Documente Academic

Documente Profesional

Documente Cultură

Mixing Sphere

Încărcat de

Ramalingam PrabhakaranDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Mixing Sphere

Încărcat de

Ramalingam PrabhakaranDrepturi de autor:

Formate disponibile

CHECKLIST FOR BOILER RECIRCULATION MIXING SPHERE (F-57)

1. The Boiler Recirculation Mixing Sphere function is to store the water from

connecting sphere and recirculate the water to boiler feed line through recirculation

pump.

2. APIL Scope is to prepare the detail drawings.

3. Collect the following inputs from API, before start the drawings.

ASME calculation sheet.

Startup System Arrangements drawings

3D Model drawings

P & I drawings.

Strainer and Diffuser details

Lifting lug location and size details.

Material Specification

4. Verify the following listed item with received inputs from API.

a) For Sphere size (ID and Thk.) ref. ASME calculation sheet.

b) Water Inlet & outlet Nozzles location, orientation size (OD, Thk. and length) and

edge preparation details ref. ASME calculation sheet, Startup system

arrangements and 3D Model drawings.

c) Strainer ref. attached Sketch No. BRMS-2

d) Diffuser ref. attached Sketch No. BRMS-3

e) Lifting lug location ref. attached Sketch No.LIFT-1

f). For nozzle edge preparation and tolerances ref. ASME calculation sheet.

g) Pressure, Temperature and Material specification ref. ASME calculation sheet.

Rprabhakaran Page 1 8/12/2020

5. No separate supports required for sphere. The total load would take care by

connecting pipes.

6. Nozzle and support lugs are not allowed on sphere Circumference weld.

7. Provide the sphere circum weld as per the attached sketch no.

8. Check the sphere and nozzle thk. are MWT (Min. wall Thk.) or AWT (Avg. wall

Thk.)

9. Provide Erection lug for all Inlet & Outlet Nozzles as per API. Standard.

10. Common manhole drawings for lower spheres and mixing sphere.

11. The orientation of the manhole is 15 degree above the horizontal centerline.

12. Provide the necessary views, sections and welding details as per reference drgs.

STRAINER ASSEMBLY (Ref. SKETCH Nos. 1 & 2)

13. Strainer height is based on total no. Off perforated holes.

14. Strainer having Dia. 0.3937 perforated holes. The total area of perforated holes

must be 1.5 times of Outlet nozzle area.

15. Strainer bottom ID and top ID are based on the outlet nozzle ID, ref. Attached

sketch No. STR-CHK-1

16. Perforated hole circumference pitch should be equal pitch or .50”

17. Perforated hole longitudinal pitch should be 0.4375”

18. Minimum 1” gap required from the strainer top to first row of perforated holes.

19. Ensure the appropriate gap between the strainer cover plate and diffuser pipe

to avoid fouling.

20. Strainer made by two half section and its connected by bolt with flange plate.

Rprabhakaran Page 2 8/12/2020

21. Flange plate having min. 4 nos. bolt holes for connecting the two half strainer.

22. Min. 1.25” gap required starting the flange plate from the strainer top.

23. No perforated holes on strainer cover plate.

24. Strainer has supported by two cleats at various location, the cleat has welded with

inside of sphere and bolt connection between the strainer and cleats.

25. Strainer having one stopper / alignment plate ant its welded with inside of sphere.

No weld / bolt connection between the strainer and stopper/alignment plate.

26. All plate thk. should be 0.25”

27. No holes on flange plate location.

28. No weld between strainer and cover plate, only bolt connection.

DIFFUSER ASSEMBLY (Ref. SKETCH No. 1 & 3)

29. Diffuser pipeline is from the feed water line.

30. Diffuser Pipe size is based on the Inlet nozzle ID, go for the one size below of the

nozzle ID size.

31. Diffuser elbow should be short radius

32. Provide the perforated holes for diffuser pipe as per the reference drawings.

33. Diffuser pipe having Dia. 0.3937 perforated holes, the total area of perforated

holes must be 2.0 times of Inlet nozzle area.

34. Ensure the appropriate gap between the weld line and perforated holes to avoid

fouling.

35. No perforated holes on diffuser pipe cover plate.

Rprabhakaran Page 3 8/12/2020

36. Provide the pad on the diffuser pipe for support between the nozzle ID hole on

sphere and diffuser pipe.

37. Pad thk. based on the gap between the nozzle ID hole on sphere and diffuser pipe

diameter.

38. Standard Drawing List (Always ref. the latest revision)

a) Detail of Erection Lug. - B-980-135 Rev.05

b) Arrangement of Erection Lug - D-980-0102 Rev.04

39. Reference Drawings List.

a) Arrangement & Detail of Recirculation Mixing Sphere (F-57) - 00105 - 1E1435

b) Detail of Diffuser Assy. & Strainer Assy. - 00105 - 1E1401

Rprabhakaran Page 4 8/12/2020

S-ar putea să vă placă și

- Front and Rear SphereDocument4 paginiFront and Rear SphereRamalingam PrabhakaranÎncă nu există evaluări

- Checklist For Separator (F-31) : Rprabhakaran 8/12/2020Document3 paginiChecklist For Separator (F-31) : Rprabhakaran 8/12/2020Ramalingam PrabhakaranÎncă nu există evaluări

- Checklist For Separator Cum Storage Tank (F-31) : Rprabhakaran 10/12/2020Document3 paginiChecklist For Separator Cum Storage Tank (F-31) : Rprabhakaran 10/12/2020Ramalingam PrabhakaranÎncă nu există evaluări

- Checklist For Storage Tank (F-33) : Rprabhakaran 10/12/2020Document3 paginiChecklist For Storage Tank (F-33) : Rprabhakaran 10/12/2020Ramalingam PrabhakaranÎncă nu există evaluări

- Connecting SphereDocument2 paginiConnecting SphereRamalingam PrabhakaranÎncă nu există evaluări

- Specification For Core & Jacket: Rev. Date Revision Description Issued by Checked by Approved byDocument13 paginiSpecification For Core & Jacket: Rev. Date Revision Description Issued by Checked by Approved byvishal bhamreÎncă nu există evaluări

- TANK Design DetailingDocument17 paginiTANK Design DetailingTiffany Vabiola100% (8)

- Checklist For Separator Cum Storage TankDocument5 paginiChecklist For Separator Cum Storage TankRamalingam PrabhakaranÎncă nu există evaluări

- Guidelines For Piping Design & ErectionDocument55 paginiGuidelines For Piping Design & ErectionKartik Varma Namburi100% (2)

- Vertical Roof EnclosureDocument5 paginiVertical Roof EnclosureRamalingam PrabhakaranÎncă nu există evaluări

- Specification For Jackets: Rev. Date Revision Description Issued by Checked by Approved byDocument14 paginiSpecification For Jackets: Rev. Date Revision Description Issued by Checked by Approved byvishal bhamreÎncă nu există evaluări

- Piping Shop Fabrication SpecificationDocument18 paginiPiping Shop Fabrication Specificationfarmanali07100% (1)

- Scientific Devices (B) Pvt. LTD.: Instruction Manual FOR by - Pass RotameterDocument5 paginiScientific Devices (B) Pvt. LTD.: Instruction Manual FOR by - Pass RotameterfaqdaniÎncă nu există evaluări

- Section 630 Tapping Sleeves, Valves and Valve Boxes On Water Lines 630.1 DESCRIPTIONDocument7 paginiSection 630 Tapping Sleeves, Valves and Valve Boxes On Water Lines 630.1 DESCRIPTIONWalter GuttlerÎncă nu există evaluări

- KochDocument181 paginiKochRichard FelipÎncă nu există evaluări

- ES 49BranchConnectionsDocument7 paginiES 49BranchConnectionsrodofgodÎncă nu există evaluări

- 8931 PDFDocument27 pagini8931 PDFPawan Kumar100% (1)

- Piping Fabrication and Erection SpecificationDocument19 paginiPiping Fabrication and Erection Specificationahmedmoin1159Încă nu există evaluări

- Equipment and PipingDocument49 paginiEquipment and Pipingnuruddin2409100% (1)

- Ibr BookDocument33 paginiIbr BookRaja JayachandranÎncă nu există evaluări

- 0497 4 Flow Straightener Catalog Sheet 05 14Document2 pagini0497 4 Flow Straightener Catalog Sheet 05 14mkfe2006Încă nu există evaluări

- Tolerance Pole MastDocument8 paginiTolerance Pole Mastpbp2956Încă nu există evaluări

- MS For Mechanical Piping System Installation WorkDocument22 paginiMS For Mechanical Piping System Installation WorkUmut Eren63% (8)

- Tube To Tube SheetDocument59 paginiTube To Tube Sheet0101100175% (12)

- SEars Riello f10 Oil Burner ManualDocument20 paginiSEars Riello f10 Oil Burner ManualLeslie FlemingÎncă nu există evaluări

- 068 180Document113 pagini068 180Ed CalheÎncă nu există evaluări

- Operating and Servide Manual 90126-IMDocument8 paginiOperating and Servide Manual 90126-IMtrpacÎncă nu există evaluări

- Piping Q & ADocument8 paginiPiping Q & AvenkateshÎncă nu există evaluări

- 19d Impeller SpacingDocument9 pagini19d Impeller Spacingbtgottlieb100% (1)

- ChecklistDocument61 paginiChecklistjhunkujha11Încă nu există evaluări

- Air Cooled Heat ExchangerDocument24 paginiAir Cooled Heat Exchangeriaft100% (2)

- Checklist For Piping IsometricsDocument3 paginiChecklist For Piping IsometricsSomnath Laha100% (1)

- Steamfitter Pipefitter Practice ExamDocument9 paginiSteamfitter Pipefitter Practice ExamAbo Hasan Abade67% (3)

- Bill No. D1: External Works & Services (All Provisional) ITE MDocument8 paginiBill No. D1: External Works & Services (All Provisional) ITE MRubbyRdÎncă nu există evaluări

- Piping Iso ChecklistDocument2 paginiPiping Iso Checklistvniranjan100% (1)

- 4780-w8 Selection and Design of Branch Connections and ReinforcementDocument8 pagini4780-w8 Selection and Design of Branch Connections and ReinforcementLorenaÎncă nu există evaluări

- Api 6D 2016Document2 paginiApi 6D 2016raulÎncă nu există evaluări

- Technical Specification For Pressure Regulating Valve (PRV)Document5 paginiTechnical Specification For Pressure Regulating Valve (PRV)Sanket SavlaÎncă nu există evaluări

- Refrigerant Piping Sample-2Document4 paginiRefrigerant Piping Sample-2Hazrat AminÎncă nu există evaluări

- Collar Bolts in Shell and Tube Heat ExchangersDocument3 paginiCollar Bolts in Shell and Tube Heat ExchangersBaher ElsheikhÎncă nu există evaluări

- Nozzle LengthDocument5 paginiNozzle LengthGanesh EshwarÎncă nu există evaluări

- Aramco Interview Questions PRDocument11 paginiAramco Interview Questions PRhemant1284100% (2)

- CM07 Sphere ConstructionDocument146 paginiCM07 Sphere ConstructionHuy Thieu Bui100% (1)

- Tender SpecDocument8 paginiTender SpecimyourscinÎncă nu există evaluări

- Brazing Procedure 1Document5 paginiBrazing Procedure 1Tina MillerÎncă nu există evaluări

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDe la EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsEvaluare: 4.5 din 5 stele4.5/5 (10)

- Pocket Guide to Flanges, Fittings, and Piping DataDe la EverandPocket Guide to Flanges, Fittings, and Piping DataEvaluare: 3.5 din 5 stele3.5/5 (22)

- All-in-One Manual of Industrial Piping Practice and MaintenanceDe la EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceEvaluare: 5 din 5 stele5/5 (1)

- Design and Analysis of Centrifugal CompressorsDe la EverandDesign and Analysis of Centrifugal CompressorsÎncă nu există evaluări

- Steam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversDe la EverandSteam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversEvaluare: 5 din 5 stele5/5 (2)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceDe la EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceÎncă nu există evaluări

- Plastic Injection Mold Design for Toolmakers - Volume II: Plastic Injection Mold Design for Toolmakers, #2De la EverandPlastic Injection Mold Design for Toolmakers - Volume II: Plastic Injection Mold Design for Toolmakers, #2Încă nu există evaluări

- Design Guidelines for Surface Mount TechnologyDe la EverandDesign Guidelines for Surface Mount TechnologyEvaluare: 5 din 5 stele5/5 (1)

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1De la EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Evaluare: 3.5 din 5 stele3.5/5 (3)

- b2020-Tdc-Fas-004 Fasteners r3Document2 paginib2020-Tdc-Fas-004 Fasteners r3Ramalingam PrabhakaranÎncă nu există evaluări

- B2020-TDC-VF-009 Vessel Fabrication R0Document5 paginiB2020-TDC-VF-009 Vessel Fabrication R0Ramalingam PrabhakaranÎncă nu există evaluări

- B2020-TDC-DEF-005 Dished End Forming R0Document2 paginiB2020-TDC-DEF-005 Dished End Forming R0Ramalingam PrabhakaranÎncă nu există evaluări

- Mitering Formula Example For 6" Concrete Wall:: Integraspec®Document2 paginiMitering Formula Example For 6" Concrete Wall:: Integraspec®Ramalingam PrabhakaranÎncă nu există evaluări

- 008 ER70S-6 Electrodes R0Document2 pagini008 ER70S-6 Electrodes R0Ramalingam PrabhakaranÎncă nu există evaluări

- B2020-TDC-SR-006 Shell Rolling R0Document2 paginiB2020-TDC-SR-006 Shell Rolling R0Ramalingam PrabhakaranÎncă nu există evaluări

- B2020-TDC-FIT-013 Coupling Plug R1Document2 paginiB2020-TDC-FIT-013 Coupling Plug R1Ramalingam PrabhakaranÎncă nu există evaluări

- Checklist - Fuel Firing - Non Pressure Parts Drgs.Document4 paginiChecklist - Fuel Firing - Non Pressure Parts Drgs.Ramalingam PrabhakaranÎncă nu există evaluări

- Checklist - Expansion Joint - Non Pressure Parts Drgs.Document3 paginiChecklist - Expansion Joint - Non Pressure Parts Drgs.Ramalingam Prabhakaran100% (2)

- Checklist - HRSG Ducting - Non Pressure Parts Drgs.Document3 paginiChecklist - HRSG Ducting - Non Pressure Parts Drgs.Ramalingam PrabhakaranÎncă nu există evaluări

- Checklist - Hoist and Pulley Block - Non Pressure Parts Drgs.Document2 paginiChecklist - Hoist and Pulley Block - Non Pressure Parts Drgs.Ramalingam PrabhakaranÎncă nu există evaluări

- Checklist - Bearing - Non Pressure Parts Drgs.Document1 paginăChecklist - Bearing - Non Pressure Parts Drgs.Ramalingam PrabhakaranÎncă nu există evaluări

- Checklist - Damper - Non Pressure Parts Drgs.Document2 paginiChecklist - Damper - Non Pressure Parts Drgs.Ramalingam PrabhakaranÎncă nu există evaluări

- Checklist - Casing - Non Pressure Parts Drgs.Document3 paginiChecklist - Casing - Non Pressure Parts Drgs.Ramalingam PrabhakaranÎncă nu există evaluări

- Checklist For Arrangement and Detail of Drum InternalsDocument5 paginiChecklist For Arrangement and Detail of Drum InternalsRamalingam PrabhakaranÎncă nu există evaluări

- Checklist For Economiser Element DrawingDocument2 paginiChecklist For Economiser Element DrawingRamalingam PrabhakaranÎncă nu există evaluări

- Checklist For Drum Internal PipingDocument2 paginiChecklist For Drum Internal PipingRamalingam PrabhakaranÎncă nu există evaluări

- Checklist - Duct Detailing - Non Pressure Parts Drgs - 01Document2 paginiChecklist - Duct Detailing - Non Pressure Parts Drgs - 01Ramalingam PrabhakaranÎncă nu există evaluări

- Checklist For Pipe SupportsDocument2 paginiChecklist For Pipe SupportsRamalingam PrabhakaranÎncă nu există evaluări

- Checklist For Arrangement of DrumDocument4 paginiChecklist For Arrangement of DrumRamalingam PrabhakaranÎncă nu există evaluări

- E-1 List of STD SpecsDocument2 paginiE-1 List of STD SpecsRamalingam PrabhakaranÎncă nu există evaluări

- 18 - PPAG-100-HD-C-001 - s018 (VBA03C013) - 0 PDFDocument1 pagină18 - PPAG-100-HD-C-001 - s018 (VBA03C013) - 0 PDFSantiago GarciaÎncă nu există evaluări

- Multispan LC 2046 Length Counter PDFDocument2 paginiMultispan LC 2046 Length Counter PDFvinod kumarÎncă nu există evaluări

- A320 Basic Edition Flight TutorialDocument50 paginiA320 Basic Edition Flight TutorialOrlando CuestaÎncă nu există evaluări

- Loading N Unloading of Tanker PDFDocument36 paginiLoading N Unloading of Tanker PDFKirtishbose ChowdhuryÎncă nu există evaluări

- Level 3 Repair: 8-1. Block DiagramDocument30 paginiLevel 3 Repair: 8-1. Block DiagramPaulo HenriqueÎncă nu există evaluări

- HSBC in A Nut ShellDocument190 paginiHSBC in A Nut Shelllanpham19842003Încă nu există evaluări

- Innovations in Land AdministrationDocument66 paginiInnovations in Land AdministrationSanjawe KbÎncă nu există evaluări

- Arduino Based Voice Controlled Robot: Aditya Chaudhry, Manas Batra, Prakhar Gupta, Sahil Lamba, Suyash GuptaDocument3 paginiArduino Based Voice Controlled Robot: Aditya Chaudhry, Manas Batra, Prakhar Gupta, Sahil Lamba, Suyash Guptaabhishek kumarÎncă nu există evaluări

- 09 WA500-3 Shop ManualDocument1.335 pagini09 WA500-3 Shop ManualCristhian Gutierrez Tamayo93% (14)

- Cic Tips Part 1&2Document27 paginiCic Tips Part 1&2Yousef AlalawiÎncă nu există evaluări

- Unit Process 009Document15 paginiUnit Process 009Talha ImtiazÎncă nu există evaluări

- TSR KuDocument16 paginiTSR KuAngsaÎncă nu există evaluări

- Sophia Program For Sustainable FuturesDocument128 paginiSophia Program For Sustainable FuturesfraspaÎncă nu există evaluări

- Unit 2Document97 paginiUnit 2MOHAN RuttalaÎncă nu există evaluări

- Mid Term Exam 1Document2 paginiMid Term Exam 1Anh0% (1)

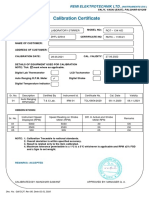

- Calibration CertificateDocument1 paginăCalibration CertificateSales GoldClassÎncă nu există evaluări

- LOG-2-8-FLEETWAREHOUSE-TEMPLATE-Waybill-Delivery Note-IFRCDocument1 paginăLOG-2-8-FLEETWAREHOUSE-TEMPLATE-Waybill-Delivery Note-IFRCMÎncă nu există evaluări

- Algorithmique Et Programmation en C: Cours Avec 200 Exercices CorrigésDocument298 paginiAlgorithmique Et Programmation en C: Cours Avec 200 Exercices CorrigésSerges KeouÎncă nu există evaluări

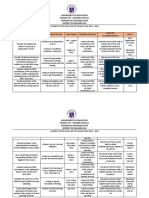

- Action Plan Lis 2021-2022Document3 paginiAction Plan Lis 2021-2022Vervie BingalogÎncă nu există evaluări

- Instructions For Microsoft Teams Live Events: Plan and Schedule A Live Event in TeamsDocument9 paginiInstructions For Microsoft Teams Live Events: Plan and Schedule A Live Event in TeamsAnders LaursenÎncă nu există evaluări

- SME-Additional Matter As Per Latest Syllabus Implementation WorkshopDocument14 paginiSME-Additional Matter As Per Latest Syllabus Implementation WorkshopAvijeet BanerjeeÎncă nu există evaluări

- 4109 CPC For ExamDocument380 pagini4109 CPC For ExamMMM-2012Încă nu există evaluări

- Reflections On Free MarketDocument394 paginiReflections On Free MarketGRK MurtyÎncă nu există evaluări

- A320 TakeoffDocument17 paginiA320 Takeoffpp100% (1)

- Epidemiologi DialipidemiaDocument5 paginiEpidemiologi DialipidemianurfitrizuhurhurÎncă nu există evaluări

- Saet Work AnsDocument5 paginiSaet Work AnsSeanLejeeBajan89% (27)

- Case Assignment 2Document5 paginiCase Assignment 2Ashish BhanotÎncă nu există evaluări

- CANELA Learning Activity - NSPE Code of EthicsDocument4 paginiCANELA Learning Activity - NSPE Code of EthicsChristian CanelaÎncă nu există evaluări

- ICSI-Admit-Card (1) - 230531 - 163936Document17 paginiICSI-Admit-Card (1) - 230531 - 163936SanjayÎncă nu există evaluări

- Squirrel Cage Induction Motor Preventive MaintenaceDocument6 paginiSquirrel Cage Induction Motor Preventive MaintenaceNishantPareekÎncă nu există evaluări