Documente Academic

Documente Profesional

Documente Cultură

ADDENDUM To IOM - Tech Notes: Electronically Commutated Motor (ECM) - Test & Info

Încărcat de

jaime palenzuela rodriguezTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

ADDENDUM To IOM - Tech Notes: Electronically Commutated Motor (ECM) - Test & Info

Încărcat de

jaime palenzuela rodriguezDrepturi de autor:

Formate disponibile

“Tech Notes” your one or two page technical solution

ADDENDUM to IOM – Tech Notes

Electronically Commutated Motor (ECM) – Test & info

Testing ECM Motors

ECM motors behave differently from standard shaded pole or PSC motors. They have an unusual start sequence which can

seem erratic and give the impression that the motor is defective. Also it is not possible to identify a bad ECM motor with an

ohm meter or a continuity tester. An ohm meter placed on the terminals of an ECM motor can show open circuit or high

impedance even when the motor is good. Because of these differences HTPG is issuing the following test method to help the

service technician identify bad ECM motors. For best results follow the test sequence in the order it appears below.

EC Motor Functional Test

Note: Startup total time can be up to 10 seconds.

1. CAUTION: DISCONNECT POWER BEFORE SERVICING! ALWAYS FOLLOW SAFE WORK PRACTICES!

USE LOCKOUT TAGOUT PROCEDURES TO PREVENT OTHERS FROM ENERGIZING THE CIRCUIT

WHILE YOU ARE WORKING!

2. Check the motor (and fan if attached) to make sure they are not obstructed from turning. When turning the shaft

manually the required torque will vary due to the motor’s internal magnets.

3. Check the motor leads and plugs for damage. Make sure the plugs mate properly with the receptacle sockets.

4. If a fan is attached, make sure that it is safely guarded so it will not hit anyone or anything. Remove the fan if

testing without a fan guard.

5. Safely energize the motor with the motor nameplate voltage. This is usually the same as the unit nameplate

voltage but in some cases they may differ. (Use care to apply the proper voltage. Applying 230V to an 115V

rated motor will destroy the motor!

6. Immediately after applying power the motor goes through an alignment routine during which the motor moves to

a starting position. During this routine the motor may start and stop or twitch and may even briefly move

backwards (it will not move if the mot or is already properly positioned).

7. The motor will then begin to run in the proper direction and ramp up to full speed.

8. If the motor is good, safely disconnect it and return it to service.

9. If the motor is faulty, pack it securely to prevent damage and return it for evaluation.

Other Considerations

ECM motors are more susceptible to shipping and handling damage than shaded pole or PSC motors. The internal control

board can separate from its mounts and destroy the motor if it is hit or dropped. Don’t use any motors which have been hit or

dropped.

See our websites for even more info www.RussellCoil.com, www.WittHtp.com, ww.ColdZone.com, and www.KramerUSA.net

under “Products and Literature” and/or “Tech Tips”.

Thank you for helping us “help” our Customer.

Heat Transfer Products Group, LLC.

3050 Enterprise Street - Brea, California 92821

(800) 772-2653 - (714) 529-8503 FAX

1/5/2010 Page 1 of 1 ECM TEST SERVICE TIPS Rev 0 0.doc

S-ar putea să vă placă și

- Elevator Troubleshooting & Repair: A Technician's Certification Study GuideDe la EverandElevator Troubleshooting & Repair: A Technician's Certification Study GuideEvaluare: 4 din 5 stele4/5 (9)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideDe la EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideEvaluare: 4.5 din 5 stele4.5/5 (8)

- Operator’S Guide to Rotating Equipment: An Introduction to Rotating Equipment Construction, Operating Principles, Troubleshooting, and Best PracticesDe la EverandOperator’S Guide to Rotating Equipment: An Introduction to Rotating Equipment Construction, Operating Principles, Troubleshooting, and Best PracticesEvaluare: 5 din 5 stele5/5 (3)

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003De la EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Evaluare: 5 din 5 stele5/5 (1)

- Backbone Microwave Technical Proposal V1.1Document23 paginiBackbone Microwave Technical Proposal V1.1Salman LabiadhÎncă nu există evaluări

- VOLVO 7748542 - US - Installation EMS 2 - D13Document62 paginiVOLVO 7748542 - US - Installation EMS 2 - D13Cui100% (4)

- ACS800 - 304 - Suppl - User Manual PDFDocument82 paginiACS800 - 304 - Suppl - User Manual PDFAlamgir Robin0% (1)

- Biến tần Emerson EV1000Document160 paginiBiến tần Emerson EV1000Masterking King50% (4)

- High-Performance Ignition Systems: Design, Build & InstallDe la EverandHigh-Performance Ignition Systems: Design, Build & InstallEvaluare: 4 din 5 stele4/5 (9)

- B Series AC Servo Drive ManualDocument76 paginiB Series AC Servo Drive ManualRashidul HasanÎncă nu există evaluări

- Electro MechanicalDocument6 paginiElectro MechanicalGlen CoronadÎncă nu există evaluări

- All-Test Iv Pro: Motor Circuit AnalyzerDocument6 paginiAll-Test Iv Pro: Motor Circuit AnalyzerJorge Luis Torrico CalatayudÎncă nu există evaluări

- MD Trophy For DriverDocument8 paginiMD Trophy For Drivervishal_bokaroÎncă nu există evaluări

- 13 Common Causes of Motor FailureDocument16 pagini13 Common Causes of Motor FailureSamrong Chek BEÎncă nu există evaluări

- Hyundai Installation and Maintenance ManualDocument15 paginiHyundai Installation and Maintenance ManualHüseyin Vedat TekinÎncă nu există evaluări

- ES Series Hardware Manual170413Document64 paginiES Series Hardware Manual170413Oscar MontañezÎncă nu există evaluări

- ASDA A2 ManualDocument583 paginiASDA A2 ManualClaudio Lourenço da Silva100% (1)

- Jc60evo ManualDocument12 paginiJc60evo ManualGerman ParamoÎncă nu există evaluări

- Ignition System - Repair ProceduresDocument79 paginiIgnition System - Repair ProcedurescayberrahmadakÎncă nu există evaluări

- ASDA B2 ManualDocument311 paginiASDA B2 ManualWill SousaÎncă nu există evaluări

- C11, C13 and C15 On-Highway Engines-Maintenance IntervalsDocument42 paginiC11, C13 and C15 On-Highway Engines-Maintenance Intervalsgordoninkl9941100% (1)

- SDE English Manual UL v105 01Document274 paginiSDE English Manual UL v105 01FehmiturkÎncă nu există evaluări

- Electric Motor Controls TutorialDocument24 paginiElectric Motor Controls TutorialKim KeatÎncă nu există evaluări

- DC Injection Motor Brake InstructionsDocument11 paginiDC Injection Motor Brake Instructionsprasiva@04Încă nu există evaluări

- Start TestDocument2 paginiStart Testhelp3rÎncă nu există evaluări

- Akbar Dan ArisDocument43 paginiAkbar Dan ArisGomzalez Bin GembozÎncă nu există evaluări

- SDE User Manual - V1.01Document242 paginiSDE User Manual - V1.01FehmiturkÎncă nu există evaluări

- SHIHLIN - SERVO-SDE Manual V1.04Document266 paginiSHIHLIN - SERVO-SDE Manual V1.04Robert PowerÎncă nu există evaluări

- How To Check An Electric Motor - 12 Steps (With Pictures) - WikihowDocument9 paginiHow To Check An Electric Motor - 12 Steps (With Pictures) - WikihowAlamin SiddiqueÎncă nu există evaluări

- Evinrude 150 & 175 FFI (Ficht) OEM Service Manual 520211Document188 paginiEvinrude 150 & 175 FFI (Ficht) OEM Service Manual 520211Jacques DionneÎncă nu există evaluări

- PCC & MCCDocument11 paginiPCC & MCCPhani VarmaÎncă nu există evaluări

- Catalog MPDocument28 paginiCatalog MPCARLOSWAR101Încă nu există evaluări

- Electrical System Motor MaintenanceDocument7 paginiElectrical System Motor MaintenanceoritasÎncă nu există evaluări

- Gas Cylinder Scale: Installation and Service ManualDocument25 paginiGas Cylinder Scale: Installation and Service ManualRicardo Vazquez SalinasÎncă nu există evaluări

- 1.troubleshoot Engine Crank But Cant StartDocument3 pagini1.troubleshoot Engine Crank But Cant StartsyahrilÎncă nu există evaluări

- Week 101Document48 paginiWeek 101Raphael SebucÎncă nu există evaluări

- FEM Rotor 2Document12 paginiFEM Rotor 2MirceaÎncă nu există evaluări

- Schneider Atv303 PDFDocument112 paginiSchneider Atv303 PDFchidambaram kasiÎncă nu există evaluări

- Mega TorqueDocument354 paginiMega TorqueGuilherme AugustoÎncă nu există evaluări

- MCC 1Document14 paginiMCC 1Arif SugestyanÎncă nu există evaluări

- AC Motor Installation - Maintenance Instructions: HandlingDocument4 paginiAC Motor Installation - Maintenance Instructions: HandlingEkakitie EseÎncă nu există evaluări

- ASTAT Plus Manual PDFDocument35 paginiASTAT Plus Manual PDFJesús Martin V MinayaÎncă nu există evaluări

- Owner's Manual: 3-Phase Charging System For "EVO" P/N ASM2005Document12 paginiOwner's Manual: 3-Phase Charging System For "EVO" P/N ASM2005Bob GinelÎncă nu există evaluări

- U660E: Diagnosing The Toyota 6-Speed: SmartDocument6 paginiU660E: Diagnosing The Toyota 6-Speed: SmartDaniel HernandezÎncă nu există evaluări

- Maintenance of Motors and GeneratorsDocument116 paginiMaintenance of Motors and GeneratorsAtiqur RahmanÎncă nu există evaluări

- AC Motor - For Maintenance and Protection Engineers-Part-1: Qazi Arsalan HamidDocument6 paginiAC Motor - For Maintenance and Protection Engineers-Part-1: Qazi Arsalan HamidkaraislimÎncă nu există evaluări

- Extend Motor Operlife Motor Systemts3Document2 paginiExtend Motor Operlife Motor Systemts3oscarÎncă nu există evaluări

- Hardware Manual ACS850-04 Drive Modules (55 160 KW, 75 200 HP)Document106 paginiHardware Manual ACS850-04 Drive Modules (55 160 KW, 75 200 HP)cuongvcs100% (1)

- Installation EMS 2 Dec-08Document70 paginiInstallation EMS 2 Dec-08DanielDosSantosLÎncă nu există evaluări

- How To Test and Repair Small Engine Ignition System ProblemsDocument5 paginiHow To Test and Repair Small Engine Ignition System ProblemsAlfred E. NewmanÎncă nu există evaluări

- Starter Motor Application & Conditions of Use: 1. ApplicationsDocument2 paginiStarter Motor Application & Conditions of Use: 1. Applicationsalfa24161305Încă nu există evaluări

- Astat Plus: GE Power ControlsDocument35 paginiAstat Plus: GE Power ControlsRafael CastilloÎncă nu există evaluări

- 9907-Tips For TroubleshootingDocument7 pagini9907-Tips For TroubleshootingnasrunÎncă nu există evaluări

- Electric Motor Controls TutorialDocument24 paginiElectric Motor Controls Tutorialvijai daniel100% (4)

- Ignition, Timing And Valve Setting: A Comprehensive Illustrated Manual of Self-Instruction for Automobile Owners, Operators, Repairmen, and All Interested in Motoring.De la EverandIgnition, Timing And Valve Setting: A Comprehensive Illustrated Manual of Self-Instruction for Automobile Owners, Operators, Repairmen, and All Interested in Motoring.Evaluare: 3 din 5 stele3/5 (4)

- Diesel Engine Care and Repair: A Captain's Quick GuideDe la EverandDiesel Engine Care and Repair: A Captain's Quick GuideEvaluare: 5 din 5 stele5/5 (1)

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusDe la EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusÎncă nu există evaluări

- Automotive Electronic Diagnostics (Course 2)De la EverandAutomotive Electronic Diagnostics (Course 2)Evaluare: 4 din 5 stele4/5 (2)

- Chainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesDe la EverandChainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesEvaluare: 5 din 5 stele5/5 (1)

- Automotive Equipment Usage and Repair StrategiesDe la EverandAutomotive Equipment Usage and Repair StrategiesEvaluare: 5 din 5 stele5/5 (1)

- Johnson Industrial Screens PDFDocument20 paginiJohnson Industrial Screens PDFjaime palenzuela rodriguezÎncă nu există evaluări

- S 00 1310 002Document13 paginiS 00 1310 002jaime palenzuela rodriguezÎncă nu există evaluări

- Goulds PMP Booster Forsta 15 BFF Opción 2Document4 paginiGoulds PMP Booster Forsta 15 BFF Opción 2jaime palenzuela rodriguezÎncă nu există evaluări

- More User Manuals OnDocument8 paginiMore User Manuals Onjaime palenzuela rodriguezÎncă nu există evaluări

- Frigidaire FGHC2335LE 23 Cu. FTDocument20 paginiFrigidaire FGHC2335LE 23 Cu. FTjaime palenzuela rodriguezÎncă nu există evaluări

- Frigidaire Freestanding TopFreezer Refrigerator FFHT1814LBDocument13 paginiFrigidaire Freestanding TopFreezer Refrigerator FFHT1814LBjaime palenzuela rodriguezÎncă nu există evaluări

- System Charging and SetupDocument2 paginiSystem Charging and SetupArun RajÎncă nu există evaluări

- Icing in Walk-In Freezers: William Salomon Quality Manager HTPG Scottsboro, AlDocument6 paginiIcing in Walk-In Freezers: William Salomon Quality Manager HTPG Scottsboro, Aljaime palenzuela rodriguezÎncă nu există evaluări

- Características Específicas de Los Seriales de Los Compresores PanasonicDocument5 paginiCaracterísticas Específicas de Los Seriales de Los Compresores PanasonicGesner piambaÎncă nu există evaluări

- Superheat: ADDENDUM To IOM - Tech NotesDocument2 paginiSuperheat: ADDENDUM To IOM - Tech Notesjaime palenzuela rodriguezÎncă nu există evaluări

- HTPG 18 Digit Serial Number: Manufacturing Facility Year Month Order Number Line Item Number Unit NumberDocument1 paginăHTPG 18 Digit Serial Number: Manufacturing Facility Year Month Order Number Line Item Number Unit Numberjaime palenzuela rodriguezÎncă nu există evaluări

- ADDENDUM To IOM - Tech Notes: Electronically Commutated Motor (ECM) - Test & InfoDocument1 paginăADDENDUM To IOM - Tech Notes: Electronically Commutated Motor (ECM) - Test & Infojaime palenzuela rodriguezÎncă nu există evaluări

- Condensing Unit Option CodesDocument5 paginiCondensing Unit Option Codesjaime palenzuela rodriguezÎncă nu există evaluări

- Frigidaire Freestanding TopFreezer Refrigerator FFHT1814LBDocument13 paginiFrigidaire Freestanding TopFreezer Refrigerator FFHT1814LBjaime palenzuela rodriguezÎncă nu există evaluări

- Flood Valve or Head Master: ADDENDUM To IOM - Tech NotesDocument2 paginiFlood Valve or Head Master: ADDENDUM To IOM - Tech Notesjaime palenzuela rodriguezÎncă nu există evaluări

- York Packaged Air ConditionerDocument1 paginăYork Packaged Air Conditionerjaime palenzuela rodriguezÎncă nu există evaluări

- Freezer - Refrigerator Glass Door RefrigeratorDocument45 paginiFreezer - Refrigerator Glass Door Refrigeratorjaime palenzuela rodriguezÎncă nu există evaluări

- Chemical Storage Tank Systems and AccessoriesDocument84 paginiChemical Storage Tank Systems and AccessoriesaymenkaramÎncă nu există evaluări

- Frigidaire Freestanding TopFreezer Refrigerator FFHT1814LBDocument13 paginiFrigidaire Freestanding TopFreezer Refrigerator FFHT1814LBjaime palenzuela rodriguezÎncă nu există evaluări

- Refrigeracion Neveras DomesticasDocument35 paginiRefrigeracion Neveras Domesticasjaime palenzuela rodriguezÎncă nu există evaluări

- Gringer CatalogueDocument2 paginiGringer Cataloguejaime palenzuela rodriguezÎncă nu există evaluări

- Selector Guide PDFDocument45 paginiSelector Guide PDFTudosie AlexeyÎncă nu există evaluări

- Spare Parts Accessories Catalogue DANFOSSDocument32 paginiSpare Parts Accessories Catalogue DANFOSSjaime palenzuela rodriguezÎncă nu există evaluări

- Smart DustbinDocument30 paginiSmart DustbinAditya ConsultancyÎncă nu există evaluări

- TD04803001E - Visual Designer Driver ListDocument8 paginiTD04803001E - Visual Designer Driver Listrogermantilla08Încă nu există evaluări

- EE-103: Electrical Engineering: Chap:6 (Part I) CapacitorsDocument27 paginiEE-103: Electrical Engineering: Chap:6 (Part I) CapacitorsZarak KhanÎncă nu există evaluări

- STC SA02511SE Installation Manual & Instructions For Continued Airworthiness CC Series Fuel Level SenderDocument35 paginiSTC SA02511SE Installation Manual & Instructions For Continued Airworthiness CC Series Fuel Level SenderJednipat Panyawipat100% (1)

- Legislation and Codes of PracticeDocument1 paginăLegislation and Codes of Practicebuddhika MadusankaÎncă nu există evaluări

- Experiment 1Document6 paginiExperiment 1Yash ShirudeÎncă nu există evaluări

- 7sr45 Self Powered Overcurrent Protection RelayDocument16 pagini7sr45 Self Powered Overcurrent Protection RelayIvan SalapićÎncă nu există evaluări

- Ob3316 PDFDocument12 paginiOb3316 PDFKareka top3Încă nu există evaluări

- Takshila VLSI BrochureDocument8 paginiTakshila VLSI Brochuretariq786Încă nu există evaluări

- Centac CMC Technical Reference Manual: Ingersoll-RandDocument177 paginiCentac CMC Technical Reference Manual: Ingersoll-RandidigitiÎncă nu există evaluări

- Weller WLC100 Electronic Soldering StationDocument4 paginiWeller WLC100 Electronic Soldering Stationrik206Încă nu există evaluări

- 9 MultimeterDocument8 pagini9 MultimeterrameshÎncă nu există evaluări

- Banco de Transformadores y Grupos de ConexiónDocument6 paginiBanco de Transformadores y Grupos de ConexiónWilson Francisco BritoÎncă nu există evaluări

- Modeling and Analysis of DC-DC Converters Under Pulse Skipping ModulationDocument6 paginiModeling and Analysis of DC-DC Converters Under Pulse Skipping ModulationJeba AntonyÎncă nu există evaluări

- Gmdss Battery Capacity TestDocument1 paginăGmdss Battery Capacity TestanusprasadÎncă nu există evaluări

- E40Document3 paginiE40Nanda Kumar100% (1)

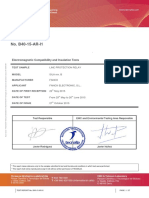

- Test Report: No. B40-15-AR-I1Document37 paginiTest Report: No. B40-15-AR-I1anbkhn90Încă nu există evaluări

- HUAWEI G526 Maintenance Manual (G526, V1.0, English, Normal) PDFDocument103 paginiHUAWEI G526 Maintenance Manual (G526, V1.0, English, Normal) PDFEdicson TarazonaÎncă nu există evaluări

- Wireless Fingerprint Attendance Marking System: Aarushi Jalundhwala Pratik Jhaveri Sandeep Khudanpur Amit DeshmukhDocument5 paginiWireless Fingerprint Attendance Marking System: Aarushi Jalundhwala Pratik Jhaveri Sandeep Khudanpur Amit Deshmukh27051977Încă nu există evaluări

- SRC5000/6000/8000/10000 Va Xli/uxi/uxich 220/230/240 VacDocument22 paginiSRC5000/6000/8000/10000 Va Xli/uxi/uxich 220/230/240 VacMian Aqeel YousafÎncă nu există evaluări

- TransformerDocument81 paginiTransformerMuluken FilmonÎncă nu există evaluări

- Work Order Number Site Name Print Date WO Due Date C0219-CI-2502-504-3-001-A Project Name: Revision Reason: Project DescriptionDocument41 paginiWork Order Number Site Name Print Date WO Due Date C0219-CI-2502-504-3-001-A Project Name: Revision Reason: Project Descriptionjulio villaÎncă nu există evaluări

- Siemens 7SJ6x V4.7 XRIO Converter Manual ENU TU2.30 V2.201Document10 paginiSiemens 7SJ6x V4.7 XRIO Converter Manual ENU TU2.30 V2.201துரைராஜ் இலட்சுமணன்Încă nu există evaluări

- Preliminary Drawing: Molded Section ViewDocument1 paginăPreliminary Drawing: Molded Section ViewTesoro HonÎncă nu există evaluări

- Control DrawingDocument7 paginiControl DrawingYasir SajjadÎncă nu există evaluări

- 4WRA (E) B Válvulas Direccionales ProporcionalesDocument8 pagini4WRA (E) B Válvulas Direccionales ProporcionalesCarlos Andrés CuelloÎncă nu există evaluări

- Accuracy: Ease of UseDocument2 paginiAccuracy: Ease of UseAbhijitÎncă nu există evaluări

- Silicon Chip 2008.03Document108 paginiSilicon Chip 2008.03David Elias Flores Escalante100% (4)

- Gewiss (SocketIsolator) PDFDocument96 paginiGewiss (SocketIsolator) PDFttyÎncă nu există evaluări