Documente Academic

Documente Profesional

Documente Cultură

Eerp (From Rcer-2015)

Încărcat de

Hedi Ben Mohamed0 evaluări0% au considerat acest document util (0 voturi)

19 vizualizări6 paginienvironnement émergence réponse plant

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentenvironnement émergence réponse plant

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

19 vizualizări6 paginiEerp (From Rcer-2015)

Încărcat de

Hedi Ben Mohamedenvironnement émergence réponse plant

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF sau citiți online pe Scribd

Sunteți pe pagina 1din 6

Appendix D

ENVIRONMENTAL EMERGENCY RESPONSE PLAN (EERP)

GUIDELINES

Del

Appendix D

ENVIRONMENTAL EMERGENCY RESPONSE PLAN (EERP) GUIDELINES

INTRODUCTION

Development and implementation of Environmental Emergency Response Plans (EERP) are

considered by the Royal Commission as a major part of any industrial operation. The

‘emergency planning is also a national pre-requisite as set by the other local government

agencies concerning industrial operation as wells as an international requirement governed

by the international agencies like the World Bank (Disaster Risk Management Guidelines),

OSHA (Hazardous waste operations and emergency response. - 1910.120, Standards - 29

CFR) and USEPA (Response Planning and Risk Management Guidlines).

The importance of EERP is derived from its very name as being the planning and

‘management of avoiding potential risks during the industrial operation. It involves preparing

fan integrated plan for tackling a disaster before it occurs as wells as after it occurs i.e.

disaster response e.g, emergency evacuation, quarantine and mass decontamination and

rebuilding site ete.

The EERP concept is @ continuous process by which RC as a legislator and industries,

operating in the industrial city manage hazards in an effort to avoid them or to eliminate their

adverse Impacts resulting from these hazards. Actions to be taken in an emergency depend

in part on the type of the industry , its design, the capacity of the units, the hazardous

materials to be released, location and perceptions risk of those exposed, An effective

emergency management relies on thorough integration of emergency plans at all levels of

Interactive actions,

‘Any facility operating in the industrial cities under RC jurisdiction shall develop i's own ERP.

for all kind of emergencies. The EERP shall be a high standard technical document which

address, as a minimum, the following areas:

4. PURPOSE OF EMERGENCY PLAN

‘The main purpose of the EERP is to define procedures to be followed in the event of

an accident or emergency at the facility premises. Scope of the plan covers natural

incidents/operational accident scenarios such as spills, fire, and road accidents which

may occur during the course of normal /abnormal operations. The aim of preparing

emergency and contingency plan for faclities operating in RC boundaries is to have

an effective procedure that can be followed by each facility in case of an unavoidable

emergency, incident and accident at the site . The facility shall conduct safety

analysis of all operational components considering it as a useful tool in designing

emergency procedures.

RC will review and approve the ERP according to procedures and incorporate it

together with the ERPs of other industries operating in the area as part of the RCs

overall emergency planning procedures,

2. REGULATORY FRAMEWORK

‘The EERP shall be prepared in compliance with RCER-2015 Volumes | and Il, and it

shall be a supplement to Royal Commission Environmental Permit Application

package (PAP) and Environmental Impact Assessment (EIA) study report in order to

‘obtain Environment Permit to Construct (EPC) and Environmental Permit to Operate

(EPO),

Del

‘The major task of EERP is preparation of an integrated preventive plan to stop a

disaster before it occurs. Further, it also requires proper response planning such as

emergency evacuation, quarantine, mass decontamination, ete for handling the

disaster after its occurrence.

3, DESCRIPTION OF SITE

‘The facility shall include a brief description of the site with reference to final

site plan as listed in PAP Form "PA-G1 (General)’. Further, the site plan shall

address all aspects of environment and safety in compliance with all

applicable RC Regulations and Guidelines.

4. PROCESS RELATED RISKS

Priorities shall be set by the facility for identifying process related risks with greatest

probability of occurring and greatest loss, and risks with lower probablity of

‘occurrence and lower loss are handled in descending order , as per technical design

‘and manufacturer's guidelines for each unit.

5. TYPE OF EMERGENCIES

All potential emergency scenarios that apply to the facility in particular shall be

discussed in detail and shall include but not limited to the following typical emergency

i. Incidents related to failure or malfunction of process equipment that may

rosult in a sudden release of chemicals including hazardous substances.

ji, Incidents/ Accidents that may result in environmental impacts, health hazard

(or material damage such as truck collision or fip over on highway or near

plant, Industrial accident on-site, site entrance blockage, absence of key staff

at one time, sudden breakdown of major units, machinery, vehicles, non=

availabilty of badly needed maintenance /repair tools.

li, Medical emergencies relatedinot related to process; trauma , dermatitis

injury , exposure to hazardous substance , sickness , sunstroke, electrocution

ete

Iv. Accidental spills or release of hazardous materials related/not related to

process equipment failure that can lead to @ medical emergency,

‘environment impacts or material damage

v. Natural events such as earthquakes, floods, sandstorm, lightning, heavy

rainfall, etc.

vi. Fires (small scale as well as large scale )

6. ROAD ACCIDENTS

‘The facilty shall consider special provisions set by RC , PME or OSHA for transport

of all toxic and hazardous chemicals including fuels, product, raw material, waste or if

regulated under international standards including US Department of Transport (DOT)

or USA National Fire Protection Association (NFPA),

Further the facility shall develop appropriate accident prevention program which will

address issues related to: possibilities of minor major road accidentsifip over of fuel

p2

10,

tankersitrucks carrying raw material or product or waste, schedule of vehicle

movement to avoid peak traffic and road accidents, driver’s education on trafic rules,

and speed limits on-site and off-site, vehicle maintenance as per owner's manual and

dealership maintenance pragram, etc

FIRE FIGHTING.

The faciity shall identify all potential fire hazards on-site and fire hazard

Characteristics that apply to fuel, raw material, product, by-product, waste with

reference to MSDS, plant design and OSHA (29 CFR Part 1910, Subpart L Fire

extinguishing equipment)

The following shall be included in the fre response section

1. Locations of fire alarm/systemsfextinguishers

ii, Staff training in safe operation of fire extinguishers, isolation and

‘extinguishing small ices.

li, Potential sources of fre

iv. Fire hose reel locations

v. External Support Services needed

vi Firefighting equipment should pass RC industrial security and Civil Defense

specifications

vi. Fire fighting measures/instructions for each material handled on-site as per

MsDs.

vil. Emergency plant shutdown

INCIDENT / ACCIDENT MANAGEMENT

Facllty shall prepare procedures for avoiding risks that include preventive

‘measuresiactions for preparing for disaster before it occurs, disaster response (e.g

‘emergency evacuation, quarantine, mass decontamination ete); and supporting, and

rebuilding after natural or human-made disasters have occurred and shall also

include Emergency Plant Shutdown to isolate equipment, process units, tanks, etc,

from one another to prevent the spread of an emergency/nazardous situation

ALARMS AND COMMUNICATION

Guidelines for communicating emergency messages/alarms shall be included in

EERP and shall also be a part of training for all employees. Faciliy shall prepare a

hotline list of all concemed government authorities/organizations for contacting in an

‘emergency by EERP team,

TRAINING PRACTICES

Al technicaVadministrative/skilled laborinon-skilled labor and other on-sitelotfsite

‘employees of the facility shall receive initial site induction into the safety rules and

basic emergency response procedures.

AAs a result of emergency training, all employees shall be well versed with available

options when responding to emergency situations so that rational and intelligent

decisions can be made.

11, ENVIRONMENTAL EMERGENCY RESPONSE PERSONNEL (EERP Team)

The EERP Team is a group of workers who prepare for and respond to any

emergency incident, although under certain circumstances the team may be an ad=

hoe group of willing volunteers after approval from the facilty

Procedures shall be set-up for selecting a designated EERP team, and developing a

Emergency Response Planning Organization (structure, authorities & responsibilities,

‘emergency personnel names and contact numbers)

‘The EERP team members shall be trained and prepared to fulfil the roles required by

each specific situation.

For large events, whore external assistance is sought by the facility , the EERP Team

shall be required to work jointly in a unified command system with RC and any other

‘concemed government agency.

42, SAFETY, HEALTH AND ENVIRONMENT (SHE)

‘The facilly shall incorporate SHE aspects into the ERP , and shall identify various

health hazards ; hazard ID , health effects hazard characteristics of each material

stored/handled on-site, exposure control , Personal Protective Equipment (PPE)

conditions to avoid , waste on-site with reference to plant design , technical supplier

specs , Matersal Safety Data Sheet (MSDS) and other factors.

AA specific log, hazard symbol signage notice boards and labeling system for all site

‘components in plant shall be developed according to conditions in each working area

All hazardous material shall be clearly marked with USA National Fire Protection

Association (NFPA) diamond labels , and selection of signs design and contents shall

be prepared in general with applicable regulations and guidelines from U.S EPA

,OSHA, NESHAP, HAZOP and HAZWOPER

43, IMMEDIATE RESPONSE MEASURES.

The facilty shall prepare easy to follow step-by-step actions in the form of a written

procedures for the ERP team to respond , contain or stop the cause of the

emergency effectively immediately with no delay; response to material damage

Incidents, response to medical emergencies, response to process. fallure

emergencies.

14, EMERGENCY PROCEDURES

All the emergency procedures shall be written procedures for responding to any

‘emergency or incident Ikely or suspected to be likely to cause material damage to the

plant, its employees (including contractors), the environment or the surrounding

‘communities and industrial installations. These procedure shall be prepared and kept

While preparing the above procedures, the following points shall be taken into

consideration

i. Noworker on-site is authorized to give public statement by any means

ji, Site shall be off-limits to non-authorized persons

iii, Internal and external responders names and contact numbers with ID copies

shall be obtained and approved by facility

iv. Facility shall be able to clearly know, identity and define type of emergency

v. Proper response measures for spills/gas releases and other emergencies

shall be prepared

D4

415, REDUCING ENVIRONMENTAL IMPACT

Faclity shall establish procedures to minimize adverse impacts as a result of the

‘emergency situation and to determine safe entry to emergency or incident area and

procedures for clean-up, repair, containment measures, rehabilitation of

contaminated land, containment and removal of spilled material

16. CORRECTIVE ACTION PLAN

Corrective Action Plan shall be prepared by the EERP Team and implemented to

avoid creating conditions that could potentially aggravate, repeat or augment the

original incident. After preparing incident report the facility shall take corrective

actions that may include

i, Compliance with RC requirements,

ji. Control the source of pollution

ii, Plan to avoid recurrence of similar incidents

iv. Study the impacts of incident on surrounding environment,

v. Procedures for cleanup or repair of the affected area affected by the hazards

vi. Facility shall ensure that repair works do not create disruptions that may

result in release of contaminants.

Vi Assess the need for mitigation

17. MATERIAL HANDLED AND STORED AT SITE

All material stored, handled on-site as well as material transported to and from the

site shall be declared by the facilly and classified in accordance with RCER 2015 and

the facility shall follow provisions stipulated in RCER-2015, specially to Section 4 for

regulations concerning "Hazardous Material Management”

18. EMERGENCY EQUIPMENT ON-SITE/OFF-SITE

A list of equipment to be used solely for the purpose of emergency response and

shall be available at a designated location on-site for the purpose of making initial

‘emergency response,

19, PPE FOR EMERGENCY PERSONNEL, FIRST AID, AND MEDICAL EXAMINATION

The facility shall ensure the availabilty of suitable PPE for the EERP team and all

other personnel to be used in emergencies. First aid boxes shall be available in

selected areas around the site for use by workers. The First Aid box shall bo

Inspected regularly,

The facility shall have a proper medical facility to conduct periodic medical

examination of employees.

20, EVACUATION ROUTES AND ENVIRONMENTAL EMERGENCY DRILLS.

‘The facility shall prepare specific guidelines for determining the extent of the area that

needs to be evacuated in an emergency, activating an evacuation, evacuation routes,

evacuation sequence and communication guidelines during an evacuation

The facility shall conduct potential environmental emergency drils periodically in

relation to the hazardous materials.

Ds

S-ar putea să vă placă și

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Hazardous Area Hazardous Area ClassificaDocument106 paginiHazardous Area Hazardous Area ClassificaHedi Ben MohamedÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Oisd GDN 178Document21 paginiOisd GDN 178Hedi Ben MohamedÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

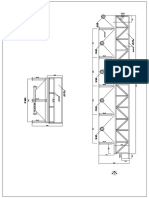

- Section Aa Section BB Fire Fighting TankDocument1 paginăSection Aa Section BB Fire Fighting TankHedi Ben MohamedÎncă nu există evaluări

- Case Study - Fire Incident On MV of SPMDocument4 paginiCase Study - Fire Incident On MV of SPMHedi Ben MohamedÎncă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Butterfly Valve K4 PVC-U - PP - PVDF Actuator ERDocument6 paginiButterfly Valve K4 PVC-U - PP - PVDF Actuator ERHedi Ben MohamedÎncă nu există evaluări

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- 6th Central Pay Commission Salary CalculatorDocument15 pagini6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

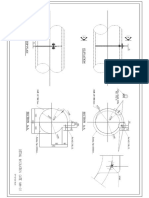

- Decanteur Ver1Document1 paginăDecanteur Ver1Hedi Ben MohamedÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Biological Odour Control System Specification - R1Document24 paginiBiological Odour Control System Specification - R1Hedi Ben MohamedÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Tank Pics-Filament Wound TanksDocument3 paginiTank Pics-Filament Wound TanksHedi Ben MohamedÎncă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Amine Plant Troubleshooting and OptimizaDocument26 paginiAmine Plant Troubleshooting and OptimizaHedi Ben MohamedÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- 9434-Sfe - Sequential Functional ExtractionDocument3 pagini9434-Sfe - Sequential Functional ExtractionHedi Ben MohamedÎncă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- FG Od en V2.0Document2 paginiFG Od en V2.0Hedi Ben MohamedÎncă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Product Technical CatalogueDocument4 paginiProduct Technical CatalogueHedi Ben MohamedÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Multimedia Filter and Activated Carbon Filter Pilot Test StudyDocument10 paginiMultimedia Filter and Activated Carbon Filter Pilot Test StudyHedi Ben MohamedÎncă nu există evaluări

- Remember: Always Call The Fire Department First: How Do Fire Extinguishers Work?Document2 paginiRemember: Always Call The Fire Department First: How Do Fire Extinguishers Work?Hedi Ben MohamedÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Detail Isolating Gate Mh-01Document1 paginăDetail Isolating Gate Mh-01Hedi Ben MohamedÎncă nu există evaluări

- Cross VentilationDocument1 paginăCross VentilationHedi Ben MohamedÎncă nu există evaluări

- Decanteur Ver1Document1 paginăDecanteur Ver1Hedi Ben MohamedÎncă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Chapter 1: Shed Basics: PurposeDocument4 paginiChapter 1: Shed Basics: PurposeHedi Ben MohamedÎncă nu există evaluări

- Centrifugal Pumps - Engineering LibraryDocument9 paginiCentrifugal Pumps - Engineering LibraryHedi Ben MohamedÎncă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Fire Zone LayoutDocument1 paginăFire Zone LayoutHedi Ben MohamedÎncă nu există evaluări

- Luxembourg Hydrant Design - EJet - Jet Fuel Engineering ConsultancyDocument3 paginiLuxembourg Hydrant Design - EJet - Jet Fuel Engineering ConsultancyHedi Ben MohamedÎncă nu există evaluări

- Purification of BiogasDocument15 paginiPurification of BiogasHedi Ben MohamedÎncă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)