Documente Academic

Documente Profesional

Documente Cultură

Technical Proposal Descaling Removal Pulai - A (2013 ASD)

Încărcat de

hash117Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Technical Proposal Descaling Removal Pulai - A (2013 ASD)

Încărcat de

hash117Drepturi de autor:

Formate disponibile

[SECTION A – TECHNICAL PROPOSAL: PROVISION OF

SUPPLY DESCALING PUMP & TECHNICIAN TO

REMOVE SCALE DETECTED AT PULAI –A PLATFORM]

TABLE OF CONTENT

SECTION A: TECHNICAL PROPOSAL

T1 GENERAL

1.0 PROJECT OBJECTIVES

2.0 GENERAL METHOD OF STATEMENT

3.0 SCOPE OF WORK

T2 WORK PROCEDURE

1.0 PURPOSE

2.0 REFERENCE DOCUMENTS

3.0 EQUIPMENT AND SUPPLIES

4.0 PREPARATION

5.0 WORK INSTRUCTION

T3 EQUIPMENT SET UP AND LAYOUT

T4 DELIVERY PLAN

T5 PROJECT ORGANIZATION CHART

T6 JOB SAFETY ANALYSIS

T7 QUALITY PLAN

SECTION B: ATTACHMENT

T8 COMMERCIAL PROPOSAL

T9 MSDS

Process Technology Expert Team | Confidential

[SECTION A – TECHNICAL PROPOSAL: PROVISION OF

SUPPLY DESCALING PUMP & TECHNICIAN TO

REMOVE SCALE DETECTED AT PULAI –A PLATFORM]

SECTION A: TECHNICAL PROPOSAL

Process Technology Expert Team | Confidential

[SECTION A – TECHNICAL PROPOSAL: PROVISION OF

SUPPLY DESCALING PUMP & TECHNICIAN TO

REMOVE SCALE DETECTED AT PULAI –A PLATFORM]

T 1: GENERAL

Process Technology Expert Team | Confidential

[SECTION A – TECHNICAL PROPOSAL: PROVISION OF

SUPPLY DESCALING PUMP & TECHNICIAN TO

REMOVE SCALE DETECTED AT PULAI –A PLATFORM]

1.0 PROJECT OBJECTIVES

The main objective of cleaning process is to remove inorganic & organic compound and

any other scale contaminate in pipe line system. This proposal provides general

guideline for execution of DESCALING activities of pipeline system for PULAI A

platform.The main contaminants to be avoided and/or eliminated are hydrocarbon oils

and greases, which are easily combustible and particulate matter, which can easily ignite

or cause ignition and also scale which clog the piping system

GENERAL METHOD OF STATEMENT

1. PTET (M) SDN BHD (PTETSB) will use 3 stages of chemical cleaning process for

descaling cleaning. Each stage will proceed in sequence to give maximum cleaning

effect at low and effective operating cost.

Alkaline Cleaning/Degreasing

Acid descaling

Neutralizing

3.0 SCOPE OF WORK

BY PTET (M) SDN BHD (PTETSB)

1. To supply of manpower, equipments, tools, materials and consumables.

2. Transportation for PTET (PTETSB) personnel to and from job location.

3. Transportation for PTET (PTETSB) equipments, tools and materials to and

from job location.

4. To supply safety equipment (PPE) for personnel carrying out the works.

5. To dismantle valve and blind flange for chemical injection and discharge point

6. To blind all identified area for chemical circulation stage

7. To perform descaling job on pipeline

8. To do regular or daily reports.

9. To prepare and discuss Safety Job Analysis (JSA) with OWNER and

contractor.

10. To generate final report.

BY PETRONAS CARIGALI SDN BHD

1. Isolation work for the pipeline before hand over to PTET (PTETSB)

2. To supply utilities (water, diesel)

3. To supply lifting equipment for mobilization/set up at site

BY PFC ENGINEERING SDN BHD

1. To erect and dismantle scaffolding if required.

2. To supply air compressor

3. To assist PTET manpower for setup equipment and rigging work.

4. To supply new gasket and bolt nut (if required)

Process Technology Expert Team | Confidential

[SECTION A – TECHNICAL PROPOSAL: PROVISION OF

SUPPLY DESCALING PUMP & TECHNICIAN TO

REMOVE SCALE DETECTED AT PULAI –A PLATFORM]

T 2: WORK PROCEDURE

Process Technology Expert Team | Confidential

[SECTION A – TECHNICAL PROPOSAL: PROVISION OF

SUPPLY DESCALING PUMP & TECHNICIAN TO

REMOVE SCALE DETECTED AT PULAI –A PLATFORM]

1.0 PURPOSE

This document outlines the procedure of

1. Descaling of pipe line service.

2.0 REFERENCE DOCUMENTS

1. PTET (M) SDN BHD (PTETSB) Quality System

2. PTS (Design & Engineering Practice - manual cleaning of equipment PTS 70108011 -

January 1998)

3. Chemical Safety Data Sheet

4. Daily log sheet

3.0 EQUIPMENTS AND SUPPLIES

1. Circulation Tank

2. Diesel Engine Skid Pump

3. Filter Skid

4. Spring Hoses

5. Test Kit

4.0 CHEMIICALS

1. PT001 (Degreaser)

2. PT002 (Acid Descaling)

3. PT003 (Neutralizing agent for acid)

4. PT004 (Anti foam)

5. PT005 (Neutralizing agent for base)

5.0 PREPARATION

1. Isolation work done by PCSB

2. Barricade place of work.

3. Set all equipment in proper place.

4. Proper hand over to PTET (M) SB (PTETSB).

Process Technology Expert Team | Confidential

[SECTION A – TECHNICAL PROPOSAL: PROVISION OF

SUPPLY DESCALING PUMP & TECHNICIAN TO

REMOVE SCALE DETECTED AT PULAI –A PLATFORM]

2.0 WORK INSTRUCTION

2.1 Chemical Cleaning

Stage 1: Leak Test/ Water Circulation

1.1 Once the hoses connection has been assembled, the system is filled up with service

water to do water leak test to ensure no leaking in the system.

1.2 Circulate water into the system while maintaining 30% - 40% water inside the

circulation tank.

1.3 Continue circulating water for at least 1 hour.

1.4 Check the all fitting and connection.

1.5 If leak stop the pump and repair the leakage.

Stage 2: Alkaline Cleaning/Degreasing

2.1 Add PT001 into the circulation system gradually until 5% to 10% alkaline

concentration is achieved. The purpose of this process is to remove oil, grease and

hydro carbon from the inside of pipe.

2.2 Check the pH and maintain the pH between 12 to 14.

2.3 Check the pH every hour. If the pH drops increase the pH concentration gradually by

adding PT001. Circulate the solution for minimum 8 hours.

2.4 Change the filter bag if the pressure reaches 3 bar during circulation process.

2.5 Check the alkali concentration by 6P meter and if the concentration becomes

constant which indicate no activities and all oil & grease have been removed.

2.6 Once the cleaning complete, naturalized the system by adding PT005.

2.7 Check the pH and drain the neutralized solution once pH achieves 6 to 8.

2.8 Flush the system with water to remove all alkaline content.

2.9 Circulate the solution through the system for 1 to 2 hours by back flushing

Stage 3: Acid Descaling

3.1 Add PT002 into the circulation system gradually until 5% to 10% acid concentration

is achieved.

3.2 Check the pH and maintain the pH between 1 to 3

3.3 Check the pH every hour. If the pH drops increase the pH concentration gradually by

adding PT002.

3.3 Circulate the solution for minimum 10 to 12 hours or until Iron content is stable.

3.4 Record pH and Iron content during circulation for every hour.

3.5 Stop the acid cleaning stage once the iron level gives a consistence reading.

3.6 Neutralized the acid solution by adding PT003.

3.7 Continue circulation until the pH reach 6 to 8 by back flushing.

3.8 Discharge the solution to disposal area.

Process Technology Expert Team | Confidential

[SECTION A – TECHNICAL PROPOSAL: PROVISION OF

SUPPLY DESCALING PUMP & TECHNICIAN TO

REMOVE SCALE DETECTED AT PULAI –A PLATFORM]

Stage 4: Neutralization

4.1 Continuously flushing system with fresh water until the pH achieves pH 7 to 8

4.2 Maintain circulation for 2 hours.

4.3 Check the pH and then drain the solution to open drain.

Revision

Revision Date Revision Description Revised By Approved By

No.

0 10/ 4 / 2013 Pipe line descaling work HH BI

Notes:

HH– Hisham Hafizin

BI – Basyaruddin Ismail

Prepared By : Approved By :

hisham BASYAR

PROJECT ENGINEER PROJECT MANAGER

Process Technology Expert Team | Confidential

[SECTION A – TECHNICAL PROPOSAL: PROVISION OF

SUPPLY DESCALING PUMP & TECHNICIAN TO

REMOVE SCALE DETECTED AT PULAI –A PLATFORM]

T 3: EQUIPMENT SET UP & LAYOUT

Process Technology Expert Team | Confidential

[SECTION A – TECHNICAL PROPOSAL: PROVISION OF SUPPLY DESCALING

PUMP & TECHNICIAN TO REMOVE SCALE DETECTED AT PULAI –A

PLATFORM]

Process Technology Expert Team | Confidential

[SECTION A – TECHNICAL PROPOSAL: PROVISION OF SUPPLY

DESCALING PUMP & TECHNICIAN TO REMOVE SCALE DETECTED AT

PULAI –A PLATFORM]

T 4: DELIVERY PLAN

[Process Technologies Expert Team] |Confidential

[SECTION A – TECHNICAL PROPOSAL: PROVISION OF SUPPLY

DESCALING PUMP & TECHNICIAN TO REMOVE SCALE DETECTED AT

PULAI –A PLATFORM]

DELIVERY PLAN

DESCALING WORK FOR PIPE LINE SYSTEM

TOTAL

ITEM DESCRIPTION 1 2 3 4 5 6 7 8 9 10 11 12 13 14

DAYS

1 Preparation

2 Mobilization

1. Equipment / Inspection

2. Manpower / Safety Briefing

3. Mobilization Equipment & Manpower

Job Execution

DESCALING WORK EXECUTION 14

3 V-130 TO CRUDE SEP (V-320) WATER LINE

3.1.Equipment Set-up & Leak Test

3.2 Degreasing Stage

3.3 Acid Cleaning Stage

3.4 Neutralization Stage

3.5 Housekeeping & Inspection

4 V-120 BOOSTER PUMP LINE

4.1.Equipment Set-up & Leak Test

4.2 Degreasing Stage

4.3 Acid Cleaning Stage

4.4 Neutralization Stage

4.5 Housekeeping & Inspection

5 CRUDE SEP TO CAISSON (WATER LINE)

5.1.Equipment Set-up & Leak Test

5.2 Degreasing Stage

5.3 Acid Cleaning Stage

5.4 Neutralization Stage

5.5 Housekeeping & Inspection

6 PIPELINE V-320 TO V-300

6.1.Equipment Set-up & Leak Test

6.2 Degreasing Stage

6.3 Acid Cleaning Stage

6.4 Neutralization Stage

6.5 Housekeeping & Inspection

6.6 Demobilization

TOTAL 14

[Process Technologies Expert Team] |Confidential

[SECTION A – TECHNICAL PROPOSAL: PROVISION OF SUPPLY

DESCALING PUMP & TECHNICIAN TO REMOVE SCALE DETECTED AT

PULAI –A PLATFORM]

T 5: PROJECT ORGANIZATION CHART

[Process Technologies Expert Team] |Confidential

[SECTION A – TECHNICAL PROPOSAL: PROVISION OF SUPPLY

DESCALING PUMP & TECHNICIAN TO REMOVE SCALE DETECTED AT

PULAI –A PLATFORM]

PROPOSED PROJECT ORGANIZATION CHART

DESCALING WORK FOR PIPE LINE SYSTEM

[Process Technologies Expert Team] |Confidential

[SECTION A – TECHNICAL PROPOSAL: PROVISION OF SUPPLY

DESCALING PUMP & TECHNICIAN TO REMOVE SCALE DETECTED AT

PULAI –A PLATFORM]

T 6: JOB SAFETY ANALYSIS

[Process Technologies Expert Team] |Confidential

[SECTION A – TECHNICAL PROPOSAL: PROVISION OF SUPPLY

DESCALING PUMP & TECHNICIAN TO REMOVE SCALE DETECTED AT

PULAI –A PLATFORM]

DESCALING WORK FOR PIPE LINE SYSTEM

JOB SAFETY ANALYSIS

Name Designation Date Signature

Prepared by Hisham Hafizin Project Engineer 10/04/13

Reviewed by Basyaruddin Ismail Project Manager 10/04/13

Approved by

Hazard Checklist

Slippery Floor Swinging Object Falling Object Escape Route Sharp Object

Falling Blocked Drain Heavy Load Secure Ladder Trap Pressure

Dust Hose Connection Environment Spill Tripping Others Object Close by

NO. JOB STEP POTENTIAL HAZARD CONTROL MEASURES ACTION BY

Setting-up equipment Air flow/ Electricity/ Slippery Conduct daily safety toolbox meeting, brief workers All workers

1 Floor at height, safe containment and arrangement of tools

at high elevation, used of proper PPE

Mobilize of equipment, Falling of items during All personnel are to abide the works procedure All workers

2 materials and tools transportation regulation to maintain highly safety precaution at

worksite

[Process Technologies Expert Team] |Confidential

[SECTION A – TECHNICAL PROPOSAL: PROVISION OF SUPPLY

DESCALING PUMP & TECHNICIAN TO REMOVE SCALE DETECTED AT

PULAI –A PLATFORM]

3 Offload items from Falling object Brief workers on precautionary, avoid working Site Supervisor

lorry / forklift and beneath area

lifting of equipment

Broken sling Use proper sling for lifting All workers

Limited space causing accident Barricade and put signage at working place All workers

Arrange equipment properly to avoid blockage access All workers

to safety equipment

4 Loosen bolt nuts, Trap pressure Loosen bolts and nuts slowly, with care

opening spool, valves, All workers

flanges or pumps Tripping hazard Wear proper PPE

All workers

Installation and Tripping hazard Watch your step, use right tools. All workers

5 removing pipes / hoses

Knock by object Arrange pipes / hoses not to obstruct access way All workers

6 Hazardous chemical Spillage Sealed and label the waste drum Site Supervisor

waste handling

Waste tainted Wear proper PPE All workers

7 House keeping Personal injury Wear complete PPE All workers

[Process Technologies Expert Team] |Confidential

[SECTION A – TECHNICAL PROPOSAL: PROVISION OF SUPPLY

DESCALING PUMP & TECHNICIAN TO REMOVE SCALE DETECTED AT

PULAI –A PLATFORM]

T 7: QUALITY PLAN

[Process Technologies Expert Team] |Confidential

[SECTION A – TECHNICAL PROPOSAL: PROVISION OF SUPPLY

DESCALING PUMP & TECHNICIAN TO REMOVE SCALE DETECTED AT

PULAI –A PLATFORM]

DESCALING WORK FOR PIPE LINE SYSTEM

PFC ENGINEERING SDN BHD

QUALITY PLAN

NO. JOB SCOPE CONTROL MEASURE ACTION BY

Site Supervisor /

1 Allocate working area Barricade and signage at work place

All workers

All tools and equipment must be inspected

2 Setting-up equipment Site Supervisor

and certified by PFCE

Site Supervisor/ All

3 Chemical Handling Hose and fitting to be proper install

workers

Sealed and label all of the waste drum- If Site Supervisor/

4 Waste Handling

applicable All Workers

6 On site testing Visual inspection Site Supervisor

Site Supervisor

7 Daily report Ensure daily report write in log book.

[Process Technologies Expert Team] |Confidential

[SECTION B – COMMERCIAL PROPOSAL

PROVISION OF SUPPLY DESCALING PUMP &

TECHNICIAN TO REMOVE SCALE DETECTED AT

PULAI –A PLATFORM]

SECTION B: ATTACHMENT

[Process Technologies Expert Team] |Confidential

[SECTION B – COMMERCIAL PROPOSAL

PROVISION OF SUPPLY DESCALING PUMP &

TECHNICIAN TO REMOVE SCALE DETECTED AT

PULAI –A PLATFORM]

T8: COMMERCIAL PROPOSAL

[Process Technologies Expert Team] |Confidential

[SECTION B – COMMERCIAL PROPOSAL

PROVISION OF SUPPLY DESCALING PUMP &

TECHNICIAN TO REMOVE SCALE DETECTED AT

PULAI –A PLATFORM]

T8: MSDS

[Process Technologies Expert Team] |Confidential

S-ar putea să vă placă și

- Sample Commissioning PlanDocument36 paginiSample Commissioning Planvan81% (16)

- Pipeline Systems Dewatering Method Statement and Work Procedure - Rev - A01Document7 paginiPipeline Systems Dewatering Method Statement and Work Procedure - Rev - A01Mitchellgrany80% (5)

- Sop WarehouseDocument6 paginiSop WarehouseVamsee Deepak100% (1)

- Furuno CA 400Document345 paginiFuruno CA 400Димон100% (3)

- Method Statement For Cable Trays & Cable Ladders InstallationDocument7 paginiMethod Statement For Cable Trays & Cable Ladders InstallationJamal Budeiri0% (1)

- Factors Affecting Physical FitnessDocument7 paginiFactors Affecting Physical FitnessMary Joy Escanillas Gallardo100% (2)

- Prorox WM 960 Sa PDFDocument1 paginăProrox WM 960 Sa PDFr afriantoÎncă nu există evaluări

- Renderoc TGDocument2 paginiRenderoc TGMansoor Ali50% (2)

- MESC SPE 74-018 - 2010 - Nickel Alloy Pipe To Astm b167Document7 paginiMESC SPE 74-018 - 2010 - Nickel Alloy Pipe To Astm b167sathi11189Încă nu există evaluări

- P68 M13 Painting Documents PDFDocument708 paginiP68 M13 Painting Documents PDFJohn TerryÎncă nu există evaluări

- MS For Fabrication of Above-Ground Storage TankDocument8 paginiMS For Fabrication of Above-Ground Storage Tankdadz mingiÎncă nu există evaluări

- Oil Pantriting ProcedureDocument5 paginiOil Pantriting ProcedureSERT-QA/QC- BUZÎncă nu există evaluări

- Document Title: Technical Proposal For 6500cbm LNG Storage TankDocument4 paginiDocument Title: Technical Proposal For 6500cbm LNG Storage Tankroni_arsyahÎncă nu există evaluări

- WPS Sa 517Document2 paginiWPS Sa 517DHANANNJAI SINGH -Încă nu există evaluări

- Work Method StatementDocument9 paginiWork Method StatementdjvhÎncă nu există evaluări

- Vessel Final BoxDocument14 paginiVessel Final Boxmanoj thakkarÎncă nu există evaluări

- Project Title - ID: Activity NameDocument5 paginiProject Title - ID: Activity NameRiaz MohammedÎncă nu există evaluări

- PA02 Spec MIT Spot & Soda Blasting (IFC)Document7 paginiPA02 Spec MIT Spot & Soda Blasting (IFC)Mohd YusriÎncă nu există evaluări

- Condenser Cladding InfoDocument37 paginiCondenser Cladding Infoabhishe_reenaÎncă nu există evaluări

- 4.2.1 HVA Adhesive Anchor: Anchoring SystemsDocument15 pagini4.2.1 HVA Adhesive Anchor: Anchoring SystemsechavarriÎncă nu există evaluări

- 0610.1 - Shell and Tube Heat ExchangersDocument30 pagini0610.1 - Shell and Tube Heat Exchangersvenkatrangan2003Încă nu există evaluări

- Pump Inatallation, Method StatementDocument8 paginiPump Inatallation, Method StatementbaparisÎncă nu există evaluări

- Tech SpecDocument16 paginiTech SpecKingston RivingtonÎncă nu există evaluări

- Hot Insulation ProcedureDocument8 paginiHot Insulation Procedurered patriotÎncă nu există evaluări

- Flange Insulation PresentationDocument10 paginiFlange Insulation PresentationNadeemÎncă nu există evaluări

- Pig Launcher Fabrication Activity PlanDocument1 paginăPig Launcher Fabrication Activity PlanbeqsÎncă nu există evaluări

- Test Package: Pt. TTN (Tambang Tondano Nusajaya)Document18 paginiTest Package: Pt. TTN (Tambang Tondano Nusajaya)unto gunungÎncă nu există evaluări

- Jacking Procedurefor Construction of Tanks OLDDocument10 paginiJacking Procedurefor Construction of Tanks OLDVikram RangasamyÎncă nu există evaluări

- 131 - 1.9.1.2-85T - 316 Stainless SteelDocument4 pagini131 - 1.9.1.2-85T - 316 Stainless SteelFtg WwfdfÎncă nu există evaluări

- Standard Specification FOR Pipeline Internal CoatingDocument2 paginiStandard Specification FOR Pipeline Internal CoatingRanjan KumarÎncă nu există evaluări

- Mgo Msds PDFDocument5 paginiMgo Msds PDFProtitNazirÎncă nu există evaluări

- Er 100 S 1Document1 paginăEr 100 S 1Oliver Quezada Inostroza100% (1)

- Ducting QAP R02 080822Document2 paginiDucting QAP R02 080822Pavul RajÎncă nu există evaluări

- Section13 Spark TestingDocument3 paginiSection13 Spark TestingGustavoÎncă nu există evaluări

- Interseal 670HDocument2 paginiInterseal 670Hmadmax_mfpÎncă nu există evaluări

- Method Statement For Vertical StructureDocument7 paginiMethod Statement For Vertical StructureAdel SaqqaÎncă nu există evaluări

- API-1000-11 - Rev - 0WPSAPI5L x42-x52 PDFDocument3 paginiAPI-1000-11 - Rev - 0WPSAPI5L x42-x52 PDFSailesh SharmaÎncă nu există evaluări

- Esab, OK Autrod 12.22 (1222252800)Document1 paginăEsab, OK Autrod 12.22 (1222252800)RodrigoÎncă nu există evaluări

- Method Statement Pipe Handling and AssemblyDocument6 paginiMethod Statement Pipe Handling and AssemblyDanny NguÎncă nu există evaluări

- C1729 Is A New ASTM Standard For Aluminum JacketingDocument2 paginiC1729 Is A New ASTM Standard For Aluminum JacketingTushar Arekar100% (2)

- Daily Consumed Productive Hours: Job No: MRT-FRM-304-109 Responsible Engineer: Saif Ullah KhanDocument4 paginiDaily Consumed Productive Hours: Job No: MRT-FRM-304-109 Responsible Engineer: Saif Ullah KhanSUKhanÎncă nu există evaluări

- Weld Cleaning MethodsDocument7 paginiWeld Cleaning MethodsTrần Thùy LinhÎncă nu există evaluări

- Pigging TerminologyDocument90 paginiPigging TerminologyNaveen TripuraneniÎncă nu există evaluări

- Offer For Kiln Tyre Crack Repair - DroliaDocument5 paginiOffer For Kiln Tyre Crack Repair - DroliaNapoleon Das100% (1)

- Conventional AirsprayDocument218 paginiConventional AirspraylambtranÎncă nu există evaluări

- 8474L-000-JSD-2310-001-4-Protective Coatings PDFDocument31 pagini8474L-000-JSD-2310-001-4-Protective Coatings PDFDo Quynh100% (2)

- Foam Monitor - F - 091318Document16 paginiFoam Monitor - F - 091318rusli bahtiarÎncă nu există evaluări

- 8474l-000-Jsd-2310-001-2-Protective CoatingDocument31 pagini8474l-000-Jsd-2310-001-2-Protective Coatinglebienthuy100% (1)

- Field Joint Coating Installation ProcedureDocument2 paginiField Joint Coating Installation Procedureunix manÎncă nu există evaluări

- (Painting Works) : Inspection and Test PlanDocument2 pagini(Painting Works) : Inspection and Test Planrize1159Încă nu există evaluări

- BTE Dome Brochure Jun 10Document2 paginiBTE Dome Brochure Jun 10م.ذكى فضل ذكىÎncă nu există evaluări

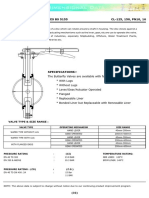

- Butterfly ValveDocument4 paginiButterfly ValveghjtyuÎncă nu există evaluări

- Method Statement For Insulation WorksDocument16 paginiMethod Statement For Insulation WorksAhmed Farman AlqaysiÎncă nu există evaluări

- CESCO Technical ProposalDocument2 paginiCESCO Technical ProposalthmaraishriÎncă nu există evaluări

- PDS-POLYKEN-1027-V1-AUG17 - AARPS-0972 PrymerDocument2 paginiPDS-POLYKEN-1027-V1-AUG17 - AARPS-0972 PrymerJoel SaucedoÎncă nu există evaluări

- KOC-P-005 Rev. 2Document36 paginiKOC-P-005 Rev. 2Hari KrishnanÎncă nu există evaluări

- Pressure Vessel Hydrotest Procedure - Google SearchDocument3 paginiPressure Vessel Hydrotest Procedure - Google SearchAsad KhanÎncă nu există evaluări

- Radiation Safety Distance DiagramDocument3 paginiRadiation Safety Distance DiagramEswaranÎncă nu există evaluări

- Welding Material Control ProcedureDocument12 paginiWelding Material Control ProcedureWalter RuedaÎncă nu există evaluări

- Doc. No Revision No Revision DateDocument6 paginiDoc. No Revision No Revision DateShyam SinghÎncă nu există evaluări

- Quality Assurance ManualDocument6 paginiQuality Assurance ManualEdgarDavidDiazCamposÎncă nu există evaluări

- Hydrotest Pressure Procedure - 2023Document15 paginiHydrotest Pressure Procedure - 2023Amit HasanÎncă nu există evaluări

- 16-Piping Flushing Procedure (KQC 16)Document4 pagini16-Piping Flushing Procedure (KQC 16)Ahmed Gomaa100% (1)

- Project Standards and Specifications Precommissioning Piping Cleaning Rev01Document5 paginiProject Standards and Specifications Precommissioning Piping Cleaning Rev01Tiago HenriquesÎncă nu există evaluări

- ANF Profile New 2019Document17 paginiANF Profile New 2019hash117Încă nu există evaluări

- Job Hazard Analysis (Jha) WorksheetDocument5 paginiJob Hazard Analysis (Jha) Worksheethash117Încă nu există evaluări

- Scope of Work PULAI - ADocument1 paginăScope of Work PULAI - Ahash117Încă nu există evaluări

- Job Hazard Analysis (Jha) WorksheetDocument5 paginiJob Hazard Analysis (Jha) Worksheethash117Încă nu există evaluări

- Jtube & Clamp IFR Drawing - RevB (Comment For Shopdrawing Preparation)Document20 paginiJtube & Clamp IFR Drawing - RevB (Comment For Shopdrawing Preparation)hash117Încă nu există evaluări

- Equipment Layout LHDP-ADocument10 paginiEquipment Layout LHDP-Ahash117Încă nu există evaluări

- Report For PULAI - A Descaling WorkDocument3 paginiReport For PULAI - A Descaling Workhash117Încă nu există evaluări

- Planning For Idemitsu PaintingDocument4 paginiPlanning For Idemitsu Paintinghash117Încă nu există evaluări

- Offshore Crew Change & Covid-19 Screening Protocol PDFDocument3 paginiOffshore Crew Change & Covid-19 Screening Protocol PDFhash117Încă nu există evaluări

- Geran Tanah FikriDocument3 paginiGeran Tanah Fikrihash117Încă nu există evaluări

- List of EquipToolConsumable LabuanDocument12 paginiList of EquipToolConsumable Labuanhash117Încă nu există evaluări

- UPDI & Kenyataan MediaDocument4 paginiUPDI & Kenyataan Mediahash117Încă nu există evaluări

- Survey Report Sample InsulationDocument21 paginiSurvey Report Sample Insulationhash117Încă nu există evaluări

- PROJECT PAPER-Hashim EditedDocument80 paginiPROJECT PAPER-Hashim Editedhash117Încă nu există evaluări

- Scpa Riser Maintenance: Surface Preparation: Painting System Ricever & Assc PipingDocument8 paginiScpa Riser Maintenance: Surface Preparation: Painting System Ricever & Assc Pipinghash117Încă nu există evaluări

- Lab Manual FGS0074Document8 paginiLab Manual FGS0074hash117Încă nu există evaluări

- Heavy Transport Multi Axle Trailer & Lifting ServicesDocument12 paginiHeavy Transport Multi Axle Trailer & Lifting ServicesKaras WillÎncă nu există evaluări

- Task BaruDocument2 paginiTask Baruhash117Încă nu există evaluări

- Moissanite SGS ReportDocument6 paginiMoissanite SGS Reporthash117Încă nu există evaluări

- Untitled Document PDFDocument1 paginăUntitled Document PDFhash117Încă nu există evaluări

- Thahis Cooking Lab: You're Invited To Join Competition For Remake One of The "Thahis Cooking Lab RecipesDocument1 paginăThahis Cooking Lab: You're Invited To Join Competition For Remake One of The "Thahis Cooking Lab Recipeshash117Încă nu există evaluări

- 2019 Sales PresentationDocument13 pagini2019 Sales Presentationhash117Încă nu există evaluări

- MPTDocument78 paginiMPThash117Încă nu există evaluări

- Air Manifold DrawingDocument3 paginiAir Manifold Drawinghash117Încă nu există evaluări

- Laws of Malaysia: ACT 651 Malaysian Health Promotion Board Act 2006Document13 paginiLaws of Malaysia: ACT 651 Malaysian Health Promotion Board Act 2006hash117Încă nu există evaluări

- QA/QC Requirements On FabricationDocument10 paginiQA/QC Requirements On Fabricationhash117Încă nu există evaluări

- OSC Incident - FAC 26 05 15Document4 paginiOSC Incident - FAC 26 05 15hash117Încă nu există evaluări

- Account Opening Form (NRI)Document4 paginiAccount Opening Form (NRI)hash117Încă nu există evaluări

- 20160323014547-16MnCr5 - 16MnCrS5Document1 pagină20160323014547-16MnCr5 - 16MnCrS5Chaitanya DattaÎncă nu există evaluări

- DCS YokogawaDocument17 paginiDCS Yokogawasswahyudi100% (1)

- Frontinus - Water Management of RomeDocument68 paginiFrontinus - Water Management of RomezElfmanÎncă nu există evaluări

- Intel Stratix 10 Avalon - MM Interface For PCI Express Solutions User GuideDocument173 paginiIntel Stratix 10 Avalon - MM Interface For PCI Express Solutions User Guideenoch richardÎncă nu există evaluări

- E-OLSS: Electronic ControlDocument12 paginiE-OLSS: Electronic ControlSamidiÎncă nu există evaluări

- Physics 101Document21 paginiPhysics 101Kuna KunavathiÎncă nu există evaluări

- Aesculap Saw GD307 - Service ManualDocument16 paginiAesculap Saw GD307 - Service ManualFredi PançiÎncă nu există evaluări

- How To Eat WellDocument68 paginiHow To Eat WelleledidiÎncă nu există evaluări

- Abnormalities of Placenta, Amniotic Fluid and Cord: Prepared By, B. Ezhilarasi, Nursing TutorDocument21 paginiAbnormalities of Placenta, Amniotic Fluid and Cord: Prepared By, B. Ezhilarasi, Nursing TutorGopala KrishnanÎncă nu există evaluări

- 04 SAMSS 005 Check ValvesDocument9 pagini04 SAMSS 005 Check ValvesShino UlahannanÎncă nu există evaluări

- Digital Signal Processing: B.E Ece (5Th Semester)Document17 paginiDigital Signal Processing: B.E Ece (5Th Semester)Saatwat CoolÎncă nu există evaluări

- Abdominal Examination OSCE GuideDocument30 paginiAbdominal Examination OSCE Guideزياد سعيدÎncă nu există evaluări

- Material Requirement Planning (MRP)Document55 paginiMaterial Requirement Planning (MRP)Lisa CarlsonÎncă nu există evaluări

- Maha Shivratri: (Shiv Avtaran, Incarnation of God)Document4 paginiMaha Shivratri: (Shiv Avtaran, Incarnation of God)Varsha RoyÎncă nu există evaluări

- Texto CuritibaDocument1 paginăTexto CuritibaMargarida GuimaraesÎncă nu există evaluări

- ReviewerDocument3 paginiReviewerKristine SantominÎncă nu există evaluări

- Sudip Praposal - 1Document20 paginiSudip Praposal - 1Usha BbattaÎncă nu există evaluări

- Army Aviation Digest - Nov 1978Document52 paginiArmy Aviation Digest - Nov 1978Aviation/Space History Library100% (1)

- Chemistry Notes: SUBJECT: Leaving Cert Chemistry Level: TEACHER: Tara LyonsDocument5 paginiChemistry Notes: SUBJECT: Leaving Cert Chemistry Level: TEACHER: Tara LyonsSevinc NuriyevaÎncă nu există evaluări

- Killer Kohler Part I IDocument17 paginiKiller Kohler Part I Irusyn100% (1)

- Updated SAP Cards Requirement JalchdDocument51 paginiUpdated SAP Cards Requirement Jalchdapi-3804296Încă nu există evaluări

- Fret Position Calculator - StewmacDocument1 paginăFret Position Calculator - StewmacJuan Pablo Sepulveda SierraÎncă nu există evaluări

- Solid Modeling Techniques: Constructive Solid Geometry (CSG)Document22 paginiSolid Modeling Techniques: Constructive Solid Geometry (CSG)amolÎncă nu există evaluări

- Ecotopia Remixed II-FormattedDocument54 paginiEcotopia Remixed II-FormattedthisisdarrenÎncă nu există evaluări

- Astm A194 2020Document12 paginiAstm A194 2020rolando cuadro blancoÎncă nu există evaluări

- Maths All FormulasDocument5 paginiMaths All FormulasVishnuÎncă nu există evaluări