Documente Academic

Documente Profesional

Documente Cultură

Datasheet Ni1000SOT 07

Încărcat de

Joe SatrianiDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Datasheet Ni1000SOT 07

Încărcat de

Joe SatrianiDrepturi de autor:

Formate disponibile

Temperature Sensor

Ni1000SOT Rev 4: 21st June 2007

INTRODUCTION

The Ni1000SOT is a nickel thin film resistance temperature detector (RTD) that is suitable for use in

contact temperature sensing. The characteristics of the temperature sensor comply with the former

DIN 43760 standard.

The Ni1000SOT are manufactured by PVD-deposition on a silicon substrate. The thin film structure is

covered by a passivation layer for environmental protection and enhanced stability. The nickel

elements are mounted on lead frames and encapsulated in SOT23 packages. This technology allows

the production of miniature, low cost, high precision temperature sensors.

The Ni1000SOT sensor is qualified for the most demanding automotive applications (including

exposure to hot oil) and is suitable for many more applications in harsh environments.

FEATURES APPLICATIONS

o

• Resistance: 1000 ohms at 0 C • Temperature Sensing, control and

o o

• Min/ Max Temp -55 C to +160 C compensation

• Package type SOT23 • General Instrumentation

• Tape and reel (8mm format) • Automotive (VW standard 801-01

• Good Linearity between resistance and vibration)

temperature (R V’s T) • Remote sensing

• Large Temperature Coefficient of Resistance

o o

(TCR): 6178 ppm/K (measured at 0 C, 100 C)

• Low power consumption

• Good Thermal contact via Pin 3 of SOT23

Parameter Typical Condition

Package SOT23

Alloy 42

Lead frame material Ag-Coating: 2 µm

Pin Coating (Sn > 99.5%): 8-10 µm

Reflow to

Soldering 96Sn4Ag

+ 260°C

Reel Size: 7” (180 mm)

3000 sensors

Packing units or

13” (330 mm)

10000 sensors

Basic resistance 1000 Ω 0°C

SOT23 Nickel Temperature coefficient of

Sensor resistance (according to DIN 6178 ppm/K 0°C to +100°C

43760, see below)

o

1000 Ω at 0 C Measurement current 1.2 mA, max: 5 mA

+23 °C

Self heating coefficient EK = (1.7 ± 0.3) mW/K

Still air

o

Operation temperature -55 C … +160°C

o

Storage temperature -55 C… +160°C

MIL

ESD Resistant Exceeds requirements

883E3015.7

Note: Self heating effect

For accurate temperature measurement it is recommended to choose a small current to avoid self

heating of the nickel sensing element. The temperature error caused by excessive measurement

current can be calculated using: ∆T = P/EK

2

where P = I X R is the power generated by the measurement current and EK is the self heating

coefficient.

The self heating coefficient for the Ni1000SOT is EK = (1.7 ± 0.3) mW/K (23 °C Still Air).

Page 1 of 5 Measurement Specialties, Inc.\ HL-Planartechnik GmbH Temperature Sensor Ni1000SOT

Temperature Sensor

Ni1000SOT Rev 4: 21st June 2007

ELECTRICAL CHARACTERISTIC

The characteristic of the nickel temperature sensor is specified as per DIN 43760. The large

Temperature Coefficient of Resistance (TCR) of the Ni-RTD, 6178 ppm/K, offers greater sensitivity

than other types of RTD’s. The electrical characteristic can be described by the following equation:

Type DIN 43760 TCR = 6178 ppm/K between 0 ... 100 °C

2 4 6

R(T) = R0 (1+aT+bT +cT +dT )

-3

Coefficients: a= 5.485 x 10

-6

b= 6.650 x 10

-11

c= 2.805 x 10

-17

d= -2.000 x 10

½ 5 7

T(R) = a´+b´(1+c´R) +d´R +e´R

Coefficients: a´= - 412.6

b´= 140.41

c´= 0.00764

-17

d´= - 6.25 x 10

-24

e´= -1.25 x 10

o

Tolerances: Class B ± (0.4+0.007 x |T|) in range from 0 C to +160 °C

o

± (0.4+0.028 x |T|) in range from -55 C to 0 °C

T/°C 0 1 2 3 4 5 6 7 8 9

-60 695.2 699.9 704.6 709.3 714.0 718.7 723.4 728.2 733.0 737.8

-50 742.6 747.4 752.2 757.0 761.9 766.8 771.6 776.5 781.4 786.4

-40 791.3 796.3 801.2 806.2 811.2 816.2 821.2 826.3 831.3 836.4

-30 841.5 846.5 851.7 856.8 861.9 867.0 872.2 877.4 882.6 887.8

-20 893.0 898.2 903.4 908.7 913.9 919.2 924.5 929.8 935.1 940.5

-10 945.8 951.2 956.5 961.9 967.3 972.7 978.2 983.6 989.1 994.5

0 1000.0 1005.5 1011.0 1016.5 1022.0 1027.6 1033.1 1038.7 1044.3 1049.9

10 1055.5 1061.1 1066.8 1072.4 1078.1 1083.8 1089.5 1095.2 1100.9 1106.6

20 1112.4 1118.1 1123.9 1129.7 1135.5 1141.3 1147.1 1153.0 1158.8 1164.7

30 1170.6 1176.5 1182.4 1188.3 1194.2 1200.2 1206.1 1212.1 1218.1 1224.1

40 1230.1 1236.1 1242.2 1248.2 1254.3 1260.4 1266.5 1272.6 1278.8 1284.9

50 1291.1 1297.2 1303.4 1309.6 1315.8 1322.0 1328.3 1334.5 1340.8 1347.1

60 1353.4 1359.7 1366.0 1372.4 1378.7 1385.1 1391.5 1397.9 1404.3 1410.8

70 1417.2 1423.7 1430.1 1436.6 1443.1 1449.7 1456.2 1462.8 1469.3 1475.9

80 1482.5 1489.1 1495.7 1502.4 1509.1 1515.7 1522.4 1529.1 1535.9 1542.6

90 1549.3 1556.1 1562.9 1569.7 1576.5 1583.4 1590.2 1597.1 1604.0 1610.9

100 1617.8 1624.7 1631.7 1638.6 1645.6 1652.6 1659.6 1666.7 1673.7 1680.8

110 1687.9 1695.0 1702.1 1709.3 1716.4 1723.6 1730.8 1738.0 1745.2 1752.5

120 1759.7 1767.0 1774.3 1781.6 1788.9 1796.3 1803.7 1811.1 1818.5 1825.9

130 1833.3 1840.8 1848.3 1855.8 1863.3 1870.9 1878.4 1886.0 1893.6 1901.2

140 1908.9 1916.5 1924.2 1931.9 1939.6 1947.4 1955.1 1962.9 1970.7 1978.5

150 1986.3 1994.2 2002.1 2010.0 2017.9 2025.9 2033.8 2041.8 2049.8 2057.8

160 2065.9 2074.0 2082.1 2090.2 2098.3 2106.5 2114.6 2122.8 2131.1 2139.3

o

Table 1: Ni1000 DIN 43760 Temperature ( C) versus Resistance (Ohms - Ω)

Page 2 of 5 Measurement Specialties, Inc.\ HL-Planartechnik GmbH Temperature Sensor Ni1000SOT

Temperature Sensor

Ni1000SOT Rev 4: 21st June 2007

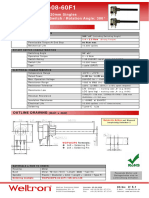

MECHANICAL DIMENSIONS

Pin 2

Pin 3

Pin 1

Millimeters Inches

DIM

Min Max Min Max

A 2.67 3.05 0.105 0.120

B 1.20 1.40 0.047 0.055

C - 1.10 - 0.043

D 0.37 0.53 0.0145 0.021

G NOM 1.9 NOM 0.075

K 0.01 0.10 0.0004 0.004

L 2.10 2.50 0.0825 0.0985

N NOM 0.95 NOM 0.37

PIN DIMENSIONS

Millimeters Inches

Dimension

Min Max Min Max

Pin Thickness 0.085 0.15 0.033 0.0059

CONNECTIONS

Pin # 1 Nickel RTD electrical contact

Pin # 2 Nickel RTD electrical contact

Pin # 3 Electrically isolated thermal contact

Page 3 of 5 Measurement Specialties, Inc.\ HL-Planartechnik GmbH Temperature Sensor Ni1000SOT

Temperature Sensor

Ni1000SOT Rev 4: 21st June 2007

RELIABILITY DATA

Test Standard Test conditions Test Criteria Remarks

Electrical

High temperature +160°C, IF=1.5 mA, in air

CECC 50000 specification No failure

life time test Duration: 1008 hours

(Class B)

-55°C / +160°C;

Rapid Electrical

IEC 68-2-14, hold time: 15 min;

temperature specification No failure

Test N transfer time: <10 s

change (Class B)

# Cycles: 1000

Temperature and +85°C / 85% R.H.; Electrical

humidity during CECC 50000 IF=1.5 mA specification No failure

operation Duration: 1008 hours (Class B)

-55°C, IF=5 mA,

Electrical

Low temperature alternating operation

specification No failure

life time test 1 hour on / 1 hour off

(Class B)

Duration: 1008 hours

T= +135°C, Electrical

Life time test in

IF=1.2 mA specification No failure

oil

Duration: 1008 hours (Class B)

o

High temperature +150 C , <0.1% Delta

No failure

exposure Duration 1000 hours (∆) Resistance

Soldering Soldering temperature: Electrical

temperature 260°C+/-5°C specification No failure

resistance Duration: 10 seconds (Class B)

Soldering temperature:

+260°C+/-5°C

duration: 2 +/-0.5 sec. No visible

Solderability

drop speed: 25 +/-5 damage

mm/sec.

Contact wetting: 90%

Page 4 of 5 Measurement Specialties, Inc.\ HL-Planartechnik GmbH Temperature Sensor Ni1000SOT

Temperature Sensor

Ni1000SOT Rev 4: 21st June 2007

APPLICATION NOTE: Interface Circuit

The following circuit has been evaluated and is designed to provide a voltage output signal that is a

linear function of temperature.

VDD

R1 R2

Op Amp 1

+

_

VRTD

Ni1000 R3 R4

R5

Fig. 1: Example of analog interface circuit using the Ni1000SOT sensor

Output Voltage Characterstics

4,500

4,000

VDD = 4.1 V

Output Voltage VRTD (V)

3,500

R1 = 56 kΩ 3,000

R2 = 56 kΩ 2,500

R3 = 3.65 kΩ 2,000

1,500

R4 = 732 Ω

1,000

R5 = 100 kΩ 0,500

0,000

0 10 20 30 40 50 60 70 80 90 100

Ambient Temperature (°C)

Application note is subject to change without notice

Temperature Products Group

Design/Sales Europe Ballybrit Business Park Galway, Ireland +353 91 753238 www.betatherm.com

Sales North America 910 Turnpike Road Shrewsbury, MA 01545 +508 8420516 www.betatherm.com

Design Centre North America 2670 Indian Ripple Rd. Dayton, OH 45440 +937 4271231 www.meas-spec.com

Design/Sales Europe Hauert 13, D-44227 Dortmund, Germany +49 231 97400 www.hlplanar.com

Measurement Specialties 1000 Lucas Way Hampton, VA23666 +757 7664297 www.meas-spec.com

Page 5 of 5 Measurement Specialties, Inc.\ HL-Planartechnik GmbH Temperature Sensor Ni1000SOT

S-ar putea să vă placă și

- Kinetic Launcher For UAVDocument13 paginiKinetic Launcher For UAVLord Vario100% (1)

- System Converts High Frequency EMF to Electrical EnergyDocument15 paginiSystem Converts High Frequency EMF to Electrical EnergyFabrice BresilÎncă nu există evaluări

- Mastering HW 1Document29 paginiMastering HW 1hieÎncă nu există evaluări

- Understanding Shaft Voltage and Grounding Currents of Turbine GeneratorsDocument12 paginiUnderstanding Shaft Voltage and Grounding Currents of Turbine GeneratorsJose PradoÎncă nu există evaluări

- DC Drives PDFDocument90 paginiDC Drives PDFkeerthi50% (2)

- Axial Generator Calculator MetricDocument48 paginiAxial Generator Calculator MetricCriss MereutaÎncă nu există evaluări

- Electromagnetic Fields of High-Speed Transportation Systems: The International Maglev BoardDocument22 paginiElectromagnetic Fields of High-Speed Transportation Systems: The International Maglev BoardMayur PuriÎncă nu există evaluări

- Ds Te3204 en CoDocument18 paginiDs Te3204 en CoHamed YadegariÎncă nu există evaluări

- NIC Components NML SeriesDocument7 paginiNIC Components NML SeriesNICCompÎncă nu există evaluări

- ABNTC-0201: MSL Level: 2A (This Product Is Packed With Dry Packaging)Document3 paginiABNTC-0201: MSL Level: 2A (This Product Is Packed With Dry Packaging)ricky syandiÎncă nu există evaluări

- SKNR 600 Preliminary 22-06-17Document3 paginiSKNR 600 Preliminary 22-06-17Clovis GajoÎncă nu există evaluări

- Temperature Sensor With Remote Probe: EE471 FeaturesDocument3 paginiTemperature Sensor With Remote Probe: EE471 FeaturesАлекс ОколотенкоÎncă nu există evaluări

- B57153S479MDocument14 paginiB57153S479Mcasa1233333Încă nu există evaluări

- Platinum - Temperature SensorsDocument8 paginiPlatinum - Temperature Sensorsenzo velasquezÎncă nu există evaluări

- Wall Mount Temperature Sensor for Indoor Outdoor UseDocument3 paginiWall Mount Temperature Sensor for Indoor Outdoor UseJavier Silva VidalÎncă nu există evaluări

- Temt 1000Document9 paginiTemt 1000Jerome JinÎncă nu există evaluări

- Cob Led SpecsDocument6 paginiCob Led SpecsMike MajesticÎncă nu există evaluări

- C2 - Condensatoare CeramiceDocument8 paginiC2 - Condensatoare CeramiceSneezy DwarfÎncă nu există evaluări

- Hart Field Temperature Transmitter Models TIF50, TIF52, TIF62Document9 paginiHart Field Temperature Transmitter Models TIF50, TIF52, TIF62jmenesesmÎncă nu există evaluări

- NIC Components NLQ SeriesDocument4 paginiNIC Components NLQ SeriesNICCompÎncă nu există evaluări

- SEMIKRON DataSheet SKN 600 02644670Document3 paginiSEMIKRON DataSheet SKN 600 02644670petriÎncă nu există evaluări

- NIC Components NNT SeriesDocument3 paginiNIC Components NNT SeriesNICCompÎncă nu există evaluări

- Application Note: Temperature Measurement With ThermocouplesDocument12 paginiApplication Note: Temperature Measurement With ThermocouplesMartinÎncă nu există evaluări

- CR Mo 4Document2 paginiCR Mo 4Mohsen ParpinchiÎncă nu există evaluări

- Infineon AIGW50N65F5 DS v02 - 01 ENDocument14 paginiInfineon AIGW50N65F5 DS v02 - 01 ENAhmedHelmyÎncă nu există evaluări

- PTC Thermistors As Limit Temperature Sensors: Motor Protection, Triple SensorsDocument12 paginiPTC Thermistors As Limit Temperature Sensors: Motor Protection, Triple SensorsjvtamilanbanÎncă nu există evaluări

- Lampiran Tugas AkhirDocument35 paginiLampiran Tugas AkhirAsrief RizkiÎncă nu există evaluări

- NIC Components NSPU SeriesDocument2 paginiNIC Components NSPU SeriesNICCompÎncă nu există evaluări

- NIC Components NRE-WY SeriesDocument7 paginiNIC Components NRE-WY SeriesNICCompÎncă nu există evaluări

- Ecs 33BDocument2 paginiEcs 33BVeraKiller 05Încă nu există evaluări

- NIC Components NRCEDocument2 paginiNIC Components NRCENICCompÎncă nu există evaluări

- SR4 ControladorDocument2 paginiSR4 ControladorErick Gabriel Chiroque SilopúÎncă nu există evaluări

- Surface Mount Aluminum Electrolytic Capacitors: NACE SeriesDocument5 paginiSurface Mount Aluminum Electrolytic Capacitors: NACE SeriesNICCompÎncă nu există evaluări

- LM61CIM3 National SemiconductorDocument11 paginiLM61CIM3 National SemiconductorEmrah CelikÎncă nu există evaluări

- LFH10-2B65 (Air Temp Humidity)Document4 paginiLFH10-2B65 (Air Temp Humidity)Anonymous XYAPaxjbYÎncă nu există evaluări

- Flextop 2202 Temperature Transmitter: DescriptionDocument4 paginiFlextop 2202 Temperature Transmitter: DescriptionHectorÎncă nu există evaluări

- Capacitor For Power Electronics: R Tan CXRDocument6 paginiCapacitor For Power Electronics: R Tan CXRHughÎncă nu există evaluări

- 18.smoke SensorDocument6 pagini18.smoke SensorBRAGPW,Karimnagar 087Încă nu există evaluări

- Baumer E910 Series Pressure TransmitterDocument4 paginiBaumer E910 Series Pressure Transmitterap16484Încă nu există evaluări

- Bedienungsanleitung 441128 Weltron 002045038962 Wcip20cips 08 60f1 4k7 20 Lin Dreh Potentiometer Mit Schalter Mono 04 W 47 K 1 STDocument2 paginiBedienungsanleitung 441128 Weltron 002045038962 Wcip20cips 08 60f1 4k7 20 Lin Dreh Potentiometer Mit Schalter Mono 04 W 47 K 1 STEanBombingÎncă nu există evaluări

- FNR 05K180 JohansonDielectricsDocument7 paginiFNR 05K180 JohansonDielectricsgulrez1991Încă nu există evaluări

- QCL Series: General Specifi Cations Equivalent Series Resistance (ESR)Document2 paginiQCL Series: General Specifi Cations Equivalent Series Resistance (ESR)Alberto Fernández VázquezÎncă nu există evaluări

- Temperature SensorDocument51 paginiTemperature SensorElxan HacinskiÎncă nu există evaluări

- Tempering Conditions For 30CrNiMo8Document2 paginiTempering Conditions For 30CrNiMo8madyeÎncă nu există evaluări

- Sra-T Indoor Temperature Sensor: FeaturesDocument2 paginiSra-T Indoor Temperature Sensor: FeatureschinitnÎncă nu există evaluări

- Mazatech Sensor de Humedad Especificaciones Tecnicas SDT 1269277Document2 paginiMazatech Sensor de Humedad Especificaciones Tecnicas SDT 1269277Antonio ZekyÎncă nu există evaluări

- Infineon-IGW25N120H3-DataSheet-v02 - 01-EN VAZNODocument16 paginiInfineon-IGW25N120H3-DataSheet-v02 - 01-EN VAZNONatasa CiricÎncă nu există evaluări

- 3030 2sin1 (CRI80) - LEMWS36X - Family DatasheetDocument30 pagini3030 2sin1 (CRI80) - LEMWS36X - Family DatasheetGiancarloRichardRivadeneyraMirandaÎncă nu există evaluări

- Model: 10Ts: Thermocouple Transmitter (2) OUTPUT 1Document4 paginiModel: 10Ts: Thermocouple Transmitter (2) OUTPUT 1eko azbilÎncă nu există evaluări

- Triacs (Thyristors) 10 Amperes RMS: ValueDocument4 paginiTriacs (Thyristors) 10 Amperes RMS: ValuealumnosjklhÎncă nu există evaluări

- SRS-008 SCA128T DatasheetDocument7 paginiSRS-008 SCA128T DatasheetmiqbalÎncă nu există evaluări

- CITILED COB Series Data SheetDocument15 paginiCITILED COB Series Data SheetJuan TricariqueÎncă nu există evaluări

- SP8 Pesaje Dinamico - B04504 PDFDocument4 paginiSP8 Pesaje Dinamico - B04504 PDFFernando PastorÎncă nu există evaluări

- Aluminum Electrolytic Capacitors: SpecificationsDocument1 paginăAluminum Electrolytic Capacitors: SpecificationsMichael KovalÎncă nu există evaluări

- Data Sheet LM301H CRI90 Rev.2.2Document22 paginiData Sheet LM301H CRI90 Rev.2.2HdhdjdÎncă nu există evaluări

- Datasheet EE462Document2 paginiDatasheet EE462Алекс ОколотенкоÎncă nu există evaluări

- Sensors 10 05604Document10 paginiSensors 10 05604Vengatesh VelusamyÎncă nu există evaluări

- Infineon IDW80C65D2 DS v02 - 01 ENDocument10 paginiInfineon IDW80C65D2 DS v02 - 01 ENpablo carrizoÎncă nu există evaluări

- sr1 - 3 - 4 - C - ShimadenDocument2 paginisr1 - 3 - 4 - C - ShimadenFernandoÎncă nu există evaluări

- K30H603_IGBT_IKW30N60H3Document16 paginiK30H603_IGBT_IKW30N60H3RuslanÎncă nu există evaluări

- Packaging Code: GRT31CR61H106KE01 - (1206, X5R, 10uf, DC50V) Reference SheetDocument28 paginiPackaging Code: GRT31CR61H106KE01 - (1206, X5R, 10uf, DC50V) Reference Sheetvax1Încă nu există evaluări

- 2 DSHK-DTDocument2 pagini2 DSHK-DTRama Aji Al HakimÎncă nu există evaluări

- Figaro Data SheetDocument2 paginiFigaro Data SheetAnonymous wMv2zGNÎncă nu există evaluări

- LF 305-S Current Transducer 300A IPNDocument3 paginiLF 305-S Current Transducer 300A IPNhitesh7kÎncă nu există evaluări

- Infineon IKZA50N65RH5 DataSheet v02 01 enDocument15 paginiInfineon IKZA50N65RH5 DataSheet v02 01 ennithinmundackal3623Încă nu există evaluări

- Handheld Calibrator 749: Model CL-477 For ThermocouplesDocument2 paginiHandheld Calibrator 749: Model CL-477 For ThermocouplesAngel ReyesÎncă nu există evaluări

- Conversion TableDocument2 paginiConversion TableAouina ChokriÎncă nu există evaluări

- CentralPark r1Document2 paginiCentralPark r1Joe SatrianiÎncă nu există evaluări

- Door Closer: - InstructionsDocument8 paginiDoor Closer: - InstructionsJoe SatrianiÎncă nu există evaluări

- WiringDocument1 paginăWiringJoe SatrianiÎncă nu există evaluări

- Pressure WsDocument3 paginiPressure WsHi everyoneÎncă nu există evaluări

- Power System Operation & Control - Lab ManualDocument33 paginiPower System Operation & Control - Lab Manualrakesh shuklaÎncă nu există evaluări

- VCE Physics Solutions 2017 Sample PaperDocument6 paginiVCE Physics Solutions 2017 Sample PaperLeo JaszÎncă nu există evaluări

- Topic 1 QuantitativeDocument19 paginiTopic 1 Quantitativemanurulez_21Încă nu există evaluări

- Rab 5 KW PAK PURDocument3 paginiRab 5 KW PAK PURilhamÎncă nu există evaluări

- Physics II Problems PDFDocument1 paginăPhysics II Problems PDFBOSS BOSSÎncă nu există evaluări

- WWW Bibliotecapleyades Net Tesla Lostjournals Lostjournals06Document20 paginiWWW Bibliotecapleyades Net Tesla Lostjournals Lostjournals06kartikkeyyanÎncă nu există evaluări

- Time Distance W10Document11 paginiTime Distance W10tamilanbaÎncă nu există evaluări

- A R K K: Chbe 6300: Kinetics and Reactor Design Homework 1Document2 paginiA R K K: Chbe 6300: Kinetics and Reactor Design Homework 1AnnÎncă nu există evaluări

- Combustion and Flame: Jun Wang, Long Zhang, Yaofeng Mao, Feiyan GongDocument7 paginiCombustion and Flame: Jun Wang, Long Zhang, Yaofeng Mao, Feiyan GongKay WhiteÎncă nu există evaluări

- Note 6 - Sound in Enclosed Space PDFDocument32 paginiNote 6 - Sound in Enclosed Space PDFABB TRX IJMÎncă nu există evaluări

- STGB30H60DFB, STGP30H60DFB: Trench Gate Field-Stop 600 V, 30 A High Speed HB Series IGBTDocument21 paginiSTGB30H60DFB, STGP30H60DFB: Trench Gate Field-Stop 600 V, 30 A High Speed HB Series IGBTJoão de barroÎncă nu există evaluări

- Bueno Eaton-Secondary-Unit-Substation-Design-GuideDocument48 paginiBueno Eaton-Secondary-Unit-Substation-Design-GuideGEISON JUNIOR CAJA GUERRAÎncă nu există evaluări

- Secondary Physics Temp NotesDocument3 paginiSecondary Physics Temp NotesHarish PrabhuÎncă nu există evaluări

- Question ReportDocument32 paginiQuestion ReporthemavarshiniÎncă nu există evaluări

- Cost Analysis and Design of A Hybrid Renewable SystemDocument63 paginiCost Analysis and Design of A Hybrid Renewable SystemSelim KhanÎncă nu există evaluări

- Catalog: LORD Vibration, Shock and Motion Control ProductsDocument133 paginiCatalog: LORD Vibration, Shock and Motion Control ProductsDulanga FernandoÎncă nu există evaluări

- Content Handbook of Energy and Economic Statistics of Indonesia 2021Document109 paginiContent Handbook of Energy and Economic Statistics of Indonesia 2021Richardo DavidÎncă nu există evaluări

- Mathematics Form 1 Exam PaperDocument26 paginiMathematics Form 1 Exam Paper洛星Încă nu există evaluări

- Vibrations of Single Degree of Freedom Systems: M X (T) F (T) KDocument25 paginiVibrations of Single Degree of Freedom Systems: M X (T) F (T) KIbraheem OlugbadeÎncă nu există evaluări

- 1 PUC Manual-17Document22 pagini1 PUC Manual-17shyla100% (1)

- Radiation Coloring Page and Crossword With Key W8cmjeDocument4 paginiRadiation Coloring Page and Crossword With Key W8cmjerenneÎncă nu există evaluări

- Projectile MotionDocument4 paginiProjectile MotionaliÎncă nu există evaluări