Documente Academic

Documente Profesional

Documente Cultură

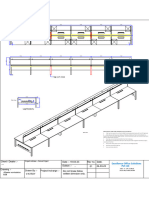

Lampiran Sop Pemeliharaan Pendant

Încărcat de

Duana ZulqaTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Lampiran Sop Pemeliharaan Pendant

Încărcat de

Duana ZulqaDrepturi de autor:

Formate disponibile

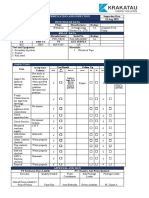

Check items during preventative maintenance:

Legend:

--- No measure required

√ Recommended inspection

√√ Recommended replacement

Part Name Maintenance Work Annually 2.5 years 5 years 10 years

Hospital’s Maquet technical service personnel or

technician authorized service partner

Gas outlets In accordance with the manuf.’s √ √ √ √

description

Power sockets Visual inspection and functional √ √ √ √

test

Brake system Functional test √ √ √ √

LED ambient light Functional test and brightness √ √ √ √

setting

Covers Visually and manually inspect if it √ √ √ √

is tighten

Appearance Visual inspection √ √ √ √

Screws connecting Beam Plus Visually inspect and tighten √ √ √ √

Adapter with LUCEA 40 or the screws (refer to Installation

screen holder as well as that of Manual)

connecting PLG-II with SATELITE

Welding parts Visual inspection --- √ √ √

Brake system Visually inspect and test braking --- √ √ √

force;

Leakage check and inspect hose

Gas spring of PLG-II Visually inspect grease leakage --- √ √√ √√

and replacement

ENERGY’s ball screws Lubricate by NIPPECO 0818 --- √ √ √

grease

Ceiling attachment Visually inspect and check the --- --- √ √

torque value of M16 nuts is

200Nm.

Electrical system Visually and functional inspect --- --- √ √

sockets;

Test grounding continuity and

leakage current;

Check the plugs of terminal

block are tighten

Mechanical system Visually inspect all assemblies; --- --- √ √

Functional test for snug fitting of

components, joint bearings and

end stoppers

Gas system Check leakage and tightness; --- --- √ √

Visually inspect hose not

pinched by a hinge and not

damaged;

Check identification label;

Gas hose Replacement --- --- --- √√

S-ar putea să vă placă și

- Flight Training Instruction: Naval Air Training CommandDocument174 paginiFlight Training Instruction: Naval Air Training CommandITLHAPN100% (1)

- XVS1100 V-Star 1100 (99-00) Service ManualDocument420 paginiXVS1100 V-Star 1100 (99-00) Service Manualbullwinkle105477675% (8)

- 2. Forsthoffer's Rotating Equipment Handbooks: PumpsDe la Everand2. Forsthoffer's Rotating Equipment Handbooks: PumpsEvaluare: 1 din 5 stele1/5 (1)

- Analysis and Design of Bridge Substructures PDFDocument195 paginiAnalysis and Design of Bridge Substructures PDFsuheilbugs100% (1)

- Feasibility Study Notes Revised PDFDocument10 paginiFeasibility Study Notes Revised PDFGilbert BettÎncă nu există evaluări

- Marine Gyro-Compasses and Automatic Pilots: A Handbook for Merchant Navy OfficersDe la EverandMarine Gyro-Compasses and Automatic Pilots: A Handbook for Merchant Navy OfficersEvaluare: 5 din 5 stele5/5 (2)

- Geothermal Project TimelinesDocument10 paginiGeothermal Project TimelinesAldwin EncarnacionÎncă nu există evaluări

- Teco VFD Operating ManualDocument69 paginiTeco VFD Operating ManualStronghold Armory100% (1)

- 4-2.0L Gasoline EngineDocument187 pagini4-2.0L Gasoline EngineMarco Antonio Tomaylla Huamani100% (1)

- CR 919Document30 paginiCR 919gebre100% (1)

- Field Quality Plan: BusbarsDocument3 paginiField Quality Plan: BusbarsSourav RanaÎncă nu există evaluări

- General Quality Assurance Plan For Substation: - Site Study, Collection of Detailed Site Data / Soil InvestigationDocument5 paginiGeneral Quality Assurance Plan For Substation: - Site Study, Collection of Detailed Site Data / Soil InvestigationNitin100% (2)

- SMA Inverter Catalogue PDFDocument290 paginiSMA Inverter Catalogue PDFxodewaÎncă nu există evaluări

- Cover ENG Heavy Vehicle PDFDocument186 paginiCover ENG Heavy Vehicle PDFjavier guerrero castilloÎncă nu există evaluări

- Maintenance PlanDocument7 paginiMaintenance PlanAris Bagoes MaladhiÎncă nu există evaluări

- NORMA - ANSI-AMCA Standard 250-05 Laboratory Methods of Testing Jet Tunnel Fans For PerformanceDocument33 paginiNORMA - ANSI-AMCA Standard 250-05 Laboratory Methods of Testing Jet Tunnel Fans For PerformanceJose Antonio100% (1)

- Traffic Management During Construction, RSA - 240608Document104 paginiTraffic Management During Construction, RSA - 240608mrasdan100% (2)

- Piping System InspectionDocument3 paginiPiping System InspectionAdi KurniaÎncă nu există evaluări

- Landrover Freelander 2 Maintenance ScheduleDocument2 paginiLandrover Freelander 2 Maintenance Schedulevincent_devine777dÎncă nu există evaluări

- 25 Powerful Business English Presentation Phrases To Impress Your AudienceDocument3 pagini25 Powerful Business English Presentation Phrases To Impress Your AudienceMutia ChimoetÎncă nu există evaluări

- Beechcraft Heritage MuseumDocument16 paginiBeechcraft Heritage MuseumCAP History LibraryÎncă nu există evaluări

- Periodic Maintenance Schedule RWL 1Document1 paginăPeriodic Maintenance Schedule RWL 1Mohammed RanaÎncă nu există evaluări

- Protection Relay Verification and Inspection Switchgear DataDocument11 paginiProtection Relay Verification and Inspection Switchgear DatamomoÎncă nu există evaluări

- Maintenance ScheduleDocument3 paginiMaintenance ScheduleAhmed MorseyÎncă nu există evaluări

- Regular Maintenance Interval For ALCU SystemDocument1 paginăRegular Maintenance Interval For ALCU SystemjaideepÎncă nu există evaluări

- Mio Amore - Periodic Maintenance and Lubrication ChartDocument1 paginăMio Amore - Periodic Maintenance and Lubrication Chartmotley crewzÎncă nu există evaluări

- Tiremaster Maintenance PlanDocument1 paginăTiremaster Maintenance PlanShylen SadienÎncă nu există evaluări

- 3.0 Aceptación Del Carro Encofrador Modelo - Debe Ser Llenado Por El Responsable Chino.Document13 pagini3.0 Aceptación Del Carro Encofrador Modelo - Debe Ser Llenado Por El Responsable Chino.juanÎncă nu există evaluări

- VDR Butterfly ValveDocument1 paginăVDR Butterfly ValveIndra SUdirmanÎncă nu există evaluări

- Periodic Maintenance and Lubrication ChartDocument1 paginăPeriodic Maintenance and Lubrication Chartmotley crewzÎncă nu există evaluări

- Yamaha Nmax 155 - Engine Oil StrainerDocument1 paginăYamaha Nmax 155 - Engine Oil Strainermotley crewzÎncă nu există evaluări

- Periodic Maintenance of Yamaha YZF R15 PDFDocument2 paginiPeriodic Maintenance of Yamaha YZF R15 PDFPraveen CNÎncă nu există evaluări

- Ferarri Crane Check ListDocument1 paginăFerarri Crane Check Listyudi jdxÎncă nu există evaluări

- Can Bus enDocument10 paginiCan Bus enMahmoud MohsenÎncă nu există evaluări

- F 3 DDocument34 paginiF 3 Dzoki100% (2)

- Mio Amore - Periodic Maintenance and AdjustmentsDocument1 paginăMio Amore - Periodic Maintenance and Adjustmentsmotley crewzÎncă nu există evaluări

- Mio Amore - Engine Oil Filter ElementDocument1 paginăMio Amore - Engine Oil Filter Elementmotley crewzÎncă nu există evaluări

- Yamaha Mio Periodic ChecksDocument1 paginăYamaha Mio Periodic Checksmotley crewzÎncă nu există evaluări

- Form Test PacketDocument24 paginiForm Test PacketYudha Andrie Sasi ZenÎncă nu există evaluări

- Diagnostic List GREAT WALL MOTOR - : Page 1 of 18Document18 paginiDiagnostic List GREAT WALL MOTOR - : Page 1 of 18Henry RomeroÎncă nu există evaluări

- Lingkup Pekerjaan Perawatan CumminsDocument1 paginăLingkup Pekerjaan Perawatan CumminsDavis JeloyÎncă nu există evaluări

- J59K Readiness Checklist-Updated Progress 21-12-2022Document1 paginăJ59K Readiness Checklist-Updated Progress 21-12-2022wadie606 dzglobalÎncă nu există evaluări

- Yamaha Nmax General Maintenance and Lubrication ChartDocument1 paginăYamaha Nmax General Maintenance and Lubrication Chartmotley crewzÎncă nu există evaluări

- Yamaha Nmax 155 - General Maintenance and Lubrication ChartDocument1 paginăYamaha Nmax 155 - General Maintenance and Lubrication Chartmotley crewzÎncă nu există evaluări

- Technical Maintain ScheduleDocument7 paginiTechnical Maintain ScheduleHENRYMARINGANÎncă nu există evaluări

- Mechanical Checksheet Day2Document1 paginăMechanical Checksheet Day2Nazim MirzaÎncă nu există evaluări

- Dump Truck Aw-19122082Document2 paginiDump Truck Aw-19122082omar sadiqÎncă nu există evaluări

- EDL Panduan Desain Rev 1Document3 paginiEDL Panduan Desain Rev 1zat572000Încă nu există evaluări

- Taian Nantai Experimental Equipment Co. LTD Nantai Automotive Technology Co., LTDDocument32 paginiTaian Nantai Experimental Equipment Co. LTD Nantai Automotive Technology Co., LTDGonzalo FinozziÎncă nu există evaluări

- VAG401 V5.6 Models Feature List Can Be Measured (Note: For Reference Only)Document7 paginiVAG401 V5.6 Models Feature List Can Be Measured (Note: For Reference Only)Michael KleinÎncă nu există evaluări

- JLR 18 27 10 - 2E - Maintenance Check Sheet - Range Rover Sport (LW) - UK & EU - From 14MY - MilesDocument2 paginiJLR 18 27 10 - 2E - Maintenance Check Sheet - Range Rover Sport (LW) - UK & EU - From 14MY - MilesmunÎncă nu există evaluări

- Service Programme Checklist-Wide Body Dump TruckDocument6 paginiService Programme Checklist-Wide Body Dump TruckRandi rÎncă nu există evaluări

- Cage Guided BrochureDocument32 paginiCage Guided Brochurearif fadhillahÎncă nu există evaluări

- Certificate of InspectionDocument3 paginiCertificate of Inspectionomar sadiqÎncă nu există evaluări

- SpecificationDocument13 paginiSpecificationAh LoutÎncă nu există evaluări

- Audit Schedule RevisedDocument4 paginiAudit Schedule Revisedmahesh naikÎncă nu există evaluări

- Bomba Caudal Variable 32Document44 paginiBomba Caudal Variable 32Edwing GRÎncă nu există evaluări

- Yamaha Nmax 155 - Periodic Maintenance ChartDocument1 paginăYamaha Nmax 155 - Periodic Maintenance Chartmotley crewzÎncă nu există evaluări

- Yamaha Nmax Kilometer-Based MaintenanceDocument1 paginăYamaha Nmax Kilometer-Based Maintenancemotley crewzÎncă nu există evaluări

- Lube Flushing Unit FAT Inhouse Report (12233)Document2 paginiLube Flushing Unit FAT Inhouse Report (12233)Idung ChristopherÎncă nu există evaluări

- Daihatsu : LK 4. Charging System Repair Vehicle DataDocument4 paginiDaihatsu : LK 4. Charging System Repair Vehicle DataNengah Saputra WijayaÎncă nu există evaluări

- Excavator AW-19122096Document2 paginiExcavator AW-19122096omar sadiqÎncă nu există evaluări

- Checklist Ps Cmt96 & Cmt106Document1 paginăChecklist Ps Cmt96 & Cmt106mhmmdrhmn76Încă nu există evaluări

- Motor InstallationDocument4 paginiMotor InstallationAjÎncă nu există evaluări

- M-4.2 Incinerator (Miura) Instruction BookDocument68 paginiM-4.2 Incinerator (Miura) Instruction Bookpas87554Încă nu există evaluări

- Inspection Report - Hired Assets: Annexure 2Document1 paginăInspection Report - Hired Assets: Annexure 2ranvijay dubeyÎncă nu există evaluări

- LogDocument2 paginiLogFerdian SumbaÎncă nu există evaluări

- Unit I - Shafts: Single ElementDocument7 paginiUnit I - Shafts: Single Elementchelam101100% (1)

- DepEd Learner Information System (LIS) PDFDocument36 paginiDepEd Learner Information System (LIS) PDFshasagailÎncă nu există evaluări

- Model Variant Description Variant Code Extended Warranty Price Royal PlatinumDocument2 paginiModel Variant Description Variant Code Extended Warranty Price Royal PlatinumRiyasÎncă nu există evaluări

- 22KW Hydraulic Power Unit GADocument1 pagină22KW Hydraulic Power Unit GAGabi GabrielÎncă nu există evaluări

- Padma Vibhushan Dr. G. Madhavan NairDocument7 paginiPadma Vibhushan Dr. G. Madhavan NairjishnusajiÎncă nu există evaluări

- Indian Standard: Stationary Valve Regulated Lead Acid Batteries - SpecificationDocument12 paginiIndian Standard: Stationary Valve Regulated Lead Acid Batteries - Specificationmukesh_kht1Încă nu există evaluări

- 000 139 PDFDocument17 pagini000 139 PDFtareqcccccÎncă nu există evaluări

- Atm MachineDocument7 paginiAtm MachineNguyen TungÎncă nu există evaluări

- A Research Submitted To: Student ResearchersDocument4 paginiA Research Submitted To: Student ResearchersDorothy Ann AllurinÎncă nu există evaluări

- IJV MARLEY AutomotiveDocument6 paginiIJV MARLEY AutomotiveUmer HamidÎncă nu există evaluări

- Lexmark-E 321 Service ManualDocument184 paginiLexmark-E 321 Service ManualRemysÎncă nu există evaluări

- PDF CatalogEngDocument24 paginiPDF CatalogEngReal Gee MÎncă nu există evaluări

- 9A01304 Fluid MechanicsDocument4 pagini9A01304 Fluid MechanicssivabharathamurthyÎncă nu există evaluări

- ATI Practice CodesDocument1 paginăATI Practice Codesvanassa johnson100% (4)

- SMAC CA12 BrochureDocument2 paginiSMAC CA12 BrochureElectromateÎncă nu există evaluări

- NDP-25 Data SheetDocument4 paginiNDP-25 Data SheetsetyaÎncă nu există evaluări

- 6seater Workstation B2BDocument1 pagină6seater Workstation B2BDid ProjectsÎncă nu există evaluări

- IV-series-monitor Monitor Um 440gb GB WW 1027-3Document360 paginiIV-series-monitor Monitor Um 440gb GB WW 1027-3Quang DuyÎncă nu există evaluări