Documente Academic

Documente Profesional

Documente Cultură

Method Statement RCUD

Încărcat de

Fa DylaDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Method Statement RCUD

Încărcat de

Fa DylaDrepturi de autor:

Formate disponibile

Method Statement for Reinforced In-situ Concrete U-Drain (RCUD)

METHOD STATEMENT

of

REINFORCED IN-SITU CONCRETE U-DRAIN (RCUD)

for

AHMAD ZAKI SDN BHD

PACKAGE V202

CONSTRUCTION AND COMPLETION OF VIADUCT GUIDEWAY AND OTHER

ASSOCIATED WORKS FROM PERSIARAN DAGANG TO JINJANG

Contractor

Apex Global Construction Sdn Bhd

ORIGINAL Prepared by: Reviewed by: Approved by:

Date : 13/3/20 Name : Mohd Shafiq Name : Name :

Hamzah

Revision : 0 Signature Signature Signature

Main Conc Comment :

Document Number Rev Date

Page 1 of 9

AGC/MRT2/AZRB/MOS 001 00 17th March 2020

Method Statement for Reinforced In-situ Concrete U-Drain (RCUD)

Table of Contents

1.0 SCOPE OF WORK

1.1 General Description

1.2 Materials

1.3 Plant and Equipment

1.4 Manpower

1.5 Construction procedures

2.0 SAFETY AND HEALTH ENVIRONMENT

2.1 Job safety & health analysis

2.2 information to personnel

2.4 Emergency Plan during Event

2.4 Permit Requirement

3.0 ENVIRONMENTAL ISSUES

3.1 Environmental Aspect Impacts and Control Measures

4.0 QUALITY ASSURANCE AND QUALITY CONTROL

4.1 Contractual Requirement

4.2 Inspection and Testing

4.3 Follow up and Evaluation

Document Number Rev Date

Page 2 of 9

AGC/MRT2/AZRB/MOS 001 00 17th March 2020

Method Statement for Reinforced In-situ Concrete U-Drain (RCUD)

1) SCOPE OF WORK

1.1 General Description

This work method statement applied to construction of Reinforced Concrete U-Drain for the

projects and presenting the resources, operation and material used.

1.2 Reference

- General Specification for Civil Engineering Works

No. Document References No.

1 General Specification for Civil Engineering Works SSP-PDP2-GENE-OVER-SPC-000001

2 Job Safety & Health Analysis (JSA) AZRB

3 Pre Task Talk (PTT) AZRB

4 Excavation Permit AZRB

5 KVMRT Safety Passport Procedure SSP-PDP2-GENE-OVER-SPC-000001

6 Machinery Checklist AZRB

7 Standard Operating Procedure Covid-19 KKR/CIDB 2020

Pandemic

1.3 Materials

Material used as approval

- Crusher Run

- Concrete Grade C32/40-20

- 12mm thick Plywood

- Timber pf 1” x 3” and 2” x 4”

- Formwork release agent (Estoform OB)

- Curing Compound (Estocure)

- Steel Wire (reinforcement ties)

- High Tensile Steel Bar

Document Number Rev Date

Page 3 of 9

AGC/MRT2/AZRB/MOS 001 00 17th March 2020

Method Statement for Reinforced In-situ Concrete U-Drain (RCUD)

1.4 Plant and Equipment

No. Equipment Plant & Tools Description Qty Remarks

1 Concrete Vibrator To compact the concrete 2 Unit

2 Generator Set To supply power to tools and 1 unit Provided by Main

equipment Conc

3 Water Pump Dewatering water at work 2 Unit

area/trench

4 Air Compressor / Air Hand Cleaning formwork from any 1 Unit

Held Cordless debris before concrete work

5 Auto Level To control Invert Level 1 Unit

1.5 Manpower

1.5.1 All site personnel to compulsory to attend Blue Card Training for Safety Passport Assurance

1.5.2 All site personnel shall have KVRMT Grey Card Passport subject to working method and

machinery involved this is to enhance safety in workplace. In additional backhoe operator only

require Blue Card.

1.5.3 PIC to submit Participant Particular form to WPC of each site personnel together enclosed

- Identification Card / Passport Card

- Valid Cidb Card

- Work Permit for Expatriate/Foreign

1.5.3 Below is detail manpower requisition for construction of RCUD

- Site Manager – 1 pax

- Site Engineer/Site Supervisor – 1 pax

- Barbender / concretor - 5 pax

- Carpenter - 5 pax

- Backhoe operator – 1 pax

1.6 Construction Procedure

RCUD Construction

Document Number Rev Date

Page 4 of 9

AGC/MRT2/AZRB/MOS 001 00 17th March 2020

Method Statement for Reinforced In-situ Concrete U-Drain (RCUD)

1.6.1 Preliminary Works

1.6.1.1 PIC to ensure using construction drawing or shop drawing that WPC has submitted to PDP/SC

1.6.1.2 PIC to ensure using material that have submitted by WPC to PDP/SC prior to procurement and

usage.

1.6.1.3 PIC shall apply Permit to Work (PTW) form relevant parties before commence work.

1.6.1.4 PIC to ensure followed Traffic Management Plan implemented by WPC

1.6.1.5 PIC to ensure working area is barricade properly according to safety and health plan

1.6.2 Survey and Setting Out

1.6.2.1 WPC surveyor shall set-out the position of RCUD alignment for center line of drain at 20 meter

interval and sump location

1.6.2.2 PIC shall ensure the invert level and gradient is based on approved drawings

1.6.3 Material Storage and Handling

1.6.3.1 PIC to ensure the specified materials for reinforcement work such rebar and plywood shall be

stored at designated area for safety reason and providing timber support at bottom to avoid any

contact with ground surface and properly covered from weather as to avoid factors that can

accelerate rusting process.

1.6.3.2 All material delivered to site shall be inspected during delivery and before commencing work

and shall be properly storage to avoid any deterioration or damage.

1.6.3.3 All material shall be stacked properly for easy identification and lifting.

1.6.4 Excavation Work

Excavation work for the RCUD will be carried out using backhoe.

The excavated soil will be transporting to designated area using dump lorry.

1.6.4.1 Temporary Working Area – Trenches Pit

- Providing save excavation trenches

Any excavation more than 2 meter to perform sloping 1:2 and exposed slope shall cover with

Document Number Rev Date

Page 5 of 9

AGC/MRT2/AZRB/MOS 001 00 17th March 2020

Method Statement for Reinforced In-situ Concrete U-Drain (RCUD)

geotextile.

Excavation trenches to be provided temporary rigid perimeter fencing red and white painted

and to be 1.5-meter height from ground.

- providing safe access to trenches

PIC to provide sturdy temporary safe access in and out for emergency event such slope collapse

or others using steel ladders from scaffold or any and providing handrails to allow safe 3-point

contact.

- Excavation surface and bedding

Area shall be firm and even. Free from water, soft layer and loose material.

Bedding material shall used approved material and thickness

1.6.4.2 Excavation material/soil

- Dump area to be determined and confirmed by main conc as any transporting out of R.O.W

require pass or slip.

- Excavation soil shall be dump 2 meters from the edge of the excavation pit area.

- Providing firm ground for backhoe rigger using steel plate or other where case the soil is loose

Excavation

1.6.4.2 Machineries

All machine such as backhoe and lory use for excavation and transporting soil must go through

inspection by main conc.

PIC to prepare the lorry or the backhoe condition physically accordingly to the requirement

require by client that stipulated in the Inspection Machinery Checklist

1.6.5 Steel Reinforcement Fabrication and Installation

To install rebar according to approved construction drawing and followed best practice

considering

- Size and shape

- Lapping

- Spacer blocks

- Weep holes area

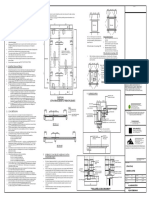

1.6.6 Assembling Formwork

To assemble formwork by considering

Document Number Rev Date

Page 6 of 9

AGC/MRT2/AZRB/MOS 001 00 17th March 2020

Method Statement for Reinforced In-situ Concrete U-Drain (RCUD)

- Formwork surface must be even

- the formwork struct must be rigid

- the tightness of jointing formwork

- the size and dimension is accordingly

- the formwork alignment must be vertical and horizontally

- to construct the weep holes

- to indicate top of drain wall level.

Construction Joints –

- To provide high ribbed at all construction joint

1.6.7 Concrete Placement

1.6.7.1 Coordinate with main conc and place concrete order 1 day before actual delivery.

1.6.7.2 Actual concrete volume and concrete grade to conform by Site Supervisor prior concrete

ordering.

1.6.7.3 To Coordinate with traffic team if road closure or traffic contra is required 2 day in advance

before work commence.

1.6.7.4 To Carry out slump test, temperature test and prepare concrete cube at site. Minimum 9 NOS of

cube to be prepared for Cube Crushing Test on 7th day and 28th day.

1.6.7.5 Ensure the concrete is properly compacted and vibrated during infill casting. Excess concrete

debris on premix road to be washed and cleaned at the end of casting work.

1.6.8 Record Concrete

- Date casting

- Record the slump test result, cube numbers and location of concrete on the delivery notes

- Kept the record to Concrete Supply Record for Cube Test Tracking for 3, 7- and 28-days strength

1.6.9 Striking Formwork

- Formwork on vertical wall surface shall be striking minimum 12 hours

- Formwork only can be removed after the concrete is truly hardened and have approval from

employer representative.

1.6.10 Curing

- Applied approved curing compound to exposed surface after removal of the formwork

Document Number Rev Date

Page 7 of 9

AGC/MRT2/AZRB/MOS 001 00 17th March 2020

Method Statement for Reinforced In-situ Concrete U-Drain (RCUD)

- curing compound is carrying out by spraying to the surface

1.6.11 Backfill and Compaction

- The perimeter of the trenches will be fill with suitable soil

- Each filling is 300mm and will be compacted with plate compactor

1.6.12 Post Concreting

Remedial action will be carried out to a defect on the surface such

- voids

- Honeycombing

- Blemishing

2.0 HAZARD IDENTIFICATION, RISK ASSESMENT AND CONTROL MEASURES

2.1 To ensure workers that work at the site

- has negative COVID result

- body temperature is below 39.0 degree

- workers are not sick

- followed social distancing

- has valid CIDB Green Card

- has attend safety training and have Blue Card

- wear proper Personnel Protective Equipment (PPE) base on the working area and project site

- Ensure worker is brief with potential hazard base on the evaluation Job Safety and Health

Analysis identified earlier

- Ensure to conduct PTT of work task before start work.

- To apply relevant permit base on work nature

2.2 Emergency Events

- to ensure the designated assembly point is clear and no obstacle along the access

- to ensure the First Aid Kit is available all the time

- to ensure the PIC is available at the site during working hours

2.3 Emergency Plan and Contact Number

Document Number Rev Date

Page 8 of 9

AGC/MRT2/AZRB/MOS 001 00 17th March 2020

Method Statement for Reinforced In-situ Concrete U-Drain (RCUD)

- Worker shall aware contact number for emergency event and pic contact number shall be

display properly at site.

- PIC to ensure worker aware of assembly point

- PIC is to ensure the emergency first aid kit is available on site

3.0 ENVIRONMENTAL ISSUES

PIC to understand the Environmental execution plan and applied to the job site

- Daily inspected on the condition of machinery before work start

- Make sure the there no contamination prior to scheduled waste

- Ensure the cleanliness by creating awarenss to workers on the important of hygiene practice

- To minimize noise and dust pollution

4.0 QUALITY ASSURANCE AND QUALITY CONTROL

4.1 Contractual requirement

Ensure work commencing base on the contract requirement

4.2 Inspection and Testing

Communicating with stakeholders prior regarding quality control and assurance

4.3 Evaluation

PIC shall organize or attend walkabout to measure, analyze progress and quality of work and to

proposed or accept improvement measures.

Document Number Rev Date

Page 9 of 9

AGC/MRT2/AZRB/MOS 001 00 17th March 2020

S-ar putea să vă placă și

- Segment Manufacturing Method StatementDocument25 paginiSegment Manufacturing Method StatementFa DylaÎncă nu există evaluări

- Ms 30 Part 8 1995 Prepdf Confirmed 2011Document6 paginiMs 30 Part 8 1995 Prepdf Confirmed 2011Munirah HassanÎncă nu există evaluări

- Beam Launching RB014 A1-P1Document14 paginiBeam Launching RB014 A1-P1MAYMODERN STEEL100% (1)

- Lord Have MercyDocument47 paginiLord Have MercyGovel EzraÎncă nu există evaluări

- Method Statement-EarthworkDocument2 paginiMethod Statement-EarthworkChung May LynnÎncă nu există evaluări

- NIWI-2654.1 Technical Specification For Supply of BallastDocument3 paginiNIWI-2654.1 Technical Specification For Supply of BallastCK TangÎncă nu există evaluări

- Method Statement Horizontal Directional DrillingDocument59 paginiMethod Statement Horizontal Directional DrillingNaser Mahamid100% (1)

- Method Statement Soil NailedDocument2 paginiMethod Statement Soil NailedFa DylaÎncă nu există evaluări

- MS For Rectification Work of Concrete CrackDocument18 paginiMS For Rectification Work of Concrete CrackFa Dyla100% (1)

- JKR Roadwork Spec - JKR-SPJ-1988 PDFDocument270 paginiJKR Roadwork Spec - JKR-SPJ-1988 PDFFa Dyla100% (3)

- WBLFFDocument10 paginiWBLFFLai ChungyiÎncă nu există evaluări

- General NotesDocument1 paginăGeneral NotesGodino ChristianÎncă nu există evaluări

- Questions For QA QC CivilDocument6 paginiQuestions For QA QC CivilButch Capistrano71% (7)

- TMS 402 - Chapter 6 PDFDocument22 paginiTMS 402 - Chapter 6 PDFAlina Shrestha100% (1)

- Repair of Concrete CracksDocument7 paginiRepair of Concrete CracksYolanda Leah Urbano100% (2)

- Apron Concrete Repair Method R01Document19 paginiApron Concrete Repair Method R01ayhanarmanÎncă nu există evaluări

- Road Pav LayerwDocument10 paginiRoad Pav LayerwAurelius GoraÎncă nu există evaluări

- Health, Safety & EnvironmentDocument7 paginiHealth, Safety & EnvironmentAhsan AfzaalÎncă nu există evaluări

- Method Statement For Road Construction Over WetlandsDocument4 paginiMethod Statement For Road Construction Over WetlandsYibeltal ChaneÎncă nu există evaluări

- TEC-031516 - MET-DoR-002 (Method Statement For Concrete Wall Construction Joint and Water Bar Repair)Document8 paginiTEC-031516 - MET-DoR-002 (Method Statement For Concrete Wall Construction Joint and Water Bar Repair)Tomi Wiryandi SaputraÎncă nu există evaluări

- 3.7 Method StatementDocument3 pagini3.7 Method StatementHenryÎncă nu există evaluări

- Clearing, Grubbing and ExcavationDocument25 paginiClearing, Grubbing and ExcavationArah Louise ApostolÎncă nu există evaluări

- Method Statement FOR Embedded Conduits, Boxes and Fittings InstallationDocument6 paginiMethod Statement FOR Embedded Conduits, Boxes and Fittings InstallationWalidÎncă nu există evaluări

- Parapet Wall Extension - MethodologyDocument2 paginiParapet Wall Extension - MethodologyRabnawaz ImamÎncă nu există evaluări

- GP209 - Method Statement For Soil Preparation and Natural Grass InstallationDocument5 paginiGP209 - Method Statement For Soil Preparation and Natural Grass Installationatef ghazyÎncă nu există evaluări

- Method Statement For Grassing: Soil Grading and PreparationDocument1 paginăMethod Statement For Grassing: Soil Grading and PreparationbhupsjangirÎncă nu există evaluări

- Method Statement and Risk Assessment For General Stone Masonry Including Dry Stone WallingDocument8 paginiMethod Statement and Risk Assessment For General Stone Masonry Including Dry Stone WallingMatin Hamid FaqiriÎncă nu există evaluări

- Simple Drilling MethodsDocument4 paginiSimple Drilling MethodsGreen Action Sustainable Technology GroupÎncă nu există evaluări

- Methodology For PQC (00) Toll Plaza L&TDocument4 paginiMethodology For PQC (00) Toll Plaza L&TDeven PatleÎncă nu există evaluări

- Concrete Gutter Construction - Methods and Work ProcedureDocument6 paginiConcrete Gutter Construction - Methods and Work Procedurevenkateswara rao PothinaÎncă nu există evaluări

- Paving Method StatementDocument7 paginiPaving Method StatementOfentse LedwabaÎncă nu există evaluări

- Method Statement - PARATEX TH C Method With Mesh Topcoat by ColorcoatDocument11 paginiMethod Statement - PARATEX TH C Method With Mesh Topcoat by ColorcoatChonTicha'Încă nu există evaluări

- Expansive Cement and Polymer ConcreteDocument13 paginiExpansive Cement and Polymer ConcreteAJAY KUMAR T.MÎncă nu există evaluări

- BS IndexDocument11 paginiBS IndexShirleyLiuÎncă nu există evaluări

- Backfilling PDFDocument4 paginiBackfilling PDFAdjei BaldanÎncă nu există evaluări

- DBM 507Document7 paginiDBM 507Mark Moni Mary ManoÎncă nu există evaluări

- Continental Engineering Corporation: Methodology For Production of Granular Sub BaseDocument8 paginiContinental Engineering Corporation: Methodology For Production of Granular Sub BasenaseebÎncă nu există evaluări

- Hollow Core Slab PDFDocument4 paginiHollow Core Slab PDFStraus WaseemÎncă nu există evaluări

- RD - ROAD FURNITUREDocument58 paginiRD - ROAD FURNITUREMuthusamy ArumugamÎncă nu există evaluări

- Earthworks and RoadworksDocument9 paginiEarthworks and RoadworkswagwahkiabatheÎncă nu există evaluări

- Checklist-Structural Concrete Post PouringDocument1 paginăChecklist-Structural Concrete Post Pouringajit karandikarÎncă nu există evaluări

- Method Statement For Drainange Construction Work: Document/Drawing Number: TNEC-STSB-KLIA-CS-MS-013 Revision: ADocument9 paginiMethod Statement For Drainange Construction Work: Document/Drawing Number: TNEC-STSB-KLIA-CS-MS-013 Revision: AAishah AliasÎncă nu există evaluări

- Department of Public Works and HighwaysDocument17 paginiDepartment of Public Works and HighwaysRolly Marc G. SoteloÎncă nu există evaluări

- Terrazzo Tiles ChecklistDocument1 paginăTerrazzo Tiles Checklistahmed samirÎncă nu există evaluări

- Work Methodology For Clearing and Grubbing of Trees and ShrubsDocument2 paginiWork Methodology For Clearing and Grubbing of Trees and ShrubsNasser Issa Abu HalimehÎncă nu există evaluări

- Method of Slotted DrainDocument5 paginiMethod of Slotted Drainzultrsb689100% (1)

- Methodology of Kerb Construction: ScopeDocument2 paginiMethodology of Kerb Construction: ScopeAnish PanchalÎncă nu există evaluări

- Method Statement of Overwatervilla and WalkwayDocument10 paginiMethod Statement of Overwatervilla and WalkwayMuhammad Uwais100% (1)

- Method Statement For Temporary Access Road (Towayya) - (Rev.)Document14 paginiMethod Statement For Temporary Access Road (Towayya) - (Rev.)skystar100% (1)

- Asphalt Overlay Method Statement-FinalDocument10 paginiAsphalt Overlay Method Statement-FinalYEHIAÎncă nu există evaluări

- HAC-10143-MS-CIV-004-Method Statement For Emergency Construction Cold JointDocument7 paginiHAC-10143-MS-CIV-004-Method Statement For Emergency Construction Cold JointHema playsÎncă nu există evaluări

- Concrete Cube Test Report FormatDocument1 paginăConcrete Cube Test Report FormatNaiyer AzamÎncă nu există evaluări

- Wooden Door Frame in Masonry Wall OpeningDocument2 paginiWooden Door Frame in Masonry Wall OpeningBijaya Raula100% (1)

- MS-04 Nilagama and Ranwediyaawa Tunnel PortalDocument59 paginiMS-04 Nilagama and Ranwediyaawa Tunnel PortalAmila Priyadarshana DissanayakeÎncă nu există evaluări

- METHOD - STATEMENTf New ForDocument48 paginiMETHOD - STATEMENTf New Forhysh89Încă nu există evaluări

- Method Statement of Brick Masonary WorkDocument6 paginiMethod Statement of Brick Masonary WorkMihirduttaÎncă nu există evaluări

- Highway Construction Civil Engineering (Ce) Notes - EdurevDocument47 paginiHighway Construction Civil Engineering (Ce) Notes - Edurevmohannad eliassÎncă nu există evaluări

- 3 BConstruction Stormwater Erosion Control PlansDocument4 pagini3 BConstruction Stormwater Erosion Control Plans许爱文Încă nu există evaluări

- Hardwood 1999Document43 paginiHardwood 1999Salvador Ramos GomezÎncă nu există evaluări

- MS Brickwork Manhole and In-Situ Cast Manhole Top SlabDocument4 paginiMS Brickwork Manhole and In-Situ Cast Manhole Top SlabCameron MayÎncă nu există evaluări

- Concrete Pre-Placement Checklist BackupDocument1 paginăConcrete Pre-Placement Checklist Backuphermano balbonÎncă nu există evaluări

- PDS - SikaSeal-402 Fillerboard MYDocument2 paginiPDS - SikaSeal-402 Fillerboard MYSiji OktoberÎncă nu există evaluări

- Method Statement of Bored Piles 21Document40 paginiMethod Statement of Bored Piles 21Dharma Pratap LamgadeÎncă nu există evaluări

- Fence InstallationDocument10 paginiFence InstallationanoopyohÎncă nu există evaluări

- Materials Terminology For Road and PavementDocument4 paginiMaterials Terminology For Road and PavementmanojÎncă nu există evaluări

- Appendix 5 Foundation Method StatementDocument15 paginiAppendix 5 Foundation Method StatementTAHER AMMARÎncă nu există evaluări

- MS-0026 Intake Structure Modification WRGDocument49 paginiMS-0026 Intake Structure Modification WRGgreg100% (2)

- Method Statement For Earthworks at VBC Kg. Titi Besi (CH 232.457)Document6 paginiMethod Statement For Earthworks at VBC Kg. Titi Besi (CH 232.457)MAYMODERN STEELÎncă nu există evaluări

- Method of Statement For The Construction and Completion of Structural Worksfor Entrances and Station Box at Conlay Station - 8.11.2018Document39 paginiMethod of Statement For The Construction and Completion of Structural Worksfor Entrances and Station Box at Conlay Station - 8.11.2018Mamat XÎncă nu există evaluări

- WMS Excavation & BACKFILLINGDocument28 paginiWMS Excavation & BACKFILLINGRepl microsoft, PuneÎncă nu există evaluări

- Method Statement For Spraying of Tack CoatDocument2 paginiMethod Statement For Spraying of Tack CoatFa DylaÎncă nu există evaluări

- Method Statement For Laying of ACWC 20Document3 paginiMethod Statement For Laying of ACWC 20Fa DylaÎncă nu există evaluări

- Method Statement of Rectification Roadwork D1-1B2 Table of ContentDocument5 paginiMethod Statement of Rectification Roadwork D1-1B2 Table of ContentFa DylaÎncă nu există evaluări

- MS For Rectification Work of Air BubblesDocument10 paginiMS For Rectification Work of Air BubblesFa DylaÎncă nu există evaluări

- MS For Rectification Work of Concrete Spalling PDFDocument32 paginiMS For Rectification Work of Concrete Spalling PDFFa DylaÎncă nu există evaluări

- Method Statement: Ahmad Zakisdn BHDDocument26 paginiMethod Statement: Ahmad Zakisdn BHDFa DylaÎncă nu există evaluări

- MS For Rectification Work of Concrete Spalling PDFDocument32 paginiMS For Rectification Work of Concrete Spalling PDFFa DylaÎncă nu există evaluări

- Method of Statement For Remedial Work: 1. General DescriptionDocument2 paginiMethod of Statement For Remedial Work: 1. General DescriptionFa DylaÎncă nu există evaluări

- Pull-Out Bebhavior of Post Installed Rebar ConnectionDocument9 paginiPull-Out Bebhavior of Post Installed Rebar ConnectionBiggsÎncă nu există evaluări

- ASTM A1034 A1034M 2010a (Reapproved 2015)Document5 paginiASTM A1034 A1034M 2010a (Reapproved 2015)Mukesh kumarÎncă nu există evaluări

- Anclajes PeikkoDocument28 paginiAnclajes PeikkopablopelaÎncă nu există evaluări

- The Universal Splicing SystemDocument4 paginiThe Universal Splicing Systemjason_wong_125Încă nu există evaluări

- Training Report Himanshu Kumar, Sid 17102103Document55 paginiTraining Report Himanshu Kumar, Sid 17102103Armaan BhatiaÎncă nu există evaluări

- Earthquake Resistant BuildingDocument36 paginiEarthquake Resistant Buildingsai projectÎncă nu există evaluări

- ACI 318 14 Changes - PCI - Journal PDFDocument25 paginiACI 318 14 Changes - PCI - Journal PDFEko UsmanÎncă nu există evaluări

- Grounding Catalog 2008Document134 paginiGrounding Catalog 2008Hilbert FloresÎncă nu există evaluări

- Hilti Anchor DesignDocument7 paginiHilti Anchor DesignKenny100% (1)

- In-Situ Evaluation of Structures Using Load TestingDocument11 paginiIn-Situ Evaluation of Structures Using Load TestingŽarko LazićÎncă nu există evaluări

- SAP2000 v22.2.0 Release Notes: Notice Date: 16-October-2020Document12 paginiSAP2000 v22.2.0 Release Notes: Notice Date: 16-October-2020st_luiseÎncă nu există evaluări

- IS 16172 2014 Coupler Splice BarDocument16 paginiIS 16172 2014 Coupler Splice BarMayank KumarÎncă nu există evaluări

- Determining Effects of Chemical Admixtures On Corrosion of Embedded Steel Reinforcement in Concrete Exposed To Chloride EnvironmentsDocument6 paginiDetermining Effects of Chemical Admixtures On Corrosion of Embedded Steel Reinforcement in Concrete Exposed To Chloride Environmentsmohammed karasnehÎncă nu există evaluări

- ITEM 515-517, 520 Latest 2012 (M) Final 4Document20 paginiITEM 515-517, 520 Latest 2012 (M) Final 4Mikhail Tabucal100% (1)

- Foundation DesignDocument254 paginiFoundation Designtekla gom-lua group100% (1)

- A Study On Novel Approaches To Measurement of Corrosion of Reinforcement in Concrete StructuresDocument6 paginiA Study On Novel Approaches To Measurement of Corrosion of Reinforcement in Concrete StructuresIJRASETPublicationsÎncă nu există evaluări

- Permanent Steel Sheet Piling (LRFD)Document2 paginiPermanent Steel Sheet Piling (LRFD)shujaÎncă nu există evaluări

- Amendment No. 1 November 2012 TO Is 1786: 2008 High Strength Deformed Bars and Wires For Concrete Reinforcement - SpecificationDocument4 paginiAmendment No. 1 November 2012 TO Is 1786: 2008 High Strength Deformed Bars and Wires For Concrete Reinforcement - SpecificationThetarun100% (1)

- Earthquake Resistant BuildingDocument47 paginiEarthquake Resistant Buildingmax pal100% (1)

- Al Jabbar Struc ConstructionDocument11 paginiAl Jabbar Struc Constructionjpmega004524Încă nu există evaluări

- Tekla 15 - Detailing ManualDocument188 paginiTekla 15 - Detailing ManualMarcel SteoleaÎncă nu există evaluări

- Bondek Design Manual 2003 PDFDocument132 paginiBondek Design Manual 2003 PDFFrank SunÎncă nu există evaluări

- National Structural Code of The Philippines: Sections 407.1 - 407.9 Details of ReinforcementDocument25 paginiNational Structural Code of The Philippines: Sections 407.1 - 407.9 Details of ReinforcementJeo CandilÎncă nu există evaluări

- Checklist For RCCDocument4 paginiChecklist For RCCAnonymous t7BQ1jvbh0% (1)

- Clinker SiloDocument58 paginiClinker SilosatydevsinghnegiÎncă nu există evaluări