Documente Academic

Documente Profesional

Documente Cultură

Hoval ST-plus Hot Water Boiler 401 To 2907 KW (Including MCP Variants)

Încărcat de

Carlos BrancoTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Hoval ST-plus Hot Water Boiler 401 To 2907 KW (Including MCP Variants)

Încărcat de

Carlos BrancoDrepturi de autor:

Formate disponibile

Hoval ST-plus

Hot water boiler

401 to 2907 kW

(including MCP

variants)

Construction

The ST-plus has a welded boiler quality steel shell with a water jacket surrounding an oval

combustion chamber. Heat transfer is completed by a third pass of tubes, housed in a

cylindrical tube suspended horizontally in the combustion chamber.

The boiler door is hinged to swing right or left and carries the burner and a sight glass. A

steel channel support base is an integral part of the boiler which can be removed to special

order to assist with access to restricted plant rooms.

The insulated casing is assembled from slotted ‘quickfit’ panels which as standard are fitted

to the boiler on delivery.

A side mounted TopTronic® E/E13.5 control panel is provided as standard on the right hand

side. (Not suitable for top mounting).

Electrical Supply

400V 50Hz 3 phase

A single phase 230V supply is required for the control panel operation. Single phase burners

are electrically supplied via the control panel. Three phase burners require a separate three

phase isolated supply (by the installer) direct to the burner, incorporating a flexible

connection to allow for boiler/burner door opening. In this case control cables fitted with

Wieland plug/socket will still run between the control panel and the burner. All power

supplies to the boiler/burner/ other associated equipment (i.e gas booster, separate oil

pump, etc.) should be isolated via the same switched isolator.

1 October 2018 MCP

Controls

The TopTronic® E/E13.5:

For operating temperature up

to 100˚C. Options for;

Control panel mounted on the Daytime room temperature.

left or right hand side of the

Night room temperature.

boiler casing depending on

Hot water temperature.

door hinging (Standard right

Operating mode selection (holiday, absent,

hand side).

extended heating operation, automatic,

Integrated control function for:

summer, continuous heating operation,

1 mixing circuit.

1 heating circuit without mixing reduced heating, frost protection).

operation. Adjusting the heating curves.

Domestic hot water loading System information.

circuit. Emission measurement and manual

Option to expand the functions operation.

by additional TopTronic® E Outdoor sensor AF.

modules. Flow sensor with plug.

Main switch “I/O”. Calorifier sensor with plug.

Safety temperature limiter Plug connection for burner.

120˚C. Connection available for

Fuse 10A. Toptronic® E Room control module.

Fault indication “Burner”. Connection availible for TopTronic® E.

Burner running time meter and Gateway module to allow remote access

start-up counter. (requires internet connection).

Plant Room Layout

Boiler sensor. Volt free signals available at extra cost.

Touch screen display

2 October 2018 MCP

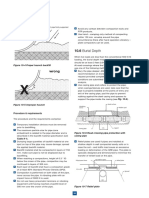

Plant Room Layout

The floor or plinth should be fireproof, flat and level.

Front clearance equal to approximately the length of the boiler base

should be allowed for tube cleaning. Shorter clearances are possible

subject to cleaning methods and plant room layout.

Side clearance to open door with burner attached space should be

allowed for the projection of the burner. As a guide burners project by

approximately the boiler width.

Side clearance (opposite sides). For battery formation boilers can be

butted together. 560mm clearance is required on the control panel side

(right as standard).

Back clearance - space should be provided for the flue off take bend,

boiler return connection and cleaning door access.

Please refer to the ST-plus Operating and Maintenance Manual for

further technical information.

3 October 2018 MCP

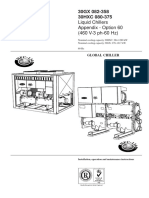

ST-plus Boiler (450 to 950 & 1150MCP to

3000MCP)

1 Flow

6 Drain

2 Return

7 Smokebox condensate drain

3 Safety valve

8 Boiler control panel

4 Explosion/ cleaning door

9 Burner mounting flange

5 Flue gas outlet

1

Model Output kW A B C D E F G H J K L M N P Dry weight Water

(kg) conte

nt

(ltrs)

450 401-475 1622 896 2034 1680 132 1271 537 1298 412 140 587 140 100 70 1352 550

600 476-581 1622 896 2034 1680 132 1271 537 1298 412 140 587 140 100 70 1374 520

750 650-756 1807 996 2416 2080 123 1475 657 1680 490 140 607 140 100 70 1857 990

950 850-894 1807 996 2416 2080 123 1475 657 1680 490 140 607 140 100 70 1934 950

1150 MCP 1050-1163 1997 1226 2980 2520 139 1314 637 2136 556 140 637 140 100 70 3001 1670

1450 MCP 1300-1343 1997 1226 2980 2520 139 1314 637 2136 556 140 637 140 100 70 3035 1600

1750 MCP 1600-1700 2274 1406 2980 2532 133 1657 687 2136 556 140 732 140 100 70 4376 2320

2500 MCP 2200-2441 2523 1586 3568 3112 137 1833 773 2720 560 140 732 140 100 70 6832 2500

3000 MCP 2700-2907 2523 1586 3568 3112 137 1833 773 2720 560 140 732 140 100 70 7032 2400

Hydraulic resistance

Connections Boiler operating data

mbar = flow rate (ltrs/sec x 3.6)² x k

Model Flow & Safety Flue Model K Max. working pressure 4.5 bar BS855

Return Valve O/D 450-600 0.0160 Test pressure 7.75 bar

450-600 DN100 PN6 DN65 PN6 250 750-950 0.0068 Operating temp 100°C

750 DN125 PN6 DN65 PN6 360 1150-1750 MCP 0.0032

950 DN125 PN6 DN65 PN6 360 2500-3000 MCP 0.0020 Open vented systems

1150 MCP DN150 PN6 DN80 PN6 450

1450 MCP DN150 PN6 DN80 PN6 450 Normal 80°C

1750 MCP DN150 PN6 DN100 PN6 450

Max. 100°C

2500 MCP DN200 PN6 DN100 PN6 500

3000 MCP DN200 PN6 DN100 PN6 550

Electrical supply Pressurised systems

400V 50Hz 3 phase Max. 100°C

1

MCP variants comply with the Medium Combustion Directive which

th Return water (all models)

comes into effect on the 20 December 2018. Suitable for gas-firing

only. Oil only suitable as a standby fuel ie: where oil is to be used in a Min. 60°C

dual fuel burner, its use must be limited to less than 500 run hours

per annum

Hoval Ltd, Northgate, Newark, Notts, NG24 1JN

Tel: 01636 672711 e-mail: boilersales@hoval.co.uk

4 October 2018 MCP

S-ar putea să vă placă și

- Water-Cooled Screw Chiller: Nominal Cooling Capacity: 335 1392kWDocument12 paginiWater-Cooled Screw Chiller: Nominal Cooling Capacity: 335 1392kWمحمد مرسيÎncă nu există evaluări

- Handbook of Heating, Ventilating and Air ConditioningDe la EverandHandbook of Heating, Ventilating and Air ConditioningEvaluare: 4 din 5 stele4/5 (6)

- Technical Manual For Air Cooled Screw Chiller (FCH02-2020,21)Document34 paginiTechnical Manual For Air Cooled Screw Chiller (FCH02-2020,21)yusuf mohd sallehÎncă nu există evaluări

- Thermodynamic Design Data for Heat Pump Systems: A Comprehensive Data Base and Design ManualDe la EverandThermodynamic Design Data for Heat Pump Systems: A Comprehensive Data Base and Design ManualÎncă nu există evaluări

- Greenbox Arrefecedores EvaporativosDocument2 paginiGreenbox Arrefecedores EvaporativosJose Luis Reyes ParraÎncă nu există evaluări

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDe la EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsÎncă nu există evaluări

- GN Boiler RangeDocument16 paginiGN Boiler Range9810482818Încă nu există evaluări

- HTTP Eto - Carrier.com Litterature Tecdata 30hxcphaseIIDocument1 paginăHTTP Eto - Carrier.com Litterature Tecdata 30hxcphaseIIJoe Israel V-Red SkidÎncă nu există evaluări

- Tappan Furnace FG6RK 096N 16BDocument4 paginiTappan Furnace FG6RK 096N 16BAnubis RahlÎncă nu există evaluări

- Marine Electrical Practice: Marine Engineering SeriesDe la EverandMarine Electrical Practice: Marine Engineering SeriesEvaluare: 4 din 5 stele4/5 (8)

- Service Manual: Washing Machine Frontloader FL 5105/ADocument14 paginiService Manual: Washing Machine Frontloader FL 5105/AjicutuÎncă nu există evaluări

- Total Energy: International Series in Heating, Ventilation and RefrigerationDe la EverandTotal Energy: International Series in Heating, Ventilation and RefrigerationÎncă nu există evaluări

- 30HXC IOM 60hz Appendix 13403Document12 pagini30HXC IOM 60hz Appendix 13403Cucup SupriatnaÎncă nu există evaluări

- 30hxyhxc-High Cop 2012Document12 pagini30hxyhxc-High Cop 2012Luciano Lopes Simões100% (2)

- Alfa Laval - Emd00308en - EhDocument4 paginiAlfa Laval - Emd00308en - EhEnder ZenginobuzÎncă nu există evaluări

- Brosur HiCOP Air To Water Heat Pump (AW) - 1Document2 paginiBrosur HiCOP Air To Water Heat Pump (AW) - 1fannyÎncă nu există evaluări

- 2 4Document14 pagini2 4rafaelki100% (2)

- Chiller Koolman CgakDocument8 paginiChiller Koolman Cgakfabieduarte440Încă nu există evaluări

- VHP7104GSI/GSID: Basic SpecificationsDocument2 paginiVHP7104GSI/GSID: Basic SpecificationsferyÎncă nu există evaluări

- Whirlpool Awt 5109Document14 paginiWhirlpool Awt 5109vacsaaÎncă nu există evaluări

- Waterco Ps HeatersDocument10 paginiWaterco Ps HeatersMarioEnriqueAlcocerÁvilaÎncă nu există evaluări

- Water Cooled Screw Chiller Brochure Final As 3 AsDocument16 paginiWater Cooled Screw Chiller Brochure Final As 3 AsSumon MahmudÎncă nu există evaluări

- Heat Recovery Unit à  ¿UTNR-HP-2Document3 paginiHeat Recovery Unit à  ¿UTNR-HP-2matumoralesÎncă nu există evaluări

- BROAD X Absorption Chiller Model Selection Design ManualDocument46 paginiBROAD X Absorption Chiller Model Selection Design Manualpseudosil0% (1)

- Service Manual: Washing Machine Toploader AWT 2288/3Document14 paginiService Manual: Washing Machine Toploader AWT 2288/3florinoteckÎncă nu există evaluări

- SH930 J Series March2013 PQDocument2 paginiSH930 J Series March2013 PQDavid Aguirre BurneoÎncă nu există evaluări

- Specifications: VHP5904LTDocument2 paginiSpecifications: VHP5904LTmuhammad wafiÎncă nu există evaluări

- Toplotna Pumpa Hidria Clint - Eu - Cha K - 182 P 604 P - cls61.7 EngDocument2 paginiToplotna Pumpa Hidria Clint - Eu - Cha K - 182 P 604 P - cls61.7 EngMuhidin KozicaÎncă nu există evaluări

- Cooling Infrastructure Solution: Room, Row and ChillerDocument18 paginiCooling Infrastructure Solution: Room, Row and ChillerMohammad AkifÎncă nu există evaluări

- Katalog Defro - en 01 - 2022Document36 paginiKatalog Defro - en 01 - 2022Octavian MrejeruÎncă nu există evaluări

- Whirlpool Polar PDT 839 Service ManualDocument14 paginiWhirlpool Polar PDT 839 Service ManualAnonymous 2GVabYh40WÎncă nu există evaluări

- 30HZ&lang Id 1Document2 pagini30HZ&lang Id 1Maxmore KarumamupiyoÎncă nu există evaluări

- Tad730ge 111797s01Document8 paginiTad730ge 111797s01roozbehxoxÎncă nu există evaluări

- Transformadores Tipo SubestacionDocument12 paginiTransformadores Tipo SubestacionRobert LiraÎncă nu există evaluări

- Whirlpool Awo 9361 Service Manual EnglishDocument19 paginiWhirlpool Awo 9361 Service Manual Englishvladimir100% (1)

- Carbolite Standard Chamber Furnace 36lDocument3 paginiCarbolite Standard Chamber Furnace 36lYessy MalindaÎncă nu există evaluări

- Whirlpool FL 5090aDocument14 paginiWhirlpool FL 5090aLiviu PetreÎncă nu există evaluări

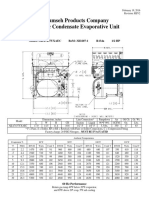

- Tecumseh Products Company Hermetic Condensate Evaporative UnitDocument2 paginiTecumseh Products Company Hermetic Condensate Evaporative UnitAlexisÎncă nu există evaluări

- Arikazan Eco MiniDocument4 paginiArikazan Eco MiniDamian OvidiuÎncă nu există evaluări

- Optyma CU Leaflet - 46CDocument8 paginiOptyma CU Leaflet - 46CRahul PatilÎncă nu există evaluări

- Gas Turbine PerformancexlsDocument15 paginiGas Turbine PerformancexlsMahmood ElnagarÎncă nu există evaluări

- Whirlpool Awt 4080 1Document14 paginiWhirlpool Awt 4080 1asseccagarbugli86Încă nu există evaluări

- Service Manual: Washing Machine Toploader AWT 2288/3Document14 paginiService Manual: Washing Machine Toploader AWT 2288/3cibocrisÎncă nu există evaluări

- Whirlpool Awt 5060Document14 paginiWhirlpool Awt 5060Vally ValyÎncă nu există evaluări

- Welding Machine Specifications PDFDocument4 paginiWelding Machine Specifications PDFrahmankhan8230% (1)

- Whirlpool Awe 6315 859363110050 1 1Document14 paginiWhirlpool Awe 6315 859363110050 1 1Teo Si DoraÎncă nu există evaluări

- AWM8143Document22 paginiAWM8143pinticaniulian9042100% (1)

- ECTI ProductCatalogueDocument16 paginiECTI ProductCatalogueCorazón GrandeÎncă nu există evaluări

- VHP5904LT: Basic SpecificationsDocument2 paginiVHP5904LT: Basic SpecificationsferyÎncă nu există evaluări

- Whirlpool Polar Pwa 630 A PDocument14 paginiWhirlpool Polar Pwa 630 A PBucur BaleanuÎncă nu există evaluări

- Broad X Non-Electric Chiller: Model Selection & Design ManualDocument27 paginiBroad X Non-Electric Chiller: Model Selection & Design ManualdokundotÎncă nu există evaluări

- Perkins A PDFDocument4 paginiPerkins A PDFbambang0% (1)

- PS 438919507en W5330S enDocument2 paginiPS 438919507en W5330S enFelix RamirezÎncă nu există evaluări

- VhHeatPump WebDocument4 paginiVhHeatPump WebSAMEERAÎncă nu există evaluări

- PGCLS1000KW: Leroy-Somer LSA49.1L11 Stamford LVI634E Tide TPA404S5Document5 paginiPGCLS1000KW: Leroy-Somer LSA49.1L11 Stamford LVI634E Tide TPA404S5crisdanielminasÎncă nu există evaluări

- Specification May Change According To Project RequirementDocument1 paginăSpecification May Change According To Project RequirementasdthuÎncă nu există evaluări

- Chiller RecipDocument4 paginiChiller RecipHerni SuharniriyantiÎncă nu există evaluări

- Air Conditioner: Owner'S ManualDocument68 paginiAir Conditioner: Owner'S ManualCarlos BrancoÎncă nu există evaluări

- Installer Manual: Versa - I - en 10/15Document36 paginiInstaller Manual: Versa - I - en 10/15Carlos BrancoÎncă nu există evaluări

- Installation / User Manual: Apsystems Yc600 MicroinverterDocument24 paginiInstallation / User Manual: Apsystems Yc600 MicroinverterCarlos BrancoÎncă nu există evaluări

- ETHM-1: TCP/IP Communication ModuleDocument20 paginiETHM-1: TCP/IP Communication ModuleCarlos BrancoÎncă nu există evaluări

- Modules - Explanations - SEMIPONT: Semipont, Bridge Rectifiers and AC ControllerDocument8 paginiModules - Explanations - SEMIPONT: Semipont, Bridge Rectifiers and AC ControllerCarlos BrancoÎncă nu există evaluări

- Usb-Rs Io en 1014 PDFDocument2 paginiUsb-Rs Io en 1014 PDFCarlos BrancoÎncă nu există evaluări

- Grandstream Networks, Inc.: Grandstream Firmware Upgrade Utility ToolDocument8 paginiGrandstream Networks, Inc.: Grandstream Firmware Upgrade Utility ToolCarolina AldanaÎncă nu există evaluări

- APsystems YC600 2019 10 ENDocument2 paginiAPsystems YC600 2019 10 ENCarlos BrancoÎncă nu există evaluări

- Zktimelite User Guide enDocument31 paginiZktimelite User Guide enCarlos BrancoÎncă nu există evaluări

- Honeywel S4560Document16 paginiHoneywel S4560Carlos BrancoÎncă nu există evaluări

- Technology A Boon or A Bane Ojas - Eng - FinalDocument12 paginiTechnology A Boon or A Bane Ojas - Eng - FinalOjasÎncă nu există evaluări

- Introducing Corpora in Translation StudiesDocument233 paginiIntroducing Corpora in Translation Studies2466334392Încă nu există evaluări

- Web ArchitectureDocument284 paginiWeb ArchitecturedArKhAcKsÎncă nu există evaluări

- Catalog Stationary Screw Compressors F en V 1 3 WebDocument28 paginiCatalog Stationary Screw Compressors F en V 1 3 WebcristiÎncă nu există evaluări

- NPBC-V3C-1 Rev1 1 ENDocument36 paginiNPBC-V3C-1 Rev1 1 ENeddixÎncă nu există evaluări

- Dell™ P170S/P190S Flat Panel Monitor User's Guide: Notes, Cautions, and WarningsDocument37 paginiDell™ P170S/P190S Flat Panel Monitor User's Guide: Notes, Cautions, and Warningssuna burakÎncă nu există evaluări

- VNX - VNX 5100 Procedures-Replacing A 3U Link Control CardDocument21 paginiVNX - VNX 5100 Procedures-Replacing A 3U Link Control CardWei LeeÎncă nu există evaluări

- Thesis On Power Factor ImprovementDocument8 paginiThesis On Power Factor ImprovementBrittany Brown100% (2)

- 42NQV035 SVMDocument99 pagini42NQV035 SVMHdnrkdÎncă nu există evaluări

- English - BAS#27 - Philips NMS 1205 Music Module Expander (Full Version)Document9 paginiEnglish - BAS#27 - Philips NMS 1205 Music Module Expander (Full Version)Luis AriasÎncă nu există evaluări

- Bomba - Weir - Curvas Warman Horizontais-Versão MetálicaDocument18 paginiBomba - Weir - Curvas Warman Horizontais-Versão MetálicaWanderson Alcantara100% (1)

- ZG3/ZGM/K-GPM20T Series Integrated PLC&HMI ManualDocument56 paginiZG3/ZGM/K-GPM20T Series Integrated PLC&HMI ManualMarcosÎncă nu există evaluări

- DIY Time & Attendance Recorder: FeaturesDocument1 paginăDIY Time & Attendance Recorder: FeaturesVasko diÎncă nu există evaluări

- AN 396 FTDI Drivers Installation Guide For Windows 10 11Document30 paginiAN 396 FTDI Drivers Installation Guide For Windows 10 11Ronald FrancoÎncă nu există evaluări

- Program Manager Vs Project Manager Salary & ResponsibilitiesDocument2 paginiProgram Manager Vs Project Manager Salary & Responsibilities1105195794Încă nu există evaluări

- 3M Green Corps 3M Green Corps Cut Off Wheels: Depressed Center WheelDocument10 pagini3M Green Corps 3M Green Corps Cut Off Wheels: Depressed Center Wheelherysyam1980Încă nu există evaluări

- 2004 Viking-Excalibur ManualDocument45 pagini2004 Viking-Excalibur ManualjackÎncă nu există evaluări

- Computer Short Cut NamesDocument4 paginiComputer Short Cut Nameshajanm100% (1)

- Condition Monitoring of Zinc Oxide Surge Arresters: August 2011Document19 paginiCondition Monitoring of Zinc Oxide Surge Arresters: August 2011Đức ThảoÎncă nu există evaluări

- Ambient Intelligence: Prof. Renato NunesDocument27 paginiAmbient Intelligence: Prof. Renato NunesMelek MaalejÎncă nu există evaluări

- Firoj SahuDocument4 paginiFiroj Sahugelhu1987Încă nu există evaluări

- An Alliance Could Answer The Growing Threat From Google and FacebookDocument2 paginiAn Alliance Could Answer The Growing Threat From Google and FacebookelfirafnÎncă nu există evaluări

- Unisalento4Talents Programme - Call For Applications For Scholarshipsfor International Students - (Academic Year 2021-2022) Application FormDocument4 paginiUnisalento4Talents Programme - Call For Applications For Scholarshipsfor International Students - (Academic Year 2021-2022) Application Formwaqar aliÎncă nu există evaluări

- ICT-CSS-12 Q1 W2 Mod 4Document16 paginiICT-CSS-12 Q1 W2 Mod 4AJ Bacarisas RochaÎncă nu există evaluări

- Amipox - SUBMITTAL 52Document1 paginăAmipox - SUBMITTAL 52norman moralesÎncă nu există evaluări

- Updating Bank Details For Shared Vendors in SAPDocument5 paginiUpdating Bank Details For Shared Vendors in SAPnasuuÎncă nu există evaluări

- Weight Per Meter of Weld MetalDocument1 paginăWeight Per Meter of Weld MetalLuis SPÎncă nu există evaluări

- Scikit LearnDocument10 paginiScikit LearnsairameshtÎncă nu există evaluări

- Atoll 2.8.0 General Features Radio Public CourseDocument61 paginiAtoll 2.8.0 General Features Radio Public CourseAmine GigiÎncă nu există evaluări

- Trends Mapping Study Digital Skills Development in Tvet Teacher TrainingDocument56 paginiTrends Mapping Study Digital Skills Development in Tvet Teacher TrainingMila NurulÎncă nu există evaluări

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterDe la EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterÎncă nu există evaluări

- A Practical Handbook for Drilling Fluids ProcessingDe la EverandA Practical Handbook for Drilling Fluids ProcessingÎncă nu există evaluări

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesDe la EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesEvaluare: 4.5 din 5 stele4.5/5 (21)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentDe la EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentEvaluare: 4.5 din 5 stele4.5/5 (21)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialDe la EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialÎncă nu există evaluări

- Shorting the Grid: The Hidden Fragility of Our Electric GridDe la EverandShorting the Grid: The Hidden Fragility of Our Electric GridEvaluare: 4.5 din 5 stele4.5/5 (2)

- Nuclear Energy in the 21st Century: World Nuclear University PressDe la EverandNuclear Energy in the 21st Century: World Nuclear University PressEvaluare: 4.5 din 5 stele4.5/5 (3)

- Introduction to Power System ProtectionDe la EverandIntroduction to Power System ProtectionEvaluare: 5 din 5 stele5/5 (1)

- A Pathway to Decarbonise the Shipping Sector by 2050De la EverandA Pathway to Decarbonise the Shipping Sector by 2050Încă nu există evaluări

- Solar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsDe la EverandSolar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsEvaluare: 4.5 din 5 stele4.5/5 (2)

- Heat Transfer Engineering: Fundamentals and TechniquesDe la EverandHeat Transfer Engineering: Fundamentals and TechniquesEvaluare: 4 din 5 stele4/5 (1)

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsDe la EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsÎncă nu există evaluări

- Internal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesDe la EverandInternal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesEvaluare: 4 din 5 stele4/5 (2)

- Power Electronics Diploma Interview Q&A: Career GuideDe la EverandPower Electronics Diploma Interview Q&A: Career GuideÎncă nu există evaluări

- Well Integrity for Workovers and RecompletionsDe la EverandWell Integrity for Workovers and RecompletionsEvaluare: 5 din 5 stele5/5 (3)

- Handbook on Battery Energy Storage SystemDe la EverandHandbook on Battery Energy Storage SystemEvaluare: 4.5 din 5 stele4.5/5 (2)

- Flow Analysis for Hydrocarbon Pipeline EngineeringDe la EverandFlow Analysis for Hydrocarbon Pipeline EngineeringÎncă nu există evaluări

- Smart Power Distribution Systems: Control, Communication, and OptimizationDe la EverandSmart Power Distribution Systems: Control, Communication, and OptimizationÎncă nu există evaluări

- Live Off Grid: Escape The City, Learn How To Travel Intelligently Using Solar PowerDe la EverandLive Off Grid: Escape The City, Learn How To Travel Intelligently Using Solar PowerÎncă nu există evaluări

- Practical Reservoir Engineering and CharacterizationDe la EverandPractical Reservoir Engineering and CharacterizationEvaluare: 4.5 din 5 stele4.5/5 (3)

- Renewable Energy: A Very Short IntroductionDe la EverandRenewable Energy: A Very Short IntroductionEvaluare: 4.5 din 5 stele4.5/5 (12)

- An Introduction to Renewable Energy Sources : Environment Books for Kids | Children's Environment BooksDe la EverandAn Introduction to Renewable Energy Sources : Environment Books for Kids | Children's Environment BooksÎncă nu există evaluări

- The Permaculture City: Regenerative Design for Urban, Suburban, and Town ResilienceDe la EverandThe Permaculture City: Regenerative Design for Urban, Suburban, and Town ResilienceÎncă nu există evaluări

- Electric Motor Control: DC, AC, and BLDC MotorsDe la EverandElectric Motor Control: DC, AC, and BLDC MotorsEvaluare: 4.5 din 5 stele4.5/5 (19)

- Photovoltaic Solar Energy: From Fundamentals to ApplicationsDe la EverandPhotovoltaic Solar Energy: From Fundamentals to ApplicationsÎncă nu există evaluări

- Global Landscape of Renewable Energy FinanceDe la EverandGlobal Landscape of Renewable Energy FinanceÎncă nu există evaluări

- Electric Motors and Drives: Fundamentals, Types and ApplicationsDe la EverandElectric Motors and Drives: Fundamentals, Types and ApplicationsEvaluare: 4.5 din 5 stele4.5/5 (12)