Documente Academic

Documente Profesional

Documente Cultură

Automatic Fault Detection and Identification of Exact Location of The Pin Insulator in Power Distribution Lines

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Automatic Fault Detection and Identification of Exact Location of The Pin Insulator in Power Distribution Lines

Drepturi de autor:

Formate disponibile

Volume 5, Issue 9, September – 2020 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Automatic Fault Detection and Identification of Exact

Location of the Pin Insulator in Power Distribution

Lines

Shubham Ashtekar 1, Mahesh Kunnurkar2

Department of Electrical & Electronics Engineering,

KLS’s Gogte Institute of Technology, Belgaum, Karnataka, India

Abstract:- One of the recent problems which is of the fault in distribution lines on the pin insulator. This

encountered and detected in the Electrical Distribution system will provide detection and exact location

Lines is in the Pin Insulator such as Breaking of identification of the fault in distribution lines. The

Conductor placed on the Pin Insulator, cracks & damage interruption of current is sensed by the Current Transformer

in the pin insulator due to its exposure to the and then the signal is given to the Analog to Digital

atmospheric conditions such as humidity, moisture & Converter and Raspberry-Pi Processor after that through

bird excretion etc. Detection and Identification of this cloud the signal is given to operator in the control room and

problem is very difficult for the operators and linemen also simultaneously to the linemen operating into that region

working because there are so many distribution lines run or area after getting the exact location of the fault the

across consumer localities and a number of pin operator can send the linemen directly to the exact location

insulators placed on each pole and there are so many or the linemen into that area goes directly to the location of

poles in each distribution lines. In Modern day of human the fault and repair and maintenance is carried out and the

life electricity has a vital importance. Consumers of the fault is corrected [2].

electricity always demand a power without interruption

and fluctuations in it, And it is also the responsibility of

the electricity supplying companies and electricity

boards across the globe to provide electrical power more

efficiently and take care of all the electrical equipments

installed on the system and the proper maintenance of

the process and equipments so that the efficiency of the

equipments and their work life will be maintained. The

proposed system will automatically detect the fault in the

distribution lines due to conductor breaking on the pin

insulator and its exact location with the help of Current

Transformer, Analog to Digital Converter and

Raspberry-Pi processor then through the cloud all the

collected data is sent at a time to the operator directly in

the control room and also to the linemen operating into

that area.

Fig. 1:- Pin type Insulator.

Keywords:- Electrical Distribution Lines, Pin Insulator,

Current Transformer, Analog to Digital Converter,

Raspberry-Pi Processor, Control Room.

I. INTRODUCTION

Insulators are attached to the supports and insulate the

conductor from the ground and other conductor material [1].

Normally Pin Insulators are used in electrical power

distribution upto 11KV voltage and sometimes upto 33KV

in primary and secondary distribution of electrical power to

the consumers [1]. So it’s a necessity for the electricity

boards and electrical supply companies to provide the

electrical power supply with uninterrupted, efficient and

Fig. 2:- Electrical Conductor Placed on a Pin Insulator in the

without any fluctuations in it. The main purpose to develop

distribution lines.

this system is that difficulty faced by the linemen and the

operators in detection and identification of the exact location

IJISRT20SEP754 www.ijisrt.com 1086

Volume 5, Issue 9, September – 2020 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

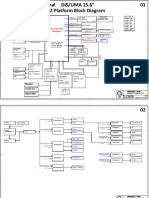

II. AUTOMATIC FAULT DETECTION AND

IDENTIFICATION UNIT

Fig. 3:- shows the condition when the conductor breaks due

to the fault.

Fig. 1: Block diagram of Automatic Fault Detection and

Identification of exact location of the Pin Insulator in Power

Distribution Lines.

Figure (1) shows the block diagram of Automatic Fault

Detection and Identification unit. Here a Current

Transformer (CT) is connected to the 11KV feeder line of

distribution near the electricity pole having a Pin Insulator

on it carrying the electrical conductor for power supply.

Current Transformer having the ratio 100:1 that is it reduces

the voltage level from 11KV to 100-110V and Current from

30A to 5-1 Ampere. Current Transformer will continuously

sense the current in the line. Then there is a protective

device such as MCB (Miniature Circuit Breaker) used for

Fig.4:- shows the condition when the damage taking place to the protection of low voltage circuit from high voltage

the Pin Insulator after fault. circuit. Then the signal is given to the Analog to Digital

Converter through a step-down transformer (110V to 5V).

The Analog to Digital Converter is used to convert the 5V

analog signal to 5V digital signal. This digital signal is

further passed through a Filter circuit in order to reduce any

harmonics present in the signal and then the 5V digital

signal is given to the Raspberry-Pi Microprocessor which

continuously sends signal to the Operator in the Control

Room as well as to the mobile phone of the Linemen.

Whenever the fault takes place in the distribution line

on the Pin insulator or the breaking of the conductor in the

distribution line the Current Transformer will sense that

there is break in the line or interruption of the signal,

Immediately it will proceed the signal to Analog to Digital

Converter from there the signal is given to the Raspberry-Pi

Microprocessor. Raspberry-Pi Processor immediately sends

the signal through cloud to the Operator operating in the

control room and Linemen of that respective area on his

respective mobile phone giving them the exact location of

Fig. 5:- shows the condition after the fault when the Pin

the fault. After getting the exact fault location the fault is

Insulator is fully damaged due to its exposure to the

corrected immediately. Thus saving much of the time of

atmospheric conditions.

IJISRT20SEP754 www.ijisrt.com 1087

Volume 5, Issue 9, September – 2020 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

identification of fault location and the consumers will get the

uninterrupted power supply.

III. RESULTS

Fig. 2: Program output when all the processes are working

properly without any fault in it in observed in the output

console window of the PYCHARM Software.

Fig. 3: Program output when the fault occurs in the

processes observed in the output console window of the

PYCHARM Software.

IV. ADVANTAGES

Speed of operation is very fast.

The system is highly accurate & reliable.

The system is precise to use for detection and

identification of fault in the electrical distribution lines.

System also has provision to send the live data through

cloud directly to the operator/linemen’s mobile phone

and also to the operator in the control room.

Lots of time will be saved since the faults get rectified

very quickly and there will be uninterrupted supply of

power to the consumers.

No need of skilled operators.

V. DISADVATNTAGES

If there is some malfunction in the Processor, the system

may misbehave. But chances of occurrence of such

misbehave is almost nil.

Fig. 1: Program code of the process written in the python Proper protection and care need to be taken on the

programming language in PYCHARM Software of Linux system side.

OS which will be implemented in Raspberry-Pi

Microprocessor in the Process.

IJISRT20SEP754 www.ijisrt.com 1088

Volume 5, Issue 9, September – 2020 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

VI. CONCLUSION

The Automatic Fault Detection & Identification of

Exact Location of the Pin Insulator in Power Distribution

Lines is having several advantages as it provides fast

correction of faults in the distribution lines due to Pin

Insulator and also provides the exact point of fault to the

working operator in the control room and the linemen

operating into that region or area, Itself through the cloud

and the provisions can be made in the system to get the data

directly on the operators or linemen’s mobile. So that the

faults in the systems are gets rectified as quickly as possible

providing consumers an uninterrupted supply of electricity.

And also we can improve the whole power scenario. The

automatic fault detection and identification of the exact

location is achieved by using the Current Transformer, Step-

down Transformer, Analog to Digital Converter and a

Raspberry-Pi Microprocessor automatically by sensing the

availability of the current in the conductor. And then

adjusting the current and voltage to suitable levels and

sending the appropriate signal to the operator or controller in

the control room directly through the cloud and after that

rectifying the faults in the distribution lines.

REFERRENCES

[1]. Electrical Power Generation, Transmission and

Distribution, S. N. Singh, P.H.I., New Delhi, 2nd

Edition.

[2]. “Automatic Fault Detection and Location of

Transmission Lines using IoT” by Sajal Menon,

Don Tommey, Rejoice Thomas Paul, Krishnapriya

Vinod, Rajalakshmi Menon.

[3]. Global Research and Development Journal for

Engineering, May 2019

[4]. E-ISSN: 2455-5703

IJISRT20SEP754 www.ijisrt.com 1089

S-ar putea să vă placă și

- Design of VCBDocument14 paginiDesign of VCBAniruth100% (1)

- Knowledge is "Real Power": Introduction to Power QualityDe la EverandKnowledge is "Real Power": Introduction to Power QualityÎncă nu există evaluări

- Code of Practice For Design, Installation and Maintenancefor Overhead Power LinesDocument22 paginiCode of Practice For Design, Installation and Maintenancefor Overhead Power LinesStarla HillÎncă nu există evaluări

- Blokset: Modular DesignationDocument2 paginiBlokset: Modular DesignationJabir Quadri100% (1)

- EATON Protection and Control RelaysDocument8 paginiEATON Protection and Control RelaysRazvan MaresÎncă nu există evaluări

- Tunorma Transformer11Document1 paginăTunorma Transformer11aliÎncă nu există evaluări

- VCB, ViderDocument47 paginiVCB, Viderhs_handsomeÎncă nu există evaluări

- HV CB For SubstationDocument28 paginiHV CB For SubstationjokotsÎncă nu există evaluări

- IEEE Guide C5712200-2022Document84 paginiIEEE Guide C5712200-2022Sontri ChiggumÎncă nu există evaluări

- Transformer Database ReserchDocument8 paginiTransformer Database ReserchJignesh100% (1)

- Technical Specification 11 KV Indoor Switchgear SCADA Controlled PDFDocument59 paginiTechnical Specification 11 KV Indoor Switchgear SCADA Controlled PDFIMRAN TUMANGGORÎncă nu există evaluări

- Fact Devices in Power System Net Work: Rakesh Dundigalla 14621A020 3Document20 paginiFact Devices in Power System Net Work: Rakesh Dundigalla 14621A020 3NSunnyJoyÎncă nu există evaluări

- Turn To Turn Insulation FaultDocument7 paginiTurn To Turn Insulation Faultzarchiwin05Încă nu există evaluări

- (Susol MCCB) Catalog en 202107Document376 pagini(Susol MCCB) Catalog en 202107paryonoÎncă nu există evaluări

- Capacitor Catalogue PDFDocument84 paginiCapacitor Catalogue PDFrajveer kumarÎncă nu există evaluări

- Substation Maintenance Inspection ListDocument327 paginiSubstation Maintenance Inspection Listjohndavsg8022Încă nu există evaluări

- Brochure ANSIDocument40 paginiBrochure ANSIDaniel PalaciosÎncă nu există evaluări

- Introduction of Electric Power SystemDocument17 paginiIntroduction of Electric Power SystemsohaibÎncă nu există evaluări

- Power Quality and Harmonic Analysis in Three PhaseDocument7 paginiPower Quality and Harmonic Analysis in Three PhaseMarcos PessanhaÎncă nu există evaluări

- LV Switchboard Dimensioning GuideDocument5 paginiLV Switchboard Dimensioning GuideMichael Bou KarimÎncă nu există evaluări

- Transformer CatalogueDocument8 paginiTransformer CatalogueAbhineet PathakÎncă nu există evaluări

- 36kV SF6 Gas Circuit Breaker Type SFG Mitsubishi ElectricDocument3 pagini36kV SF6 Gas Circuit Breaker Type SFG Mitsubishi ElectricSunil G Parakkal100% (1)

- Metal Enclosed Switched Shunt Reactor BanksDocument13 paginiMetal Enclosed Switched Shunt Reactor BanksaramirezbenitesÎncă nu există evaluări

- High-Voltage Circuit-Breakers 3AP1/2 72.5 KV Up To 550 KV: Answers For EnergyDocument12 paginiHigh-Voltage Circuit-Breakers 3AP1/2 72.5 KV Up To 550 KV: Answers For EnergySung Hye ChoiÎncă nu există evaluări

- AbbDocument12 paginiAbbAH IMRANÎncă nu există evaluări

- EDOC-Practical Considerations in Surge ProtectionDocument15 paginiEDOC-Practical Considerations in Surge ProtectionEl Comedor BenedictÎncă nu există evaluări

- 991 PDFDocument93 pagini991 PDFLucio Loyloy SanchezÎncă nu există evaluări

- Surge ArresterDocument17 paginiSurge ArrestermoosuhaibÎncă nu există evaluări

- 01 - Schneider I-Line II Catalogue 2017Document120 pagini01 - Schneider I-Line II Catalogue 2017SuryaRaoTirumallasettiÎncă nu există evaluări

- Sri RamachandranDocument7 paginiSri RamachandranNavaneethakrishnan MurugesanÎncă nu există evaluări

- Transmission Line Fault Detection and Localisation Methodology Using PMU MeasurementsDocument10 paginiTransmission Line Fault Detection and Localisation Methodology Using PMU Measurementswvargas926Încă nu există evaluări

- Restricted Earth FaultDocument4 paginiRestricted Earth FaultmoosuhaibÎncă nu există evaluări

- SR - No. Description Particulars: Shilchar Technologies Limited::::::::::::::::::::::::::::::::: Gauranteed & Other ParticularsDocument1 paginăSR - No. Description Particulars: Shilchar Technologies Limited::::::::::::::::::::::::::::::::: Gauranteed & Other Particularsram krishnanÎncă nu există evaluări

- Prismatic Oil Level GaugeDocument2 paginiPrismatic Oil Level GaugevipulpanchotiyaÎncă nu există evaluări

- 1.035 Transformer-15KVA CooperDocument24 pagini1.035 Transformer-15KVA CooperAra AkramÎncă nu există evaluări

- X012 Designation Code For Power Cables PDFDocument1 paginăX012 Designation Code For Power Cables PDFSunil SinghÎncă nu există evaluări

- Power Xpert CX (Actualizado)Document20 paginiPower Xpert CX (Actualizado)GUSTAVO DUARTEÎncă nu există evaluări

- Synergy Elektrik (PVT.) LTD PDFDocument3 paginiSynergy Elektrik (PVT.) LTD PDFMuhammad KashifÎncă nu există evaluări

- Power Xpert UX - BR - AU - Oct2013 - 150dpiDocument20 paginiPower Xpert UX - BR - AU - Oct2013 - 150dpiDony SaputraÎncă nu există evaluări

- Maintenance GuideDocument45 paginiMaintenance GuideRatheesh KumarÎncă nu există evaluări

- HV Equipment Failure Data 2017Document164 paginiHV Equipment Failure Data 2017ipraoÎncă nu există evaluări

- Aluminum Vs Copper in TrafoDocument6 paginiAluminum Vs Copper in TrafosamuraivickyÎncă nu există evaluări

- Vacuum Type OLTCDocument4 paginiVacuum Type OLTCAbdul AzimÎncă nu există evaluări

- Cables VFD MotorDocument19 paginiCables VFD MotorMarius RotaruÎncă nu există evaluări

- VIZIMAX - CIGRE Toronto - Using A Controlled Switching Device For A Power Transformer PDFDocument8 paginiVIZIMAX - CIGRE Toronto - Using A Controlled Switching Device For A Power Transformer PDFgeorge_cpp2Încă nu există evaluări

- Siemens ENEAS Solutions For Substation Automation and ProtectionDocument14 paginiSiemens ENEAS Solutions For Substation Automation and Protectionఅల్లంరాజుశివకుమార్Încă nu există evaluări

- Schneider Electric OKKEN IntroductionDocument26 paginiSchneider Electric OKKEN IntroductionDuško TovilovićÎncă nu există evaluări

- Overhead Lines Future Planning Oman PDFDocument139 paginiOverhead Lines Future Planning Oman PDFArun RajahÎncă nu există evaluări

- POWERGRID Experience On Life Assessment of EHV Current TransformersDocument7 paginiPOWERGRID Experience On Life Assessment of EHV Current TransformersOm BhaskarÎncă nu există evaluări

- Inter Trip RelayDocument10 paginiInter Trip RelayNam Hoai Le100% (1)

- MG Transformers and Packaged Substations TX5299.V2Document20 paginiMG Transformers and Packaged Substations TX5299.V2engnajeeb75Încă nu există evaluări

- Product: Complete Diagnostic SolutionsDocument8 paginiProduct: Complete Diagnostic SolutionsbhpÎncă nu există evaluări

- Abb VCB DetailsDocument20 paginiAbb VCB DetailsSher Bahadur VermaÎncă nu există evaluări

- S1-2-Transformers For Future Power Networks - Mahesh Nene-Tata PowerDocument8 paginiS1-2-Transformers For Future Power Networks - Mahesh Nene-Tata PowerMohd Ghazali JPMM100% (1)

- TransformersDocument76 paginiTransformersPRAVEEN KUMAR SINGH100% (1)

- Voltage Transformer TestingDocument19 paginiVoltage Transformer TestingAfrin HossainÎncă nu există evaluări

- Design and Construction of 0 500V 3KVA Variac With Digital DisplayDocument9 paginiDesign and Construction of 0 500V 3KVA Variac With Digital DisplayEditor IJTSRDÎncă nu există evaluări

- Overhead SwitchesDocument24 paginiOverhead SwitchesAnthony LagradaÎncă nu există evaluări

- Impact of Stress and Emotional Reactions due to the Covid-19 Pandemic in IndiaDocument6 paginiImpact of Stress and Emotional Reactions due to the Covid-19 Pandemic in IndiaInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Utilization of Waste Heat Emitted by the KilnDocument2 paginiUtilization of Waste Heat Emitted by the KilnInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Detection and Counting of Fake Currency & Genuine Currency Using Image ProcessingDocument6 paginiDetection and Counting of Fake Currency & Genuine Currency Using Image ProcessingInternational Journal of Innovative Science and Research Technology100% (9)

- Entrepreneurial Creative Thinking and Venture Performance: Reviewing the Influence of Psychomotor Education on the Profitability of Small and Medium Scale Firms in Port Harcourt MetropolisDocument10 paginiEntrepreneurial Creative Thinking and Venture Performance: Reviewing the Influence of Psychomotor Education on the Profitability of Small and Medium Scale Firms in Port Harcourt MetropolisInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- An Overview of Lung CancerDocument6 paginiAn Overview of Lung CancerInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Ambulance Booking SystemDocument7 paginiAmbulance Booking SystemInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Designing Cost-Effective SMS based Irrigation System using GSM ModuleDocument8 paginiDesigning Cost-Effective SMS based Irrigation System using GSM ModuleInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Unmasking Phishing Threats Through Cutting-Edge Machine LearningDocument8 paginiUnmasking Phishing Threats Through Cutting-Edge Machine LearningInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Digital Finance-Fintech and it’s Impact on Financial Inclusion in IndiaDocument10 paginiDigital Finance-Fintech and it’s Impact on Financial Inclusion in IndiaInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Auto Tix: Automated Bus Ticket SolutionDocument5 paginiAuto Tix: Automated Bus Ticket SolutionInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Effect of Solid Waste Management on Socio-Economic Development of Urban Area: A Case of Kicukiro DistrictDocument13 paginiEffect of Solid Waste Management on Socio-Economic Development of Urban Area: A Case of Kicukiro DistrictInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Computer Vision Gestures Recognition System Using Centralized Cloud ServerDocument9 paginiComputer Vision Gestures Recognition System Using Centralized Cloud ServerInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Predictive Analytics for Motorcycle Theft Detection and RecoveryDocument5 paginiPredictive Analytics for Motorcycle Theft Detection and RecoveryInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Study Assessing Viability of Installing 20kw Solar Power For The Electrical & Electronic Engineering Department Rufus Giwa Polytechnic OwoDocument6 paginiStudy Assessing Viability of Installing 20kw Solar Power For The Electrical & Electronic Engineering Department Rufus Giwa Polytechnic OwoInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Forensic Advantages and Disadvantages of Raman Spectroscopy Methods in Various Banknotes Analysis and The Observed Discordant ResultsDocument12 paginiForensic Advantages and Disadvantages of Raman Spectroscopy Methods in Various Banknotes Analysis and The Observed Discordant ResultsInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- An Industry That Capitalizes Off of Women's Insecurities?Document8 paginiAn Industry That Capitalizes Off of Women's Insecurities?International Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Cyber Security Awareness and Educational Outcomes of Grade 4 LearnersDocument33 paginiCyber Security Awareness and Educational Outcomes of Grade 4 LearnersInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Factors Influencing The Use of Improved Maize Seed and Participation in The Seed Demonstration Program by Smallholder Farmers in Kwali Area Council Abuja, NigeriaDocument6 paginiFactors Influencing The Use of Improved Maize Seed and Participation in The Seed Demonstration Program by Smallholder Farmers in Kwali Area Council Abuja, NigeriaInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Parastomal Hernia: A Case Report, Repaired by Modified Laparascopic Sugarbaker TechniqueDocument2 paginiParastomal Hernia: A Case Report, Repaired by Modified Laparascopic Sugarbaker TechniqueInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Blockchain Based Decentralized ApplicationDocument7 paginiBlockchain Based Decentralized ApplicationInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Insights Into Nipah Virus: A Review of Epidemiology, Pathogenesis, and Therapeutic AdvancesDocument8 paginiInsights Into Nipah Virus: A Review of Epidemiology, Pathogenesis, and Therapeutic AdvancesInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Implications of Adnexal Invasions in Primary Extramammary Paget's Disease: A Systematic ReviewDocument6 paginiImplications of Adnexal Invasions in Primary Extramammary Paget's Disease: A Systematic ReviewInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Impact of Silver Nanoparticles Infused in Blood in A Stenosed Artery Under The Effect of Magnetic Field Imp. of Silver Nano. Inf. in Blood in A Sten. Art. Under The Eff. of Mag. FieldDocument6 paginiImpact of Silver Nanoparticles Infused in Blood in A Stenosed Artery Under The Effect of Magnetic Field Imp. of Silver Nano. Inf. in Blood in A Sten. Art. Under The Eff. of Mag. FieldInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Smart Health Care SystemDocument8 paginiSmart Health Care SystemInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Visual Water: An Integration of App and Web To Understand Chemical ElementsDocument5 paginiVisual Water: An Integration of App and Web To Understand Chemical ElementsInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Air Quality Index Prediction Using Bi-LSTMDocument8 paginiAir Quality Index Prediction Using Bi-LSTMInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Predict The Heart Attack Possibilities Using Machine LearningDocument2 paginiPredict The Heart Attack Possibilities Using Machine LearningInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Compact and Wearable Ventilator System For Enhanced Patient CareDocument4 paginiCompact and Wearable Ventilator System For Enhanced Patient CareInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Smart Cities: Boosting Economic Growth Through Innovation and EfficiencyDocument19 paginiSmart Cities: Boosting Economic Growth Through Innovation and EfficiencyInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Parkinson's Detection Using Voice Features and Spiral DrawingsDocument5 paginiParkinson's Detection Using Voice Features and Spiral DrawingsInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Smart HealthCare by Cerner Healthcare Solutions 17ME061Document14 paginiSmart HealthCare by Cerner Healthcare Solutions 17ME061NPMYS23Încă nu există evaluări

- PolarFire SoC Product OverviewDocument50 paginiPolarFire SoC Product OverviewGraham PeytonÎncă nu există evaluări

- 1.1-5 Storage, I O DeviceDocument13 pagini1.1-5 Storage, I O Devicesherryll robrigadoÎncă nu există evaluări

- Pavitran A/L Pupathe A170632 Operating Systems: Assignment 1Document3 paginiPavitran A/L Pupathe A170632 Operating Systems: Assignment 1Pavitran NeymarÎncă nu există evaluări

- Quotation - Dell Latitude 3540R1Document1 paginăQuotation - Dell Latitude 3540R1Manu KaewmuangÎncă nu există evaluări

- Single Mode Family: Data Sheet 09/97Document12 paginiSingle Mode Family: Data Sheet 09/97Сергей КолосовÎncă nu există evaluări

- DroidInfo PDFDocument7 paginiDroidInfo PDFdilawer99Încă nu există evaluări

- HPEnvyx36015.6TouchLaptopIntelCore i716GBMemory1TBHardDriveSilverM6-AQ105DX PDFDocument1 paginăHPEnvyx36015.6TouchLaptopIntelCore i716GBMemory1TBHardDriveSilverM6-AQ105DX PDFLuis ZambranoÎncă nu există evaluări

- Esktop: Pulse OximeterDocument3 paginiEsktop: Pulse OximeterBrevas CuchoÎncă nu există evaluări

- BukuDocument4 paginiBukuInumaki TogeÎncă nu există evaluări

- Graphic Prosser UnitDocument3 paginiGraphic Prosser Unitمحمد الكمالÎncă nu există evaluări

- Questionnaire FinishedDocument6 paginiQuestionnaire FinishedTamarah PaulaÎncă nu există evaluări

- AIS Transponder Block Diagram PDFDocument1 paginăAIS Transponder Block Diagram PDFhamed hÎncă nu există evaluări

- Complex Programmable Logic Devices (CPLD) & Field-Programmable Gate Array (Fpga)Document29 paginiComplex Programmable Logic Devices (CPLD) & Field-Programmable Gate Array (Fpga)Prathap VuyyuruÎncă nu există evaluări

- EC1001-L Zener DiodeDocument28 paginiEC1001-L Zener DiodeSouradeep GuptaÎncă nu există evaluări

- Introduction To Python: Department of Mechanical EngineeringDocument20 paginiIntroduction To Python: Department of Mechanical EngineeringSubbu Suni100% (1)

- Infineon-EZ-PD (TM) CCG3PA Datasheet USB Type-C Port Controller-DataSheet-v09 00-ENDocument45 paginiInfineon-EZ-PD (TM) CCG3PA Datasheet USB Type-C Port Controller-DataSheet-v09 00-ENkrishÎncă nu există evaluări

- Physics Project Class 12Document20 paginiPhysics Project Class 12vr331784Încă nu există evaluări

- Activity, Class, Sequence, Collaboration, Deployment DiagramDocument5 paginiActivity, Class, Sequence, Collaboration, Deployment DiagramPatrick D CernaÎncă nu există evaluări

- BIT101-02-Computer OverviewDocument57 paginiBIT101-02-Computer OverviewZech PackÎncă nu există evaluări

- Surface Mount Triac: SOT223 (Plastic)Document4 paginiSurface Mount Triac: SOT223 (Plastic)Mike BrdnÎncă nu există evaluări

- Quanta G7H R1ADocument106 paginiQuanta G7H R1AskyloveasdfÎncă nu există evaluări

- E85005-0132 - Io Series Submittal Guide PDFDocument51 paginiE85005-0132 - Io Series Submittal Guide PDFgndurangoÎncă nu există evaluări

- 12 Physics Notes Ch14 Semiconductor ElectronicsDocument6 pagini12 Physics Notes Ch14 Semiconductor ElectronicsAryan MeenaÎncă nu există evaluări

- East West University: Department of CSEDocument5 paginiEast West University: Department of CSEFatema SadiaÎncă nu există evaluări

- Four Layer Diode, Diac, SCR & TriacDocument28 paginiFour Layer Diode, Diac, SCR & Triaczeeshan aslam 19-Arid-31Încă nu există evaluări

- PLC History: in The Late 1960'S Plcs Were First Introduced To Replace Complicated Relay Based Control SystemsDocument77 paginiPLC History: in The Late 1960'S Plcs Were First Introduced To Replace Complicated Relay Based Control SystemsPK KÎncă nu există evaluări

- 5.4 UAIS DEBEG 3400, Setting-to-Work and Configuration: Section 5.4.1 5.4.2 5.4.3Document4 pagini5.4 UAIS DEBEG 3400, Setting-to-Work and Configuration: Section 5.4.1 5.4.2 5.4.3Balasaheb AdhalraoÎncă nu există evaluări

- What Is Continuous Monitoring?: New Section 2 Page 1Document3 paginiWhat Is Continuous Monitoring?: New Section 2 Page 1Shankar NagÎncă nu există evaluări

- Computer Memory ResearchDocument10 paginiComputer Memory ResearchjojoÎncă nu există evaluări