Documente Academic

Documente Profesional

Documente Cultură

Siphon Breaker Valves (Accessories)

Încărcat de

mikeswordsDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Siphon Breaker Valves (Accessories)

Încărcat de

mikeswordsDrepturi de autor:

Formate disponibile

SIPHON BREAKER VALVES

TAKE ADVANTAGE OF NATURE

Are you doing this... When you could be doing this...

Flow 500 l/s Flow 500 l/s

Head 10 metres Head 7 metres

Motor 75kW Motor 50kW

The two illustrations above are for exactly the same application; the first shows a

typical installation with a free discharge. The second takes advantage of siphonic

recovery, and in so doing, offers a significant reduction in pump head and power.

The concept of siphonic assistance has been around for centuries, but is often

overlooked for pumping applications. By submerging the outlet of the discharge

pipe, the pump static head is reduced simply to the difference between the sump

water level and the discharge surface water level.

Traditionally, this method has been widely used in the Land

Drainage industry, but can equally be used in many other

applications. All that is required is a slight modification to

the pipework design and the installation of a siphon breaker

valve. The benefits are recouped whenever the plant is running.

How does it work?

The siphon breaker valve is a small paddle operated butterfly

valve designed to automatically control the priming and

de-priming of the siphonic discharge. It is mounted on top of

the discharge pipework siphon loop.

With the pump stopped, the valve is held open by the weight

of the operating paddle.

On pump start-up, the valve allows air to discharge from the

top of the siphon.

As the pipe fills, flow, acting upon the paddle, closes the valve.

The siphon designed into the system is now established.

The flow of water in the forward direction maintains

pressure on the paddle and keeps the valve closed, thus

maintaining the siphon.

When the pump stops, the reverse flow acts on the paddle and opens the valve thereby destroying the vacuum in the

pipe and preventing continuing reverse flow through the pump.

Advantages of a siphonic system:

The saving on power consumption can be considerable, as the head reduction will result in a proportional

decrease in power absorbed.

The complete absence of any valves, other than the siphon-breaker, results in capital cost savings and

enables automatic, maintenance-free operation.

The prime mover cannot be overloaded.

The siphon-breaker valves are supplied in three sizes: 100, 150 and 200mm diameter, covering pipe sizes

between 400-2000mm diameter.

Features:

The Bedford Pumps Ltd Siphon Breaker valve incorporates the

following features, some of which are optional:

Heating element to prevent freezing in the closed position.

Provision for a proximity switch to indicate when the valve is

open / closed.

A close fitting bowl-shaped cowl as standard, or vent pipe

extension / silencer if required.

Design of a siphonic system:

Each pump must have its own discharge main. The invert of the siphon must be slightly above the flood level.

otherwise water can flow back irrespective of the siphon breaker.

For the few seconds of start-up, the pump head is from the level in the suction well to the soffit (top) of the siphon

pipe.

The flow velocity in the siphon must be approx. 1.8 m/s to maintain prime, otherwise the rising water will simply

“weir” over the invert. This flow velocity must also be achieved against the startup level.

Brooklands Woburn Road Industrial Estate, Kempston, Beds. MK42 7UH Tel: +44 (0)1234 852071

Fax: +44 (0)1234 856620 email: sales@bedfordpumps.co.uk Web: www.bedfordpumps.co.uk SIPHON05/09

S-ar putea să vă placă și

- Design of Distillation TraysDocument25 paginiDesign of Distillation Trayssatishchemeng100% (8)

- Meteorology - Mesoscale Dynamics PDFDocument646 paginiMeteorology - Mesoscale Dynamics PDFMohamed Nabhani100% (2)

- Condenser Siphon Seal-WellsDocument3 paginiCondenser Siphon Seal-Wellstwins19564839100% (1)

- OLGA User ManualDocument660 paginiOLGA User ManualHoàng Nguyên83% (6)

- Smoke & Ventilation CalculationsDocument7 paginiSmoke & Ventilation CalculationsZine ModelsÎncă nu există evaluări

- BOQ-MTO CompareDocument11 paginiBOQ-MTO ComparexxxÎncă nu există evaluări

- Well Control EquiptDocument115 paginiWell Control EquiptGhavban David100% (3)

- Mip Bohler PipelineDocument32 paginiMip Bohler PipelineDaniel StuparekÎncă nu există evaluări

- Painting and Galvanizing Specification SummaryDocument22 paginiPainting and Galvanizing Specification SummaryRicardo NapitupuluÎncă nu există evaluări

- Cb3 Ec 50 MT 001 A4 Rev.1 Mto For Civil WorkDocument5 paginiCb3 Ec 50 MT 001 A4 Rev.1 Mto For Civil WorkRomawi StevyandiÎncă nu există evaluări

- Valves, fittings and gasketsDocument32 paginiValves, fittings and gasketsPeter RodriguezÎncă nu există evaluări

- Enbridge Pipeline Repair Workplan Welding PDFDocument23 paginiEnbridge Pipeline Repair Workplan Welding PDFquiron2014Încă nu există evaluări

- Comparison of SA106 Against ASTM A106 StandardsDocument15 paginiComparison of SA106 Against ASTM A106 Standardsshamoojee100% (1)

- MiniElcor EngDocument131 paginiMiniElcor Engroberto casca0% (1)

- API - ANSI Flange Conversation ChartDocument1 paginăAPI - ANSI Flange Conversation ChartvaliullahÎncă nu există evaluări

- Price Kitazawa ValveDocument9 paginiPrice Kitazawa ValveAhmad Syaifudin ZÎncă nu există evaluări

- A134 PDFDocument4 paginiA134 PDFAlberto DiazÎncă nu există evaluări

- RD-I-CI-G00-1020-02 - Rev.1 - Layout of Instrument Plot Plan Wiring & Grounding For Well PAD RD-MDocument3 paginiRD-I-CI-G00-1020-02 - Rev.1 - Layout of Instrument Plot Plan Wiring & Grounding For Well PAD RD-MInsan Aziz100% (1)

- Steel Pipes - Pipe Schedule ChartDocument1 paginăSteel Pipes - Pipe Schedule ChartAlzaki AbdullahÎncă nu există evaluări

- Elbow Trimming ProcedureDocument5 paginiElbow Trimming ProcedureMechanical Static WRKÎncă nu există evaluări

- Daftar Harga Fire Hydrant AppronDocument2 paginiDaftar Harga Fire Hydrant AppronWeri IsvebriantiÎncă nu există evaluări

- Prosedur Kerja Tie-In Pipa 10 Dan Demolish Pipa 8Document7 paginiProsedur Kerja Tie-In Pipa 10 Dan Demolish Pipa 8Rio Cristovan MantiriÎncă nu există evaluări

- Air Reciver Vessel-1 (Compressor Unit-2)Document5 paginiAir Reciver Vessel-1 (Compressor Unit-2)MD Shadikul Huq ShezanÎncă nu există evaluări

- AV-C Butterfly ValveDocument20 paginiAV-C Butterfly ValveSopon SrirattanapiboonÎncă nu există evaluări

- 001 Manual Data Sheet PipaDocument3 pagini001 Manual Data Sheet Pipawahyu hutamaÎncă nu există evaluări

- Inspection & Test Plan PT. Barata Indonesia: Fabrication DocumentDocument22 paginiInspection & Test Plan PT. Barata Indonesia: Fabrication DocumentmoddysÎncă nu există evaluări

- Presentasi Design WPS - 1 Dec 10 BWDocument43 paginiPresentasi Design WPS - 1 Dec 10 BWWahyu PurbaÎncă nu există evaluări

- Fluxi 2000 TZ EN-03 - 18Document4 paginiFluxi 2000 TZ EN-03 - 18Praveen KumarÎncă nu există evaluări

- Trepanning Positioning Welding ManualDocument14 paginiTrepanning Positioning Welding ManualGovindan PerumalÎncă nu există evaluări

- Sop-Pemasangan Spectacle BlindDocument5 paginiSop-Pemasangan Spectacle BlindRidwan PradityaÎncă nu există evaluări

- Katalog ARITA - 2019Document68 paginiKatalog ARITA - 2019Sugeng Arief Van'tbowoÎncă nu există evaluări

- Pipes FittingsDocument7 paginiPipes FittingsTushar ArekarÎncă nu există evaluări

- Procedure Welding Consumible ProcedureDocument11 paginiProcedure Welding Consumible ProcedureCilobong Kubuk KubingÎncă nu există evaluări

- FL Bng-A1 Rev. RBDocument48 paginiFL Bng-A1 Rev. RBAditya Fariz PermanaÎncă nu există evaluări

- Aligment Methods-Act 20161119Document104 paginiAligment Methods-Act 20161119Mohamed MusaÎncă nu există evaluări

- Form Welding SchematicDocument1 paginăForm Welding SchematicZainudinÎncă nu există evaluări

- List of Machines in Mechanical WorkshopDocument3 paginiList of Machines in Mechanical WorkshopHamza Nouman100% (1)

- Minimum Length and Spacing For Welded Nozzles PDFDocument7 paginiMinimum Length and Spacing For Welded Nozzles PDFSoniÎncă nu există evaluări

- Design and Analysis of Gear PumpDocument7 paginiDesign and Analysis of Gear PumpMahesh KudtarkarÎncă nu există evaluări

- Method Statement AGI Train 2 Inspection & Repair Plan: Approval SheetDocument9 paginiMethod Statement AGI Train 2 Inspection & Repair Plan: Approval SheetGunawan MSÎncă nu există evaluări

- Fan Merk Kruger Model APMDocument4 paginiFan Merk Kruger Model APMKarin Aca OviÎncă nu există evaluări

- Katalog TSP PTDocument24 paginiKatalog TSP PTendroÎncă nu există evaluări

- Manajemen Material PembangkitDocument46 paginiManajemen Material Pembangkitramdana satriaÎncă nu există evaluări

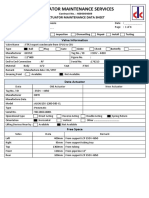

- Actuator Maintenance ServicesDocument7 paginiActuator Maintenance ServicesKevin MuhalingÎncă nu există evaluări

- b002 - Report Construction of Sheet PileDocument7 paginib002 - Report Construction of Sheet PileMOHAMMAD KAZIÎncă nu există evaluări

- Catalog Valve Technology 2ndedition PDFDocument106 paginiCatalog Valve Technology 2ndedition PDFtpichileÎncă nu există evaluări

- Tabel PulleyDocument4 paginiTabel PulleyDimas D'rooyal Borooss'Încă nu există evaluări

- Copper WeldingDocument13 paginiCopper Weldingkatchani123Încă nu există evaluări

- Actuation Product Catalogue - OneSteelDocument65 paginiActuation Product Catalogue - OneSteelJOHN100% (1)

- PVC Material Safety Data SheetDocument4 paginiPVC Material Safety Data SheetRegian Fajar AriesandiÎncă nu există evaluări

- TB 10Document10 paginiTB 10Ankur PandeyÎncă nu există evaluări

- Fabrication Procedure For Piping Pr-Skm-24a18012019164730Document4 paginiFabrication Procedure For Piping Pr-Skm-24a18012019164730Danang Edi Prasetyo100% (1)

- Hydro-Test Report Report No: Ecl/Ht/0005Document29 paginiHydro-Test Report Report No: Ecl/Ht/0005Muhammad Faisal JavedÎncă nu există evaluări

- Filtro y StrainerDocument2 paginiFiltro y StrainerJose HuguetÎncă nu există evaluări

- MSFJ020D - Denso - CPT 1000 Innerwrap and CPT 1000 OuterwrapDocument7 paginiMSFJ020D - Denso - CPT 1000 Innerwrap and CPT 1000 OuterwrapMakamu Max Las MokgaoganyiÎncă nu există evaluări

- Industrial TrainingDocument59 paginiIndustrial TrainingSatnam SinghÎncă nu există evaluări

- Klingersil: Optimum Flange SecurityDocument7 paginiKlingersil: Optimum Flange SecurityjbertralÎncă nu există evaluări

- Stainless Steel Aisi 304 Terhadap Sifat MekanisDocument10 paginiStainless Steel Aisi 304 Terhadap Sifat Mekanis-AS-Încă nu există evaluări

- 16 - SGU - RT - ASME - 16 - Radiographic - REV - 00Document53 pagini16 - SGU - RT - ASME - 16 - Radiographic - REV - 00pankrasius herbudiÎncă nu există evaluări

- Codes, Standards & Regulations OverviewDocument8 paginiCodes, Standards & Regulations OverviewDzaka LanaaÎncă nu există evaluări

- SEJIN ProfileDocument42 paginiSEJIN ProfilehungleteÎncă nu există evaluări

- Heading SUPPORT: Software - Support@dnvgl.c: Open Case Save CaseDocument10 paginiHeading SUPPORT: Software - Support@dnvgl.c: Open Case Save CaseSatxiemaÎncă nu există evaluări

- Building Service Course WorkDocument20 paginiBuilding Service Course WorkKemigisa MarthaÎncă nu există evaluări

- Forbes Marshall Turbine Bypass Valves PDFDocument28 paginiForbes Marshall Turbine Bypass Valves PDFAnonymous lmCR3SkPrKÎncă nu există evaluări

- PENETRATION Guide To Wall Penetration PDFDocument20 paginiPENETRATION Guide To Wall Penetration PDFmikeswordsÎncă nu există evaluări

- Electric Actuator WiringDocument16 paginiElectric Actuator WiringmikeswordsÎncă nu există evaluări

- Ashrae D 86142Document1 paginăAshrae D 86142ดั๊มพ์ วาสนาทิพย์Încă nu există evaluări

- Summary of Cases and Locations VisitedDocument6 paginiSummary of Cases and Locations VisitedmikeswordsÎncă nu există evaluări

- KFC Froyo Stores 2020Document1 paginăKFC Froyo Stores 2020mikeswordsÎncă nu există evaluări

- Relief, By-Pass, Back Pressure & Anti-Siphon ValvesDocument12 paginiRelief, By-Pass, Back Pressure & Anti-Siphon ValvesmikeswordsÎncă nu există evaluări

- List STBDocument21 paginiList STBmikeswordsÎncă nu există evaluări

- MANKENBERG - Vacuum Valve PDFDocument10 paginiMANKENBERG - Vacuum Valve PDFmikeswordsÎncă nu există evaluări

- Heat Transfer in A Pulsed Fluidized Bed of Biomass ParticlesDocument17 paginiHeat Transfer in A Pulsed Fluidized Bed of Biomass ParticlesmikeswordsÎncă nu există evaluări

- Compact, Self-Closing Vacuum Breakers Protect Against Hazards, Damage and Financial Losses Caused by Vacuum!Document2 paginiCompact, Self-Closing Vacuum Breakers Protect Against Hazards, Damage and Financial Losses Caused by Vacuum!mikeswordsÎncă nu există evaluări

- GPCDOC - X - Cbe - 24855 - Key - 140002282412 - 1C93 (Thermia B) PDFDocument2 paginiGPCDOC - X - Cbe - 24855 - Key - 140002282412 - 1C93 (Thermia B) PDFfadilah permata sariÎncă nu există evaluări

- AsdsasafaDocument1 paginăAsdsasafamikeswordsÎncă nu există evaluări

- Document layouts with titles, lists, charts, tables and SmartArtDocument11 paginiDocument layouts with titles, lists, charts, tables and SmartArtLoh Li YiÎncă nu există evaluări

- Inquery Water Meter Sofrel LS42Document2 paginiInquery Water Meter Sofrel LS42megiternadoÎncă nu există evaluări

- PHT MsbteDocument24 paginiPHT MsbteRick KingÎncă nu există evaluări

- NVD2 Directional Control Valves CatalogueDocument53 paginiNVD2 Directional Control Valves CataloguepurnomoÎncă nu există evaluări

- Reynolds Experiment FinalDocument4 paginiReynolds Experiment FinalArindam MandalÎncă nu există evaluări

- PDS1 Transmisi Air Bersih MCPK PumpDocument5 paginiPDS1 Transmisi Air Bersih MCPK PumpBudi SÎncă nu există evaluări

- FLUID MECHANICS COURSE OUTCOMESDocument94 paginiFLUID MECHANICS COURSE OUTCOMESnazreenÎncă nu există evaluări

- Pressure Distribution of NACA Airfoil Aerodynamic CharactersiticsDocument6 paginiPressure Distribution of NACA Airfoil Aerodynamic CharactersiticsAnkithaÎncă nu există evaluări

- British Standar - 1042 - 1 - 4 - 1992 - , - Measurement - of PDFDocument38 paginiBritish Standar - 1042 - 1 - 4 - 1992 - , - Measurement - of PDFAnonymous r1QbjmvU2Încă nu există evaluări

- Renewable and Sustainable Energy Reviews: A B C D e A F G H I J KDocument18 paginiRenewable and Sustainable Energy Reviews: A B C D e A F G H I J KNabilaDheaAmmaraÎncă nu există evaluări

- Gallegos - 17 - Flags As Vortex Generators For Heat Transfer Enhancement - HighlightDocument13 paginiGallegos - 17 - Flags As Vortex Generators For Heat Transfer Enhancement - Highlightfelipecondo92Încă nu există evaluări

- Enerflex-041620 RFQ LN 42-PCV-0034 Rev 4 Vendor's DSDocument4 paginiEnerflex-041620 RFQ LN 42-PCV-0034 Rev 4 Vendor's DSHamza ShujaÎncă nu există evaluări

- Stagnation Properties and Nozzle FlowDocument18 paginiStagnation Properties and Nozzle FlowNadeem TanwariÎncă nu există evaluări

- Modeling Time-Temperature History and Sterilization Value of Mango Puree Under Conventional and Microwave Assisted PasteurizationDocument9 paginiModeling Time-Temperature History and Sterilization Value of Mango Puree Under Conventional and Microwave Assisted PasteurizationTamires OishiÎncă nu există evaluări

- AP PGECET Chemical Engg 2015 Question Paper - Answer Key DownloadDocument16 paginiAP PGECET Chemical Engg 2015 Question Paper - Answer Key DownloadpavaniÎncă nu există evaluări

- PcourseiitdDocument110 paginiPcourseiitdShanmugam SubramanyanÎncă nu există evaluări

- Me 321: Fluid Mechanics-I: Dr. A.B.M. Toufique HasanDocument4 paginiMe 321: Fluid Mechanics-I: Dr. A.B.M. Toufique HasanankitaÎncă nu există evaluări

- Vehicle Aerodynamics KTH1Total PDFDocument55 paginiVehicle Aerodynamics KTH1Total PDFMarcos SoarÎncă nu există evaluări

- Final Assessment - Paper PFF 260S (2019) PDFDocument3 paginiFinal Assessment - Paper PFF 260S (2019) PDFcarleston thurgoodÎncă nu există evaluări

- Main Principles of Pumps SelectionDocument19 paginiMain Principles of Pumps Selectionbrian qlpÎncă nu există evaluări

- Free Vortex ApparatusDocument4 paginiFree Vortex ApparatusgpradiptaÎncă nu există evaluări

- Exhaust System Design CalculationsDocument2 paginiExhaust System Design CalculationsZa YonÎncă nu există evaluări

- Lecture 1 (Introduction)Document18 paginiLecture 1 (Introduction)mÎncă nu există evaluări

- The Analysis of Heat Transfer in Automotive TurbochargersDocument12 paginiThe Analysis of Heat Transfer in Automotive TurbochargersyaminijayaramanÎncă nu există evaluări

- Dokumen - Tips - Pressure Loss of Orifice Plates According To Iso 5167 1Document3 paginiDokumen - Tips - Pressure Loss of Orifice Plates According To Iso 5167 1Tomi GánnÎncă nu există evaluări

- Gear Pumps Group 10Document68 paginiGear Pumps Group 10HIDRAULICA MANSE SERVICIO TECNICOÎncă nu există evaluări

- SPE-108181 Transient Analysis-Hysys Dynamics and OLGADocument11 paginiSPE-108181 Transient Analysis-Hysys Dynamics and OLGAWilfred Enock100% (1)