Documente Academic

Documente Profesional

Documente Cultură

Discussion and Conclusion

Încărcat de

irfan bashirDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Discussion and Conclusion

Încărcat de

irfan bashirDrepturi de autor:

Formate disponibile

Discussion:

The initial features of the samples are very significant. Figure 1 shows that the sample is fully

austenitic and coarse regime are available. From result’s it is clear that various particle sizes are

present in the specimen ranges from coarser to finer. In order to get the homogenous

microstructure we should have to reduce the coarser particles into smaller particles. It also

helps us to develop high r value. As the particle size reduced to small, the stored energy

increases which ultimately produce low deformations and larger strain values. The stored

energy in fine particles are due to increase in the boundary area. Therefore, the stored energy

is linked with the particle size and uniformity of the microstructure of the stainless steel. The

growth rate and nucleation affect the particle size. Greater the stored energy, higher will be the

nucleation rate.

In figure, it is clear that there are much coarser particles than the finer particles. Therefore, the

stored energy is less. From the result’s it is also clear that the number of particles in each

process (ImageJ and Manual) are different from each other’s but the particle size is almost

same which is 26 larger than the average grain size of stainless steel. The number of grain in

ImageJ process were 37645851.17 while in manual process they were 35804478.01. The

temperature affect the grain size distribution of the stainless steel. As the temperature goes

above 1200 oC, the error in the prediction of the grain size is larger and the results will fall in

unacceptable range. At high temperature, some particles behave abnormal because those

particles active on high temperatures. In order to study the grain growth rate, the grain size

analysis expanded to high temperatures.

Conclusion:

This experiment was performed to study the grain size distribution of the stainless steel. Some

metallography techniques used to study the grain size. The material used was AISI 1045 Plain

Carbon Steel. In first step treatment was done to remove all impurities from surface. In second

step, the sample was grinded and different sizes sandpaper’s were used. In next step we

polished the sample and studied it through microscope to get the idea of the grain size. This

study gave the idea of grain size and number of grains present in stainless steel using Manual

process and ImageJ process. It was also noticed that the grain size affect’s the mechanical

properties of the stainless steel, work hardening, fracture surface etc.

S-ar putea să vă placă și

- 3Document1 pagină3irfan bashirÎncă nu există evaluări

- 1Document1 pagină1irfan bashirÎncă nu există evaluări

- 5Document1 pagină5irfan bashirÎncă nu există evaluări

- Gen Zia Ul HaqDocument7 paginiGen Zia Ul Haqirfan bashirÎncă nu există evaluări

- For The Beam Section Shown On The Effect of The To...Document3 paginiFor The Beam Section Shown On The Effect of The To...irfan bashirÎncă nu există evaluări

- 4Document1 pagină4irfan bashirÎncă nu există evaluări

- Design ParametersDocument6 paginiDesign Parametersirfan bashirÎncă nu există evaluări

- Calculus Trigonometry Statistics: Quality Work Reliability 24/7 AvailabilityDocument1 paginăCalculus Trigonometry Statistics: Quality Work Reliability 24/7 Availabilityirfan bashirÎncă nu există evaluări

- Designand Analysisof PEBWarehouse Using STAADPRODocument11 paginiDesignand Analysisof PEBWarehouse Using STAADPROirfan bashirÎncă nu există evaluări

- Tensile Test Lab Report: Strength of MaterialDocument5 paginiTensile Test Lab Report: Strength of Materialirfan bashirÎncă nu există evaluări

- Students Name Roll Number Experiment No. 05 Title of The Experiment Date of Performance Date of Completion RemarksDocument6 paginiStudents Name Roll Number Experiment No. 05 Title of The Experiment Date of Performance Date of Completion Remarksirfan bashirÎncă nu există evaluări

- Fixed Rate Loan PaymentsDocument9 paginiFixed Rate Loan Paymentsirfan bashirÎncă nu există evaluări

- 1.2mx1.8m Cabin DetailsDocument3 pagini1.2mx1.8m Cabin Detailsirfan bashirÎncă nu există evaluări

- Problem # 01:: A) Interpretation of Number 64,100Document2 paginiProblem # 01:: A) Interpretation of Number 64,100irfan bashirÎncă nu există evaluări

- Lab BernoulliDocument9 paginiLab Bernoulliirfan bashirÎncă nu există evaluări

- 5 Numner Summary Lab PDFDocument1 pagină5 Numner Summary Lab PDFirfan bashirÎncă nu există evaluări

- Lab-BernoulliDocument11 paginiLab-Bernoulliirfan bashirÎncă nu există evaluări

- 2.4 ProblemsDocument7 pagini2.4 Problemsirfan bashirÎncă nu există evaluări

- Tensile Test: ME 3501 L: Behavior and Selection of MaterialsDocument8 paginiTensile Test: ME 3501 L: Behavior and Selection of Materialsirfan bashirÎncă nu există evaluări

- HistogramDocument1 paginăHistogramirfan bashirÎncă nu există evaluări

- Design Report (Term Project CE 3610) DescriptionDocument3 paginiDesign Report (Term Project CE 3610) Descriptionirfan bashirÎncă nu există evaluări

- Lab BoxDocument2 paginiLab Boxirfan bashirÎncă nu există evaluări

- Wind Loads: The Nature of Wind: CE 694R - Fall 2007 T. Bart Quimby, P.E., Ph.D. UAA Civil Engineering Quimby & AssociatesDocument12 paginiWind Loads: The Nature of Wind: CE 694R - Fall 2007 T. Bart Quimby, P.E., Ph.D. UAA Civil Engineering Quimby & Associatesirfan bashirÎncă nu există evaluări

- Students Count by Year: Exercise # 05Document3 paginiStudents Count by Year: Exercise # 05irfan bashirÎncă nu există evaluări

- Faris Abualshamat Beam DesignDocument1 paginăFaris Abualshamat Beam Designirfan bashirÎncă nu există evaluări

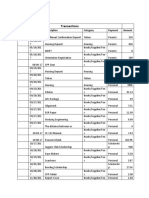

- Category Payment (Empty) Books/Supplier/Fees Parents Personal Housing Parents Personal Tution Parents (Empty) ScholorshipDocument12 paginiCategory Payment (Empty) Books/Supplier/Fees Parents Personal Housing Parents Personal Tution Parents (Empty) Scholorshipirfan bashirÎncă nu există evaluări

- Transactions: Term Date Description Category Payment Amount Fall 2017Document10 paginiTransactions: Term Date Description Category Payment Amount Fall 2017irfan bashirÎncă nu există evaluări

- Students Count by Year: Exercise # 05Document3 paginiStudents Count by Year: Exercise # 05irfan bashirÎncă nu există evaluări

- Metric Ruler Length Widht Thickness Random Uncertainity 147.14 Uncertainity in Volume Mean STD DevDocument2 paginiMetric Ruler Length Widht Thickness Random Uncertainity 147.14 Uncertainity in Volume Mean STD Devirfan bashirÎncă nu există evaluări

- GraphDocument2 paginiGraphirfan bashirÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Objective: Theory: 1. Motion Economy:: Lab Session: 2Document5 paginiObjective: Theory: 1. Motion Economy:: Lab Session: 2Ali NoraizÎncă nu există evaluări

- Armco Pure Iron PDB Euro Final Secured 92Document24 paginiArmco Pure Iron PDB Euro Final Secured 92Tanzil ZaidiÎncă nu există evaluări

- Tenax 88s HR (E 50 6 Mn1ni B 32 h5)Document1 paginăTenax 88s HR (E 50 6 Mn1ni B 32 h5)brunizzaÎncă nu există evaluări

- Sae Ams 5523G-2012Document5 paginiSae Ams 5523G-2012Mehdi MokhtariÎncă nu există evaluări

- 26875303Document9 pagini26875303Haresh RaisinghaniÎncă nu există evaluări

- GalvInfoNote 3-6Document6 paginiGalvInfoNote 3-6Vasudev BhanajiÎncă nu există evaluări

- Material PropertiesDocument16 paginiMaterial PropertiesMadan Kulkarni100% (1)

- Hollow Bar ChartDocument1 paginăHollow Bar Charthornet121Încă nu există evaluări

- Steel Pickling Ip 12 1993Document134 paginiSteel Pickling Ip 12 1993m daneshpour100% (1)

- GALVOTEC Aluminium Catalogue (Draft 2020)Document18 paginiGALVOTEC Aluminium Catalogue (Draft 2020)bello imamÎncă nu există evaluări

- Corrosion TextDocument40 paginiCorrosion TextAlex PazmiñoÎncă nu există evaluări

- A693-13 Standard Specification For Precipitation-Hardening Stainless and Heat-Resisting Steel Plate, Sheet, and StripDocument9 paginiA693-13 Standard Specification For Precipitation-Hardening Stainless and Heat-Resisting Steel Plate, Sheet, and Striptjt4779100% (2)

- Stainless India CompaniesDocument12 paginiStainless India CompaniesRæhul SÄlvé100% (1)

- Aisi A6Document1 paginăAisi A6123vigenÎncă nu există evaluări

- I II III IV V VI VII Viii H He: SC Ti V CR MN Fe Co Ni Cu ZNDocument2 paginiI II III IV V VI VII Viii H He: SC Ti V CR MN Fe Co Ni Cu ZNMuhammad KhanÎncă nu există evaluări

- Practical Data HandbookDocument120 paginiPractical Data Handbookjtamminga100% (18)

- Ahss Guidelines V 23Document113 paginiAhss Guidelines V 23Radesh VangipuramÎncă nu există evaluări

- Rejection FaisalDocument62 paginiRejection Faisalpranav1947Încă nu există evaluări

- Vdocuments - MX - Customer Specification Specification Specification Specification Name RevisionDocument67 paginiVdocuments - MX - Customer Specification Specification Specification Specification Name Revisionedgar50% (2)

- NES 747 Part1 PDFDocument38 paginiNES 747 Part1 PDFRicardo Huanca TrejoÎncă nu există evaluări

- Koyo SuffixsDocument10 paginiKoyo SuffixsOktavianus Paul Mulalinda100% (1)

- Color Metallography PDFDocument2 paginiColor Metallography PDFLoryÎncă nu există evaluări

- Pre Dispatch ChecklistDocument2 paginiPre Dispatch ChecklistBhawna100% (1)

- We Know How: Product RangeDocument5 paginiWe Know How: Product RangeMohamed RaafatÎncă nu există evaluări

- Metals and Materials For Low Temperatures and Cryogenic Applications - Gasparini IndustriesDocument7 paginiMetals and Materials For Low Temperatures and Cryogenic Applications - Gasparini IndustriesDianna LambertÎncă nu există evaluări

- Material Specification Sheet Saarstahl - 30Mnvs6 (27mnsivs6) - Saarform 900Document1 paginăMaterial Specification Sheet Saarstahl - 30Mnvs6 (27mnsivs6) - Saarform 900RajaSekarsajja100% (1)

- Abrasive Wear Behavior of Boronized AISI 8620 Steel 2008 PDFDocument7 paginiAbrasive Wear Behavior of Boronized AISI 8620 Steel 2008 PDFSteffen AichholzÎncă nu există evaluări

- Steel Industry Embraces A992Document6 paginiSteel Industry Embraces A992Jagadeesh Nandam100% (1)

- S500 Grade Steel SpecificationsDocument2 paginiS500 Grade Steel SpecificationsSmriti Agarwalla100% (1)

- Forging Design ConsiderationsDocument81 paginiForging Design ConsiderationssuneethaÎncă nu există evaluări