă nu există evaluări

- Material Safety Data Sheet Megacheck DeveloperDocument5 paginiMaterial Safety Data Sheet Megacheck DeveloperhieuÎncă nu există evaluări

- Material Safety Data Sheet Magnetic Particlespray SM 15Document8 paginiMaterial Safety Data Sheet Magnetic Particlespray SM 15hieuÎncă nu există evaluări

- Material Safety Data Sheet Mega Check PenetrantDocument6 paginiMaterial Safety Data Sheet Mega Check PenetranthieuÎncă nu există evaluări

- En Iso 3822-3-1997 - 1875 PDFDocument16 paginiEn Iso 3822-3-1997 - 1875 PDFhieuÎncă nu există evaluări

- ASME, b31.3Document40 paginiASME, b31.3SoorajÎncă nu există evaluări

- chương 5 chế tạo, lắp ráp và lắp ghép PDFDocument8 paginichương 5 chế tạo, lắp ráp và lắp ghép PDFhieuÎncă nu există evaluări

- JISG3459Document39 paginiJISG3459Son-Tuan PhamÎncă nu există evaluări

- ASME Sec VIII Div 1 Table UHT-56Document1 paginăASME Sec VIII Div 1 Table UHT-56hieuÎncă nu există evaluări

- ASME, b31.3Document40 paginiASME, b31.3SoorajÎncă nu există evaluări

- Gmaw FcawDocument80 paginiGmaw FcawmarboledtÎncă nu există evaluări

- Ray Optics PDFDocument21 paginiRay Optics PDF1996vishakÎncă nu există evaluări

- Damage and Failure For Ductile MetalsDocument10 paginiDamage and Failure For Ductile Metalsp_rameshreddy2006Încă nu există evaluări

- Four Types of Climate in The PhilippinesDocument2 paginiFour Types of Climate in The PhilippinesAnonymous P1iMibÎncă nu există evaluări

- 175 023400Document2 pagini175 023400Abu Anas M.SalaheldinÎncă nu există evaluări

- Lattice Energy I Unit 4 New SpecificationsDocument12 paginiLattice Energy I Unit 4 New SpecificationsLoh Jun XianÎncă nu există evaluări

- Microsoft Word MecvinaDocument37 paginiMicrosoft Word MecvinaRam RamirezÎncă nu există evaluări

- Understanding Differences in Elemental Analysis MethodsDocument2 paginiUnderstanding Differences in Elemental Analysis Methodsmehdi kamaliÎncă nu există evaluări

- Earthquake Analysis of Quay Walls - J.W. Liang PDFDocument89 paginiEarthquake Analysis of Quay Walls - J.W. Liang PDFJunwhan KimÎncă nu există evaluări

- Earth Science Q2 Week1Document10 paginiEarth Science Q2 Week1MCAPUZ, MARK JOHN, V.Încă nu există evaluări

- PHY 205 Slide 2Document46 paginiPHY 205 Slide 2Idris Usnan100% (1)

- 1 s2.0 S2214860421001585 MainDocument9 pagini1 s2.0 S2214860421001585 MainGuilherme SampaioÎncă nu există evaluări

- E300 List DatasetsDocument5 paginiE300 List Datasetsrezagholami870% (1)

- AHU Vs FCU Comparison PDFDocument5 paginiAHU Vs FCU Comparison PDFamirin_kingÎncă nu există evaluări

- Poly Plug 1Document5 paginiPoly Plug 1Aquiles CarreraÎncă nu există evaluări

- Plastic Material in AutomotiveDocument17 paginiPlastic Material in AutomotiveMuthu KumarÎncă nu există evaluări

- Lecture 20 Thermal Engineering II (12.08.2020)Document30 paginiLecture 20 Thermal Engineering II (12.08.2020)Dr. BIBIN CHIDAMBARANATHAN100% (1)

- Krishna Sie FPT 2000Document33 paginiKrishna Sie FPT 2000Chia Sheng WuÎncă nu există evaluări

- The Particle Nature of MatterDocument25 paginiThe Particle Nature of MatterJessa alajid80% (5)

- Sae J20-2022Document15 paginiSae J20-2022Vedpal Singh ChoudharyÎncă nu există evaluări

- Thermo QualsDocument26 paginiThermo QualsLuc LeÎncă nu există evaluări

- Review of Literature On Steam AccumulatorDocument10 paginiReview of Literature On Steam Accumulatortamil vaananÎncă nu există evaluări

- Catalog Subzero Insulated Sandwich PanelDocument8 paginiCatalog Subzero Insulated Sandwich PanelTommy Dwi Hartanto100% (1)

- Activity 2.1.2 Beam Deflection: Preliminary Lab Calculations To Determine Beam Modulus of ElasticityDocument8 paginiActivity 2.1.2 Beam Deflection: Preliminary Lab Calculations To Determine Beam Modulus of ElasticityJulius PaganÎncă nu există evaluări

- 7 MultiphaseFreeSurfaceFilmDocument25 pagini7 MultiphaseFreeSurfaceFilmJesthyn VC100% (1)

- Development and Characterization of Mixed EmulgelDocument41 paginiDevelopment and Characterization of Mixed EmulgelJeevan KhanalÎncă nu există evaluări

- Basic of PipingDocument64 paginiBasic of Pipingparameswaran shivakumar96% (46)

- Mixer GrinderDocument29 paginiMixer GrinderChockalingam AthilingamÎncă nu există evaluări

- Beam Powered PropulsionDocument19 paginiBeam Powered PropulsionSai Sushma100% (1)

- Inverted T BeamsDocument234 paginiInverted T BeamsAnna GÎncă nu există evaluări