Documente Academic

Documente Profesional

Documente Cultură

Proctor TP - 1 3881

Încărcat de

wafikmh4Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Proctor TP - 1 3881

Încărcat de

wafikmh4Drepturi de autor:

Formate disponibile

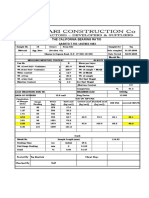

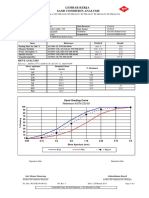

COMPACTION TEST REPORT

Curve No.

1.8 1

Test Specification:

10%, 1.70 g/cm3 AASHTO T 99-01 Method A Standard

1.75

Preparation Method

Dry density, g/cm3

Hammer Wt. 5.5 lb.

1.7

Hammer Drop 12 in.

Number of Layers three

Blows per Layer 25

1.65 Mold Size 0.9439 liters

Test Performed on Material

Passing #4 Sieve

1.6 NM LL PI

Sp.G. (ASTM D 854)

%>#4 %<No.200

1.55 USCS AASHTO

0 5 10 15 20 25 30

Date Sampled

Water content, % Date Tested 1/8/2017

Tested By Arti: Mustafa

TESTING DATA

1 2 3 4 5 6

WM + WS 5941.4 6021.0 6087.5 6155.0 6109.0

WM 4340.0 4340.0 4340.0 4340.0 4340.0

WW + T #1 85.6 94.7 106.5 91.6 145.3

WD + T #1 83.0 91.0 100.3 83.9 128.0

TARE #1 28.6 31.9 18.6 21.4 24.8

WW + T #2

WD + T #2

TARE #2

MOISTURE 4.7 6.4 7.6 12.3 16.8

DRY DENSITY 1.62 1.67 1.72 1.71 1.60

TEST RESULTS Material Description

Maximum dry density = 1.70 g/cm3

Optimum moisture = 10 % Remarks:

Project No. Client: ALWADI COMMUNICATIONS CO.

Project: ENC LIBYA NATIONWIDE TETRA NETWORK

Source of Sample: 3881 TP#1 Depth: 1.0-2.0 Checked by: Eng. Wafik

Title:

Figure

S-ar putea să vă placă și

- Cone Penetration Testing: Methods and InterpretationDe la EverandCone Penetration Testing: Methods and InterpretationEvaluare: 5 din 5 stele5/5 (3)

- Miranda: Compaction Test ReportDocument1 paginăMiranda: Compaction Test ReportJuan Carlos Miranda ColqueÎncă nu există evaluări

- Raw Data Sheet: Date: Lab Ref. No.: Batch Code: Client Ref.: Retention No.: Sample DescriptionDocument1 paginăRaw Data Sheet: Date: Lab Ref. No.: Batch Code: Client Ref.: Retention No.: Sample DescriptionfaikÎncă nu există evaluări

- Iran Choque: Compaction Test ReportDocument1 paginăIran Choque: Compaction Test ReportJuan Carlos Miranda ColqueÎncă nu există evaluări

- Example PROCTOR StandardDocument1 paginăExample PROCTOR StandardArshad AliÎncă nu există evaluări

- R.E Wall Test SummaryDocument1 paginăR.E Wall Test SummaryBiplab dattaÎncă nu există evaluări

- Soil Test Report: Materials Testing LaboratoryDocument6 paginiSoil Test Report: Materials Testing LaboratoryVero YonduaiÎncă nu există evaluări

- Lembar Kerja Sand Condition Analysis: Sample IdentificationDocument1 paginăLembar Kerja Sand Condition Analysis: Sample IdentificationJoel Alfonso ManurungÎncă nu există evaluări

- Sieve Analisis Sub-Base Course - XlxsDocument6 paginiSieve Analisis Sub-Base Course - XlxsNanang SuryanaÎncă nu există evaluări

- Wt. of Original Sample: (G) : ProjectDocument1 paginăWt. of Original Sample: (G) : ProjectzeekoÎncă nu există evaluări

- 10CDCF LM-1600406 (PFGD)Document2 pagini10CDCF LM-1600406 (PFGD)Sohaib AhmadÎncă nu există evaluări

- Voids Ratio Vs Pressure: General InformationDocument6 paginiVoids Ratio Vs Pressure: General InformationMaruda8382Încă nu există evaluări

- WK231207 Mill CertificateDocument1 paginăWK231207 Mill CertificatemrwolveringÎncă nu există evaluări

- Soil Test - Sira - Ak SirDocument4 paginiSoil Test - Sira - Ak SirMohan MylarappaÎncă nu există evaluări

- In Uence of Aging On Surface Free Energy of Asphalt BinderDocument10 paginiIn Uence of Aging On Surface Free Energy of Asphalt BinderAnonymous x7VY8VF7Încă nu există evaluări

- Finished Fabric Test Report: StandardDocument1 paginăFinished Fabric Test Report: StandardSohaib AhmadÎncă nu există evaluări

- 14-Sieve Analysis of Aggregates Fine Agg.Document6 pagini14-Sieve Analysis of Aggregates Fine Agg.Khizar HayatÎncă nu există evaluări

- CBR Empty FormDocument24 paginiCBR Empty FormJosephÎncă nu există evaluări

- ME Performance Test 25.11.2022Document3 paginiME Performance Test 25.11.2022Taha FaÎncă nu există evaluări

- Central Lab D-53: Siddiqsons LimitedDocument2 paginiCentral Lab D-53: Siddiqsons LimitedTahir NizamÎncă nu există evaluări

- Brown SandDocument10 paginiBrown Sandmarufum777Încă nu există evaluări

- AmberTech Falex ASTMD5183Document2 paginiAmberTech Falex ASTMD5183Banti SidhiwalaÎncă nu există evaluări

- 9.marshall Trial Compaction Ac WC25092020Document20 pagini9.marshall Trial Compaction Ac WC25092020Ramdan Pramedis SetyaÎncă nu există evaluări

- T2 Sem 0800100Document2 paginiT2 Sem 0800100gadÎncă nu există evaluări

- The California Bearing Ratio: Aashto T 193 / Astm D 1883Document13 paginiThe California Bearing Ratio: Aashto T 193 / Astm D 1883mdalgamouniÎncă nu există evaluări

- Abrasion TestDocument47 paginiAbrasion Testratoooooja24Încă nu există evaluări

- The California Bearing Ratio: Aashto T 193 / Astm D 1883Document13 paginiThe California Bearing Ratio: Aashto T 193 / Astm D 1883Arham SheikhÎncă nu există evaluări

- Omega: ConsultantDocument7 paginiOmega: ConsultantSumit JainÎncă nu există evaluări

- Test Results Reference Sample 1 Sample 2: IS 2720 (Part 4) - 1985 (RA 2006)Document1 paginăTest Results Reference Sample 1 Sample 2: IS 2720 (Part 4) - 1985 (RA 2006)Mohan MylarappaÎncă nu există evaluări

- Lembar Kerja Sand Condition Analysis: Sample IdentificationDocument1 paginăLembar Kerja Sand Condition Analysis: Sample IdentificationJoel Alfonso ManurungÎncă nu există evaluări

- Sieve Analisis CR 2-4-19Document3 paginiSieve Analisis CR 2-4-19Nanang SuryanaÎncă nu există evaluări

- Inspection ReportDocument1 paginăInspection Reportharrydev27Încă nu există evaluări

- 2 Turbin 0511 Ob2123174Document1 pagină2 Turbin 0511 Ob2123174BennyÎncă nu există evaluări

- 75 MM PN 20 Tensile Test Report28.08.2020 He3460lsDocument2 pagini75 MM PN 20 Tensile Test Report28.08.2020 He3460lsCalebÎncă nu există evaluări

- Board Line: - 022 66595154: As Per Iso 2341Document1 paginăBoard Line: - 022 66595154: As Per Iso 2341BARKAT ALIÎncă nu există evaluări

- Test Report Sieve Analysis of Extracted Mineral Aggregates (ASTM D5444 & C136 / AASHTO T 27)Document6 paginiTest Report Sieve Analysis of Extracted Mineral Aggregates (ASTM D5444 & C136 / AASHTO T 27)Shafiqullah GowharyÎncă nu există evaluări

- Bitumen Extraction - BBC (A) New 13.10.2018Document1 paginăBitumen Extraction - BBC (A) New 13.10.2018Motaz AbdallahÎncă nu există evaluări

- Test Report Only For Information: Echaar Equipments PVT - Ltd. (UNIT-I)Document2 paginiTest Report Only For Information: Echaar Equipments PVT - Ltd. (UNIT-I)ananda_beloshe75Încă nu există evaluări

- American Express GurgaonDocument9 paginiAmerican Express Gurgaonanil.limrafsÎncă nu există evaluări

- Ac Extraction Permanent Works FormDocument2 paginiAc Extraction Permanent Works Formbest essaysÎncă nu există evaluări

- Contoh Form TRIAL COMPACTION ACWCDocument20 paginiContoh Form TRIAL COMPACTION ACWCC-pang MinorityÎncă nu există evaluări

- AL-905-R-11202 Spec AG01 Rev. T02Document3 paginiAL-905-R-11202 Spec AG01 Rev. T02altipatlarÎncă nu există evaluări

- Bitumen Extraction - BBC (C) New 30.08.2019Document1 paginăBitumen Extraction - BBC (C) New 30.08.2019Motaz AbdallahÎncă nu există evaluări

- 2new Consult Subgrade Quality TestsDocument7 pagini2new Consult Subgrade Quality TestsmulÎncă nu există evaluări

- G Top G Mid G BotDocument16 paginiG Top G Mid G Botmariem.soueidiÎncă nu există evaluări

- Wallnut DatasheetDocument14 paginiWallnut DatasheetajengÎncă nu există evaluări

- Acacia Pure Spec (Nov 2016)Document1 paginăAcacia Pure Spec (Nov 2016)Adriel KurniawanÎncă nu există evaluări

- BBC Superpave - 2Document47 paginiBBC Superpave - 2mido_20067581Încă nu există evaluări

- Operator's Manual: CP7731/CP7732 Series 3/8 & 1/2 Impact WrenchDocument32 paginiOperator's Manual: CP7731/CP7732 Series 3/8 & 1/2 Impact WrenchGabriela de Jesús Ruíz OrantesÎncă nu există evaluări

- Pembangunan Jalan Tol Semarang-Batang SEKSI4&5: Aashto T 27 - 82 / Astm C. 33Document40 paginiPembangunan Jalan Tol Semarang-Batang SEKSI4&5: Aashto T 27 - 82 / Astm C. 33Budhi KurniawanÎncă nu există evaluări

- Coa 230107Document1 paginăCoa 230107Asha Dicka Purchasing PT. Sin A 615Încă nu există evaluări

- Test Report For Sieve Analysis of Fine Aggregate: Posco E & CDocument1 paginăTest Report For Sieve Analysis of Fine Aggregate: Posco E & CHasan al MahmudÎncă nu există evaluări

- Draft: Test Report For Sieve Analysis-ASTM C-136Document1 paginăDraft: Test Report For Sieve Analysis-ASTM C-136civillabÎncă nu există evaluări

- Material Test Report: Sample Details Particle Size DistributionDocument1 paginăMaterial Test Report: Sample Details Particle Size Distribution100livÎncă nu există evaluări

- Raw Data Sheet: Date: Lab Ref. No.: Batch Code: Client Ref.: Retention No.: Sample DescriptionDocument1 paginăRaw Data Sheet: Date: Lab Ref. No.: Batch Code: Client Ref.: Retention No.: Sample DescriptionfaikÎncă nu există evaluări

- 5 MM Sieve Analysis 01.06.2013Document2 pagini5 MM Sieve Analysis 01.06.2013Mubashar Islam JadoonÎncă nu există evaluări

- Quality Control FormatsDocument13 paginiQuality Control FormatsAdakole ObekaÎncă nu există evaluări

- U4b. FALLING HEAD PERMEABILITYDocument1 paginăU4b. FALLING HEAD PERMEABILITYamiraÎncă nu există evaluări

- Naptha Flowmeter SizingDocument4 paginiNaptha Flowmeter SizingahmedÎncă nu există evaluări

- Sahib Enterprise - PDIR Report-DM011102C000810091Document3 paginiSahib Enterprise - PDIR Report-DM011102C000810091surender vimalÎncă nu există evaluări

- Shear Box Test ASTM D3080: R e Sults Summa RyDocument2 paginiShear Box Test ASTM D3080: R e Sults Summa Rywafikmh4Încă nu există evaluări

- BH#1#3888 SieveBH#13888 GS ChartReportDocument3 paginiBH#1#3888 SieveBH#13888 GS ChartReportwafikmh4Încă nu există evaluări

- Sieve BH#1 & BH#2 3881Document7 paginiSieve BH#1 & BH#2 3881wafikmh4Încă nu există evaluări

- Design Criteria For Infrastructure ProjectsDocument7 paginiDesign Criteria For Infrastructure Projectswafikmh4Încă nu există evaluări

- NTS: The Following Two Paragraphs Should Be Deleted For Smaller ProjectsDocument18 paginiNTS: The Following Two Paragraphs Should Be Deleted For Smaller Projectswafikmh4Încă nu există evaluări

- LL&PL BH#1 & BH#2 3881Document2 paginiLL&PL BH#1 & BH#2 3881wafikmh4Încă nu există evaluări

- Health and Safety PlanDocument11 paginiHealth and Safety Planwafikmh4Încă nu există evaluări

- TOC Vol.1 Part 6Document1 paginăTOC Vol.1 Part 6wafikmh4Încă nu există evaluări

- TOC Vol.1 Part 4Document1 paginăTOC Vol.1 Part 4wafikmh4Încă nu există evaluări

- TOC Vol.1 Part 5Document2 paginiTOC Vol.1 Part 5wafikmh4Încă nu există evaluări

- Design Criteria For Infrastructure Projects - Rev 03 - Nov 2010Document456 paginiDesign Criteria For Infrastructure Projects - Rev 03 - Nov 2010wafikmh4100% (2)

- HIB Spec Draft-FormatDocument19 paginiHIB Spec Draft-Formatwafikmh4Încă nu există evaluări

- 1Hduvxuidfhgrzqkrohvkhduzdyhvxuyh/V$Sulphu: D C, Wireless Seismic IncDocument7 pagini1Hduvxuidfhgrzqkrohvkhduzdyhvxuyh/V$Sulphu: D C, Wireless Seismic Incwafikmh4Încă nu există evaluări

- Invoices For UEG IstanbulDocument7 paginiInvoices For UEG IstanbulIesaw IesawÎncă nu există evaluări

- Lateritic NickelDocument27 paginiLateritic NickelRAVI1972100% (2)

- #Angles Are in Degrees: EGR2313 HW SOLUTIONS (2021)Document4 pagini#Angles Are in Degrees: EGR2313 HW SOLUTIONS (2021)SolomonÎncă nu există evaluări

- Ds-Module 5 Lecture NotesDocument12 paginiDs-Module 5 Lecture NotesLeela Krishna MÎncă nu există evaluări

- Mark Magazine#65Document196 paginiMark Magazine#65AndrewKanischevÎncă nu există evaluări

- Ymrtc LogDocument26 paginiYmrtc LogVinicius Silveira0% (1)

- Freshers Jobs 26 Aug 2022Document15 paginiFreshers Jobs 26 Aug 2022Manoj DhageÎncă nu există evaluări

- Information Technology Project Management: by Jack T. MarchewkaDocument44 paginiInformation Technology Project Management: by Jack T. Marchewkadeeps0705Încă nu există evaluări

- Model TB-16Document20 paginiModel TB-16xuanphuong2710Încă nu există evaluări

- MV Lec PDFDocument102 paginiMV Lec PDFJonas Datu100% (1)

- The Piano Lesson Companion Book: Level 1Document17 paginiThe Piano Lesson Companion Book: Level 1TsogtsaikhanEnerelÎncă nu există evaluări

- Suspend and Resume Calls: Exit PlugDocument4 paginiSuspend and Resume Calls: Exit PlugrajuÎncă nu există evaluări

- Hydrogeological Survey and Eia Tor - Karuri BoreholeDocument3 paginiHydrogeological Survey and Eia Tor - Karuri BoreholeMutonga Kitheko100% (1)

- Participant Observation: Qualitative Research Methods: A Data Collector's Field GuideDocument17 paginiParticipant Observation: Qualitative Research Methods: A Data Collector's Field GuideMarta CabreraÎncă nu există evaluări

- Lesson: The Averys Have Been Living in New York Since The Late NinetiesDocument1 paginăLesson: The Averys Have Been Living in New York Since The Late NinetiesLinea SKDÎncă nu există evaluări

- Morse Potential CurveDocument9 paginiMorse Potential Curvejagabandhu_patraÎncă nu există evaluări

- Research Paper On Air QualityDocument4 paginiResearch Paper On Air Qualityluwahudujos3100% (1)

- LS01 ServiceDocument53 paginiLS01 ServicehutandreiÎncă nu există evaluări

- Adime 2Document10 paginiAdime 2api-307103979Încă nu există evaluări

- Adverbs of Manner and DegreeDocument1 paginăAdverbs of Manner and Degreeslavica_volkan100% (1)

- Linear Dynamic Analysis of Free-Piston Stirling Engines OnDocument21 paginiLinear Dynamic Analysis of Free-Piston Stirling Engines OnCh Sameer AhmedÎncă nu există evaluări

- Rubric For Aet570 BenchmarkDocument4 paginiRubric For Aet570 Benchmarkapi-255765082Încă nu există evaluări

- Zygosaccharomyces James2011Document11 paginiZygosaccharomyces James2011edson escamillaÎncă nu există evaluări

- s15 Miller Chap 8b LectureDocument19 paginis15 Miller Chap 8b LectureKartika FitriÎncă nu există evaluări

- Antibiotics MCQsDocument4 paginiAntibiotics MCQsPh Israa KadhimÎncă nu există evaluări

- Ginger Final Report FIGTF 02Document80 paginiGinger Final Report FIGTF 02Nihmathullah Kalanther Lebbe100% (2)

- Restaurant Report Card: February 9, 2023Document4 paginiRestaurant Report Card: February 9, 2023KBTXÎncă nu există evaluări

- Aquaculture - Set BDocument13 paginiAquaculture - Set BJenny VillamorÎncă nu există evaluări

- 2a Unani Medicine in India - An OverviewDocument123 pagini2a Unani Medicine in India - An OverviewGautam NatrajanÎncă nu există evaluări

- TW BT 01 - Barstock Threaded Type Thermowell (Straight) : TWBT - 01Document3 paginiTW BT 01 - Barstock Threaded Type Thermowell (Straight) : TWBT - 01Anonymous edvYngÎncă nu există evaluări