Documente Academic

Documente Profesional

Documente Cultură

Service Bulletin: Examining Compressor Failures in The Field

Încărcat de

nkrish21856Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Service Bulletin: Examining Compressor Failures in The Field

Încărcat de

nkrish21856Drepturi de autor:

Formate disponibile

Form #COM-304AS

SERVICE BULLETIN

EXAMINING COMPRESSOR FAILURES IN THE FIELD

This guide can be used as a reference to diagnose compressor failures, and is specifically designed to help you differentiate

between unwarrantable failures and those which would normally fall under possible warranty consideration. Next to refrigerant

leaks, compressors represent the next highest rate of failure of any a/c component. Use of this guide will enable mechanics to

properly diagnose and observe more closely the primary causes of compressor failures. Observance and examination of both

the compressor and clutch during diagnosis will greatly improve your analysis in determining exactly what happened. Since

subsequent problems or failures often happen as a result of primary failure causes, this guide is divided into the following

sections:

A. COMPRESSOR COMPONENTS & TERMINOLOGY

B. CLUTCH RELATED FAILURES

C. COMPRESSOR FAILURES & CAUSES

D. INSTALLATION RELATED FAILURES

E. SUMMARY FAILURE CHART

A. COMPRESSOR COMPONENTS & TERMINOLOGY

To assist you in analyzing compressor failures, a diagram of a typical compressor & clutch assembly is shown.

This diagram should be used as a reference when attempting to determine the cause of failures in the various

components of the compressor. The terminology used below will be referred to throughout this Service Bulletin.

© 2004 MEI Corporation -1-

B. CLUTCH RELATED FAILURES

Since many compressors are sold as complete assemblies (such as Sanden, Seltec, Ford, CCI, & GMC compressors)

the following are the most frequent symptoms and causes of clutch related failures and how they relate to the

compressor itself. Many times a compressor is submitted for warranty listed as having only clutch symptoms, such

as “bad clutch bearing” or “clutch doesn’t engage” or “clutch locked up”. In most cases the clutch was just a result

of a related failure, not the cause.

B1. Burnt Clutch Hub, Pulley, and/or Coil

Inadequate voltage to the coil will result in overheating of the internal winding, and cause the clutch hub to slip

against the face of the pulley. A compressor in the stages of failing due to slugging or loss of lubrication, or

operating under a high pressure condition will also cause the clutch to slip. The slipping occurs continuously

and in just a short time will subject both the clutch and coil to extreme temperatures up to 1,200 degrees F.

This will quickly destroy the clutch and its internal components. Visual evidence of this type of failure can be

found in the illustrations on page 2. This type of failure affects both the compressor and clutch and subsequently

voids the warranty on the entire assembly.

B2. Clutch Bearing Failure

Bearing failures are usually caused by system related problems. Very seldom is a bearing itself the culprit of

a failed or locked up compressor. For example, if the clutch slips severely due to a high pressure or low

voltage condition, or due to compressor slugging, the excessive heat generated by the slipping will quickly

melt and destroy the bearing seal. The bearing then loses its grease and locks up or falls apart, usually

destroying the clutch in the process. This type of bearing failure is not covered under warranty, since the

bearing was not the root cause of the problem. Manufacturing defects in clutch bearings are rare, and warranty

allowances are usually associated with excessive noise symptoms only (see following condition).

B3. Noisy Clutch Bearing

If the complaint is noise related only, a defective clutch bearing could be the source of the problem. Check for

a rough or poorly operating bearing by holding the clutch armature hub stationary, and rotating just the pulley.

If excessive noise or difficulty in ease of rotation is observed, the bearing may be suspect. However, as with

the failed bearing situation described above, several factors can cause the bearing to become noisy or rough

in operation. A rough bearing can also be one that is in the early stages of failing due to system problems

involving extreme heat. This is usually the case if the compressor clutch has been operating sufficiently for

some time and then becomes noisy. Most factory bearing defects become evident in the first hours of compressor

operation. Warranty consideration for failed compressors and clutches described as noisy will be provided

only if there are no obvious signs that the failure was caused by other factors.

B4. Unburnished Clutch

Burnishing is the cycling of the clutch to allow a wearing in of the engagement surface area. The reason for

burnishing a clutch is to increase the initial starting torque. Most technicians fail to follow this important

procedure when replacing a compressor or clutch. An unburnished clutch can produce a low torque condition,

causing the clutch to slip and thereby fail. When replacing a clutch or compressor & clutch assembly, follow

this important burnishing procedure. Run the engine at 1,500 to 2,500 RPM. Using the controls on the dash,

cycle the clutch ON and OFF at a rate of 10 to 15 times per minute for a total of 50 cycles minimum. This

should bring the clutch up to operating torque capacity.

B5. Improper Rotor to Hub Air Gap

An incorrect air gap can cause a clutch to engage or disengage improperly. This is particularly true on Sanden,

Seltec, and Frigidaire/GMC style compressor clutches. Before operating a compressor of this type, check the

hub/armature to rotor/pulley air gap. Check the required specifications for your particular type of compressor

clutch in the illustrated section of the A/C parts catalog. These clutches may involve adding or removing shims

to properly gap the hub. New manufactured compressor & clutch assemblies are properly gapped at the

factory. Most clutch failures or problems relating to improper air gap can be traced to improper clutch replacement

procedures used in the field. Check to see if this applies before returning possible warranties.

B6. Faulty Coil Lead Wire or Inadequate Voltage to Coil

If the lead wire connected to the field coil is faulty, the clutch becomes inoperative. This will be evident at the

time of installation, and seldom occurs afterwards. However, evidence of obviously damaged or cut lead wires

is not a cause for warranty consideration. There must be adequate voltage to the coil in order for the clutch to

function properly. A compressor clutch that fails to engage can usually be traced to an open or faulty circuit.

Since many compressor clutches are now equipped with a separate wiring harness to ground the clutch,

insufficient grounding of the circuit may be the problem. Compressors returned for warranty which check out

to function properly but have evidence of being mounted and cannot be resold as new, will be denied.

-2- © 2004 MEI Corporation

ILLUSTRATION FOR CONDITION - B1 ILLUSTRATION FOR CONDITION - B2

ILLUSTRATION FOR CONDITION - B1 ILLUSTRATION FOR CONDITION - B6

C. COMPRESSOR FAILURES & CAUSES

The following are the most frequent types of compressor failures. These can all be traced to a problem in the A/C

system. As in the case of the clutch, the compressor is usually not the culprit for the failure.

C1. Seized (Locked Up) Compressor due to Loss of Lack of Lubrication

Compressor lock-ups also involve the clutch. The clutch’s function is to engage and disengage the compressor

from the vehicle’s accessory drive system. If there is a system problem that prevents proper rotation of the

compressor input shaft while the clutch is energized, the clutch will slip. A slipping clutch can generate

tremendous heat, up to 1,200 degrees F. In a matter of minutes, components can start to fail. There is a

progression of effects generated from slipping, all leading to overall clutch and/or compressor failure.

Causes and Symptoms of seized compressors are listed below:

a.) In some ways a compressor can be likened unto the human heart. A continuous loss of blood will starve

the heart of what it needs to provide essential nutrients to the entire body. Without an adequate blood

supply, it will continue to pump until it collapses and fails. In like manner, a compressor needs oil to

function, and relies on the refrigerant to supply what it needs. It is the refrigerant’s job to carry the oil

through the entire system. A continuous loss of refrigerant will starve the compressor, preventing oil from

returning to it, causing it to bind, lockup and fail. Since refrigerant leaks represent the highest rate of

failure in A/C systems, many times a lockup occurs simply because the system has lost some or all of its

charge.

b.) Since a number of compressors are being shipped dry, it is up to the installer to determine the proper

amount and type of oil to be added. If the technician does not follow the manufacturer’s recommendations,

the compressor could be damaged due to lack of lubrication. Use of an oil type not designed for a

particular style of compressor can also adversely affect the flow of lubrication throughout the system.

c.) Just as a restriction or blockage in your bloodstream can bring on a fatal heart attack, a blockage or

restriction in your A/C system can be fatal to your compressor. A blockage will inhibit or prevent the

adequate return of oil needed to lubricate the compressor, thereby causing the compressor and clutch to

slip, bind, or lockup.

(continued)

© 2004 MEI Corporation -3-

C. COMPRESSOR FAILURES & CAUSES (cont.)

C2. Seized (Locked Up) Compressors due to Excessive A/C System Pressure

Every one of the following conditions will increase system pressure. Just as too high blood pressure causes

the heart to overwork, and prematurely fail, excessive A/C system pressure can cause the compressor to

overwork and begin to seize. This in turn increases the torque requirements of the clutch. The clutch then

begins to slip, producing tremendous heat build-up. The clutch bearing fails, and the clutch seizes. As the

compressor attempts to continue operating under this overwhelming condition, failure is eminent.

a.) Incorrect Amount of Oil in System

Too much oil can cause compressor slugging and a slipping clutch. The compressor is not designed to

pump liquids. Excessive oil will also accumulate in the a/c condenser, causing poor performance, and

increase system discharge pressures. Not enough oil will cause compressor binding, clutch slipping, and

in most cases, a lockup.

b.) Inadequate Air Flow across the Condenser

If the condenser is restricted internally, or has inadequate airflow across it, the result is a higher discharge

pressure. This can cause the clutch to slip. An inoperative or faulty radiator or condenser fan could also

be suspect. Faulty shutter systems or fan clutches likewise cause problems of this nature. A bug shield

can impede airflow as well. Any foreign material blocking airflow through the condenser’s cooling coils

(such as dirt and bugs) will cause inadequate airflow and increased high side pressure.

c.) A Blockage in the High Pressure Side of the A/C System

A blockage anywhere in the system will cause the discharge pressure to increase and cause clutch

slipping. A blockage can be pinpointed by an immediate temperature (pressure) drop just after it. Remember

that a drop in pressure means a drop in temperature, and vice versa. Check the inlet and outlet temperatures

of the condenser with an infrared pyrometer. A difference of over 35 degrees can indicate a problem.

Another problematic condition can arise when the condenser has been impacted with a heavy load of

contaminates (usually after a compressor failure). The entire system needs to be flushed after such an

occurrence. A technician attempts to do the job right, flushes the system, and assumes the condenser is

clean because the flush came out clean. However, since many newer designs of condensers feature dual

pass flow (having two parallel passages), a blockage may exist in only one of the passages. The solvent

he is using will actually take the path of least resistance and clean only the unclogged portion of the

condenser. This leaves a significant amount of contaminates left in the condenser. As the system is put

back into operation, the contaminates will then make their way to other components and cause the slowing

or stoppage of lubricant flowing through the system. In some cases, especially on Ford products with an

FS10 style compressor, the condenser must be replaced after a major system failure. The proper installation

of an in-line filter can also help to avoid this problem.

d.) System Overcharge

An overcharged a/c system will cause pressures to increase and cause slipping. Excessive compressor

noise is also a symptom of an overcharged system. When checking for an overcharged system, remember

to also check for the presence of non-condensable gasses (air). They will also increase system pressures.

Faulty recovery machine vent valves, designed to release non-condensable gasses during refrigerant

recovery, are prime suspects. Out of sight and mind, your recovery tank could be filled to capacity with an

excessive level of air, which is then charged into the next A/C system you encounter. Using a refrigerant

identifier or gauge which measures the percentage of non-condensable gas will prevent this from happening.

e.) Cross Contamination of Refrigerant Types

The lubricant inside an A/C system will retain a certain amount of the refrigerant, even after normal

evacuation. If the system is then charged with a different refrigerant (as in R12 to R134a), there is a

certain amount of refrigerant cross-contamination that occurs. Once the original refrigerant is “out-gassed”

from the oil, it combines with the replacement refrigerant. This condition can lead to a reduction in A/C

performance, and an increase in high side pressure. The abnormal increase in pressure can cause

premature compressor failure. Proper A/C flushing and drain procedures should be performed at the time

of retrofit to prevent cross-contamination.

f.) Use of Blends or Non-Approved Refrigerants

All compressor warranty is limited to the use of either R12 or R134a, with the correct type of oil used for

those refrigerants. Use of any other refrigerant will void the warranty on all system components.

g.) Use of Non-Approved Dyes

In some cases, use of certain inappropriate brands of aftermarket UV dyes have proven to be detrimental

to the system and will cause high pressure situations. If warranty analysis shows any indication of these

dyes being present in the compressor, warranty will be refused.

© 2004 MEI Corporation

-4-

The following conditions apply to non-seized compressors

C3. Broken or Deformed Reed Valve

Symptoms will usually be a lack of cooling associated with unusually high suction (low side) pressure and

unusually low discharge (high side) pressure. Complaint may be that the compressor won’t pump. Insure that

a low refrigerant charge is not related to the problem. Reed valves can also be damaged by an assault of

liquid refrigerant. If the evaporator becomes flooded with liquid refrigerant due to a stuck open expansion

valve or missing orifice, sufficient evaporation will not take place, and a harmful amount of liquid refrigerant

will make its way back to the compressor. A technician dumping a liquid refrigerant charge right into the

compressor during servicing can also damage reed valves. A broken reed valve will usually cause a clacking

sound at idle. A foreign substance under the reed valve or gasket can also cause a problem in cooling. In

addition, it is not uncommon to find a corroded reed valve due to excessive moisture present in the system.

C4. Leaking Compressor Shaft Seal

Another failure that can be attributed to a system problem is a failed compressor shaft seal. While shaft seal

failure is often blamed on the manufacturer as a factory defect, remember that an excessive heat/pressure

condition in the system can cause a shaft seal to fail and leak. Once the seal leaks, compressor oil also

escapes and may find its way into the clutch bearing. This oil can contaminate the bearing grease and lead to

grease purging through the bearing seal. If the compressor is being used in an environment where dust and

dirt are a real problem, the shaft seal’s life will be shortened unless it is protected. Off-road vehicles fall under

this class, and usually require compressors with dust seals and covers. Make sure the compressor you

replaced was designed for the right application. Overall, shaft seal designs have improved dramatically over

the last few years, and a leak usually indicates a problem has occurred somewhere in the system. Following

the important procedure of turning a replacement compressor clutch by hand 10-12 times (making certain the

shaft rotates) before initially starting the compressor into operation will help avoid premature shaft seal leaks.

(also see following condition)

C5. Blown Head Gasket

Symptoms will usually be a lack of cooling associated with unusually high suction (low side) pressure and

unusually low discharge (high side) pressure at idle. Run the system for 5 minutes at idle and shut off.

Observe time for both pressures to equalize. If it takes less than 2 minutes on a TXV system, a gasket may be

damaged or blown. CCOT systems will equalize even more quickly. A blown head gasket is usually the result

of excessive head pressure. Determine the cause of the high pressure condition and repair.

C6. CCI/York Compressors with Oil Leaks

Sometimes a warranty is claimed if a compressor is found to be soaked with oil before ever being sold or

installed onto a system. This is usually the case when someone notices the compressor’s box to be discolored,

oil stained, and possibly sitting in a pool of oil, while still on the shelf. Sometimes the oil has even penetrated

adjoining compressor boxes alongside. What to do? The compressor(s) are not defective. In nearly every

case we have found the following to apply. The compressor’s shipping caps, which are plastic, unknowingly

become cracked or loosened during shipment. The compressors are then stocked on the shelf in a horizontal

position, which allows gravity to take effect and leak oil onto the compressor body and box. Should you find

this to happen, do not call for RGA’s to return them. The problem is limited to CCI/York style compressors and

we can supply replacement boxes for any you might have. Stocking these compressors in the upright position

they are intended to be stored will help prevent this from happening. Again, this is not a warranty situation.

C7. Mis-Machined Compressor Mounting Boss

If there is a dimensional problem with the mounting bosses used for attaching the field coil assembly to the

compressor, an interference condition may be created between the field coil and rotor assembly. This problem

seldom occurs, and is usually associated with using poor quality remanufactured compressors.

C8. Re-Machined Compressor Shaft

During the course of remanufacturing a compressor, the taper of the input shaft may be re-machined. As a

result, the shaft will be shortened and less clearance will remain between the clutch and the compressor. This

can create interference and hinder the rotation of the rotor assembly. Again, this problem is almost always

linked to poor quality remanufacturers using poor quality cores.

© 2004 MEI Corporation

-5-

Visual Symptoms of the preceding problems are as follows. See the following illustrations

1.) Discoloration of Pulley and/or Armature Disc

The extreme heat generated from slipping will quickly cause the component(s) to take on a discolored

appearance. They will appear “frosted”, or “blued”, or even charred.

2.) Melting of Rubber Spacers in Armature

If the slipping continues, the temperature can reach a point where the rubber spacers between the armature

plate and disc begin to melt. Not all clutches utilize rubber spacers.

3.) Melting of Epoxy in Field Coil

The extreme heat can also affect the field coil, causing the epoxy to show visual signs of melting or “charring”.

Under extreme situations, the coil winding will become exposed and/or unseated.

4.) Melting of Bearing Seal

The heat will eventually cause the bearing seal to melt, allowing the grease to escape. Without grease to

lubricate the bearing, it is quickly destroyed.

ILLUSTRATION FOR CONDITION - C1 ILLUSTRATION FOR CONDITIONS - C1, C2

ILLUSTRATION FOR CONDITIONS - C1, C2 ILLUSTRATION FOR CONDITION - C6

-6- © 2004 MEI Corporation

D. Installation Related Failures

The following are the most frequent causes of installation related clutch failures. Please note that clutch failures

resulting from improper installation void all possibilities of warranty.

D1. Broken Mounting Ear(s) on Compressor

If the compressor is mounted improperly, or in any way as would subject it to cross-torque on its mounting

ears, one or more of the ears will likely crack or break. This may lead to additional damage of the compressor

itself. The same problem can occur if the compressor’s engine mounting brackets are cracked, warped, or

broken. A vehicle with loose or broken motor mounts can also subject the compressor to additional strain and

crack or break off its ears. Excessive noise during compressor operation may be evident during these types

of situations. Simply replacing the compressor will not fix the problem. Unless the cause of the problem is

found and fixed, the likelihood of another broken compressor is high. Many times ears are broken or cracked

simply as a result of excessive torque applied during installation of the mounting hardware, such as from use

of an impact wrench.

D2. Broken (or Stripped) Fittings on Compressor

Broken fittings can usually be traced to either excessive torque applied during installation of the service valves

or hose fittings, such as from use of an impact or oversize wrench, or cross-torque being applied to the fittings.

The most common cause stems from one of the hose assemblies (suction or discharge) being replaced with

one shorter in length than the original OE hose. As the driver increases engine RPM, torque is applied to the

hose. Because of the decreased distance in hose length between the two fitting attachments, the law of least

resistance takes effect and the aluminum compressor head fitting snaps off. This may lead to additional

damage of the rest of the compressor. Stripped fittings on the other hand, are always due to incorrect fastening

techniques on the part of the installer. In some cases a replacement compressor head is available to salvage

the loss.

D3. Use of Excessive Torque on Compressor Shaft Mounting Bolt

Broken or twisted clutch shaft bolts are the result of excessive torque applied during installation, such as from

use of an impact wrench. Check manufacturer’s torque specifications when installing clutch hardware.

D4. Loose Field Coil Mounting Bolts

If the bolts used to mount the field coil are not tightened adequately, vibration from the vehicle will loosen the

bolts and cause the coil to become loose. Eventually the field coil will begin to contact the rotor assembly, as

evidenced by rubbing on the field core outer diameter. This rubbing can generate heat that melts the field coil

epoxy, leading to an open circuit and inoperative clutch. This condition is specific to CCI/York/Tecumseh style

compressors. The replacement clutches for these compressors are now normally supplied with special thread-

lock treated fasteners. New CCI Compressor & Clutch assemblies are already equipped with them. Use of

the fasteners normally solve this kind of problem, unless a severe vibration problem exists.

D5. Short or Open Circuit in Field Coil Wire

If the clutch lead wire is routed in such a way as to subject it to possible rubbing or cutting by another object,

the wire’s insulation can be rubbed through and the bare wire exposed. A short circuit or open circuit will likely

develop, causing the clutch to become inoperative. This type of failure is evidenced by a lead wire worn down

to bare metal in one or more locations along it’s length, or a lead wire that gets cut in half.

D6. Improperly Installed Coil Ground Wire

On CCI/York/Tecumseh style field coils, the ground wire terminal should be installed on top of the coil mounting

flange. If the terminal is improperly installed underneath the flange (touching the compressor), the alignment

of the outer coil and inner pulley interface will be adversely affected and create the potential for rubbing

between the rotor and coil assemblies.

D7. Shaft Key not Seated Properly in Armature Hub

If the key is not properly inserted into the keyway on the compressor input shaft during a clutch installation, a

severe misalignment of the pulley relative to the shaft will occur. This misalignment will create interference

between the rotor and field coil assemblies. Evidence of severe rubbing of the pulley on the field coil will be

present.

D8. Improperly Installed or Wrong Snap Ring

Use of a wrong snap ring, or an improperly installed snap ring on the field coil or pulley can cause the clutch

to be noisy, fail to disengage, or in some cases come completely off. Resultant clutch damage can follow. This

is especially true on some Ford FS6 compressor clutches, where several types and thicknesses of snap rings

were originally used. Consult manual for further instructions.

(continued)

© 2004 MEI Corporation -7-

D. Installation Related Failures (cont.)

D9. Mismatched Clutch Components

Especially in the case of Ford FS6 and FX15/FS10 type clutches, complete replacement of the clutch and coil

assembly is required. Original or replacement Ford O.E. clutch components cannot be mixed with aftermarket

type clutch components (such as a Ford O.E. coil and an aftermarket pulley and hub). Mixing these different

types of components together can cause clutch failure and/or faulty clutch operation.

D10. Failure to Service A/C System Properly

All compressor manufacturer warranty policies stipulate that in order for the compressor to be eligible for

warranty, all proper A/C procedures must be followed, and the following items must be replaced: Accumulator

or Receiver Drier, Orifice Tube (if equipped). If a compressor failure was involved, the system must be flushed

with an approved liquid flush solvent, and the expansion valve should be checked for contamination or replaced.

Proof of replaced parts and copy of invoice showing all services performed are required.

ILLUSTRATION FOR CONDITION - D1 ILLUSTRATION FOR CONDITION - D2

ILLUSTRATION FOR CONDITION - D3 ILLUSTRATION FOR CONDITION - D4

ILLUSTRATION FOR CONDITION - D5 ILLUSTRATION FOR CONDITION - D7

-8- © 2004 MEI Corporation

E . Failure Summary Chart - Use this chart to compare possible warranty compressors you have to return

IMPORTANT-ANSWER ALL QUESTIONS 1-19 BEFORE PROCEEDING TO EXPLANATION CHART

(If any listed condition exists, answer YES)

Refer to the Failure Explanation(s) indicated on the following page.

1. Are there obvious signs of discoloration (frosting, blueing, or charring) on the clutch?

Yes Go to A No proceed to next question

2. Is the compressor locked up?

Yes Go to A No proceed to next question

3. Does the clutch show any signs of melting, or missing parts?

Yes Go to B No proceed to next question

4. Is the clutch bearing seal deteriorated? Has grease escaped? Is it stiff or seized or gritty?

Yes Go to B No proceed to next question

5. Is the clutch’s condition similar to any of the photos on the previous pages?

Yes Go to C No proceed to next question

6. Are any of the ears broken or cracked?

Yes Go to D No proceed to next question

7. Are either of the fittings on the rear (or top) head broken, cracked, damaged, or stripped?

Yes Go to E No proceed to next question

8. Was the compressor received back without any oil in it?

Yes Go to F No proceed to next question

9. Is the oil inside the compressor black or discolored, gritty, or show signs of contamination?

Yes Go to G No proceed to next question

10. Does the nature of defect have to do with the clutch not engaging/disengaging, or slipping?

Yes Go to K, O, & P No proceed to next question

11. Is the nature of defect associated with either “not pumping” or “insufficient pressure”?

Yes Go to L No proceed to next question

12. Is the shaft seal leaking?

Yes Go to H No proceed to next question

13. Was the failed compressor put on as part of a retrofit installation (R12 to R134a)?

Yes Go to I No proceed to next question

14. Is the compressor an unsold/uninstalled CCI/York style upright and is the box oil soaked?

Yes Go to J No proceed to next question

15. Is the compressor a remanufactured unit? Does the clutch show signs of interference?

Yes Go to L & O No proceed to next question

16. Did you check the date on the ID tag? Does it indicate the compressor is over 24 months old?

(see illustration on page 12)

Yes Go to M No proceed to next question

17. Is the problem noise related, with all the clutch components (incl. bearing) appearing to be OK?

Yes Go to N No proceed to next question

18. Does the clutch fail to engage or disengage properly?

Yes Go to O & K No proceed to next question

19. Does the manufacturer’ tag indicate this to be the OE compressor? (see illustration page 11)

Yes Go to Q No go to R

© 2004 MEI Corporation -9-

F. Failure Explanations (refer to Failure Summary Chart on previous page)

A. Failure of clutch and/or compressor is due to (1) a seized or slugging compressor and/or (2) may be the result

of excessive a/c system pressure, and/ or (3) insufficient voltage to coil. Clutch may be seized or burnt, or

slipping. Evidence of extreme heat build-up. No warranty allowed. Read all of Section B and C. (both

causes and symptoms). Note: If the problems which caused the clutch to fail are not remedied, the

probability is high that simply installing another compressor will result in a repeated failure.

B. Failure of clutch and/or compressor is due to (1) slippage caused by loss/lack of lubrication, and/or (2) excessive

pressure in system, and/or (3) insufficient voltage to coil, and/or (4) improper procedures used during repair/

installation, and/or (5) a seized-up compressor, and/or (6) mismatched clutch components used during

installation of compressor. The clutch was subjected to extreme heat. No warranty allowed. Read all of

Section B, and Section C1a-c, and C2a-f.

C. Failure of clutch does not meet warranty conditions. See A & B explanations above. No warranty allowed.

Read all of Sections B and C.

D. There is no warranty for compressors returned with broken or cracked mounting ears. This is a result of an

installation or mounting bracket problem. No warranty allowed. Read Section D1.

E. There is no warranty for compressors returned with broken, cracked, damaged, or stripped fittings. This is a

result of either faulty installation procedures, or having been dropped and damaged. It may be related to a

cross-torque condition being applied to the fitting under high RPM’s. No warranty allowed. Read Section

D2.

F. Failure of compressor is due to loss or severe lack of lubrication. Possibly lost most or all of refrigerant

charge. A blockage in the system may exist. Even if not totally seized, compressor was operated for an

undetermined period of time in an oil-starved condition. It likely has internal damage and/or advanced stages

of wear. Determine problem and fix before installing another compressor. No warranty allowed. Read

Sections C1a thru C1c, and C2a.

G. Failure of compressor is due to contamination in the system. May not have been properly flushed when

compressor was initially installed. Drier may have not been replaced. System may have been cross

contaminated if retrofitted. Condition may also be due to use of incorrect type of oil or use of unapproved UV

dyes. No warranty allowed. Read Sections C2c, C2e, f,g and D10.

H. Possible warranty. Make sure the compressor was not operating under excessive pressures. Determine if

this is an off-road application. Read Section C4 before returning. See R below.

I. Possible warranty. Determine who performed the initial repair. Were all the proper procedures performed?

What are the symptoms if all the other tests passed OK? Read all of Sections C and D10 before returning.

See R below.

J. This is not a warranty related problem. The shipping caps are either cracked or loose. The box is being

stored in a horizontal position, rather than upright as it should. The compressor is still good and usable. Do

not return! Read Section C6.

K. An open circuit may exist in the field coil. Possibility exists that A/C thermostat or pressure switch has a

malfunction. Possible warranty. Check the circuit for continuity to positively identify the coil as the source of

the problem. Resistance will be infinite if coil has “open circuit”. If coil has a “short circuit”, resistance value will

be between zero and 3.16 to 3.5 on 12-volt coils; and between zero and 13.3 on 24-volt coils. An ohmmeter

with temperature compensation should be used for resistance specification tests. Read Section B6 before

returning. See R below.

L. Insure that the clutch is actually engaging. If not, fix problem. If it still won’t engage, the compressor has

possible failed internal parts, a blown or damaged reed valve, or leaking gaskets/seals. If originally attached

with clutch and signs of clutch interference are evident, the possibility of defective workmanship may apply. If

all other outward observations have proven OK, make sure there are no system problems responsible for the

problem. Read the causes of blown reed plates or gaskets and how to check for these in Section C3 & C5.

If tests reveal one of these conditions, warranty may be void. Possible warranty only. Also read Sections

C8 and D10 before returning. See R below.

M. Compressors with date tags indicating the unit is over 24 months old may not be returned. Except under rare

circumstances where proof can be submitted showing the unit was recently sold & installed, the 1 warranty

period has graciously expired. No warranty allowed.

- 10 - © 2004 MEI Corporation

N. Noise associated problems can vary. The noise may be due to a misaligned, improperly tensioned, or slipping

belt, or failing idler pulley. Or the possibility exists that either the clutch is incorrect or contains improperly

installed components. Also check for a loose or cracked compressor mounting bracket. Noise problems can

also be due to low oil level (compressor will be very hot to touch) or an overcharged system (a rumbling noise

or vibration in the high pressure line usually present). A broken reed valve will also cause excessive noise).

No warranty allowed. Read Sections D1, D4, D7, D8, D9, and D10.

Also see Belt Tension chart on page 11.

O. Clutch rotor/pulley and hub/armature may not be properly gapped. Clutch may have been improperly installed

with wrong snap ring, or contain mismatched components. Follow proper installation procedures to gap the

hub before submitting for warranty. Also check for adequate voltage to coil if either procedure does not fix

problem. Possible warranty. Read Sections B5, B6,. D4. and D5 before returning. See R below.

P. Clutch slippage can be contributed to a number of problems. Check first for proper voltage to coil. Diagnose

electrical system and repair. No warranty allowed. Read Sections B4.,B5.,B6., and B7.; and all of

Section C (both causes and symptoms); and D5. Also see Belt Tension chart.

Q. This is the original compressor that was installed from the factory. It is not a part that was sold or installed in

the field. No warranty allowed. Do not return.

R. If all visual checks are OK, and all questions on page 9 have been answered No, possibility of warranty is

good. However, all warranty determination shall be made according the compressor manufacturer’s warranty

policy. Any warranty given shall be for the part only and will not include any related expense such as freight,

labor, refrigerant, or otherwise. No liability or responsibility is accepted resulting from any consequential or

incidental damages pertaining to warranties. Please note that all compressors returned for warranty must

have the shipping caps in place to prevent moisture, dirt, and foreign substances from entering the compressor.

Compressors returned with open non-capped ports will most likely void any warranty otherwise due.

Belt Tention Specifications (recommended for maximum clutch bearing life)

Grooves Belt Wdth Tention (lbs.) Grooves Grv Wdth Tention (lbs.)

1 or 2 1/2" 121 (+ -) 5 6 Multi 1/8" 180 ( + - ) 5

1 variable 1/2" - 9/16" 132 (+ -) 5 7 Multi 1/8" 210 ( + - ) 5

1 5/8" 132 (+ -) 5 8 Multi 1/8" 240 ( + - ) 5

10 Multi 1/8" 300 ( + - ) 5

(Tolerance + - 4.95 lb: Multi Grooves bases on 30 lb per groove)

ILLUSTRATIONS FOR “OEM” CCI COMPRESSORS

© 2004 MEI Corporation - 11 -

ILLUSTRATIONS FOR COMPRESSOR DATE CODES

3X

9285 Part Number

12345 01 1 70 Lubricant Amount

REFRIGERANT:

Lubricant Type

Year of Manufacture (first digit)

Month of manufacture (last digit)

Jan-Sept.: 1-9

Serial Number

00-06 Japan Oct.:X

Month of Manufacture

70-79 USA Nov.:Y

Year of Manufacture

80-89 Singapore Dec.:Z

Country Code

Type and Model

Seltec Body Assembly Number

TM HS

99 Serial Number

Lubricant Type 08 MEI 994456

Lubricant

Amount

Month Produced:

1-6 January thru June

7-12 July thru December

Refrigerant Type Decade Code:

4 Represents first half of 1980's

Designates Year of Manufacture: 5 Represents second half of 1980's

0 Represents 2000 6 Represents first half of 1990's

7 Represents second half of 1990's

8 Represents first half of 2000's

Year of Manufacture

Month of Manufacture

© 2004 MEI Corporation

S-ar putea să vă placă și

- Instruction Manual Twin Lobe CompressorDocument10 paginiInstruction Manual Twin Lobe Compressorvsaagar100% (1)

- 132kV capacitor banks specificationDocument12 pagini132kV capacitor banks specificationHasnain AwanÎncă nu există evaluări

- KDF 806 Maintenance Manual 006 05511 0008 8Document229 paginiKDF 806 Maintenance Manual 006 05511 0008 8Collazo Aviation100% (1)

- Topic Test Oxfordaqa Int A Level Physics Electric Fields and CapacitanceDocument15 paginiTopic Test Oxfordaqa Int A Level Physics Electric Fields and Capacitanceandhi soesiloÎncă nu există evaluări

- How To Modify Guitar PedalsDocument25 paginiHow To Modify Guitar PedalsChristopher Karl100% (17)

- 9 Most Common Clutch FailuresDocument3 pagini9 Most Common Clutch FailuresJohn StephenÎncă nu există evaluări

- Eaton Fuller Failure AnalysisDocument48 paginiEaton Fuller Failure Analysisramon hidalgoÎncă nu există evaluări

- Why Compressors Fail Part 1 - Refrigerant Flood BackDocument4 paginiWhy Compressors Fail Part 1 - Refrigerant Flood BackvickersÎncă nu există evaluări

- Lab Manual Rac MaintenanceDocument42 paginiLab Manual Rac Maintenanceonkar kalaskarÎncă nu există evaluări

- Boiler Starting Failure - TroubleshootingDocument11 paginiBoiler Starting Failure - TroubleshootingRahul ChandrawarÎncă nu există evaluări

- Installation, Operation and Maintenance of Airflex@ CM Marine ClutchDocument12 paginiInstallation, Operation and Maintenance of Airflex@ CM Marine Clutchaiyubi2Încă nu există evaluări

- Emerson Facts and QuestionsDocument8 paginiEmerson Facts and QuestionsambuenaflorÎncă nu există evaluări

- Compressor FailureDocument14 paginiCompressor FailureJose ThomÎncă nu există evaluări

- Refrigeration Compressor Failure: Cause & Cure - Part 1Document5 paginiRefrigeration Compressor Failure: Cause & Cure - Part 1ADARSH GADDAMÎncă nu există evaluări

- Refrigeration Compressor Failure: Cause & Cure - Part 1Document5 paginiRefrigeration Compressor Failure: Cause & Cure - Part 1ADARSH GADDAMÎncă nu există evaluări

- Refrigeration Compressor Failure: Cause & Cure - Part 1Document5 paginiRefrigeration Compressor Failure: Cause & Cure - Part 1ADARSH GADDAMÎncă nu există evaluări

- Undetected Bearing Wear Leads To Catastrophic Compressor FailureDocument5 paginiUndetected Bearing Wear Leads To Catastrophic Compressor FailureMuhammad ImranÎncă nu există evaluări

- Vertical Ammonia CompressorsDocument41 paginiVertical Ammonia CompressorsIulian12345Încă nu există evaluări

- Powerstroke Cooling System FlushDocument40 paginiPowerstroke Cooling System FlushJoshua Hopper100% (3)

- CompressorDocument8 paginiCompressorLOKIÎncă nu există evaluări

- Suzuki GT750 '79 Service Manual CorrectionsDocument4 paginiSuzuki GT750 '79 Service Manual CorrectionsNikolas KarrerÎncă nu există evaluări

- Discovering Misalignment With Infrared: The Damage Is DoneDocument5 paginiDiscovering Misalignment With Infrared: The Damage Is DoneManel MontesinosÎncă nu există evaluări

- Pump-Elite - Operating InstructionsDocument12 paginiPump-Elite - Operating Instructionsbookslover1Încă nu există evaluări

- Engine Compressor Stall and Surge Causes and EffectsDocument1 paginăEngine Compressor Stall and Surge Causes and EffectsvinayÎncă nu există evaluări

- Training ManualDocument135 paginiTraining ManualVinithra Rajesh100% (1)

- Common Problems With Air Compressors - The Titus CompanyDocument11 paginiCommon Problems With Air Compressors - The Titus CompanyNabedNoorÎncă nu există evaluări

- 26, Til 1621 Prevention of Water Accumulation Inside The Atomizing Air SystemDocument5 pagini26, Til 1621 Prevention of Water Accumulation Inside The Atomizing Air Systemankarao69Încă nu există evaluări

- Ac 8100 IomDocument63 paginiAc 8100 IomPumpxpertÎncă nu există evaluări

- Pattern Failures: Plagued With Problems by DesignDocument2 paginiPattern Failures: Plagued With Problems by DesignavinashjhamechxÎncă nu există evaluări

- Air CompressorDocument12 paginiAir CompressorBirtukan AsmareÎncă nu există evaluări

- Cooling System Check-OverheatingDocument3 paginiCooling System Check-OverheatingRahmat tullahÎncă nu există evaluări

- DDocument18 paginiDMahmoud El-abdÎncă nu există evaluări

- WG Instruction ManualDocument84 paginiWG Instruction ManualsercopetrolÎncă nu există evaluări

- Sabp G 028Document19 paginiSabp G 028Krishnamoorthy100% (1)

- Answer:-T Is A Known Fact That Every Running Machine Has A Tendency To VibrateDocument92 paginiAnswer:-T Is A Known Fact That Every Running Machine Has A Tendency To VibrateSri VasanÎncă nu există evaluări

- Chinh Kim CoDocument67 paginiChinh Kim ColeminhÎncă nu există evaluări

- C11, C13 and C15 On-Highway Engines-Maintenance IntervalsDocument42 paginiC11, C13 and C15 On-Highway Engines-Maintenance Intervalsgordoninkl9941100% (1)

- Bumping ClearanceDocument3 paginiBumping Clearanceranvir_raj100% (1)

- Aire Acondicionado ServicioDocument6 paginiAire Acondicionado ServicioTEROÎncă nu există evaluări

- E36PowerSteeringHoseDocument2 paginiE36PowerSteeringHoseMárcio K.Încă nu există evaluări

- Fallas ScrollDocument8 paginiFallas ScrollLucas MaturanoÎncă nu există evaluări

- Top 5 Troubleshooting Issues For Blower SystemsDocument4 paginiTop 5 Troubleshooting Issues For Blower SystemsUdhayakumar VenkataramanÎncă nu există evaluări

- Labrie Right-Hand Co-Mingle Troubleshooting 90252Document48 paginiLabrie Right-Hand Co-Mingle Troubleshooting 90252stainless31620039126100% (2)

- Revitalizing Vertical Lineshaft TurbinesDocument7 paginiRevitalizing Vertical Lineshaft TurbinesRagerishcire KanaalaqÎncă nu există evaluări

- Failure Analysis Guide: Eaton Fuller Clutches February 2008Document48 paginiFailure Analysis Guide: Eaton Fuller Clutches February 2008Angel DlsgÎncă nu există evaluări

- wJGAIHuDI0EBhB Y062522-001-EN WEB2Document6 paginiwJGAIHuDI0EBhB Y062522-001-EN WEB2Pedro CardenasÎncă nu există evaluări

- C11 Troubleshooting High Coolant Temperature PDFDocument3 paginiC11 Troubleshooting High Coolant Temperature PDFmanu luvungaÎncă nu există evaluări

- Pulse Fuel Pump Maintenance and TroubleshootingDocument5 paginiPulse Fuel Pump Maintenance and TroubleshootingdiegoÎncă nu există evaluări

- Eaton Clutch ManualDocument46 paginiEaton Clutch ManualEric Porter100% (4)

- 3guide Line Examining Soupapes3Document13 pagini3guide Line Examining Soupapes3chokriÎncă nu există evaluări

- KKC Compressor Cycling RatesDocument2 paginiKKC Compressor Cycling RateszayerirezaÎncă nu există evaluări

- 09-014 Oil in Turbocharger and Air PipingDocument6 pagini09-014 Oil in Turbocharger and Air PipingVictor MontesdeocaÎncă nu există evaluări

- Compresor Tuflo 550Document6 paginiCompresor Tuflo 550Ramón José Aponte FrancoÎncă nu există evaluări

- Diagnosing Misfires: Steady MisfireDocument3 paginiDiagnosing Misfires: Steady MisfireDawood SubedarÎncă nu există evaluări

- Benefits Shaft AlignmentDocument4 paginiBenefits Shaft AlignmentCarolina PBÎncă nu există evaluări

- SA英文使用手册NEWDocument49 paginiSA英文使用手册NEWBernad Orlando0% (1)

- PowerplantDocument64 paginiPowerplantChristine PuaÎncă nu există evaluări

- Fluidizing Blower ResearchDocument4 paginiFluidizing Blower ResearchEmmanuelÎncă nu există evaluări

- Engine Top BracingDocument14 paginiEngine Top Bracingcall_manishÎncă nu există evaluări

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesDe la EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesEvaluare: 5 din 5 stele5/5 (1)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementDe la EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementÎncă nu există evaluări

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceDe la EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceÎncă nu există evaluări

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesDe la EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesÎncă nu există evaluări

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDe la EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitÎncă nu există evaluări

- Ptfe DSCDocument23 paginiPtfe DSCnkrish21856Încă nu există evaluări

- Speciality Carbon BlackDocument8 paginiSpeciality Carbon Blacknkrish21856Încă nu există evaluări

- SR51-Power Steering: Uniform Procedures For Collision RepairDocument8 paginiSR51-Power Steering: Uniform Procedures For Collision Repairnkrish21856Încă nu există evaluări

- Measurement System AnalysisDocument17 paginiMeasurement System AnalysisAkash KumarÎncă nu există evaluări

- Injection MouldingDocument8 paginiInjection Mouldingnkrish21856Încă nu există evaluări

- DIN16742 2013A Eng Plastics Moulded Parts Tolerance Acceptance ConditionsDocument1 paginăDIN16742 2013A Eng Plastics Moulded Parts Tolerance Acceptance ConditionsNoe MarinÎncă nu există evaluări

- Teflon AF Amorphous FluoropolymersDocument23 paginiTeflon AF Amorphous Fluoropolymersnkrish21856Încă nu există evaluări

- US20030178790A1Document5 paginiUS20030178790A1nkrish21856Încă nu există evaluări

- US20020185819A1Document7 paginiUS20020185819A1nkrish21856Încă nu există evaluări

- Steel ReferenceDocument2 paginiSteel Referencenkrish21856Încă nu există evaluări

- Suspension 001Document26 paginiSuspension 001Vincentius NikimÎncă nu există evaluări

- Thermoplastic Polyurethane Desmopan 445 for Injection MoldingDocument4 paginiThermoplastic Polyurethane Desmopan 445 for Injection Moldingnkrish21856Încă nu există evaluări

- Processing of Dyneon PTFE Processing of Dyneon PTFE: Fine Powder Fine PowderDocument28 paginiProcessing of Dyneon PTFE Processing of Dyneon PTFE: Fine Powder Fine Powdernkrish21856Încă nu există evaluări

- DIN16742 2013A Eng Plastics Moulded Parts Tolerance Acceptance ConditionsDocument1 paginăDIN16742 2013A Eng Plastics Moulded Parts Tolerance Acceptance ConditionsNoe MarinÎncă nu există evaluări

- Global 8D WorkbookDocument52 paginiGlobal 8D WorkbookBalaji100% (10)

- Global 8D WorkbookDocument52 paginiGlobal 8D WorkbookBalaji100% (10)

- 17 22 ProcessingDocument30 pagini17 22 Processingnkrish21856Încă nu există evaluări

- Leadership Disrupted White PaperDocument16 paginiLeadership Disrupted White PaperDr Thomas GohÎncă nu există evaluări

- Week 6 Seven Basic Tools of Quality ControlDocument11 paginiWeek 6 Seven Basic Tools of Quality ControlDoah DidongÎncă nu există evaluări

- 849 BWI Customer Specific Requirements For IATF16949 2016 Rev 0 27oct2017Document33 pagini849 BWI Customer Specific Requirements For IATF16949 2016 Rev 0 27oct2017nkrish21856Încă nu există evaluări

- Thermoplastic Polyurethane Desmopan 445 for Injection MoldingDocument4 paginiThermoplastic Polyurethane Desmopan 445 for Injection Moldingnkrish21856Încă nu există evaluări

- Dynamic stiffness of engine mounts comparison test rigsDocument1 paginăDynamic stiffness of engine mounts comparison test rigsnkrish21856Încă nu există evaluări

- Renault Group CSR For IATF 169494Document10 paginiRenault Group CSR For IATF 169494nkrish21856Încă nu există evaluări

- Global Supplier Manual Appendix M - Suzuki Customer Specific Requirements For SuppliersDocument4 paginiGlobal Supplier Manual Appendix M - Suzuki Customer Specific Requirements For Suppliersnkrish21856Încă nu există evaluări

- Volkswagen Group CSR IATF 16949 Sept 2017Document6 paginiVolkswagen Group CSR IATF 16949 Sept 2017Selvaraj SÎncă nu există evaluări

- Volkswagen Group CSR IATF 16949 Sept 2017Document6 paginiVolkswagen Group CSR IATF 16949 Sept 2017Selvaraj SÎncă nu există evaluări

- Wheel End LeaksDocument5 paginiWheel End Leaksnkrish21856Încă nu există evaluări

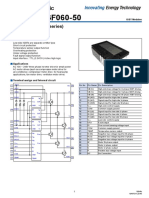

- 6MBP15XSF060-50: IGBT MODULE (X Series) 600V / 15A / IPMDocument13 pagini6MBP15XSF060-50: IGBT MODULE (X Series) 600V / 15A / IPMphetronyo ferreira de oliveiraÎncă nu există evaluări

- CROWBAR OperationDocument5 paginiCROWBAR Operationbspassov6Încă nu există evaluări

- Power Quality Problems Compensation With Universal Power Quality Conditioning System+++++++ PDFDocument9 paginiPower Quality Problems Compensation With Universal Power Quality Conditioning System+++++++ PDFazerty2547809Încă nu există evaluări

- 7UM62 - Rotor Earth Fault ProtectionDocument26 pagini7UM62 - Rotor Earth Fault ProtectionfourwheelerÎncă nu există evaluări

- Elecs Diagnostic ExamDocument2 paginiElecs Diagnostic ExammgoldiieeeeÎncă nu există evaluări

- ABB ACS300 Users ManualDocument99 paginiABB ACS300 Users ManualWilliam Jaldin CorralesÎncă nu există evaluări

- VISHAY CG3/DG3 Standard Sinterglass DiodeDocument5 paginiVISHAY CG3/DG3 Standard Sinterglass DiodeJorge Rene GerardoÎncă nu există evaluări

- SPPU First Year Engineering Exam Video Explains Basic Electronics MilestonesDocument57 paginiSPPU First Year Engineering Exam Video Explains Basic Electronics MilestonesAdityaÎncă nu există evaluări

- A Closer Look at State of Charge and State Health Estimation Techniques ...Document8 paginiA Closer Look at State of Charge and State Health Estimation Techniques ...Adri PratamaÎncă nu există evaluări

- Katrina M. Estrada 12 STEM-E9: V V V VDocument3 paginiKatrina M. Estrada 12 STEM-E9: V V V VJOHN RAVEN BUCAOÎncă nu există evaluări

- 55 Watt Gas CO2 Laser TubeDocument66 pagini55 Watt Gas CO2 Laser TubeFitzwalter100% (1)

- Inverter FR-E700-SC (-EC) (-NA) /NF/NC: Safety Stop Function Instruction ManualDocument15 paginiInverter FR-E700-SC (-EC) (-NA) /NF/NC: Safety Stop Function Instruction ManualAbderraouf AmellalÎncă nu există evaluări

- Operator'S Manual Manuel de L'Utilisateur Manual Del OperadorDocument15 paginiOperator'S Manual Manuel de L'Utilisateur Manual Del OperadorCarlos SoutoÎncă nu există evaluări

- LBritton Static Hazards in FIBCDocument22 paginiLBritton Static Hazards in FIBCAnonymous 1XHScfCIÎncă nu există evaluări

- DIY Powerful Induction Heater: InstructablesDocument16 paginiDIY Powerful Induction Heater: Instructablesdaritemanmu100% (1)

- RT412 TM EN HWA 4v2 PDFDocument45 paginiRT412 TM EN HWA 4v2 PDFJhonatan TerraÎncă nu există evaluări

- Chap-2-Transient Over VoltagesDocument68 paginiChap-2-Transient Over VoltageschalaÎncă nu există evaluări

- High-Frequency Model of The Power Transformer Based On Frequency-Response MeasurementsDocument9 paginiHigh-Frequency Model of The Power Transformer Based On Frequency-Response MeasurementsFernando PaezÎncă nu există evaluări

- Good Electricity and Water AnalogyDocument63 paginiGood Electricity and Water AnalogywalyatÎncă nu există evaluări

- FetronDocument40 paginiFetronJeremy Cutstone100% (2)

- Forma Scientific Freezers ManualDocument38 paginiForma Scientific Freezers ManualEzsilvasilva SilvaÎncă nu există evaluări

- User's ManualDocument24 paginiUser's ManualMARKO021Încă nu există evaluări

- AS320 Series Elevator-Used Inverter2021.12.14Document214 paginiAS320 Series Elevator-Used Inverter2021.12.14n340.3x3Încă nu există evaluări

- IEEE Recommended Practice For Routine Impulse Test For Distribution TransformersDocument56 paginiIEEE Recommended Practice For Routine Impulse Test For Distribution TransformersIngTec2016 IngTec2016Încă nu există evaluări

- Rife Frequencies, The Skin Effect and Bio-Electrical Impedance AnalysisDocument3 paginiRife Frequencies, The Skin Effect and Bio-Electrical Impedance AnalysisKhalid IbrahimÎncă nu există evaluări

- Hyundai Inverter–Powerful Operation, Easy MaintenanceDocument40 paginiHyundai Inverter–Powerful Operation, Easy MaintenanceHossein KarimiÎncă nu există evaluări