Documente Academic

Documente Profesional

Documente Cultură

Big Truck and Big Tire - Caterpillar and Michelin: Tim O'Neil, Editor

Încărcat de

HENRY TORRES0 evaluări0% au considerat acest document util (0 voturi)

35 vizualizări2 paginiTitlu original

000-020-001-277

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

35 vizualizări2 paginiBig Truck and Big Tire - Caterpillar and Michelin: Tim O'Neil, Editor

Încărcat de

HENRY TORRESDrepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 2

Click here to return to TOC

Big truck and big tire —

Caterpillar and Michelin

I

f you build a big truck, build a big tire to match it. Let dynamics. How did they interface? How did they handle

that haulage synergy aid the economics, productivity high torque inputs and stresses? And what were the

and lessened maintenance for the unit. Now, Cater- thermal consequences? The object was to have a long-

pillar and Michelin have done just that. life tire despite the rigors imposed by the big truck.

Discussions began in 1996. Caterpillar was making So the truck/tire system was tested beyond its nor-

plans for its 797 ultra-class haul truck. The development mal limits. Tests were conducted with increased loads, at

team realized the need for a tire that could withstand higher speeds, higher than normal capacities and on

extreme loads. The 797 would weigh 558 t (615 st) and be steep grades. The system was also tested through sharp,

capable of 64 km/h (40 mph) speeds. So Caterpillar ap- cutting rocks and serpentine curves, at various deflec-

proached Michelin. The two companies realized the tions, and up and down ramps. The truck was quickly

benefits of jointly developing a tire for the 797. started and stopped on proving grounds roads. That

tested the side-to-side and front-to-back load distribu-

Caterpillar teamed with Michelin to develop a tire large

tion.

enough to fit Cat’s 345-t (380-st) payload 797B haul All this simulated conditions in openpit mines. Dy-

truck. The result was the 59/80R63 XDR tire. namic loads and lateral forces were analyzed. Puncture

resistance and wear rating were monitored. The ability

was tested of the tire to deal with cuts.

Michelin tested new, tougher and more heat-resis-

tant rubber compounds and new tread-belt configura-

tions. More than 50 individual tests were performed on

the bead area and the lower sidewall. At least 30 addi-

tional tests were performed on more than 60 survey tires.

Tire wear was measured. So was the temperature of

the tire’s internal components. Tire dynamics were

checked as were deflection characteristics and tire-rim

interface. Every 100 hours, the tires were taken off the

truck and X-rayed. This analysis allowed the engineers

to monitor any internal areas of stress and fatigue.

Special test tracks were developed. An extremely

bumpy, channeled course was created. It measured truck

vibrations. Michelin and Caterpillar engineers were bet-

ter able to understand the conditions in which the truck

began to vibrate. As a result, a truck/tire system was pro-

duced that enhanced operator comfort regardless of the

Background and development vibrations.

Before Caterpillar assembled the first 326 t (360 st)

payload 797 in late 1998, the two companies simulated Operators tested, too

the new truck with a 218-t (240-st) capacity Cat 793 at On the truck side, the 797 test operators went

the Michelin proving grounds in Almeria, Spain. through the same training and certification process that

The development team simulated 797 loads with the Caterpillar offers for mine truck operators. Productivity,

793 by mounting single tires in place of duals and by however, was not a priority. The idea was to drive each

carefully designing the test track. The Michelin 55/ run within a test the same way. Precisely repeat the ac-

80R63 XKD1 tire was born from this development and tions in each run to help isolate the variables being mea-

testing process. sured. Tires, for example, were subjected to more than

The first generation 797 and Michelin tire system 31,500 test hours. That is the equivalent of 442,560 test

delivered high productivity and a low cost per ton. But km (275,000 test miles).

another adaptation was needed of the truck and the tire.

While engineering that system, Michelin and Caterpillar Results are impressive

offered an interim solution, the 55/80R63 XKD1. The joint testing effort resulted in a truck, the Cater-

Then Michelin and Caterpillar began to develop the pillar 797B, that can carry a 345-t (380-st) payload at high

new truck/tire system. Enter the speeds. And the Michelin 59/80R63 XDR tire is seen as

Caterpillar 797B and the Michelin a technological breakthrough for ultra-class haul trucks.

59/80R63 XDR tire. The net here is that bigger truck payloads increase

Tim O’Neil, Having the Caterpillar 797 at productivity. And the new tire helps provide longer

Almeria allowed Michelin and Cat- operating life, which contributes to lower operating

Editor erpillar to study the truck and tire costs.

36 SEPTEMBER 2002 ■ MINING ENGINEERING

o'neil, p. 36-37 copy 36 9/16/02, 9:03 AM

Michelin’s proving grounds are located in Almeria, The world’s biggest tire, the Michelin 59/80R63 XDR is

Spain. The facility provides nearly 3,642 hm2 (9,000 inspected while it cools.

acres) for testing truck and tire dynamics.

• Top speed 64 km/h (40 mph)

• Tire size 59/80R63

The first 797B mining truck was shipped recently

from Caterpillar’s manufacturing plant in Decatur, IL.

For more information, visit the Caterpillar Web site at

www.cat.com.

797B — higher payload, lower cost

And now a little detail about the truck itself. The

Caterpillar 797B is the world’s biggest truck. It features Michelin’s 59/80R3 XDR radial tire

an increase in nominal payload from 326 t (360 st), with Michelin’s 59/80R63 XDR tire is designed for trucks

a standard body. Gross engine power has been increased operating in large surface mines. It is currently being

from 2.54 to 2.65 MW (3,400 to 3,550 hp). These and tested in the oil sands of Canada. How big is this tire, the

other improvements enable the new truck to reduce largest tire in the world? It is more than 4 m (13 ft) tall

hauling cost per ton by 3% to 5% compared with the and nearly (5 ft) wide. It weighs more than 4.5 t (5 st).

797, which the 797B replaces. And it can support a load of more than 91 t (100 st) a tire.

Caterpillar teamed with Michelin to develop an op- Michelin is the first tire manufacturer to put this innova-

timized tire for the 797B. The new tire uses advanced tive tire to use in real operating conditions.

low-profile 80 series technology developed by Michelin. During the past few years, the mining world has

The XDR super-deep tread should extend tire life. And been developing larger machines. They move ever larger

robust bead architecture handles the high torque and the amounts of material faster and under extreme condi-

high loads created by the 797B. tions. Economies of scale is the buzz phrase.

To ensure reliable performance at a greater vehicle The new Michelin 59/80R63 XDR tire makes pos-

weight, braking and steering capacity has been increased sible this latest load increase. It can offer up to 25%

on the 797B. Increased service-brake pressure and park- longer life, compared with the 58/80R63 XKD1 tire.

ing-brake capacity provide stopping and staying power. The extra-deep tread design of the XDR tire is com-

Larger steering cylinders, stronger steering linkage and prised of independent tread blocks. They are located in

more accumulator capacity assure responsive and reli- the centerline of the tire, to help improve tire life. The

able steering in tough mine conditions. tread is engineered to allow for lower heat generation

Many of the mild steel castings that comprise the without compromising tire life, according to Michelin.

load-bearing frame have been strengthened while reduc- The 59/80R63 XDR tire is the latest addition to the

ing the frame weight. Field testing of the first 797s began XDR line and the 80 series technology, which was intro-

in 1999. Since then, serviceability improvements have duced in 1998. The 59/80R63 XDR is a technological

reduced by 36% the labor needed for the 500-hour ser- breakthrough for giant haul trucks. Michelin will be in-

vice. troducing two versions of the tire. One version will have

The 797B retains the 3524B high-displacement die- an extra-deep E4 tread for use in the harshest operating

sel engine and the mechanical power train. Electronic conditions. The other version is designed for high-speed

controllers integrate the engine and the mechanical operations.

power train information. This helps performance, ex- The Michelin 59/80R63 XDR tire is standard equip-

tends component life and improves operator comfort. ment on the Caterpillar 797B. But is can also be retrofit-

Basic specifications for the 797B mining truck: ted for all existing Caterpillar 797s so they, too, can

benefit from the tire’s performance. Michelin offers

• Gross machine weight 624 t (688 st) more than 110 earthmoving tire sizes. And it is the only

• Nominal payload 345 t (380 st) tire manufacturer to have an earthmoving test facility —

• Engine model Cat 3524B HD the one mentioned in Almeria, Spain. For more informa-

• Gross engine power 2.65 MW (3,550 hp) tion about Michelin’s tires, check its Web site, www.-

• Transmission seven-speed planetary power shift michelin.com/earthmover. ■

MINING ENGINEERING ■ SEPTEMBER 2002 37

o'neil, p. 36-37 copy 37 9/16/02, 9:03 AM

S-ar putea să vă placă și

- The Design of Piled Foundations: Structures and Solid Body MechanicsDe la EverandThe Design of Piled Foundations: Structures and Solid Body MechanicsEvaluare: 4 din 5 stele4/5 (8)

- Michel inDocument31 paginiMichel inRosamel CespedesÎncă nu există evaluări

- Hauling and Tyres at Escondida Mine 2002Document26 paginiHauling and Tyres at Escondida Mine 2002walterloliÎncă nu există evaluări

- How to Rebuild & Modify Rochester Quadrajet CarburetorsDe la EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsEvaluare: 5 din 5 stele5/5 (2)

- Cat® 993K vs. Komatsu WA900-3Document12 paginiCat® 993K vs. Komatsu WA900-3Mónica Rada Urbina100% (1)

- Farm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsDe la EverandFarm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsÎncă nu există evaluări

- Mining Truck BodiesDocument41 paginiMining Truck Bodies2spÎncă nu există evaluări

- Motor Truck Logging Methods Engineering Experiment Station Series, Bulletin No. 12De la EverandMotor Truck Logging Methods Engineering Experiment Station Series, Bulletin No. 12Încă nu există evaluări

- Tires: Ton-Kilometer Per Hour Rating SystemDocument4 paginiTires: Ton-Kilometer Per Hour Rating Systemali alilouÎncă nu există evaluări

- Trommel: PerformanceDocument1 paginăTrommel: PerformanceFrancisco Javier López BarrancoÎncă nu există evaluări

- Defense University, College of EngineeringDocument39 paginiDefense University, College of EngineeringtesfayeÎncă nu există evaluări

- Chaseling CompanyDocument6 paginiChaseling CompanyLuis MoyaÎncă nu există evaluări

- Stockpile Coal Handling-Section 23Document10 paginiStockpile Coal Handling-Section 23pmcisissengueÎncă nu există evaluări

- Ijirt151158 Paper PDFDocument2 paginiIjirt151158 Paper PDFNukul MahajanÎncă nu există evaluări

- 12 796 and 798 Update - Jeff - 20nov18Document17 pagini12 796 and 798 Update - Jeff - 20nov18tatiana100% (1)

- Sec23 Sebd0350Document10 paginiSec23 Sebd0350pmcisissengueÎncă nu există evaluări

- Six Sigma Quality at Flyrock TiresDocument3 paginiSix Sigma Quality at Flyrock TiresAbeyÎncă nu există evaluări

- Tech Bulletin106Document2 paginiTech Bulletin106Dan PatchÎncă nu există evaluări

- 2 20071125 Material Test Framework For WMA Trials Dec2006Document6 pagini2 20071125 Material Test Framework For WMA Trials Dec2006jorge alberto sanchezÎncă nu există evaluări

- A Report On The Winter Internship at Apollo Tyre1Document17 paginiA Report On The Winter Internship at Apollo Tyre1Krishnakumar ErattemparambilÎncă nu există evaluări

- Kal Tire Electra Tire Recycling SolutionsDocument2 paginiKal Tire Electra Tire Recycling SolutionsNazeeh Abdulrhman AlbokaryÎncă nu există evaluări

- Asphalt Mix Performance Testing For Warm Mix Asphalt Field Project On Ministry of Transportation Ontario Highway 10Document19 paginiAsphalt Mix Performance Testing For Warm Mix Asphalt Field Project On Ministry of Transportation Ontario Highway 10greatpicÎncă nu există evaluări

- Camellia SinensisDocument7 paginiCamellia SinensisnaderÎncă nu există evaluări

- A Look at Cat's New 797 Haul Truck - Caterpillar Inc: Print FriendlyDocument3 paginiA Look at Cat's New 797 Haul Truck - Caterpillar Inc: Print FriendlyJuan BarrazaÎncă nu există evaluări

- C-3 Six Sigma Quality at Flyrock TiresDocument3 paginiC-3 Six Sigma Quality at Flyrock TiresRahul JainÎncă nu există evaluări

- 793F PDFDocument4 pagini793F PDFJaime RuizÎncă nu există evaluări

- Kent Cams Catalogue 2016Document45 paginiKent Cams Catalogue 2016stalin100% (1)

- Work Trucks: KenworthDocument20 paginiWork Trucks: KenworthAbdelkader DraïÎncă nu există evaluări

- SafariDocument2 paginiSafariAndres Oyaga LoewyÎncă nu există evaluări

- CM20240223 3ae9f 82582Document32 paginiCM20240223 3ae9f 82582Dan PatchÎncă nu există evaluări

- HEMM Dumper22Document17 paginiHEMM Dumper22miningnova2Încă nu există evaluări

- Terex TR 45 Spec PDFDocument6 paginiTerex TR 45 Spec PDFarimbi jatisasongkoÎncă nu există evaluări

- BELTCON 12 Efficient Conveyors PaperDocument17 paginiBELTCON 12 Efficient Conveyors PapermatheusÎncă nu există evaluări

- Data Book 2009 Michelin OtrDocument102 paginiData Book 2009 Michelin OtrMiguel A Parra Baeza50% (2)

- Toyota Forklift 1kd Ce302 Diesel Engine Repair ManualDocument22 paginiToyota Forklift 1kd Ce302 Diesel Engine Repair Manualtamimaldonado110395eno100% (58)

- Backstop To Prevent Reversal of Inclined Conveyor and Vertical Bucket ElevatorsDocument15 paginiBackstop To Prevent Reversal of Inclined Conveyor and Vertical Bucket ElevatorsoliveiralauroÎncă nu există evaluări

- Sandwich SpringDocument1 paginăSandwich SpringZiggy GregoryÎncă nu există evaluări

- Caterpillar'S 794 Ac Truck To Be Displayed at Minexpo For The First TimeDocument2 paginiCaterpillar'S 794 Ac Truck To Be Displayed at Minexpo For The First TimeBobby AnggaraÎncă nu există evaluări

- Good Machine Management Cuts Operating Expenses, Extends Landfill Life For Yakima CountyDocument4 paginiGood Machine Management Cuts Operating Expenses, Extends Landfill Life For Yakima CountyjohnribarÎncă nu există evaluări

- Magnum Presentation English VersionDocument120 paginiMagnum Presentation English VersionMAGNUM COMPANIES100% (1)

- Untitled PDFDocument7 paginiUntitled PDFhvermesanÎncă nu există evaluări

- Esperanza Mine Testing On Magna-Skin Red Magnetic LinersDocument10 paginiEsperanza Mine Testing On Magna-Skin Red Magnetic LinersTalabarteria RaygozaÎncă nu există evaluări

- Competitive Bulletin: Cat 980H vs. Komatsu WA500-6 Wheel LoaderDocument26 paginiCompetitive Bulletin: Cat 980H vs. Komatsu WA500-6 Wheel LoaderDAnielÎncă nu există evaluări

- Cat 966M CM20190323-60875-42013Document16 paginiCat 966M CM20190323-60875-42013Mostafa SaadÎncă nu există evaluări

- CH65EDocument16 paginiCH65EGuido MarconiÎncă nu există evaluări

- Appraising A Used Dozer: An Earthmover & Civil Contractor Special FeatureDocument12 paginiAppraising A Used Dozer: An Earthmover & Civil Contractor Special Featureminingnova2100% (2)

- Product Bulletin: Cat 777D Off-Highway TrucksDocument36 paginiProduct Bulletin: Cat 777D Off-Highway TrucksDipendra BhattacharyaÎncă nu există evaluări

- Surface Belt Structure: Cema C & D SeriesDocument8 paginiSurface Belt Structure: Cema C & D SeriesSari Ully SibaraniÎncă nu există evaluări

- Wear Thermal Analysis of Disc Brake Rotor For Different Materials Ijariie6191Document8 paginiWear Thermal Analysis of Disc Brake Rotor For Different Materials Ijariie6191Rizki Eka PutraÎncă nu există evaluări

- Cargadores de Ruedas Cat Specalog 992k Wheel Loader PDFDocument20 paginiCargadores de Ruedas Cat Specalog 992k Wheel Loader PDFpercyÎncă nu există evaluări

- Asphaltic MixturesDocument30 paginiAsphaltic MixturesFlorin MatisÎncă nu există evaluări

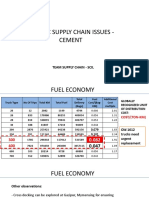

- Specific Supply Chain Issues - CEMENTDocument19 paginiSpecific Supply Chain Issues - CEMENTriyadh al kamalÎncă nu există evaluări

- S TR15 PDFDocument8 paginiS TR15 PDFGeeryl TayoneÎncă nu există evaluări

- Agricultural Tyres For Tractors: DLG Test Report 6289Document8 paginiAgricultural Tyres For Tractors: DLG Test Report 6289Kartik ModiÎncă nu există evaluări

- Esp Minas Indonesia Sumatra SLBDocument10 paginiEsp Minas Indonesia Sumatra SLBGuillermo Ramirez AvilaÎncă nu există evaluări

- Westrac CAT 6015B White Paper Final WebDocument7 paginiWestrac CAT 6015B White Paper Final WebvitaliyÎncă nu există evaluări

- Civil Engineering CatalogueDocument9 paginiCivil Engineering CatalogueSantoshÎncă nu există evaluări

- Cat 980M 982M Wheel Loader BrochureDocument36 paginiCat 980M 982M Wheel Loader BrochureAMÎncă nu există evaluări

- Bridgestone Marine Fender Ver1.9Document73 paginiBridgestone Marine Fender Ver1.9matiasregis85% (20)

- Synergy Effects in T - 0000Document20 paginiSynergy Effects in T - 0000HENRY TORRESÎncă nu există evaluări

- Defining Clusters of Related IndustriesDocument48 paginiDefining Clusters of Related IndustriesDIKSHA TIWARIÎncă nu există evaluări

- The Gold Mine of The Future: Nick Holland, CEO Gold FieldsDocument28 paginiThe Gold Mine of The Future: Nick Holland, CEO Gold FieldsHENRY TORRESÎncă nu există evaluări

- Joking Teasing or BullyingDocument4 paginiJoking Teasing or BullyingHENRY TORRESÎncă nu există evaluări

- Regional Synergies in The Kwinana Industrial AreaDocument6 paginiRegional Synergies in The Kwinana Industrial AreaHENRY TORRESÎncă nu există evaluări

- Selection of Practical Bench Height in Open Pit Mining Using A Multi-Criteria Decision Making SolutionDocument12 paginiSelection of Practical Bench Height in Open Pit Mining Using A Multi-Criteria Decision Making SolutionHENRY TORRESÎncă nu există evaluări

- Essay On AmazonDocument51 paginiEssay On AmazonJasonFernandes0% (1)

- Fatal Accidents Due To FlyrockDocument12 paginiFatal Accidents Due To FlyrockHENRY TORRESÎncă nu există evaluări

- Harvard Bussines AMAZONDocument37 paginiHarvard Bussines AMAZONHENRY TORRESÎncă nu există evaluări

- A Thousands Paths To LeadershipDocument23 paginiA Thousands Paths To LeadershipHENRY TORRESÎncă nu există evaluări

- Blast PatternsDocument10 paginiBlast Patternsrajasekar21Încă nu există evaluări

- Benefits and Succes Factors of Regional Resource Synergies in Gladstone and Kwinana PDFDocument10 paginiBenefits and Succes Factors of Regional Resource Synergies in Gladstone and Kwinana PDFHENRY TORRESÎncă nu există evaluări

- A New Cost Model For Estimation of Open Pit Copper Mine Capital ExpenditureDocument9 paginiA New Cost Model For Estimation of Open Pit Copper Mine Capital ExpenditureHENRY TORRESÎncă nu există evaluări

- Clusters Convergence and Economic Perfor PDFDocument53 paginiClusters Convergence and Economic Perfor PDFMarius TeodorÎncă nu există evaluări

- Joking Teasing or BullyingDocument4 paginiJoking Teasing or BullyingHENRY TORRESÎncă nu există evaluări

- Benefits and Succes Factors of Regional Resource Synergies in Gladstone and Kwinana PDFDocument10 paginiBenefits and Succes Factors of Regional Resource Synergies in Gladstone and Kwinana PDFHENRY TORRESÎncă nu există evaluări

- Copia de Park and Nelson - October 2013 Journal - Part OneDocument4 paginiCopia de Park and Nelson - October 2013 Journal - Part OneHENRY TORRESÎncă nu există evaluări

- A Thousands Paths To LeadershipDocument23 paginiA Thousands Paths To LeadershipHENRY TORRESÎncă nu există evaluări

- Methods For Underground Mining Atlas CopcoDocument144 paginiMethods For Underground Mining Atlas Copcoandrijapopovic80% (5)

- Accuity: High Speed Automated 2D & 3D Optical Gauging Single Click Setup and InspectionDocument4 paginiAccuity: High Speed Automated 2D & 3D Optical Gauging Single Click Setup and InspectionAPPLEÎncă nu există evaluări

- TranscriptDocument1 paginăTranscriptapi-310448954Încă nu există evaluări

- Navy Supplement To The DOD Dictionary of Military and Associated Terms, 2011Document405 paginiNavy Supplement To The DOD Dictionary of Military and Associated Terms, 2011bateljupko100% (1)

- Tsel Manual ThermoselDocument25 paginiTsel Manual ThermoselPedro AlvelaisÎncă nu există evaluări

- Material Requirement Planning (MRP)Document55 paginiMaterial Requirement Planning (MRP)Lisa CarlsonÎncă nu există evaluări

- Firestone & Scholl - Cognition Does Not Affect Perception, Evaluating Evidence For Top-Down EffectsDocument77 paginiFirestone & Scholl - Cognition Does Not Affect Perception, Evaluating Evidence For Top-Down EffectsRed JohnÎncă nu există evaluări

- Time Value of Money LectureDocument54 paginiTime Value of Money LectureRanin, Manilac Melissa SÎncă nu există evaluări

- Binder 3 of 4 Dec-2018Document1.169 paginiBinder 3 of 4 Dec-2018Anonymous OEmUQuÎncă nu există evaluări

- 10th Aug. 2011 Structural Calculation (For Sub.) - 03Document29 pagini10th Aug. 2011 Structural Calculation (For Sub.) - 03Nguyễn Tiến Việt100% (1)

- All Pop SongsDocument53 paginiAll Pop SongsMadeleneQuiogueÎncă nu există evaluări

- Meet The Profesor 2021Document398 paginiMeet The Profesor 2021Raúl AssadÎncă nu există evaluări

- The Joy Luck Club Book 1Document12 paginiThe Joy Luck Club Book 1loronalicelÎncă nu există evaluări

- Poems Prescribed For 2012-2014 English B CSEC ExamsDocument24 paginiPoems Prescribed For 2012-2014 English B CSEC ExamsJorge Martinez Sr.100% (2)

- Mini Project 1 - 1Document9 paginiMini Project 1 - 1Sameer BaraÎncă nu există evaluări

- 2 Contoh Narative TextDocument9 pagini2 Contoh Narative TextRini RienzÎncă nu există evaluări

- Natural Disasters Vocabulary Exercises Fun Activities Games Icebreakers Oneonone Activiti 42747Document2 paginiNatural Disasters Vocabulary Exercises Fun Activities Games Icebreakers Oneonone Activiti 42747Andrea Tercero VillarroelÎncă nu există evaluări

- Chapter 5 AGVDocument76 paginiChapter 5 AGVQuỳnh NguyễnÎncă nu există evaluări

- Properties of Matter ReviewDocument8 paginiProperties of Matter Reviewapi-290100812Încă nu există evaluări

- Pre RmoDocument4 paginiPre RmoSangeeta Mishra100% (1)

- L2 Biostatistics ProbabilityDocument84 paginiL2 Biostatistics ProbabilityAaron CiudadÎncă nu există evaluări

- LPG GasDocument39 paginiLPG Gasv prasanthÎncă nu există evaluări

- Uji Efektivitas Mikroba Rumpun BambuDocument7 paginiUji Efektivitas Mikroba Rumpun BambuUse Real ProjectÎncă nu există evaluări

- Zincanode 304 pc142Document3 paginiZincanode 304 pc142kushar_geoÎncă nu există evaluări

- John Sisler CISSP Study GuideDocument126 paginiJohn Sisler CISSP Study GuideAnthonyÎncă nu există evaluări

- Dizziness - Vertigo and HomoeopathyDocument38 paginiDizziness - Vertigo and HomoeopathyDr. Rajneesh Kumar Sharma MD HomÎncă nu există evaluări

- Relationships, 365 Day Devotional Mylesunroe 377pgDocument377 paginiRelationships, 365 Day Devotional Mylesunroe 377pgEla100% (7)

- YogaDocument116 paginiYogawefWE100% (2)

- Chemistry Notes: SUBJECT: Leaving Cert Chemistry Level: TEACHER: Tara LyonsDocument5 paginiChemistry Notes: SUBJECT: Leaving Cert Chemistry Level: TEACHER: Tara LyonsSevinc NuriyevaÎncă nu există evaluări

- Class 12 - Maths - MatricesDocument87 paginiClass 12 - Maths - MatricesAishwarya MishraÎncă nu există evaluări

- Automotive Electronic Diagnostics (Course 1)De la EverandAutomotive Electronic Diagnostics (Course 1)Evaluare: 5 din 5 stele5/5 (6)

- Why We Drive: Toward a Philosophy of the Open RoadDe la EverandWhy We Drive: Toward a Philosophy of the Open RoadEvaluare: 4 din 5 stele4/5 (6)

- CDL Study Guide 2024-2025: Exam Prep Book With 425+ Questions and Explained Answers to Pass the Commercial Driver’s License Exam on Your First Try, With the Most Complete and Up-To-Date Practice Tests [Complete Version]De la EverandCDL Study Guide 2024-2025: Exam Prep Book With 425+ Questions and Explained Answers to Pass the Commercial Driver’s License Exam on Your First Try, With the Most Complete and Up-To-Date Practice Tests [Complete Version]Evaluare: 5 din 5 stele5/5 (2)

- OBD-I and OBD-II: A Complete Guide to Diagnosis, Repair, and Emissions ComplianceDe la EverandOBD-I and OBD-II: A Complete Guide to Diagnosis, Repair, and Emissions ComplianceÎncă nu există evaluări

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerDe la EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerEvaluare: 4.5 din 5 stele4.5/5 (54)

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestDe la EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestEvaluare: 4 din 5 stele4/5 (28)

- The RVer's Bible (Revised and Updated): Everything You Need to Know About Choosing, Using, and Enjoying Your RVDe la EverandThe RVer's Bible (Revised and Updated): Everything You Need to Know About Choosing, Using, and Enjoying Your RVEvaluare: 5 din 5 stele5/5 (2)

- Tips On How to Build a Street Legal Motorized Bicycle; (That Will Save You a Lot of Aggravation and Money)De la EverandTips On How to Build a Street Legal Motorized Bicycle; (That Will Save You a Lot of Aggravation and Money)Încă nu există evaluări

- ANSYS Workbench 2023 R2: A Tutorial Approach, 6th EditionDe la EverandANSYS Workbench 2023 R2: A Tutorial Approach, 6th EditionÎncă nu există evaluări

- The Official Highway Code: DVSA Safe Driving for Life SeriesDe la EverandThe Official Highway Code: DVSA Safe Driving for Life SeriesEvaluare: 3.5 din 5 stele3.5/5 (25)

- New Hemi Engines 2003 to Present: How to Build Max PerformanceDe la EverandNew Hemi Engines 2003 to Present: How to Build Max PerformanceÎncă nu există evaluări

- Chrysler TorqueFlite A-904 and A-727 Transmissions: How to RebuildDe la EverandChrysler TorqueFlite A-904 and A-727 Transmissions: How to RebuildEvaluare: 5 din 5 stele5/5 (1)

- Turbo: Real World High-Performance Turbocharger SystemsDe la EverandTurbo: Real World High-Performance Turbocharger SystemsEvaluare: 5 din 5 stele5/5 (3)

- Top 21 Hypercars: The Best and Fastest Car Ever MadeDe la EverandTop 21 Hypercars: The Best and Fastest Car Ever MadeEvaluare: 3 din 5 stele3/5 (1)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideDe la EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideEvaluare: 4.5 din 5 stele4.5/5 (8)

- Building Honda K-Series Engine PerformanceDe la EverandBuilding Honda K-Series Engine PerformanceEvaluare: 5 din 5 stele5/5 (2)

- Weld Like a Pro: Beginning to Advanced TechniquesDe la EverandWeld Like a Pro: Beginning to Advanced TechniquesEvaluare: 4.5 din 5 stele4.5/5 (6)

- Ford AOD Transmissions: Rebuilding and Modifying the AOD, AODE and 4R70WDe la EverandFord AOD Transmissions: Rebuilding and Modifying the AOD, AODE and 4R70WEvaluare: 4.5 din 5 stele4.5/5 (6)

- Allison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyDe la EverandAllison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyEvaluare: 5 din 5 stele5/5 (1)

- Internal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesDe la EverandInternal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesEvaluare: 4 din 5 stele4/5 (2)

![CDL Study Guide 2024-2025: Exam Prep Book With 425+ Questions and Explained Answers to Pass the Commercial Driver’s License Exam on Your First Try, With the Most Complete and Up-To-Date Practice Tests [Complete Version]](https://imgv2-1-f.scribdassets.com/img/audiobook_square_badge/710834945/198x198/00b81cbbd3/1714482720?v=1)