Documente Academic

Documente Profesional

Documente Cultură

Grade Conveyor Belt

Încărcat de

dedison_rTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Grade Conveyor Belt

Încărcat de

dedison_rDrepturi de autor:

Formate disponibile

ConveyorBeltGuide Engineering Production Installation Monitoring

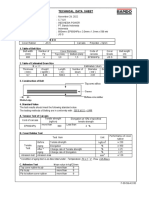

BELT DESIGNATION

Textile Conveyor Belt Steel Cord Conveyor Belt

Example: 1000 m DIN 22102 AB 1000 EP 630/4 6/2 Y Example: 2000 m DIN 22131 AB 1200 St 1600 7T/5 X

1000 m Length 2000 m Length

DIN 22102 Applicable standard/norm DIN 22131 Applicable standard/norm

AB Manufacturer's acronym AB Manufacturer's acronym

1000 Belt width in mm 1200 Belt width in mm

EP Carcass material *) St Carcass material (steel cords)

630 Belt min. breaking strength in kN/m 1600 Belt min. breaking strength in kN/m *)

4 Number of plies 7 Top cover thickness in mm

6 Top cover thickness in mm T Additional reinforcement (if any) **)

2 Bottom cover thickness in mm 5 Bottom cover thickness in mm

Y Cover grade X Cover grade

*) Note 1: In some regions, PN is used instead of EP, where P stands

for Polyester and N for Nylon.

Note 2: For textile conveyor belts it should additionally be indicated

whether solid, sealed or cut edges are preferred.

Example for a solid woven

carcass designation:

t = pitch, d = diameter, bk = edge width, B = belt width, s1 = belt

thickness, s2 = top cover thickness, s3 = bottom cover thickness, s4

= thickness between steel cords and protection layer, bt = tension

width, 1 = protection layer,

Notes:

4-ply belt *) A requirement of DIN standards for steel cord conveyor belts is that

the breaking force of a vulcanized steel cord in the conveyor belt shall

be at least as great as the product of the minimum breaking strength

of the conveyor belt by the cord spacing with an addition of

approximately 10%.

**) The exact construction of a textile damage protection system,

2-ply belt above referred to as "T", is not standardized.

In some world regions it is common to ignore norm values like

minimum breaking strength (meaning that not a single test value must

be below the agreed minimum). Sometimes the "root mean square"

For belt nomenclature in the USA, please see here. method is used, where the average value may be above the minimum

in spite of individual unacceptable low figures.

*) Other grades are E (antistatic), K and S (antistatic and flame retardent), T (high temperature

resistant), R (low temperature resistant), G (oil and fat resistant) and C (chemical resistant).

The physical data for such grades need to be agreed upon between user and manufacturer.

The above data are given without obligation. Please use the data of the latest relevant standard/norm.

2003-2020 Copyright ConveyorBeltGuide.com

S-ar putea să vă placă și

- Conveyor Belt DesignationDocument2 paginiConveyor Belt DesignationUğur GözkayaÎncă nu există evaluări

- Designation GuideDocument3 paginiDesignation GuidesharemwÎncă nu există evaluări

- Steel CordDocument20 paginiSteel CordrajksharmaÎncă nu există evaluări

- Part II PDFDocument28 paginiPart II PDFAdrian OprisanÎncă nu există evaluări

- Electric Tape P029eDocument8 paginiElectric Tape P029esakthivelÎncă nu există evaluări

- ORI - Maxx AromourDocument4 paginiORI - Maxx Aromourjose castilloÎncă nu există evaluări

- Tds Wikon Ip. C 7&8Document1 paginăTds Wikon Ip. C 7&8deni prastikoÎncă nu există evaluări

- Sikawrap®-300 C: Product Data SheetDocument4 paginiSikawrap®-300 C: Product Data SheetHenri DormoyÎncă nu există evaluări

- EU Data Sheet Chainflex CFSOFT2Document7 paginiEU Data Sheet Chainflex CFSOFT2Jérôme MeugnierÎncă nu există evaluări

- Conveyor BeltsDocument12 paginiConveyor BeltsEGS_1977Încă nu există evaluări

- Extruded PVC Coated Steel Chain Link Fence FabricDocument2 paginiExtruded PVC Coated Steel Chain Link Fence FabricMahfuz AlamÎncă nu există evaluări

- Ts-Po16392-2cx10mm, 3CX6MM, 3CX10MM, 4CX6MM, 4CX16MMDocument2 paginiTs-Po16392-2cx10mm, 3CX6MM, 3CX10MM, 4CX6MM, 4CX16MMmohd darusÎncă nu există evaluări

- TSNZ Brochure March 2017Document24 paginiTSNZ Brochure March 2017arlene joy paredesÎncă nu există evaluări

- Single Mode-Loose Tube Armoured Fiber Optic CableDocument2 paginiSingle Mode-Loose Tube Armoured Fiber Optic Cablesunil kumarÎncă nu există evaluări

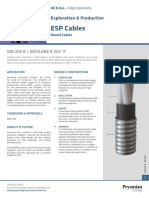

- Prysmian Esp Cable DW 205 R PDFDocument2 paginiPrysmian Esp Cable DW 205 R PDFJava Cable Center50% (2)

- Technical Specification - Instrument Cable - WP4Document7 paginiTechnical Specification - Instrument Cable - WP4nnÎncă nu există evaluări

- Rhomboidal Steel Wire Rope Net Panels SpecificationDocument5 paginiRhomboidal Steel Wire Rope Net Panels SpecificationSOMNATH JANAÎncă nu există evaluări

- 1 DATA SHEET FOR ST BELT ST1600 CBT Brand 230329Document1 pagină1 DATA SHEET FOR ST BELT ST1600 CBT Brand 230329wycingenieriaÎncă nu există evaluări

- Dowel Bar-Tie Bar-IRC-58-2015Document3 paginiDowel Bar-Tie Bar-IRC-58-2015SONU SINGHÎncă nu există evaluări

- Sikawrap 300 cDocument5 paginiSikawrap 300 cAkram ShakirÎncă nu există evaluări

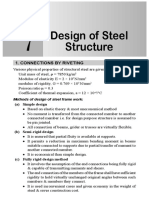

- ستيل ستركشرDocument73 paginiستيل ستركشرAws SamaÎncă nu există evaluări

- Timber StructureDocument34 paginiTimber StructureSabin RautÎncă nu există evaluări

- Corbel Design Calculation and Reinforcement DetailsDocument19 paginiCorbel Design Calculation and Reinforcement Detailsniranjan paudelÎncă nu există evaluări

- Sloan2003 - Improving Bend-over-Sheave Fatigue in Fiber RopesDocument4 paginiSloan2003 - Improving Bend-over-Sheave Fatigue in Fiber Ropesgoooga299Încă nu există evaluări

- Flange Insulating Materials: Cathodic Protection Technology Pte LTDDocument3 paginiFlange Insulating Materials: Cathodic Protection Technology Pte LTDAmir HoseiniÎncă nu există evaluări

- CF37.D Sort110 EU Data Sheetchainflex CF37.DDocument6 paginiCF37.D Sort110 EU Data Sheetchainflex CF37.DAhmad FaujiÎncă nu există evaluări

- 12 Core Multimode Direct BuriedDocument1 pagină12 Core Multimode Direct BuriedMuhammad Jazztyan Indra PradanaÎncă nu există evaluări

- Sikawrap - 300 CDocument4 paginiSikawrap - 300 CJhune UrabaÎncă nu există evaluări

- Datasheet Armoured Cable PVC SheathedDocument9 paginiDatasheet Armoured Cable PVC SheathedDave KousudhanÎncă nu există evaluări

- Sika Anchorfix 2 PDFDocument7 paginiSika Anchorfix 2 PDFUnited Construction Est. TechnicalÎncă nu există evaluări

- Puvvnl GTPDocument3 paginiPuvvnl GTPshivam dwivediÎncă nu există evaluări

- WTEC 35KV MV Cable LLDPE Rev S 20160226Document5 paginiWTEC 35KV MV Cable LLDPE Rev S 20160226carloÎncă nu există evaluări

- Datos CableDocument3 paginiDatos CablePablo Briceño NavarroÎncă nu există evaluări

- Fire Alarm-Fir (Shield) : 2 Core (Cu/Mica Tape/PVC-FR/CAM+ATC Drain wire/PVC-FRLS)Document1 paginăFire Alarm-Fir (Shield) : 2 Core (Cu/Mica Tape/PVC-FR/CAM+ATC Drain wire/PVC-FRLS)Cost RootsÎncă nu există evaluări

- XTEInterface ServletDocument2 paginiXTEInterface ServletRodni EmslieÎncă nu există evaluări

- Sikawrap - 300 CDocument4 paginiSikawrap - 300 CAlexis KarampasÎncă nu există evaluări

- Nema Rn1 1998Document1 paginăNema Rn1 1998AXEL OMAR SANCHEZÎncă nu există evaluări

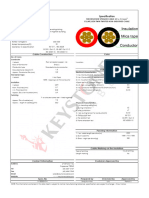

- Keystone Fire Alarm Cables (Twisted Pair Non Sheathed)Document3 paginiKeystone Fire Alarm Cables (Twisted Pair Non Sheathed)Edwin LoquinaÎncă nu există evaluări

- Box girder Final March23Document34 paginiBox girder Final March23dereje werkuÎncă nu există evaluări

- Cable Cross LayoutDocument4 paginiCable Cross LayoutWong Chung MengÎncă nu există evaluări

- C7CH20050 - Wall - Reinforcement - WR2Document20 paginiC7CH20050 - Wall - Reinforcement - WR2Mahadev Sastry100% (1)

- Belting Correia de BorrachaDocument54 paginiBelting Correia de BorrachaFilype NascimentoÎncă nu există evaluări

- 10X4 A2xfy Alum - ArmdDocument2 pagini10X4 A2xfy Alum - ArmdParth DhobiÎncă nu există evaluări

- Instrumentation-Cables 1.5SQMM 4 300-500-V Copper Stranded Pvc-Type-A Overall-Al-Mylar PVC-ST1 Gi-Wire FRLSH TDSDocument2 paginiInstrumentation-Cables 1.5SQMM 4 300-500-V Copper Stranded Pvc-Type-A Overall-Al-Mylar PVC-ST1 Gi-Wire FRLSH TDShydrothermsÎncă nu există evaluări

- OS1LTSTA12UBKDocument2 paginiOS1LTSTA12UBKShimahÎncă nu există evaluări

- Rockfall Mesh Technical Data SheetDocument2 paginiRockfall Mesh Technical Data SheetSudipto PaulÎncă nu există evaluări

- ZTTSC MV Power Cables XJ10078 SPECDocument5 paginiZTTSC MV Power Cables XJ10078 SPECMarco VillalobosÎncă nu există evaluări

- TDS - Flexible AluminiumDocument3 paginiTDS - Flexible Aluminiumvysakh5588Încă nu există evaluări

- General BICC 279700Document4 paginiGeneral BICC 279700Byron PanchiÎncă nu există evaluări

- Astm e 2016 WireDocument29 paginiAstm e 2016 WireDavid KlinkenbergÎncă nu există evaluări

- Sikawrap - 230 CDocument4 paginiSikawrap - 230 CNyein ZawÎncă nu există evaluări

- CBG7370 en Service MaterialDocument8 paginiCBG7370 en Service Materialluis martinezÎncă nu există evaluări

- 0.75PX1TSCNARMDDocument2 pagini0.75PX1TSCNARMDnmpkumarÎncă nu există evaluări

- Crack Width CalculationDocument7 paginiCrack Width CalculationSrinivas RegulavalasaÎncă nu există evaluări

- R1 - Calculation Report of Waste Water Storage Tank - Bangchack BiofuelDocument12 paginiR1 - Calculation Report of Waste Water Storage Tank - Bangchack BiofuelPete Rueangchim100% (3)

- Nexans 10px 0.75mm2 MGT Xlpe Isos LSZH Swa LSZHDocument2 paginiNexans 10px 0.75mm2 MGT Xlpe Isos LSZH Swa LSZHRijo RajanÎncă nu există evaluări

- Inspection Report for Phoenix Conveyor Belt IndiaDocument22 paginiInspection Report for Phoenix Conveyor Belt IndiaAdeeb RizviÎncă nu există evaluări

- Tensioned Monitoring String Techdata LTRDocument1 paginăTensioned Monitoring String Techdata LTRAnonymous EP0GKhfÎncă nu există evaluări

- Fibrestong Above GroundDocument22 paginiFibrestong Above GroundArunprasad MurugesanÎncă nu există evaluări

- Rema-Tip-Top-Remasleeve RemagripDocument16 paginiRema-Tip-Top-Remasleeve Remagripdedison_rÎncă nu există evaluări

- Working Principle: Contact Free Conveyor Belt SkirtingDocument4 paginiWorking Principle: Contact Free Conveyor Belt Skirtingdedison_rÎncă nu există evaluări

- Rema Tip Top Unigrip CR L 385Document2 paginiRema Tip Top Unigrip CR L 385dedison_rÎncă nu există evaluări

- Rema Tip Top Unigrip CR L 215Document2 paginiRema Tip Top Unigrip CR L 215dedison_rÎncă nu există evaluări

- Brochure Coal Fired Power Industry PDFDocument12 paginiBrochure Coal Fired Power Industry PDFdedison_rÎncă nu există evaluări

- SuprA Company Profile (2019)Document28 paginiSuprA Company Profile (2019)dedison_rÎncă nu există evaluări

- REMA TIP TOP PerformanceGrip 70 SLDocument1 paginăREMA TIP TOP PerformanceGrip 70 SLdedison_rÎncă nu există evaluări

- Polyslick UHMWsheet Rev6 010818 WebDocument2 paginiPolyslick UHMWsheet Rev6 010818 Webdedison_rÎncă nu există evaluări

- Technical Data Sheet Rubber Cushion Gum FillingDocument3 paginiTechnical Data Sheet Rubber Cushion Gum Fillingdedison_rÎncă nu există evaluări

- Air Canon Tyhoon - Martin EngineeringDocument2 paginiAir Canon Tyhoon - Martin Engineeringdedison_rÎncă nu există evaluări

- Universal Hardener ER-42Document3 paginiUniversal Hardener ER-42dedison_r100% (1)

- 1.3 Diaphragm WallsDocument13 pagini1.3 Diaphragm Wallsanku4frenz100% (1)

- TOS III B.ArchDocument213 paginiTOS III B.ArchSunny Varghese A KÎncă nu există evaluări

- Chapter 9Document4 paginiChapter 9ahmed abdohÎncă nu există evaluări

- Saep 1024Document5 paginiSaep 1024balajiÎncă nu există evaluări

- ACI 304R Guide For Meas., Mix., Transp., & Placing ConcDocument41 paginiACI 304R Guide For Meas., Mix., Transp., & Placing ConcVasanth KumarÎncă nu există evaluări

- Lecture Note About Project Life CycleDocument4 paginiLecture Note About Project Life CycleSaid Abdi MohamudÎncă nu există evaluări

- Bidding Document For Construction of Indoor Stadium at Zuangtui, Aizawl Volume-IiDocument104 paginiBidding Document For Construction of Indoor Stadium at Zuangtui, Aizawl Volume-Iisonmezender9100% (1)

- Engineering Geology Assignment 29.11.12Document4 paginiEngineering Geology Assignment 29.11.12Richard WestonyÎncă nu există evaluări

- Fermacell Orange BookDocument138 paginiFermacell Orange BookabudabeejajaÎncă nu există evaluări

- Individual Qeustions 1springsDocument17 paginiIndividual Qeustions 1springsslv_prasaadÎncă nu există evaluări

- Pump SCE B 2Document8 paginiPump SCE B 2Zankar R ParikhÎncă nu există evaluări

- GuidetoConnectionofSupply Full en PDFDocument323 paginiGuidetoConnectionofSupply Full en PDFESM PÎncă nu există evaluări

- Designing a hose reel systemDocument6 paginiDesigning a hose reel systemSyafiqah ShahuriÎncă nu există evaluări

- Session 5-Thermal Spray Coatings For Corrosion Protection-What You Need To KnowDocument48 paginiSession 5-Thermal Spray Coatings For Corrosion Protection-What You Need To KnowBala SingamÎncă nu există evaluări

- Cooling Tower TNCDocument6 paginiCooling Tower TNCAarol Hatta100% (1)

- VRF DX indoor, outdoor unit schedulesDocument10 paginiVRF DX indoor, outdoor unit schedulesnazile_05Încă nu există evaluări

- HSC Engineering StudiesDocument13 paginiHSC Engineering StudiesRick ThuranÎncă nu există evaluări

- Bill of Quantities: 1 Provisional SumDocument3 paginiBill of Quantities: 1 Provisional Sumnitish JhaÎncă nu există evaluări

- National Product Catalogue Orrcon Steel 120711Document76 paginiNational Product Catalogue Orrcon Steel 120711Sara CoffeyÎncă nu există evaluări

- Guntur NBCC SorDocument57 paginiGuntur NBCC SorPrawinkumar RajanÎncă nu există evaluări

- Abraham MitikuDocument58 paginiAbraham MitikubeleteÎncă nu există evaluări

- Ds FlowserveDocument5 paginiDs FlowservejmeleÎncă nu există evaluări

- GF Gravel Filter - ENDocument2 paginiGF Gravel Filter - ENMariusCapraÎncă nu există evaluări

- Atlas Copco: Stationary Air CompressorsDocument66 paginiAtlas Copco: Stationary Air CompressorsChriss Vzz100% (4)

- PWA IAN 021 Rev A1 - Cycleways and Footways Pavement Design GuidelinesDocument31 paginiPWA IAN 021 Rev A1 - Cycleways and Footways Pavement Design GuidelinesHenry TuganoÎncă nu există evaluări

- ConcreteDesign PDFDocument64 paginiConcreteDesign PDFJuanAlfaroRodríguezÎncă nu există evaluări

- Econolite CastableDocument1 paginăEconolite CastableJosue MorenoÎncă nu există evaluări

- Largest Brick Structure in The World JetavanaramayaDocument7 paginiLargest Brick Structure in The World JetavanaramayaTharindu Edirisinghe100% (1)

- SPB Acienda Mechanical Plans - For TenderDocument13 paginiSPB Acienda Mechanical Plans - For TenderRyan DizonÎncă nu există evaluări

- ESB Construction SafetyDocument12 paginiESB Construction Safetytexas_peteÎncă nu există evaluări