Documente Academic

Documente Profesional

Documente Cultură

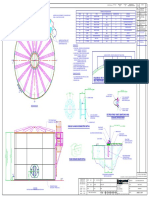

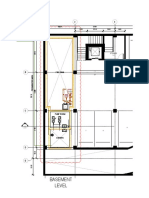

Ecospace: Hoistway Plan View

Încărcat de

Howard RoarkTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Ecospace: Hoistway Plan View

Încărcat de

Howard RoarkDrepturi de autor:

Formate disponibile

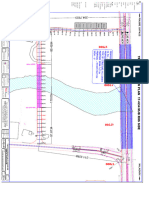

BRKTS ABOVE TOPMOST LANDING - IMPACT LOADING REACTIONS (kN)

REACTION LOCATION A B C

X DIRECTION 5.87 1.07 0.27

Y DIRECTION 2.49 6.18 0.49

8" HOISTBEAM

BRKTS BELOW TOPMOST LANDING - RUNNING REACTIONS (kN) PROVIDED BY KONE

X DIRECTION 1.29 1.07 0.27 INSTALLED BY OTHERS

Y DIRECTION 0.89 0.45 0.49

HOISTWAY WIDTH 2642mm MAX DEFLECTION NOT TO EXCEED 0.125" (3mm) DUE TO APPLIED LOADS

INTERIOR WIDTH 2032mm

SEISMIC ZONES 3 & 4 - ALL BRKTS LOCATIONS - IMPACT LOADING (kN)

X DIRECTION 10.23 6.67 3.56

Y DIRECTION 10.23 3.56 7.12

MAX DEFLECTION NOT TO EXCEED 0.125" (3mm) DUE TO APPLIED LOADS

* ORTHOGONAL REACTIONS DO NOT OCCUR SIMULTANEOUSLY

*CALCULATIONS BASED UPON UBC SEISMIC ZONE 3-4 AND IBC 0 < Ip x Sds 1.0

* ACCEPTABLE GUIDE RAIL BRACKET ATTACHMENT MATERIAL: CONCRETE, STEEL, OR

HOISTWAY DEPTH 1905mm

4216mm UNDERSIDE OF ROOF

INSERTS

INTERIOR DEPTH 1524mm

4013mm CLEAR OVERHEAD

VERTICAL FORCES ONTO PIT FLOOR (kN)

REACTION LOCATION A B C D E

Z DIRECTION 78.73 40.92 21.35 54.71 82.74

**VERTICAL REACTIONS A, B & C OCCUR SIMULTANEOUSLY. VERTICAL REACTIONS D & E

CENTER LINE OF

OCCUR INDIVIDUALLY AND SEPERATELY FROM A, B & C.

GUIDERAIL

944mm

2438mm CAB HEIGHT

HOISTBEAM & LIFE LINE VERTICAL FORCES (kN)

2134mm DOOR HEIGHT

REACTION LOCATION A B C D

Z DIRECTION 21.35 20.91 22.24 22.24

656mm 1067mm 919mm

DOOR WIDTH

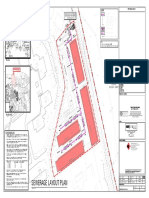

HOISTWAY PLAN VIEW

FLOOR BY FLOOR HEIGHTS CHART

.

203mm

LANDING 5 3000 LANDING 10 N/A LANDING 15 N/A

HOIST BEAM

.

(BY KONE)

I

LANDING 4 3000 LANDING 9 2540 LANDING 14 N/A

LANDING 3 2800 LANDING 8 3000 LANDING 13 N/A

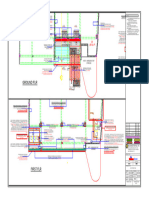

TWO LAYERS OF 6mm DRY WALL (MIN) TOP MACHINE LANDING 2 3000 LANDING 7 3500 LANDING 12 N/A

24800mm TRAVEL

REQUIRED AT BACK OF CONTROLLER BRACKET

LANDING 1 3000 LANDING 6 3500 LANDING 11 N/A

2134mm DOOR HEIGHT

4216mm UNDERSIDE OF ROOF

4013mm CLEAR OVERHEAD

TOP LANDING ENTRANCE / INTEGRATED CONTROL DETAIL

CONCRETE

BOTTOM MACHINE

BRACKET

TWO LAYERS OF 6mm DRY WALL (MIN)

REQUIRED AT BACK OF CONTROLLER

1524mm PIT

TOP LANDING ENTRANCE / INTEGRATED CONTROL DETAIL

DRYWALL

TOP LANDING

SECTION VIEW

ELEVATION IN HOISTWAY LOOKING

AT MACHINE

SCALE: NOT TO SCALE

PREPARATORY WORK BY OTHERS: THE CUSTOMER OR CUSTOMER'S CONTRACTOR, SHALL BE RESPONSIBLE FOR THE FOLLOWING CONDITIONS PRIOR TO THE

COMMENCEMENT OF WORK AT NO COST TO KONE, INC LOCAL CODES SHALL PREVAIL WHEN APPLICABLE ONE KONE COURT

MOLINE

1. PROVIDE A CLEAR, PLUMB HOISTWAY OF THE SIZE SHOWN ON THE FINAL KONE LAYOUT. VARIATIONS MUST NOT EXCEED 1". (TOLERANCE = -0" + 1")

2. PROVIDE ADEQUATE SUPPORT FOR GUIDE RAIL BRACKETS (INCLUDING DIVIDER BEAMS FOR MULTIPLE ELEVATORS IN A COMMON HOISTWAY) FROM PIT FLOOR TO THE TOP

OF THE HOISTWAY AND NOT SPANNING FURTHER THAN ALLOWED BY THE GOVERNING CODE AUTHORITY. FIREPROOFING SHALL BE AFTER INSTALLATION OF BRACKETS.

10. A PIT LADDER IS SUPPLIED BY KONE UNLESS OTHERWISE NOTED ON THE LAYOUT DRAWING. LOCATE AND INSTALL PER KONE FINAL LAYOUT DRAWINGS.

11. AN I-BEAM, PROVIDED BY KONE, MUST BE INSTALLED IN THE ELEVATOR HOISTWAY OVERHEAD PER THE KONE FINAL LAYOUT DRAWINGS.

12. FOR PROPER EQUIPMENT OPERATION; THE MACHINE SPACE AT THE TOP OF THE HOISTWAY MUST BE PROPERLY VENTED PER CODE REQUIREMENTS.

EcoSpace P: P: 1-800-956-KONE (5663)

F: F: 309-743-5469

www.KONE.com

3. HOISTWAY VENTILATION SHALL BE PROVIDED PER CODE REQUIREMENTS MAX ALLOWED HUMIDITY IS 95% NON-CONDENSING. HOISTWAY MUST MAINTAIN A TEMPERATURE BETWEEN 41 F AND 104 F.

4. PROJECTIONS REQUIRING BEVELING IN ACCORDANCE WITH CODE REQUIREMENTS SHALL BE BEVELED AT AN ANGEL NOT LESS THAN 75 DEGREES FROM THE HORIZONTAL. 13. THE ACCESS DOOR TO THE CONTROL SPACE OR THE CONTROL ROOM MUST BE SECURED AGAINST UNAUTHORIZED ACCESS. SPECIFICATIONS

5. PROVIDE REMOVABLE, OSHA COMPLIANT BARRICADES AROUND ALL HOISTWAY OPENINGS AND BETWEEN ELEVATORS INSIDE OF THE HOISTWAY AS REQUIRED. IT SHALL BE SELF LOCKING AND SELF CLOSING. PRODUCT NAME: KONE ECOSPACE ELEVATOR BUILDING (PROJECT NAME) LOCATION

PROVIDE TWO LIFELINE ATTACHMENTS AT THE TOP, FRONT OF THE HOISTWAY. 14. PROVIDE A 15-AMP 102V AC FUSED SERVICE WITH GROUND (VIA EMERGENCY LIGHT SUPPLY IF AVAILABLE) CONNECTED TO EACH CONTROL CABINET FOR SEISMIC

6. ARRANGE FOR ALL BLOCK OUT / CUTOUT OF OPENINGS TO INSTALL HALL PUSHBUTTONS, SIGNAL FIXTURES, AND HATCH DUCT. LIGHTING AND FAN. PROVIDE DEDICATED PHONE LINE TERMINATING AT THE ELEVATOR CONTROL CABINET. CAPACITY SHAPE: 1361 KG

7. PROVIDE A DRY PIT REINFORCED TO SUSTAIN VERTICAL FORCE FROM RAILS AND BUFFERS. REFERENCE THE REACTION LOAD TABLES FOR VERTICAL FORCES. SUMPS 15. FOR CONTROL SPACES LOCATED REMOTELY FROM THE ELEVATOR HOISTWAY, PROVIDE A GOVERNOR ACCESS DOOR OF SIZE AND LOCATION PER SPEED: 1.00 M/S ARCHITECT DATE

AND / OR PUMPS PUMPS (WHERE PERMITTED) LOCATED WIHTIN THE PIT MAY NOT INTRFERE WITH THE ELEVATOR EQUIPMENT. KONE FINAL LAYOUT DRAWINGS. THE ACCESS DOOR SHALL BE SECURED AGAINST UNAUTHORIZED ACCESS. DOOR: CENTEROPENING

15\7\2016

8. PROVIDE SUITABLE LIGHTING FOR THE MACHINE SPACE WITH A LIGHT SWITCH LOCATED IN THE HOISTWAY. PROVIDE A LIGHT FIXTURE WITH AND A SEPARATE GFCI 16. PROVIDE A SUITABLE WORKING ENVIRONMENT INCLUDING ADEQUATE ACCESS TO THE BUILDING, PROPER LIGHTING IN ALL AREAS, CLEAN AND SAFE TRAVEL: 24800 mm

PROTECTED DUPLEX CONVENIENCE OUTLET IN THE ELEVATOR PIT. STORAGE ADJACENT TO THE HOISTWAY, AND SUFFICIENT ON-SITE REFUSE CONTAINERS FOR THE DISPOSAL OF ELEVATOR PACKING MATERIALS. CONTROL LOCATION: INTEGRATED DRAWING# SHEET

9. ENTRANCE WALLS ARE TO BE LEFT OPEN UNTIL THE ELEVATOR EQUIPMENT IS INSTALLED. ADEQUATE SUPPORT FOR ENTRANCE ATTACHMENT POINTS IS 17. THIS DRAWING MUST BE REVIEWED AND APPROVED BY A LICENCED PROFESSIONAL TO ENSURE COMPLIANCE WITH LOCAL BUILDING CODES. POWER SUPPLY: 240

1

REQUIRED ALL LANDINGS. ALL FINISHED FLOORING AND GROUTING IS TO BE INSTALLED AFTER THE ENTRANCE FRAMES ARE INSTALLED. 18. THESE DRAWINGS ARE FOR INFORMATION PURPOSES ONLY AND MUST NOT BE USED FOR CONSTRUCTION PURPOSES. FULLY DETAILED REQUIRED FUSE AMPS: 50

CONSTRUCTION DRAWINGS ARE AVAILABLE FROM THE PRODUCT MANUFACTURER. CONTROLLER HEAT OUTPUT: 3.6

MACHINE HEAT OUTPUT: 1.9

S-ar putea să vă placă și

- Ecospace: Hoistway Plan ViewDocument1 paginăEcospace: Hoistway Plan ViewHoward RoarkÎncă nu există evaluări

- Ecospace: Hoistway Plan ViewDocument1 paginăEcospace: Hoistway Plan Viewvishnumani3011Încă nu există evaluări

- FP-07 - All Home Cdo - 070317 PDFDocument1 paginăFP-07 - All Home Cdo - 070317 PDFLowentan LaxamanaÎncă nu există evaluări

- ITTO Matrix 6thed MatrixDocument13 paginiITTO Matrix 6thed MatrixGillianiÎncă nu există evaluări

- Iwk KM LayoutDocument1 paginăIwk KM LayoutArman ManÎncă nu există evaluări

- 28-8-23 R1 17+634 Diversion PlanDocument1 pagină28-8-23 R1 17+634 Diversion PlanBiplabÎncă nu există evaluări

- A10-22 FARHAN KHAN (FINAL) - ModelDocument1 paginăA10-22 FARHAN KHAN (FINAL) - ModelAlok VermaÎncă nu există evaluări

- 4217 CSD C 1a 0504 r2 Details Typical Fence Sheet 01Document1 pagină4217 CSD C 1a 0504 r2 Details Typical Fence Sheet 01Adi PriyapurnatamaÎncă nu există evaluări

- Typical Hoistway Plan: Car Interior Design 3D View NtsDocument1 paginăTypical Hoistway Plan: Car Interior Design 3D View NtsHabibulla BavajiÎncă nu există evaluări

- 4217-Csd-C-1a-0504-R1-Details - Typical Fence - Sheet 01Document1 pagină4217-Csd-C-1a-0504-R1-Details - Typical Fence - Sheet 01Adi PriyapurnatamaÎncă nu există evaluări

- Plans For Griffy Lake BoardwalkDocument3 paginiPlans For Griffy Lake BoardwalkIndiana Public Media NewsÎncă nu există evaluări

- 1701-Discrepancy Bored Pile Example From STR-003Document1 pagină1701-Discrepancy Bored Pile Example From STR-003kingngai2013Încă nu există evaluări

- 04-R.C.C DETAIL IN R.I.B-ModelDocument1 pagină04-R.C.C DETAIL IN R.I.B-ModelManvendra Singh RaghuwanshiÎncă nu există evaluări

- 01 PMCDocument1 pagină01 PMCsrishtiÎncă nu există evaluări

- Proposed 2 Storey Residential BLDG - BT3 1 PDFDocument13 paginiProposed 2 Storey Residential BLDG - BT3 1 PDFJaybenz Jazon100% (1)

- SMRTBH23049 - Nso Smart - Dehri - Bihar - Civil Interior GFC - R00 - As Per ML - R01 - Dated 18 Oct 2023-Shop Front PlanDocument1 paginăSMRTBH23049 - Nso Smart - Dehri - Bihar - Civil Interior GFC - R00 - As Per ML - R01 - Dated 18 Oct 2023-Shop Front PlanR AND J ASSOCIATES PVT LTDÎncă nu există evaluări

- PM-1 Front Side ViewDocument1 paginăPM-1 Front Side Viewdelvi.panjaitan097Încă nu există evaluări

- Apu Central Wastewater: Sectional ViewDocument1 paginăApu Central Wastewater: Sectional ViewOrkhon.j OrkhonÎncă nu există evaluări

- 179SKN02 3G Gen 04030 02R00Document1 pagină179SKN02 3G Gen 04030 02R00罗国伦Încă nu există evaluări

- 35ah - SD - RPDS - Sanskardham - Ground Floor Toilet Detail - R1 - 05.12.2023Document1 pagină35ah - SD - RPDS - Sanskardham - Ground Floor Toilet Detail - R1 - 05.12.2023zaketpatelÎncă nu există evaluări

- KAAR COW PW IC NTU FZS DWG STR 24633 Rev.01 PDFDocument1 paginăKAAR COW PW IC NTU FZS DWG STR 24633 Rev.01 PDFSatyanarayana MukkuÎncă nu există evaluări

- DMM 1 e 007Document1 paginăDMM 1 e 007mahesh reddy mÎncă nu există evaluări

- P203 Sie DWG 008 Arc 600010Document1 paginăP203 Sie DWG 008 Arc 600010viswanathanÎncă nu există evaluări

- K H110984001V00Document1 paginăK H110984001V00Anonymous X3PnFL6Încă nu există evaluări

- 1 PDFDocument1 pagină1 PDFNoothan JXÎncă nu există evaluări

- Bertyl-10 PDFDocument1 paginăBertyl-10 PDFKripa SriramÎncă nu există evaluări

- Bertyl-10 PDFDocument1 paginăBertyl-10 PDFKripa SriramÎncă nu există evaluări

- 20024-000000u-D003 - Ufd - Plant Water Rev 0Document1 pagină20024-000000u-D003 - Ufd - Plant Water Rev 0oscar alfredoÎncă nu există evaluări

- Elevation SCALE-1:100 Section A-A: Key PlanDocument1 paginăElevation SCALE-1:100 Section A-A: Key Planbrijesh varshneyÎncă nu există evaluări

- Plan at Canopy Top Level: Detail - ZDocument1 paginăPlan at Canopy Top Level: Detail - ZEr navneet jassiÎncă nu există evaluări

- Shiplift Docking Plan For ICGS VIKRAM - 23032018 (Keel Beam) 1Document2 paginiShiplift Docking Plan For ICGS VIKRAM - 23032018 (Keel Beam) 1Kyaw Win TunÎncă nu există evaluări

- Approved Plan PDFDocument1 paginăApproved Plan PDFpavan kumar sudaÎncă nu există evaluări

- APPROVAL DRAWING-ModelDocument1 paginăAPPROVAL DRAWING-Modelnandkishormore1112Încă nu există evaluări

- 127-CIV-BRT-TD-202-REV01 (TRAFFIC SIGNAL PLANS) - SHT 2 - SgndABDocument1 pagină127-CIV-BRT-TD-202-REV01 (TRAFFIC SIGNAL PLANS) - SHT 2 - SgndABryanÎncă nu există evaluări

- WA 229860.0001.002 Default 000Document1 paginăWA 229860.0001.002 Default 000Maein AbreenÎncă nu există evaluări

- See Enlarged Plan & Section: IC ICDocument1 paginăSee Enlarged Plan & Section: IC ICAnonymous X3PnFL6Încă nu există evaluări

- LUXURIOUS LIFTS THE CITY CEIG DRG PAGE 01-Layout1Document1 paginăLUXURIOUS LIFTS THE CITY CEIG DRG PAGE 01-Layout1Sarfaraz ShaikhÎncă nu există evaluări

- Section1 1Document1 paginăSection1 1sahil bishtÎncă nu există evaluări

- Oily Water Treatment PackageDocument1 paginăOily Water Treatment Packagecliffrajjoel100% (1)

- Enlarged View Showing Anchor Bolt Positions On Foundation AngleDocument1 paginăEnlarged View Showing Anchor Bolt Positions On Foundation AngleMohamedHussein MohamedHusseinÎncă nu există evaluări

- Building Plan DetailsDocument1 paginăBuilding Plan DetailsAsiimwe KasirikaÎncă nu există evaluări

- J014101001PEDocument1 paginăJ014101001PESehna SerajÎncă nu există evaluări

- 1 Ground Floor Ceiling DrawingDocument1 pagină1 Ground Floor Ceiling DrawingAnishma AyyappanÎncă nu există evaluări

- 20024-000000u-D005 - Ufd - Ammonia Lines Rev 0Document1 pagină20024-000000u-D005 - Ufd - Ammonia Lines Rev 0oscar alfredoÎncă nu există evaluări

- Sector NDocument1 paginăSector Nmtanveerhasan2001Încă nu există evaluări

- Elevation: Saudi Arabian Oil CompanyDocument1 paginăElevation: Saudi Arabian Oil CompanyDomie Neil Bucag SalasÎncă nu există evaluări

- STH Poster Winter 2013Document2 paginiSTH Poster Winter 2013SakuragiÎncă nu există evaluări

- 179SKN02 3G Gen 04020 02R00Document1 pagină179SKN02 3G Gen 04020 02R00罗国伦Încă nu există evaluări

- Site PlanDocument1 paginăSite PlanestategoaidcÎncă nu există evaluări

- Aa 038608 001Document1 paginăAa 038608 001hai sunÎncă nu există evaluări

- PD 0158 SM 06Document1 paginăPD 0158 SM 06FAIZAN AHMEDÎncă nu există evaluări

- UntitledDocument10 paginiUntitledSergio MercadoÎncă nu există evaluări

- Short Circuit 4storey PDFDocument1 paginăShort Circuit 4storey PDFmayasÎncă nu există evaluări

- Saudi Arabian Oil Company: CA-932993 001 A 656 Restricted 00Document1 paginăSaudi Arabian Oil Company: CA-932993 001 A 656 Restricted 00Mohamed Wasim ShaikhÎncă nu există evaluări

- DATE: 12 / 12 / 2018 Drawing CertifiedDocument1 paginăDATE: 12 / 12 / 2018 Drawing CertifiedAnonymous X3PnFL6Încă nu există evaluări

- Shock Absorber: CatalogueDocument144 paginiShock Absorber: CatalogueAung zinÎncă nu există evaluări

- Dela Cruz For Blueprint Checking 12-05-2022Document14 paginiDela Cruz For Blueprint Checking 12-05-2022Patrick Jerald CamilonÎncă nu există evaluări

- APT Shoring Drawings From Various ProjectDocument15 paginiAPT Shoring Drawings From Various ProjectBinSayeedÎncă nu există evaluări

- A16-22 JYOTI EYE HOSPITAL-ModelDocument1 paginăA16-22 JYOTI EYE HOSPITAL-ModelAlok VermaÎncă nu există evaluări

- 4 FiDocument1 pagină4 FiHoward RoarkÎncă nu există evaluări

- Annex B Zone Boundaries: 1. Residential 1.1 R-1 Low Density ResidentialDocument38 paginiAnnex B Zone Boundaries: 1. Residential 1.1 R-1 Low Density ResidentialHoward RoarkÎncă nu există evaluări

- Phase VDocument10 paginiPhase VHoward RoarkÎncă nu există evaluări

- DT J09 SectionlDocument1 paginăDT J09 SectionlHoward RoarkÎncă nu există evaluări

- Unassigned 0 HRS: ID Resource Name WorkDocument12 paginiUnassigned 0 HRS: ID Resource Name WorkHoward RoarkÎncă nu există evaluări

- DT - J17 and J19 Typical SectionDocument1 paginăDT - J17 and J19 Typical SectionHoward RoarkÎncă nu există evaluări

- DT - LC01 - Resto ChairDocument1 paginăDT - LC01 - Resto ChairHoward RoarkÎncă nu există evaluări

- DT - J02 - J03 - Resto Bench SeatDocument1 paginăDT - J02 - J03 - Resto Bench SeatHoward RoarkÎncă nu există evaluări

- DT - J05 - J06 - J07 Resto TableDocument1 paginăDT - J05 - J06 - J07 Resto TableHoward RoarkÎncă nu există evaluări

- Plan - J04 - Restaurant Table: Legends & FinishesDocument1 paginăPlan - J04 - Restaurant Table: Legends & FinishesHoward RoarkÎncă nu există evaluări

- Cistern & Firetank Basement Level PDFDocument1 paginăCistern & Firetank Basement Level PDFHoward RoarkÎncă nu există evaluări

- People v. Del RosarioDocument2 paginiPeople v. Del RosarioLyleThereseÎncă nu există evaluări

- Claymore Sports LTD Working Practices Improvement Evaluation CCDocument8 paginiClaymore Sports LTD Working Practices Improvement Evaluation CCCarlos CastillaÎncă nu există evaluări

- Abayon v. House of Representatives Electoral Tribunal, 791 SCRA 242 (May 3, 2016) G.R. No. 222236 PDFDocument15 paginiAbayon v. House of Representatives Electoral Tribunal, 791 SCRA 242 (May 3, 2016) G.R. No. 222236 PDFMarc YuÎncă nu există evaluări

- Characteristics and Competencies of TeachersDocument16 paginiCharacteristics and Competencies of TeachersBrian Jay Giman100% (1)

- Managing Primary Secondary SchoolsDocument155 paginiManaging Primary Secondary SchoolsAudy FakhrinoorÎncă nu există evaluări

- Philosophy of CaringDocument8 paginiPhilosophy of CaringKaye Cor100% (1)

- 5E Instructional Model OnlineDocument20 pagini5E Instructional Model Onlinewaktong811Încă nu există evaluări

- Berde Score Sheet TemplateDocument7 paginiBerde Score Sheet TemplateKRISSELLE TAYCO0% (1)

- Case Study Format 2021 2022Document12 paginiCase Study Format 2021 2022maryhamelnet rojasÎncă nu există evaluări

- NRLDocument69 paginiNRLanitaaimÎncă nu există evaluări

- Morshed Mannan - Single - WebDocument72 paginiMorshed Mannan - Single - WebManuu VilardoÎncă nu există evaluări

- Affidavit of Loss Id's StolenDocument1 paginăAffidavit of Loss Id's StolenMarcko LimÎncă nu există evaluări

- Research ProposalDocument6 paginiResearch Proposalanon-48724100% (3)

- Website Planning Template ForDocument10 paginiWebsite Planning Template ForDeepak Veer100% (2)

- Maximilien RobespierreDocument20 paginiMaximilien Robespierreapi-443978182Încă nu există evaluări

- UBD LessonDocument4 paginiUBD LessonLeahNewtonÎncă nu există evaluări

- POEADocument2 paginiPOEAJaimie Paz AngÎncă nu există evaluări

- UcDocument9 paginiUcBrunxAlabastroÎncă nu există evaluări

- The 10th HouseDocument7 paginiThe 10th HouseRavindra LeleÎncă nu există evaluări

- Lesson Plan PDFDocument5 paginiLesson Plan PDFsyed aliÎncă nu există evaluări

- AI Sample SyllabusDocument3 paginiAI Sample SyllabusArvin F. VillodresÎncă nu există evaluări

- Contrastive and Error AnalysisDocument22 paginiContrastive and Error AnalysisAan SafwandiÎncă nu există evaluări

- Using Social Media For BusinessDocument21 paginiUsing Social Media For BusinessmiriamvergheseÎncă nu există evaluări

- Employee Involvement QuestionnaireDocument3 paginiEmployee Involvement Questionnairehedo7100% (10)

- Letter of Inquiry RegardingDocument10 paginiLetter of Inquiry RegardingPradyumn Kumar ShuklaÎncă nu există evaluări

- IEEE - C37.48 - 1997 HV Fuses, Switches, Circuit BreakersDocument45 paginiIEEE - C37.48 - 1997 HV Fuses, Switches, Circuit BreakersElvis MNÎncă nu există evaluări

- KCA University Application-2011Document3 paginiKCA University Application-2011Steve PerkinsÎncă nu există evaluări

- Career Management ProgramDocument8 paginiCareer Management ProgramLeah Laag IIÎncă nu există evaluări

- Level 6 Diploma in Business ManagementDocument4 paginiLevel 6 Diploma in Business ManagementGibsonÎncă nu există evaluări

- 143 Narra ST., Mountview Subdivision, Tanauan City, Batangas Contact Nos.: (043) 778-6352 - (043) 778-6893Document2 pagini143 Narra ST., Mountview Subdivision, Tanauan City, Batangas Contact Nos.: (043) 778-6352 - (043) 778-6893Alyssa MariÎncă nu există evaluări