Documente Academic

Documente Profesional

Documente Cultură

PilotOperatedPrinciple PDF

Încărcat de

marioLhrTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

PilotOperatedPrinciple PDF

Încărcat de

marioLhrDrepturi de autor:

Formate disponibile

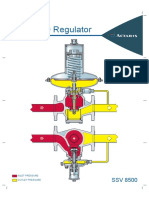

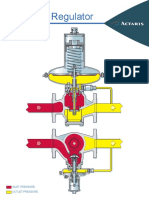

Pilot Operated Regulators:

Principle of Operation

Inlet pressure is piped through external tubing to the pilot system. First the inlet pressure is

filtered through a fine filter and pressure is reduced to the outlet pressure plus enough

pressure to overcome the regulator closing spring (feeding pressure).

This feeding pressure is then modulated by the pilot valve: the outlet pressure – sensed by

the pilot sensing line - moves the pilot diaphragm which controls the pilot valve flow.

Modulated pressure (motorization pressure) is piped to the regulator actuator where it opposes

the closing spring and the outlet pressure, and bleeds downstream though a bleed hole.

< As downstream demand increases, outlet pressure drops slightly, and the pilot diaphragm

moves to open further the pilot valve. The motorization pressure increases and moves the

regulator valve thus allowing flow to increase to match the increased demand.

< As downstream demand decreases, outlet pressure increases, moving the pilot diaphragm

to reduce the pilot valve flow. The motorization pressure decreases and regulator closing

spring causes the main valve to move closer to the seat. This restricts flow to match the

decreased demand and recovers desired outlet pressure.

< When demand is shut off, the pilot valve locks up bubble-tight. The regulator closing

spring maintains bubble-tight lockup at the main valve.

INLET PRESSURE

OUTLET PRESSURE

FEEDING PRESSURE Pilot

Feeder valve

MOTORIZATION PRESSURE

Filter

Bleed

hole

Sensing

line

INLET PRESSURE

OUTLET PRESSURE

FEEDING PRESSURE

MOTORIZATION PRESSURE

Main

Closing regulator

spring

S-ar putea să vă placă și

- Valve Timing DiagramDocument4 paginiValve Timing DiagramBoopathi RajÎncă nu există evaluări

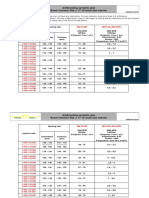

- Dieselland Catalog Eng 26.06.20co PDFDocument261 paginiDieselland Catalog Eng 26.06.20co PDFEphrem MichaelÎncă nu există evaluări

- Solenoid Valve Colis For Siemens Continental VDO Common Rail Injector A2C59517051 BK2Q9K546AG and Other Vdo InjectorDocument8 paginiSolenoid Valve Colis For Siemens Continental VDO Common Rail Injector A2C59517051 BK2Q9K546AG and Other Vdo InjectorWinston Wolf0% (1)

- Manualdemontagemecalibragemdebombavezexel 150821011345 Lva1 App6892 PDFDocument71 paginiManualdemontagemecalibragemdebombavezexel 150821011345 Lva1 App6892 PDFMichael Wohali0% (1)

- Manual DayelDocument30 paginiManual Dayelkittisak RunganothaiÎncă nu există evaluări

- Sabre Expert Brochure PDFDocument6 paginiSabre Expert Brochure PDFayaz100% (1)

- T2001 - S12-13 DensoDocument2 paginiT2001 - S12-13 DensomihajlovichenkelÎncă nu există evaluări

- Bosch MaquinasDocument13 paginiBosch MaquinasnomecÎncă nu există evaluări

- 780 7030Document3 pagini780 7030Miguel ChaconÎncă nu există evaluări

- 2013 - Technical Service Bulletin - No 01 PDFDocument2 pagini2013 - Technical Service Bulletin - No 01 PDFSutiknoÎncă nu există evaluări

- Makalah Wirausahawan SuksesDocument6 paginiMakalah Wirausahawan SuksesSurya IrawanÎncă nu există evaluări

- Common Rail Direct InjectionDocument9 paginiCommon Rail Direct InjectionJoe SparksÎncă nu există evaluări

- VP PDFDocument8 paginiVP PDFEphrem MichaelÎncă nu există evaluări

- Bosch Knock Sensors PiezoDocument2 paginiBosch Knock Sensors Piezoschraeuble100% (1)

- How A Turbo WorksDocument2 paginiHow A Turbo WorksSubhojit SamontaÎncă nu există evaluări

- Fuel Injector Holes: (Fabrication of Micro-Orifices For Fuel Injectors)Document23 paginiFuel Injector Holes: (Fabrication of Micro-Orifices For Fuel Injectors)DenisEcheverriÎncă nu există evaluări

- The Common Rail Diesel Injection System Explained: Technical FeaturesDocument3 paginiThe Common Rail Diesel Injection System Explained: Technical FeaturesDejan MihajlovicÎncă nu există evaluări

- hk1400 - NMDocument2 paginihk1400 - NMAhmet BuyrucuÎncă nu există evaluări

- Application Data Sheet For HK877 - TIB 230/12: Used On: AVM2-PC With HK870Document3 paginiApplication Data Sheet For HK877 - TIB 230/12: Used On: AVM2-PC With HK870Jorge RAÎncă nu există evaluări

- Protocolo EPS 200: Prueba Inyector Common RailDocument2 paginiProtocolo EPS 200: Prueba Inyector Common RailMauricio Navarro santanaÎncă nu există evaluări

- 1995 Model Series NSX/NSX-T Body Repair Manual: WarningDocument1 pagină1995 Model Series NSX/NSX-T Body Repair Manual: WarningCristian CernaÎncă nu există evaluări

- TECHNEWS 12 2016 - Piezo RegenerationDocument3 paginiTECHNEWS 12 2016 - Piezo RegenerationAbraaj-TTSÎncă nu există evaluări

- TK1035 enDocument2 paginiTK1035 enSutiknoÎncă nu există evaluări

- Test Equipment And Tools 最新 PDFDocument40 paginiTest Equipment And Tools 最新 PDFJe MotorÎncă nu există evaluări

- Inline Pump SpecsDocument1 paginăInline Pump SpecsAgustinus Leonardo SijabatÎncă nu există evaluări

- Ke & Pe PracticeDocument2 paginiKe & Pe PracticeCamille FrancoÎncă nu există evaluări

- English PDFDocument10 paginiEnglish PDFQuý MinhÎncă nu există evaluări

- Engine Spect MitsubishiDocument4 paginiEngine Spect MitsubishiFalgon IslamÎncă nu există evaluări

- CRDiDocument18 paginiCRDiSuhel InamdarÎncă nu există evaluări

- 2018 Training Prospectus External PrintDocument48 pagini2018 Training Prospectus External PrintMügïshá ÆlfieÎncă nu există evaluări

- Pizzo InjiDocument3 paginiPizzo InjiprakashÎncă nu există evaluări

- 1805-CreditParts + Fuel Injector Repair Kits Catalogue PDFDocument25 pagini1805-CreditParts + Fuel Injector Repair Kits Catalogue PDFRespaldo GregoryÎncă nu există evaluări

- Valve Timing DiagramDocument43 paginiValve Timing Diagramѕυdeѕн ĸÎncă nu există evaluări

- Bosch Common - Rail Antiknocking Syntactic PlanDocument6 paginiBosch Common - Rail Antiknocking Syntactic PlandieseldvÎncă nu există evaluări

- 2019 BEACON Product List PDFDocument106 pagini2019 BEACON Product List PDFMiguel Angel Alvarado Alarcon100% (1)

- HL070 (En)Document104 paginiHL070 (En)Ryo ChannelÎncă nu există evaluări

- Diesel Exchange 2012Document8 paginiDiesel Exchange 2012gemÎncă nu există evaluări

- DTech CatalogDocument82 paginiDTech CatalogJuan Gabriel OchoaÎncă nu există evaluări

- Cambox 100Document13 paginiCambox 100SoeAyeÎncă nu există evaluări

- Cruces Stanadyne - JhondeeereDocument2 paginiCruces Stanadyne - JhondeeereJuan Gabriel OchoaÎncă nu există evaluări

- KTA50-G3: Fuel OptimizedDocument3 paginiKTA50-G3: Fuel Optimizedamirali ansariÎncă nu există evaluări

- Preparation PDFDocument63 paginiPreparation PDFtavi2meÎncă nu există evaluări

- Test PlanDocument4 paginiTest PlanOFFICE DANACÎncă nu există evaluări

- Engine Governors - WoodwardDocument4 paginiEngine Governors - WoodwardJoe Discourt100% (1)

- ESI2.0 - Prices & Order FormDocument5 paginiESI2.0 - Prices & Order FormAmr MohamedÎncă nu există evaluări

- For BOSCHDocument99 paginiFor BOSCHAdministración DieseltruckÎncă nu există evaluări

- Diesel InjectorDocument15 paginiDiesel InjectorAlvin AuÎncă nu există evaluări

- SOLENOIDS Publication PDFDocument3 paginiSOLENOIDS Publication PDFalcoholahmedÎncă nu există evaluări

- EMS GasolineDocument39 paginiEMS GasolineKha TrầnÎncă nu există evaluări

- Piezo Injector For Common-Rail Systems: Low Fuel ConsumptionDocument1 paginăPiezo Injector For Common-Rail Systems: Low Fuel Consumptionalmia tronicsÎncă nu există evaluări

- Heui InjectorDocument1 paginăHeui InjectorJuan Gabriel OchoaÎncă nu există evaluări

- Advanced Driver Assistance SystemsDocument57 paginiAdvanced Driver Assistance SystemsharisÎncă nu există evaluări

- 1kz-Te Turbocharger PDFDocument18 pagini1kz-Te Turbocharger PDFwill meridithÎncă nu există evaluări

- 05 Fuel Injection SystemDocument42 pagini05 Fuel Injection SystemVishal JohaheerÎncă nu există evaluări

- 2017 Volvo V90 Cross Country Technical SpecificationsDocument3 pagini2017 Volvo V90 Cross Country Technical Specificationssergio davidsÎncă nu există evaluări

- Pilot Operated Regulators: Principle of OperationDocument1 paginăPilot Operated Regulators: Principle of OperationmarioLhrÎncă nu există evaluări

- Constant Loaded Regulators: Principle of Operation: Pilot RegulatorDocument1 paginăConstant Loaded Regulators: Principle of Operation: Pilot RegulatormarioLhrÎncă nu există evaluări

- Denso g4Document6 paginiDenso g4DenisEcheverri50% (4)

- Spring Loaded Regulators: Principle of OperationDocument1 paginăSpring Loaded Regulators: Principle of OperationmarioLhrÎncă nu există evaluări

- Presentación DirecciónDocument27 paginiPresentación DirecciónRuben Solari AlcayagaÎncă nu există evaluări

- Spring Loaded Regulators: Principle of OperationDocument1 paginăSpring Loaded Regulators: Principle of OperationmarioLhrÎncă nu există evaluări

- Constant Loaded Regulators: Principle of Operation: Pilot RegulatorDocument1 paginăConstant Loaded Regulators: Principle of Operation: Pilot RegulatormarioLhrÎncă nu există evaluări

- RB4000 SSV8500 PDFDocument1 paginăRB4000 SSV8500 PDFmarioLhrÎncă nu există evaluări

- RB4000 SSV8600 PDFDocument1 paginăRB4000 SSV8600 PDFmarioLhrÎncă nu există evaluări

- A Unique Safety Feature: The Actaris Internal Monitor: Inlet Pressure Outlet PressureDocument1 paginăA Unique Safety Feature: The Actaris Internal Monitor: Inlet Pressure Outlet PressuremarioLhrÎncă nu există evaluări

- Big Foot Systems Support Frame Products User Guide V2Document3 paginiBig Foot Systems Support Frame Products User Guide V2marioLhrÎncă nu există evaluări

- RB4000 PDFDocument2 paginiRB4000 PDFmarioLhrÎncă nu există evaluări

- RB2000 3200 PDFDocument1 paginăRB2000 3200 PDFmarioLhrÎncă nu există evaluări

- Spring Loaded Regulators: Principle of OperationDocument1 paginăSpring Loaded Regulators: Principle of OperationmarioLhrÎncă nu există evaluări

- Regulating & Metering StationsDocument4 paginiRegulating & Metering StationsmarioLhrÎncă nu există evaluări

- RB1700 PDFDocument1 paginăRB1700 PDFmarioLhrÎncă nu există evaluări

- Gas Meter Modules For C & I ServicesDocument4 paginiGas Meter Modules For C & I ServicesmarioLhrÎncă nu există evaluări

- RB4700 PDFDocument1 paginăRB4700 PDFmarioLhrÎncă nu există evaluări

- GTSThielmann Energietechnik GMB HDocument1 paginăGTSThielmann Energietechnik GMB HmarioLhrÎncă nu există evaluări

- A Unique Safety Feature: The Actaris Internal Monitor: Inlet Pressure Outlet PressureDocument1 paginăA Unique Safety Feature: The Actaris Internal Monitor: Inlet Pressure Outlet PressuremarioLhrÎncă nu există evaluări

- Transmission StationsDocument1 paginăTransmission StationsmarioLhrÎncă nu există evaluări

- Pressure Regulator HR 91: Characteristics Applications DescriptionDocument4 paginiPressure Regulator HR 91: Characteristics Applications DescriptionmarioLhrÎncă nu există evaluări

- Spring Loaded Regulators: Principle of OperationDocument1 paginăSpring Loaded Regulators: Principle of OperationmarioLhrÎncă nu există evaluări

- Izdržljivi Prethodno Obloženi Sustav Armaflex Otporan Na Mehaničko NaprezanjeDocument4 paginiIzdržljivi Prethodno Obloženi Sustav Armaflex Otporan Na Mehaničko NaprezanjemarioLhrÎncă nu există evaluări

- WMR NLDocument4 paginiWMR NLmarioLhrÎncă nu există evaluări

- Constant Loaded Regulators: Principle of Operation: Pilot RegulatorDocument1 paginăConstant Loaded Regulators: Principle of Operation: Pilot RegulatormarioLhrÎncă nu există evaluări

- Svestrana Fleksibilna Izolacija Bazirana Na Armaflex® TehnologijiDocument8 paginiSvestrana Fleksibilna Izolacija Bazirana Na Armaflex® TehnologijimarioLhrÎncă nu există evaluări

- Pilot Operated Regulators: Principle of OperationDocument1 paginăPilot Operated Regulators: Principle of OperationmarioLhrÎncă nu există evaluări

- ArmaflexACE HRDocument6 paginiArmaflexACE HRmarioLhrÎncă nu există evaluări

- 59 Ae 4243 e 9899417663120Document1 pagină59 Ae 4243 e 9899417663120marioLhrÎncă nu există evaluări

- 59 e 4884 C 4229 C 586357335Document1 pagină59 e 4884 C 4229 C 586357335marioLhrÎncă nu există evaluări

- 59 Ae 431 e 2 CFD 9108918724Document18 pagini59 Ae 431 e 2 CFD 9108918724marioLhr100% (1)

- 59 Ae 419 C 639 e 1916269038Document1 pagină59 Ae 419 C 639 e 1916269038marioLhrÎncă nu există evaluări

- Compressed Air CompendiumDocument225 paginiCompressed Air CompendiumHelmi MuradÎncă nu există evaluări

- Iec 61000-2-5-2017 TR PDFDocument150 paginiIec 61000-2-5-2017 TR PDFMehdi MakarovÎncă nu există evaluări

- Chapter 6-State ManagementDocument79 paginiChapter 6-State ManagementHeng PhinÎncă nu există evaluări

- Client Satisfaction Surveys: BackgroundDocument9 paginiClient Satisfaction Surveys: BackgroundsumitÎncă nu există evaluări

- Work and Equipment Provided by Builder. 1. Well.: Kone Elevator India (P) LimitedDocument1 paginăWork and Equipment Provided by Builder. 1. Well.: Kone Elevator India (P) Limited04 Ananthu AÎncă nu există evaluări

- 13.375 CASING Tally KH #C Wspace OutDocument14 pagini13.375 CASING Tally KH #C Wspace OutnabiÎncă nu există evaluări

- (Fa-) Mpy, Mpyc, MpycyDocument3 pagini(Fa-) Mpy, Mpyc, MpycyPT. Sari MandaÎncă nu există evaluări

- Lubrizol 1038 - Auto Gear Oil - TdsDocument3 paginiLubrizol 1038 - Auto Gear Oil - TdsPranit More Arabian Petroleum LimitedÎncă nu există evaluări

- Elegant Plants Research Poster by SlidesgoDocument26 paginiElegant Plants Research Poster by SlidesgoAfifah Nisa RahmadaniÎncă nu există evaluări

- FullStack Cafe Interview PlanDocument6 paginiFullStack Cafe Interview PlanAnkurÎncă nu există evaluări

- U-C RT B M: Harge Attery OduleDocument24 paginiU-C RT B M: Harge Attery OduleFiel A'nÎncă nu există evaluări

- Preparation Checklist For The TOEFL iBT Home Edition TestDocument3 paginiPreparation Checklist For The TOEFL iBT Home Edition TestCheujeu chaldouÎncă nu există evaluări

- Motherboard Flow Chart TroubleshootingDocument1 paginăMotherboard Flow Chart TroubleshootingKubeta AkihiroÎncă nu există evaluări

- IP Project Class 12th AnupriyaDocument22 paginiIP Project Class 12th Anupriyaanu870906Încă nu există evaluări

- Special Stock & Special Procurement in SAPDocument17 paginiSpecial Stock & Special Procurement in SAProbnunesÎncă nu există evaluări

- Diagnostic Report: Component Fault Codes 7 Total / 1 Active / 6 InactiveDocument2 paginiDiagnostic Report: Component Fault Codes 7 Total / 1 Active / 6 Inactivealexis nuñez hernandezÎncă nu există evaluări

- Benchmark H4000 Hotplate Stirrer Instruction ManualDocument1 paginăBenchmark H4000 Hotplate Stirrer Instruction ManualKenneth SaganÎncă nu există evaluări

- A Survey On OLE For Process Control (OPC)Document6 paginiA Survey On OLE For Process Control (OPC)scadaprimaciptaÎncă nu există evaluări

- Material Handling and Material Storage SystemDocument56 paginiMaterial Handling and Material Storage SystemRishi vardhiniÎncă nu există evaluări

- 3.4 Requirements Traceability MatrixDocument1 pagină3.4 Requirements Traceability MatrixnaveedÎncă nu există evaluări

- Lector BilletesL - Series - Installation - Guide (EN) LectorICT - GROUP - NET - CNDocument21 paginiLector BilletesL - Series - Installation - Guide (EN) LectorICT - GROUP - NET - CNJaime ZambranoÎncă nu există evaluări

- Data Sheet 29 - Fig Tc704 Conical (Witches Hat) StrainerDocument1 paginăData Sheet 29 - Fig Tc704 Conical (Witches Hat) StrainerSteve Newman0% (1)

- 1 s2.0 S1877050922018336 MainDocument8 pagini1 s2.0 S1877050922018336 MainIdvano IdboyÎncă nu există evaluări

- Satellite Interception SolutionsDocument8 paginiSatellite Interception Solutionsalt.fm-fo4iecpuÎncă nu există evaluări

- CTX-10 User's Manual FINAL Less Block Diagram Rev H 1-18-2021Document48 paginiCTX-10 User's Manual FINAL Less Block Diagram Rev H 1-18-2021Bob MartinÎncă nu există evaluări

- SMAJ Transient Voltage Suppressor Diode Series: Features ApplicationsDocument6 paginiSMAJ Transient Voltage Suppressor Diode Series: Features ApplicationsTirwanda EdhoÎncă nu există evaluări

- D193 Exp V1.00Document190 paginiD193 Exp V1.00jarin taglientoÎncă nu există evaluări

- Sebp4321 20 00 AllDocument785 paginiSebp4321 20 00 AllNataly Mendoza100% (1)

- Tubesheet LayoutDocument5 paginiTubesheet LayoutMehta MehulÎncă nu există evaluări

- Interactive Cares Laravel Career Path Outline 1Document15 paginiInteractive Cares Laravel Career Path Outline 1Neamotullah NaimÎncă nu există evaluări

- Datapatch: Database 12c or Later Post Patch SQL Automation (Doc ID 1585822.1)Document4 paginiDatapatch: Database 12c or Later Post Patch SQL Automation (Doc ID 1585822.1)Biplab ParidaÎncă nu există evaluări