Documente Academic

Documente Profesional

Documente Cultură

Kor-N-Seal Technical Spec

Încărcat de

John Bolger0 evaluări0% au considerat acest document util (0 voturi)

15 vizualizări1 paginăDrepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

15 vizualizări1 paginăKor-N-Seal Technical Spec

Încărcat de

John BolgerDrepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 1

Kor-N-Seal®

Product Line

Technical Specifications

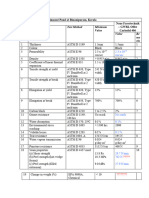

PERFORMANCE

Performed on all standards sizes of Kor-N-Seal Connectors

Test ASTM Method Test Requirements Kor-N-Seal Products

Head Pressure C923 - 7.1 0° - 13 psi (30 ft) for 10 min. +13 psi for 10 min.

7° - 10 psi (23 ft) for 10 min. +10 psi for 10 min.

Deflection Test C923 - 7.2.2 7° in any direction Over 7° in any direction

Load Test C923 - 7.2.3 150 lbs/in. pipe dia. Over 150 lbs/in. pipe dia.

RESILIENT RUBBER MATERIAL

Conforms to ASTM C923

Test ASTM Method Test Requirements Kor-N-Seal Products

Chemical Resistance D543, at 22°C for 48 h

1 N Sulfuric Acid No weight loss No weight loss

1 N Hydrochloric Acid No weight loss No weight loss

Tensile Strength D412 1200 psi 1580 psi

Elongation at Break 350% min 500%

± 5 from the manufacturer’s

Hardness D2240 (shore A durometer) 48 ± 5

specified hardness

Decrease of 15%, max. of original

10.1% tensile decrease 4%

Accelerated Oven-Aging D573 70 ± 1°C for 7 days tensile strength, decrease of 20%

elongation decrease

max. of elongation

D395, method B, at 70°C for Decrease of 25%, max. of original

Compression Set 13% decrease

22h deflection

D471, immerse 0.75 by 2-in.

Increase of 10%, max. of original

Water Absorption specimen in distilled water at .8% increase

by weight

70°C for 48

Ozone Resistance D1171 Rating 0 Rating 0

Low-temperature Brittle Point D746 No fracture at -40°C No fracture at -40°C

Tear Resistance D624, method B 200 lbf/in. No tear at 210 lbf/in.

300 SERIES STAINLESS STEEL

Conforms to ASTM C923, ASTM A666 and A240

Test Kor-N-Seal Products

Tensile Strength 75,000 psi

Yield Strength (min.) 30,000 psi

Elongation in 2” (min. %) 40%

Hardness Rockwell ”B” 95

W W W.T R E L L E B O R G .CO M / P I P E - S E A L S

S-ar putea să vă placă și

- Physical Properties Elastomeric Bearing MSTDocument4 paginiPhysical Properties Elastomeric Bearing MSTBudhi KurniawanÎncă nu există evaluări

- Kpic Yuhwa p600Document1 paginăKpic Yuhwa p600quanghoang10986Încă nu există evaluări

- Propriedades NBR 70 Shore ADocument2 paginiPropriedades NBR 70 Shore AGabriel NunesÎncă nu există evaluări

- Current Material - 5323-70-Epdm-Seals - 020217Document2 paginiCurrent Material - 5323-70-Epdm-Seals - 020217Brent TairaÎncă nu există evaluări

- Viton-O-Rings-CommercialDocument1 paginăViton-O-Rings-CommercialErhanÎncă nu există evaluări

- EPDM - Test by Romac Inc PDFDocument2 paginiEPDM - Test by Romac Inc PDFRajendra Kumar SharmaÎncă nu există evaluări

- DoW LDPE 2685GDocument4 paginiDoW LDPE 2685Gtariquekhan143Încă nu există evaluări

- EPDM 70 Specifications PDFDocument1 paginăEPDM 70 Specifications PDFfirebolt_hari2006Încă nu există evaluări

- Nap-Gard 7-2500 PDFDocument2 paginiNap-Gard 7-2500 PDFPietro ViganÎncă nu există evaluări

- Soft Natural Rubber Lining: Technical Data SheetDocument2 paginiSoft Natural Rubber Lining: Technical Data SheetArmanda SiryogiawanÎncă nu există evaluări

- Dow Elite 5401G TDSDocument3 paginiDow Elite 5401G TDSAli RazuÎncă nu există evaluări

- Request Quote 70 Duro NBRDocument2 paginiRequest Quote 70 Duro NBRAlaa SaadÎncă nu există evaluări

- Material 72 NBR 872: Black Cross Linking: SulfurDocument3 paginiMaterial 72 NBR 872: Black Cross Linking: SulfurPhong DuongÎncă nu există evaluări

- High Density Film Grade Excellent StrengthDocument1 paginăHigh Density Film Grade Excellent StrengthRPM28XIÎncă nu există evaluări

- Hanwha LLDPE 7635Document1 paginăHanwha LLDPE 7635M. Kürşad ArslanÎncă nu există evaluări

- XringDocument2 paginiXringJoão Pedro Marin De GodoiÎncă nu există evaluări

- TDS - 7-0008 - Internal Pipe Coating - EngDocument3 paginiTDS - 7-0008 - Internal Pipe Coating - Englong chanÎncă nu există evaluări

- Elite NG 5401BDocument3 paginiElite NG 5401BAbdo WalidÎncă nu există evaluări

- Product Comparison - GE SSG4400 UltraGlaze Vs SSG4600 UltraGlaze Vs DC98...Document8 paginiProduct Comparison - GE SSG4400 UltraGlaze Vs SSG4600 UltraGlaze Vs DC98...Nguyễn SơnÎncă nu există evaluări

- Globalene 7011: Polypropylene Impact copolymer 聚丙烯耐衝擊共聚合物Document1 paginăGlobalene 7011: Polypropylene Impact copolymer 聚丙烯耐衝擊共聚合物medo.k016Încă nu există evaluări

- Test Report ConformanceDocument2 paginiTest Report ConformancePriyadarshini KrishnaswamyÎncă nu există evaluări

- O-Ring Compound Data SheetDocument3 paginiO-Ring Compound Data SheetScarlet BlancoÎncă nu există evaluări

- High Performance Stretch Film ResinDocument3 paginiHigh Performance Stretch Film Resinujang sukartaÎncă nu există evaluări

- Hempaline Defend 630: Product DescriptionDocument3 paginiHempaline Defend 630: Product DescriptionJorge Alberto MontalatÎncă nu există evaluări

- ELITE™ 5230G: Enhanced Polyethylene ResinDocument3 paginiELITE™ 5230G: Enhanced Polyethylene ResinRoberto De Mesa PÎncă nu există evaluări

- Material Spec For 6600Document1 paginăMaterial Spec For 6600Namelezz ShadowwÎncă nu există evaluări

- DOW™ Butene 1220P: Polyethylene ResinDocument1 paginăDOW™ Butene 1220P: Polyethylene Resinvantuan17792Încă nu există evaluări

- ACE 2010 - YL056F Akzo Powder CoatingDocument3 paginiACE 2010 - YL056F Akzo Powder CoatingNitin BalapureÎncă nu există evaluări

- 7-2500 FbeDocument3 pagini7-2500 FbejleonosÎncă nu există evaluări

- LLDPE-218BJ_edit (1)Document3 paginiLLDPE-218BJ_edit (1)Chu ChuÎncă nu există evaluări

- Ico PlainDocument2 paginiIco PlainHafiani HichamÎncă nu există evaluări

- Poly-Cote 110 (Aug'22)Document4 paginiPoly-Cote 110 (Aug'22)David cÎncă nu există evaluări

- CEFOR™ 1221P: Linear Low Density Polyethylene ResinDocument3 paginiCEFOR™ 1221P: Linear Low Density Polyethylene ResincuppycuppycupÎncă nu există evaluări

- Dow ELITE 5220G Enhanced Polyethylene ResinDocument2 paginiDow ELITE 5220G Enhanced Polyethylene Resinusman3549606Încă nu există evaluări

- High Density Polyethylene (HDPE Injection) : Technical Data SheetDocument1 paginăHigh Density Polyethylene (HDPE Injection) : Technical Data SheetEleannys GarciasÎncă nu există evaluări

- SABIC Innovative Plastics Lexan® 940 PC Data SheetDocument3 paginiSABIC Innovative Plastics Lexan® 940 PC Data SheetMRC RailÎncă nu există evaluări

- Globalene ST031: Technical Data Sheet / 技術資料表Document1 paginăGlobalene ST031: Technical Data Sheet / 技術資料表Ale AriasÎncă nu există evaluări

- HD6200B/HD6600B High Density Polyethylene Resin Product DescriptionDocument1 paginăHD6200B/HD6600B High Density Polyethylene Resin Product DescriptionRizaldi Nur Imani100% (1)

- Durajoint Type 60 Data Sheet - PVC - DJDocument1 paginăDurajoint Type 60 Data Sheet - PVC - DJmenh thieutuÎncă nu există evaluări

- Marco Material Datasheet E1097Document3 paginiMarco Material Datasheet E1097phoenixenggworkÎncă nu există evaluări

- BinanizincspecsDocument6 paginiBinanizincspecsJimmy ThomasÎncă nu există evaluări

- Scotch Heavy Duty Mining Tape 31: Data Sheet June 2013Document2 paginiScotch Heavy Duty Mining Tape 31: Data Sheet June 2013Kishan MohtaÎncă nu există evaluări

- Performance Grade 76 (PG 76) : Aspal Yang Digunakan Adalah Aspal Modifikasi Polimer (Polymer Modified Bitumen) SetaraDocument1 paginăPerformance Grade 76 (PG 76) : Aspal Yang Digunakan Adalah Aspal Modifikasi Polimer (Polymer Modified Bitumen) SetaraPT. Nur Straits EngineeringÎncă nu există evaluări

- LLDPE Dowlex 2645G TDSDocument3 paginiLLDPE Dowlex 2645G TDSAli RazuÎncă nu există evaluări

- Unival™ Dmdg-6200 NT 7: High Density Polyethylene ResinDocument3 paginiUnival™ Dmdg-6200 NT 7: High Density Polyethylene Resinyesenia flores rosadoÎncă nu există evaluări

- PA 6.6 Nylon 6.6Document2 paginiPA 6.6 Nylon 6.6Naeem KhanÎncă nu există evaluări

- Formosa Taisox: High Density Polyethylene (HDPE) - Fi L M GR Ade Dat A Sheet SDocument1 paginăFormosa Taisox: High Density Polyethylene (HDPE) - Fi L M GR Ade Dat A Sheet SluisalbertolvÎncă nu există evaluări

- Properties of PVC & CPVC PIPE Fitting: Item Test Method SI Unit Unit PVC CPVCDocument1 paginăProperties of PVC & CPVC PIPE Fitting: Item Test Method SI Unit Unit PVC CPVCsidsaleemÎncă nu există evaluări

- Request Quote for NBR O-Ring MaterialDocument2 paginiRequest Quote for NBR O-Ring MaterialChang MikeÎncă nu există evaluări

- 0001 - POLYFOAM Super (Gen) 09-30.11.2020Document1 pagină0001 - POLYFOAM Super (Gen) 09-30.11.2020Meeran MohamedÎncă nu există evaluări

- LG Chem TDS SP988 EnglishDocument1 paginăLG Chem TDS SP988 EnglishSérgio BarbosaÎncă nu există evaluări

- Kocetal K700 Property DataDocument1 paginăKocetal K700 Property DataRanjan GnanaoliÎncă nu există evaluări

- Bradybondz (TM) B-423 Thermal Transfer Printable Glossy White Polyester Label StockDocument4 paginiBradybondz (TM) B-423 Thermal Transfer Printable Glossy White Polyester Label StockDeep SharmaÎncă nu există evaluări

- PVC and CPVC properties referenceDocument2 paginiPVC and CPVC properties referenceAdnan KhanÎncă nu există evaluări

- Pds CPD D30 SikaGrout 300 PT UsDocument2 paginiPds CPD D30 SikaGrout 300 PT UsJonathan FelixÎncă nu există evaluări

- Envision Guidance Manual (v3)Document192 paginiEnvision Guidance Manual (v3)John BolgerÎncă nu există evaluări

- Bulletin 11 Allowable StressesDocument17 paginiBulletin 11 Allowable StressesJonas FernandezÎncă nu există evaluări

- Leica Flexline Ts10 Manual Total StationDocument2 paginiLeica Flexline Ts10 Manual Total StationJohn BolgerÎncă nu există evaluări

- SWDM 2015 CHPTR 08Document48 paginiSWDM 2015 CHPTR 08AamirKhattakÎncă nu există evaluări

- TimberLogic Log Wall Estimator 8x8 D Log HALH 2014Document32 paginiTimberLogic Log Wall Estimator 8x8 D Log HALH 2014John BolgerÎncă nu există evaluări

- Roof System Design Guide: Featuring Trus Joist Timberstrand LSL, Microllam LVL, and Parallam PSLDocument16 paginiRoof System Design Guide: Featuring Trus Joist Timberstrand LSL, Microllam LVL, and Parallam PSLJohn BolgerÎncă nu există evaluări

- Packaging N Labelling of Packaged Drinking WaterDocument10 paginiPackaging N Labelling of Packaged Drinking WaterISHFAQ ASHRAFÎncă nu există evaluări

- Boiler Water TreatmentDocument50 paginiBoiler Water Treatmentak_thimiriÎncă nu există evaluări

- Flushing and Passivation SystemDocument2 paginiFlushing and Passivation Systemmyo myint aungÎncă nu există evaluări

- Greener One-Pot Synthesis of Chromeno Oxazin and Oxazin Quinoline Derivatives and Their Antibacterial ActivityDocument5 paginiGreener One-Pot Synthesis of Chromeno Oxazin and Oxazin Quinoline Derivatives and Their Antibacterial ActivityIJAERS JOURNALÎncă nu există evaluări

- PaperDocument48 paginiPaperAnonymous MHKrd6RÎncă nu există evaluări

- Formulating elixirs and calculating alcohol contentDocument16 paginiFormulating elixirs and calculating alcohol contentMikaela LaoÎncă nu există evaluări

- Group 4 Biological Membranes RevisedDocument20 paginiGroup 4 Biological Membranes RevisedDjanelle Mei San MiguelÎncă nu există evaluări

- Organic Structures From Spectra-Edition 4-Solutions Manual-LibreDocument39 paginiOrganic Structures From Spectra-Edition 4-Solutions Manual-LibreBill Odette100% (5)

- Orgo2 Lab Report1Document2 paginiOrgo2 Lab Report1api-382264943Încă nu există evaluări

- Pyrite Oxidation in Tailings DamDocument6 paginiPyrite Oxidation in Tailings DamAnonymous NSbxWMÎncă nu există evaluări

- Lithium Metaborate: Libo Formula WT 49.75 CAS No. 13453-69-5Document4 paginiLithium Metaborate: Libo Formula WT 49.75 CAS No. 13453-69-5jycortesÎncă nu există evaluări

- NCSE 2013 Integrated ScienceDocument22 paginiNCSE 2013 Integrated ScienceMicahÎncă nu există evaluări

- Synthesis of AspirinDocument3 paginiSynthesis of AspirinShoomyla RashidÎncă nu există evaluări

- Aluminum 6351-T6 6351-T651Document2 paginiAluminum 6351-T6 6351-T651Mathi Engineers And Builders Private LimitedÎncă nu există evaluări

- Choose the Right Lubricant for Your Komatsu Forest MachineDocument4 paginiChoose the Right Lubricant for Your Komatsu Forest MachineyovannyÎncă nu există evaluări

- MSDS Mindray M-30Document8 paginiMSDS Mindray M-30Murai Funny100% (1)

- Organic Chemistry Question and AnswerDocument53 paginiOrganic Chemistry Question and Answergoi_pin100% (1)

- Trabelsi 2019Document10 paginiTrabelsi 2019Հեղինե ՂազոյանÎncă nu există evaluări

- Project Topics For CL 10Document8 paginiProject Topics For CL 10Nihaas Reddy KoppulaÎncă nu există evaluări

- Metal Forming Processes: Dr. Sunil JhaDocument16 paginiMetal Forming Processes: Dr. Sunil JhaarulmuruguÎncă nu există evaluări

- Significance of Coordination Compounds in Daily LifeDocument4 paginiSignificance of Coordination Compounds in Daily LifeMalaika YousafÎncă nu există evaluări

- School Training Report on Practice at District HospitalDocument34 paginiSchool Training Report on Practice at District Hospitalsumit sharmaÎncă nu există evaluări

- Carbohydrate ChemistryDocument78 paginiCarbohydrate ChemistryNikhil NathÎncă nu există evaluări

- How to Prevent Sulfate Attack on ConcreteDocument19 paginiHow to Prevent Sulfate Attack on ConcreteIrvebry Ayu WulandaryÎncă nu există evaluări

- Awt 11 SDS 4001Document14 paginiAwt 11 SDS 4001Vyrax FalconÎncă nu există evaluări

- Whiskers The Root Cause of Spontaneous Short Circuits - PCIC - 2006Document5 paginiWhiskers The Root Cause of Spontaneous Short Circuits - PCIC - 2006wy6279Încă nu există evaluări

- Effective Approaches To Improve The Electrical Conductivity of PEDOT:PSS: A ReviewDocument16 paginiEffective Approaches To Improve The Electrical Conductivity of PEDOT:PSS: A ReviewSasa PetrovicÎncă nu există evaluări

- Fosroc Nitocote EPS Protective CoatingDocument4 paginiFosroc Nitocote EPS Protective CoatingmangjitÎncă nu există evaluări

- Ix - Give ReasonsDocument3 paginiIx - Give ReasonsVansh DangÎncă nu există evaluări

- Pentose Phosphate PathwayDocument2 paginiPentose Phosphate PathwayIshita SinghÎncă nu există evaluări