Documente Academic

Documente Profesional

Documente Cultură

The Development of Cotton-Yarn-Quality Predicting System: Ying Xiao

Încărcat de

Jacob Priyadharshan0 evaluări0% au considerat acest document util (0 voturi)

13 vizualizări4 paginiTitlu original

xiao2011

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

13 vizualizări4 paginiThe Development of Cotton-Yarn-Quality Predicting System: Ying Xiao

Încărcat de

Jacob PriyadharshanDrepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 4

The Development of Cotton-yarn-quality Predicting System

Ying Xiao1 Shulin Zhao2

Tianjin Polytechnic University, School of Textiles Tianjin Polytechnic University, School of Textiles

Tianjin, China Tianjin, China

yingxiao_sun@tom.com

Abstract: A new cotton-yarn-quality predicting system was

developed by using the merging programming technique of

VB and Matlab in the paper. Using this system, the tenacity

and evenness CV% of the cotton-yarn processing by

conventional spinning at standard temperature and

humidity can be predicted through inputting some fiber

properties into the system, such as the percentage of

impurities, the principal length, the percentage of short

fiber, the degree of maturity, fiber strength and the value of

Micronaire. And also it was verified that the system did the

good job for predicting yarn tenacity and evenness CV%

exactly with the relative error of less than 4% after the

model being trained. The accuracy can meet the demand of

spinning factories and so the predicting results would be

useful for guiding the spinning practice.

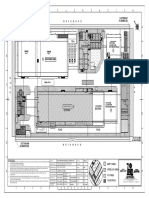

Figure1.The Overall System structure

Key words: BP network; network model; yarn quality

prediction; merging programming of VB and Matlab

The system mainly consisted of the neural network

I. INTRODUCTION building module, network training module, yarn-quality

predicating module, the model database and other

The quality of yarns is mainly determined by fiber

modules. Each module could operate coordinately under

properties, spinning processing, spinning equipments and

the domination and regulation of main control program of

the temperature and humidity of workshops, and so on. In

VB and realize many functions, such as data document

these factors, fiber properties are the most important one

read and writing, network modeling, network model

for the yarn quality. In order to predict the yarn quality

training, retention, call, and yarn quality prediction.

through digital simulation, it is essential to analyze the

relationship between fiber properties and yarn quality III. BP NEURAL NETWORK MODEL DEVELOPMENT

under any other conditions unchanged, such as processing

temperature and humidity. In this paper, a BP neural 1. The Introduction of BP Neural Network

network model was set up and based on the model, a new The BP Neural Network ( short for BP network), also

yarn-quality predicting system was developed by which known as back propagation network, is a multiple layer

the tenacity and evenness CV %of cotton yarns by ring feed-forward network, which generally includes an input

spinning process at the standard temperature and humidity layer, an output layer and one or several hidden layers,

could be predicted through inputting six fiber properties with its operation mainly consisting of two processes: the

into the system. Furthermore, it was validated that the feed-forward transmission of the information and the

system model did a good job for predicting both the yarn reverse transmission of the error[1]. In the former process,

tenacity and the evenness CV% exactly with the relative the information was calculated from the input layer to

error of less than 4%. output layer, layer by layer via hidden layer ,with the

neural unit state of each layer only affecting the next

II. THE DESIGN OF THE OVERALL STRUCTURE one's ;and in output layer, the system would turn to back

A system was developed by using the merging propagation if the desired results were not achieved when

programming technology of VB and Matlab and the compared with the target value. Then the error was

system integrated the user-friendly interface of VB and transferred from the output layer to input layer with the

the powerful function for data processing of Matlab. The network algorithmically adjudging its own weights and

overall system structure was shown in Figure 1. thresholds and the adjusting process was repeated till it

reached the desired results.

2. Neural Network Model Development

Aiming at the above issue, the strength and evenness

CV % of the yarns was predicted when the 3 layers and 4

layers BP networks were developed with neural network

978-1-4577-0860-2/11/$26.00 ©2011 IEEE

toolbox in Matlab environment and trained [2-3]; viewed reduce the time for network training. Meanwhile, the

from the training effect, not only the training time of network model structure was not too complicated and the

3-layer-network was shorter than the 4-layer-network, the problems were relatively simple in the quality predicting

prediction precision was also higher. Therefore, 3-layer system, the actual total memory consumption was not too

network model network structure was chosen in this much when the network was trained by this method.

yarn-quality predicting system, which consisted of an The network model has been built completely after the

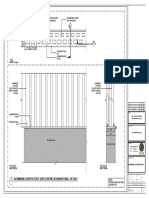

input layer, a hidden layer and an output layer. above design, according to which the topology map could

be drawn in Figure 2. The BP network could be divided

A. Neurons Number in Input Layer

into three layers: the input layer, the hidden layer, and the

This system was mainly used to predict the yarn output layer. There were 6 nodes in the input layer, an

tenacity and its evenness CV% under any other conditions adjustable number in the intermediate hidden layer, and 2

unchanged, such as processing, temperature and humidity. in the output layer.

To reach the above objective, the yarns quality was

predicted through inputting six indicators of fiber quality

such as impurity rate, the principal length, the percentage

of short fiber, the degree of maturity, fiber strength and

Micronaire [4].Firstly, the 11 fiber quality indicators the

spinning plants often measured were statistically analyzed

and then the experts' opinions were gotten in this field,

finally six neurons were taken in this layer to meet the

requirement that the network neurons number should

correspond to the fiber index number.

B. Neurons Number in Hidden Layer

There was no effective principle to follow to

determine the neurons numbers in this layer, so the Figure2. The BP Net Structure

optional one was mainly determined by training and

contrast on different neurons numbers. It was revealed that IV. SYSTEM DEVELOPMENTS

the network predicting accuracy was highest when the

neurons number in this layer was 16 through training and 1. The Neural Network Construction Module

contrast in the course of modeling the network. However, Developments

this was only for the training data used by the author, if According to the requirements of network mode

the training sample changed, the optional number of mentioned above, this part was developed by Matlab

neurons would have a corresponding change, therefore the neural network toolbox, in which the Newcf. Function was

neurons number in hidden layer could be set to a variables called to design the BP network; finally the designed

with a recommended value 16 in the quality predicting network was packaged into the same function file named

system, and the best suited hidden nodes number for net.m together with the data pre-designed program and the

samples could be determined by the system operator network training program. During the construction and

through training and contrast. training process, the network was activated by transferring

the external data information and the design of the

C. Neurons Number in Output Layer network nodes of hidden layer into the internal of function

The yarn tenacity and evenness CV % were chosen for file through a call to this function file, after that the

the predicting output items in this system. As a result, the network training was completed.

corresponding output layer neurons number in the network

2. The Modules Developments on Network

was taken as 2.

Training and Yarn Quality Prediction

D. Activation Function of Each Layer These two parts were developed with the technique of

The common hyperbolic tangent function VB and Matlab merging programming, the running of

−2 n −2 n

f (n) = (1 − e ) (1 + e ) in BP network was adopted Matlab application program was controlled by the master

control program of VB and the data transfer was carried

as activation function in the hidden layer. This function

out between the environments of VB and Matlab.

could compress each input to a value between -1 and 1;

while the linear function f (n) = w×n +bcould be adopted

A. The Realization Base of VB and Matlab

Merging Programming

as the activation function in the output layer [5].

ActiveX Automation protocol is a protocol that allows

E. Network Training Algorithm one application program (the control side) to control

Levenberg-Marquardt algorithm was adopted to train another (the server side). As VB could supports the

the network model in the system to overcome the ActiveX automation control side protocol and Matlab was

disadvantages of criteria BP algorithm, such as long able to support automated server-side protocol, therefore

training time and vulnerability to local optimum. It has when the ActiveX connection established between them.

been proved that the improved algorithm could markedly The Matlab command could be called directly in VB

environment, and then the realization of data transfer object named MT being created in the VB environment,

between the two programs followed. the trained network model the user specified was loaded to

Matlab environment through a call for Matlab to

B. The Network Training Module Developments

implement the "LOAD" command by MT.Execute

The function this module require to be achieved was method;Then fiber index value was transferred into

completing the network training and the retention of the Matlab environment from the VB environment by

trained model on the basis of transferring the input MT.Putfullmatrix method and passed to the loaded

messages from the network training interface in VB network mode after being pre-processed, then the yarn

environment to the network models in Matlab quality was predicted through a call for the neural network

environment as well as making them activated. The emulation function "SIM". Finally the predicting results

realization processes were as follows: First, a Matlab. obtained were processed, transmitted in the VB

application object named MT was created in the VB environment by MT.Getfullmatrix method and displayed

environment so that the ActiveX connection could be on the quality-predicting interface [7].

achieved between VB and Matlab ; then the activation and

training of the network could be realized on the basement V. MODEL LIBRARY CONSTRUCTING

of transferring the input messages from the network Cotton yarns with different count were collected from

training interface in VB environment to Matlab several cotton mills within a year, along with the

environment by MT.Putfullmatrix method, the call for corresponding raw cotton information indicators. After

Matlab by MT.Execute method to implement the net.m being analyzed and processed, the data could be used to

function files and the transfer of data information and the train the network models constructed by this system, and

setting to the network hidden layer nodes to the network then all the trained models were saved in model database

through function parameters latter ; After training, the for the yarn quality prediction.

trained network model was saved into model base, which

was available to be called by yarn quality prediction VI. THE INSTANCE AND ANALYSIS

module through a call for Matlab program to implement The model"JC18.2T" was called from the model

the "SAVE" order by MT.Execute method [6]. library to predict the quality of the JC18.2T yarn produced

C. The Yarn Quality Predicting Module by a factory. The properties of the raw cotton the yarn

used were summarized in Table 1, while both the

The function this module to be realized was

predictive values and the measured values were shown in

transferring the fiber quality index value from the

Table 2; As it could be seen in Table 2, the yarn tenacity

quality-predicting interface in VB environment to the

trained network model that loaded in Matlab environment and its evenness CV%were predicted with the relative

to realize the prediction and not only returning the error of less than 4% by the trained model. Since the

prediction results to VB environment but also displaying predicting accuracy was in an acceptable range, the

them on quality prediction interface, the above functions predicting results would be useful for guiding yarn

was realized as follows: after the Matlab application -spinning practice.

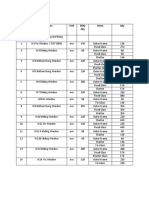

TABLE I. THE PROPERTIES OF COTTON FIBER

Group Impurity Principle Length Short Fiber Content Strength

Maturity Micronaire

Number (%) (mm) (%) (cN)

1 1.34 30.03 9.75 1.44 4.5940 3.84

2 1.06 30.18 9.46 1.40 4.4523 3.84

3 1.22 30.18 11.00 1.39 4.4113 3.84

4 1.17 30.21 10.53 1.40 4.4021 3.79

5 0.98 30.10 9.50 1.38 4.5115 3.73

TABLE II. THE TABLE OF COMPARISON BETWEEN PREDICTING VALUE AND MEASURING VALUE

Predictive Value Measured Value Relative Error

Group

Number Strength CV % Strength CV % Strength CV %

(cN·tex-1) (%) (cN·tex-1) (%) (%) (%)

1 15.7 12.6 15.5 12.5 +1.29 +0.80

2 15.3 12.6 14.9 13.0 +2.61 -3.08

3 14.3 12.8 14.8 12.9 -3.38 +0.78

4 14.5 12.7 14.8 13.0 -2.03 -2.31

5 14.6 12.9 14.1 12.8 +3.55 -0.78

VII. CALCULATIONS

In order to predict the yarn quality through digital

simulation, it is essential to predict the yarn quality with

higher accuracy in the spinning process. In this paper, a

further exploration was made to this part and artificial

neural network model was built to predict yarn strength

and evenness. And also it was verified that the system

did the good job for predicting yarn tenacity and

evenness CV% exactly with the relative error of less

than 4% after the model being trained. The accuracy can

meet the demand of spinning factories and so the

predicting results would be useful for guiding the

spinning practice.

REFERENCES

[1] Xiangsheng Huang,Hanbin Xiao.Application of Wavelet

Analysis and ANN in Ultrasonic Quantitative Testing[J],Port

Engineering Technology,2008(6):13-15.

[2] Bao Liu, Gang Wu. Surface Prediction Model Based on BP

Neural Network [J].Heat Treatment Technology and Equipment,

2006(6):37-40.

[3] Xiancai Gui. Realization of BP Networks and Their Application

on MATLAB [J].Journal of Zhanjiang Normal College, 2004, 25

(3):79-84.

[4] Xiaomei Zou, Guan Liang. The Relationships of Performance of

Rraw Cotton,Spinning Process and Yarn Quality[J]. Inspection

and Quarantine Science, 2005, (12):143-144.

[5] Cong Shuang.Matlab Neural Network Toolbox and its

Application [M]. University of Science and Technology of China

Press.2003-5 (2).

[6] Zhisong Zhu, Xiaoli Guo. Research on Merging Programming of

VB and MATLAB [J]. Computer Applications, 2003(9):18-19.

[7] Li Feng, Ju Li. Method of Hybird Programming with VB and

Matlab[J], Software Technology, 2005 (5):110-112.

S-ar putea să vă placă și

- ImagineFX Presents - The Digital Artist's Survival GuideDocument116 paginiImagineFX Presents - The Digital Artist's Survival GuideEsteban Millan Pinzon92% (49)

- Matlab Iris RBFDocument21 paginiMatlab Iris RBFЯу МдÎncă nu există evaluări

- SharePoint Configuration Guidance For 21 CFR Part 11 ComplianceDocument72 paginiSharePoint Configuration Guidance For 21 CFR Part 11 CompliancewiwiwoÎncă nu există evaluări

- Network Coding: Fundamentals and ApplicationsDe la EverandNetwork Coding: Fundamentals and ApplicationsMuriel MedardÎncă nu există evaluări

- Stellaris Launchpad Work BookDocument278 paginiStellaris Launchpad Work BookJulianaMarianaÎncă nu există evaluări

- TS - JGS320-C81-Landfill - 1300m - 35C-Deg - 480V - Operadora-Ferrocarriles - V5-21 - Final PDFDocument43 paginiTS - JGS320-C81-Landfill - 1300m - 35C-Deg - 480V - Operadora-Ferrocarriles - V5-21 - Final PDFMarti H J100% (1)

- Artificial Neural Network Seminar ReportDocument15 paginiArtificial Neural Network Seminar ReportNeha Singh50% (2)

- Computer Networks Lab Manual-17ECL68Document87 paginiComputer Networks Lab Manual-17ECL68LikithaReddy Yenumula80% (5)

- Cocoa FundamentalsDocument238 paginiCocoa FundamentalsDaniel MaccarroneÎncă nu există evaluări

- Material Submittal AluminiumDocument1 paginăMaterial Submittal AluminiumJacob PriyadharshanÎncă nu există evaluări

- BP Neural Network Principle and MATLAB Simulation: Xiong Xin Nie MingxinDocument6 paginiBP Neural Network Principle and MATLAB Simulation: Xiong Xin Nie MingxinjÎncă nu există evaluări

- A Neural-Network Approach For Semiconductor Wafer Post-Sawing InspectionDocument7 paginiA Neural-Network Approach For Semiconductor Wafer Post-Sawing InspectionMohd Nurfirdaus Mohd ShamsuriÎncă nu există evaluări

- ReqDocument62 paginiReqAnurag KhannaÎncă nu există evaluări

- Σύστημα αντι - Drone βασισμένο σε βαθιά μάθηση χρησιμοποιώντας τεχνολογία ραντάρDocument2 paginiΣύστημα αντι - Drone βασισμένο σε βαθιά μάθηση χρησιμοποιώντας τεχνολογία ραντάρDinos KaltsasÎncă nu există evaluări

- Eait 2018 8470438Document5 paginiEait 2018 8470438Ahmed EmadÎncă nu există evaluări

- BARD: A Novel Application of Bayesian Reasoning For Proactive Network ManagementDocument6 paginiBARD: A Novel Application of Bayesian Reasoning For Proactive Network Managementsubscribeme11Încă nu există evaluări

- Evolutionary Neural Networks For Product Design TasksDocument11 paginiEvolutionary Neural Networks For Product Design TasksjlolazaÎncă nu există evaluări

- Chapter - 6 Artificial Neural Network (Ann) ModelingDocument24 paginiChapter - 6 Artificial Neural Network (Ann) ModelingRajeshwari NarayanamoorthyÎncă nu există evaluări

- Neural NWDocument3 paginiNeural NWKapil KumarÎncă nu există evaluări

- Errissya Telkomnika 2022februariDocument11 paginiErrissya Telkomnika 2022februariErrissyaRasywirÎncă nu există evaluări

- A Pneumonia Detection Method Based On ImprovedDocument6 paginiA Pneumonia Detection Method Based On ImprovedAmílcar CáceresÎncă nu există evaluări

- Neural Network Modeling of A Power Generation Gas TurbineDocument11 paginiNeural Network Modeling of A Power Generation Gas TurbineWilliam Jaldin CorralesÎncă nu există evaluări

- An Analog Neural Network Processor Programmable Topology: Boser, Jane DDocument9 paginiAn Analog Neural Network Processor Programmable Topology: Boser, Jane DApoorva MahajanÎncă nu există evaluări

- Neural Network Seminar ReportDocument17 paginiNeural Network Seminar ReportJainendra SinghÎncă nu există evaluări

- SeminarDocument13 paginiSeminaryuli0.0yuli.0Încă nu există evaluări

- A Dynamic Affinity Propagation Clustering Algorithm For Cell Outage Detection in Self-Healing NetworksDocument5 paginiA Dynamic Affinity Propagation Clustering Algorithm For Cell Outage Detection in Self-Healing NetworkshardwellarminÎncă nu există evaluări

- Image/Data Encryption-Decryption Using Neural Network: Shweta R. Bhamare, Dr. S.D.SawarkarDocument7 paginiImage/Data Encryption-Decryption Using Neural Network: Shweta R. Bhamare, Dr. S.D.SawarkarPavan MasaniÎncă nu există evaluări

- Ijeces 13 07 07 939Document9 paginiIjeces 13 07 07 939Karama AbdelJabbarÎncă nu există evaluări

- Spam Email Detection Using Neural Networks TrainingDocument7 paginiSpam Email Detection Using Neural Networks TrainingDiana BeltranÎncă nu există evaluări

- Can Neural Networks Be Easily Interpreted in Software Cost Estimation?Document6 paginiCan Neural Networks Be Easily Interpreted in Software Cost Estimation?jagannath_singhÎncă nu există evaluări

- Improved Optical Character Recognition With Deep Neural NetworkDocument5 paginiImproved Optical Character Recognition With Deep Neural NetworkharshithaysÎncă nu există evaluări

- 1) Image Encryption Using Chaotic Based Artificial Neural Network PDFDocument4 pagini1) Image Encryption Using Chaotic Based Artificial Neural Network PDFAyshÎncă nu există evaluări

- Ijser: Image Encryption Using Chaotic Based Artificial Neural NetworkDocument4 paginiIjser: Image Encryption Using Chaotic Based Artificial Neural NetworkbhattajagdishÎncă nu există evaluări

- Autonomously-Reconfigurable Wireless Mesh NetworksDocument3 paginiAutonomously-Reconfigurable Wireless Mesh NetworksKelsey RyanÎncă nu există evaluări

- Efficient Error-Tolerant Quantized Neural Network AcceleratorsDocument6 paginiEfficient Error-Tolerant Quantized Neural Network AcceleratorsmajunhuiuweÎncă nu există evaluări

- Computer Network Performance Evaluation Based On Different Data Packet Size Using Omnet++ Simulation EnvironmentDocument5 paginiComputer Network Performance Evaluation Based On Different Data Packet Size Using Omnet++ Simulation Environmentmetaphysics18Încă nu există evaluări

- Wireless Networks Throughput Enhancement Using Artificial IntelligenceDocument5 paginiWireless Networks Throughput Enhancement Using Artificial Intelligenceabs sidÎncă nu există evaluări

- Kim Improving Accuracy of CVPR 2021 SupplementalDocument1 paginăKim Improving Accuracy of CVPR 2021 SupplementalRod MarchÎncă nu există evaluări

- Fault TolerantDocument10 paginiFault TolerantKmp SathishkumarÎncă nu există evaluări

- Genetic CNNDocument10 paginiGenetic CNNserpsaipong navanuraksaÎncă nu există evaluări

- Simple Hardware Implementation of Neural Networks For Instruction in Analog ElectronicsDocument12 paginiSimple Hardware Implementation of Neural Networks For Instruction in Analog ElectronicsGeraud Russel Goune ChenguiÎncă nu există evaluări

- Implementation of A Library For Artificial Neural Networks in CDocument10 paginiImplementation of A Library For Artificial Neural Networks in COscar OlivaresÎncă nu există evaluări

- Structured Pruning of Deep Convolutional Neural Netw Orks: Sajid Anwar, Kyuyeon Hwang and Wonyong SungDocument11 paginiStructured Pruning of Deep Convolutional Neural Netw Orks: Sajid Anwar, Kyuyeon Hwang and Wonyong Sungali shaarawyÎncă nu există evaluări

- Neural-Network QuestionsDocument3 paginiNeural-Network Questions66umer660% (1)

- An Approach To Recognize Characters Using Neural Network in LPR SystemDocument4 paginiAn Approach To Recognize Characters Using Neural Network in LPR SystemKamel SaifÎncă nu există evaluări

- (IJCST-V10I5P59) :hadeel Ahmed, Mohand KechadiDocument12 pagini(IJCST-V10I5P59) :hadeel Ahmed, Mohand KechadiEighthSenseGroupÎncă nu există evaluări

- 181-Article Text-292-1-10-20200406Document10 pagini181-Article Text-292-1-10-20200406Nhi NguyễnÎncă nu există evaluări

- Optimum Architecture of Neural Networks Lane Following SystemDocument6 paginiOptimum Architecture of Neural Networks Lane Following SystemJ.Încă nu există evaluări

- SH A Sri 07Document116 paginiSH A Sri 07nktuÎncă nu există evaluări

- Graph Convolutional Networks Adaptations and ApplicationsDocument6 paginiGraph Convolutional Networks Adaptations and ApplicationsInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Vasilic2005Document9 paginiVasilic2005fernando ceballosÎncă nu există evaluări

- Comparison of Frameworks-For High-Performance Packet IO2015Document10 paginiComparison of Frameworks-For High-Performance Packet IO2015Bename DoostÎncă nu există evaluări

- A Degredation Interval Prediction Method Based OnDocument6 paginiA Degredation Interval Prediction Method Based OnSeira LoyardÎncă nu există evaluări

- MAC For ANN Using VerilogDocument6 paginiMAC For ANN Using VerilogJayant SinghÎncă nu există evaluări

- Neural Network EnsemblesDocument9 paginiNeural Network EnsembleskronalizedÎncă nu există evaluări

- An Optimized K Means Clustering For Improving Accuracy in Traffic ClassificationDocument13 paginiAn Optimized K Means Clustering For Improving Accuracy in Traffic ClassificationCristianÎncă nu există evaluări

- ANN & FingerprintDocument26 paginiANN & FingerprintFodelman FidelÎncă nu există evaluări

- Accelerated Deep Learning Inference From Constrained Embedded DevicesDocument5 paginiAccelerated Deep Learning Inference From Constrained Embedded DevicesBhargav BhatÎncă nu există evaluări

- Analysis of Behavior of MAC Protocol and Simulation of Different MAC Protocol and Proposal Protocol For Wireless Sensor NetworkDocument7 paginiAnalysis of Behavior of MAC Protocol and Simulation of Different MAC Protocol and Proposal Protocol For Wireless Sensor NetworkAnkit MayurÎncă nu există evaluări

- Neural Network Technique in The Study of Selected Chemical Engineering Unit Operations Data Using MATLABDocument7 paginiNeural Network Technique in The Study of Selected Chemical Engineering Unit Operations Data Using MATLABInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Neural Networks Embed DDocument6 paginiNeural Networks Embed DL S Narasimharao PothanaÎncă nu există evaluări

- Intrusion Detecting in Computer System by Using ArtificialDocument18 paginiIntrusion Detecting in Computer System by Using ArtificialJerome GumaroÎncă nu există evaluări

- Human Action Recognition System For Elderly and Children Care Using Three Stream ConvNetDocument5 paginiHuman Action Recognition System For Elderly and Children Care Using Three Stream ConvNetMitchell Angel Gomez OrtegaÎncă nu există evaluări

- Amaitik WESIC2003 PaperDocument8 paginiAmaitik WESIC2003 PaperSalehÎncă nu există evaluări

- Gender Classification: A Convolutional Neural Network ApproachDocument17 paginiGender Classification: A Convolutional Neural Network ApproachSadiq NazeerÎncă nu există evaluări

- Deep Learning with Python: A Comprehensive Guide to Deep Learning with PythonDe la EverandDeep Learning with Python: A Comprehensive Guide to Deep Learning with PythonÎncă nu există evaluări

- Plastic Glazing SpecsDocument9 paginiPlastic Glazing SpecsJacob PriyadharshanÎncă nu există evaluări

- 2363 - Bill of QuantitiesDocument32 pagini2363 - Bill of QuantitiesJacob PriyadharshanÎncă nu există evaluări

- Dec. 26, 1967 R. T. Casebolt 3,359,573: Vouss), '43 Guns)Document4 paginiDec. 26, 1967 R. T. Casebolt 3,359,573: Vouss), '43 Guns)Jacob PriyadharshanÎncă nu există evaluări

- UntitledDocument15 paginiUntitledJacob PriyadharshanÎncă nu există evaluări

- Marina MenuDocument1 paginăMarina MenuJacob PriyadharshanÎncă nu există evaluări

- Plan-Pergola Section-Aa: Ur BanDocument1 paginăPlan-Pergola Section-Aa: Ur BanJacob PriyadharshanÎncă nu există evaluări

- Expert Series:: Glass Acoustic PerformanceDocument3 paginiExpert Series:: Glass Acoustic PerformanceJacob PriyadharshanÎncă nu există evaluări

- UntitledDocument88 paginiUntitledJacob PriyadharshanÎncă nu există evaluări

- Print Ratecard W.E.F. 1st January 2022: Khaleej Times Base Rates City TimesDocument1 paginăPrint Ratecard W.E.F. 1st January 2022: Khaleej Times Base Rates City TimesJacob PriyadharshanÎncă nu există evaluări

- Individual and Family Application Checklist (Uae) : How To ApplyDocument9 paginiIndividual and Family Application Checklist (Uae) : How To ApplyJacob PriyadharshanÎncă nu există evaluări

- Cummulative Work Report-17.04.2019Document1 paginăCummulative Work Report-17.04.2019Jacob PriyadharshanÎncă nu există evaluări

- Mic-Value Analyse and Test Design: Fanlimin1 Huanghao3Document3 paginiMic-Value Analyse and Test Design: Fanlimin1 Huanghao3Jacob PriyadharshanÎncă nu există evaluări

- Aluminium Louvers Fence Over Existing Boundary Wall Details 1Document1 paginăAluminium Louvers Fence Over Existing Boundary Wall Details 1Jacob PriyadharshanÎncă nu există evaluări

- Pergola Section P1: AdditionDocument6 paginiPergola Section P1: AdditionJacob PriyadharshanÎncă nu există evaluări

- Moisture Sensing in Baled CropsDocument132 paginiMoisture Sensing in Baled CropsJacob PriyadharshanÎncă nu există evaluări

- Disclosure To Promote The Right To InformationDocument18 paginiDisclosure To Promote The Right To InformationJacob PriyadharshanÎncă nu există evaluări

- Identification of Trash and of Ginned Cotton Soft TechniquesDocument4 paginiIdentification of Trash and of Ginned Cotton Soft TechniquesJacob PriyadharshanÎncă nu există evaluări

- Kompass - Aircrete Building Materials EN PrintDocument6 paginiKompass - Aircrete Building Materials EN PrintJacob PriyadharshanÎncă nu există evaluări

- SL - No Particulars Unit BOQ Qty Items QtyDocument2 paginiSL - No Particulars Unit BOQ Qty Items QtyJacob PriyadharshanÎncă nu există evaluări

- Catted Values: English - Short Long - DescriptioDocument2 paginiCatted Values: English - Short Long - DescriptioJacob PriyadharshanÎncă nu există evaluări

- Missing ValuesDocument361 paginiMissing ValuesJacob PriyadharshanÎncă nu există evaluări

- M/S: Airolink International Construction LLC.: Project: International Indian School, Abu Dhabi Details As Per BoqDocument8 paginiM/S: Airolink International Construction LLC.: Project: International Indian School, Abu Dhabi Details As Per BoqJacob PriyadharshanÎncă nu există evaluări

- Side Arm Selection Calculation: W22-Window Is Selected For Calculation. Window Size - 850mm X 1650mmDocument2 paginiSide Arm Selection Calculation: W22-Window Is Selected For Calculation. Window Size - 850mm X 1650mmJacob PriyadharshanÎncă nu există evaluări

- Bhatia Installation 22-11-15Document1 paginăBhatia Installation 22-11-15Jacob PriyadharshanÎncă nu există evaluări

- Al Qaffy G+1 Staff AccoDocument10 paginiAl Qaffy G+1 Staff AccoJacob PriyadharshanÎncă nu există evaluări

- CW50MM Page42Document106 paginiCW50MM Page42Jacob Priyadharshan100% (1)

- Asg Ant MS 002Document1 paginăAsg Ant MS 002Jacob PriyadharshanÎncă nu există evaluări

- Central Contracting (G+2)Document4 paginiCentral Contracting (G+2)Jacob PriyadharshanÎncă nu există evaluări

- 31Document142 pagini31Kemalist Editss1Încă nu există evaluări

- Ieee Format Sample Research PaperDocument8 paginiIeee Format Sample Research Paperafeaupyen100% (1)

- People Soft Bundle Release Note 9 Bundle16Document26 paginiPeople Soft Bundle Release Note 9 Bundle16rajiv_xguysÎncă nu există evaluări

- KNX 100G - Setup Guide: E G H C D FDocument4 paginiKNX 100G - Setup Guide: E G H C D FSkrapÎncă nu există evaluări

- 4 - Networks and Cloud ComputingDocument4 pagini4 - Networks and Cloud Computingcyka blyatÎncă nu există evaluări

- Logcat Prev CSC LogDocument309 paginiLogcat Prev CSC LogJesus Arsceli MontesinosÎncă nu există evaluări

- Bochspwn ReloadedDocument100 paginiBochspwn ReloadedalexÎncă nu există evaluări

- Ajay AnandDocument17 paginiAjay AnandSanjaÎncă nu există evaluări

- Why & What Is Cooperative Learning at The Computer: Teaching TipsDocument8 paginiWhy & What Is Cooperative Learning at The Computer: Teaching Tipsapi-296655270Încă nu există evaluări

- HP Z-Series Workstations - Configuring RAID Devices HP® Customer SupportDocument4 paginiHP Z-Series Workstations - Configuring RAID Devices HP® Customer SupportShaikh DanialÎncă nu există evaluări

- GitHub - Janpetzold - Prince2-Foundation-Summary - A Summary of The Necessary Knowledge For The PRINCE2 Foundation ExamDocument26 paginiGitHub - Janpetzold - Prince2-Foundation-Summary - A Summary of The Necessary Knowledge For The PRINCE2 Foundation ExamSylwia Chadaj0% (1)

- Endorsement-JJWC - BVAWCDocument33 paginiEndorsement-JJWC - BVAWCBarangay TaguiticÎncă nu există evaluări

- US/OPS - OP1511 - FPS02.pdf: Program Name / Task Recommended FrequencyDocument2 paginiUS/OPS - OP1511 - FPS02.pdf: Program Name / Task Recommended FrequencyRajeswarÎncă nu există evaluări

- PRESENSI WEBINAR MGMP GEOGRAFI KE 2 (Responses)Document3 paginiPRESENSI WEBINAR MGMP GEOGRAFI KE 2 (Responses)MUHAMMAD YAMINIÎncă nu există evaluări

- Chapter 2 - 3 Validating DataDocument5 paginiChapter 2 - 3 Validating DataasyrafÎncă nu există evaluări

- 8600-320 Workbook AirDocument30 pagini8600-320 Workbook AirMohammad NazahÎncă nu există evaluări

- B105M - B125M - B155M Brochure - 2Document7 paginiB105M - B125M - B155M Brochure - 2Gary EarlÎncă nu există evaluări

- FJ 310Document2 paginiFJ 310shalarthiÎncă nu există evaluări

- Aamir Hussain KhanDocument3 paginiAamir Hussain KhanMuhammad FahadÎncă nu există evaluări

- New Trends in Image and Video CompressionDocument7 paginiNew Trends in Image and Video CompressionSrinivasan JeganÎncă nu există evaluări

- Project of IseDocument14 paginiProject of IseReiaz MaroofÎncă nu există evaluări

- Babypips ComDocument5 paginiBabypips ComSchuleiman JmÎncă nu există evaluări

- HTZ Communications v2022 - News and Modifications PDFDocument78 paginiHTZ Communications v2022 - News and Modifications PDFMarcos Duván Pineda AlhucemaÎncă nu există evaluări

- Infotec Ai 1000 Program-hcia-Ai Lab GuideDocument82 paginiInfotec Ai 1000 Program-hcia-Ai Lab Guidemicke juarezÎncă nu există evaluări

- MM TAXBRA Migracao BatchDocument3 paginiMM TAXBRA Migracao BatchMárcio NascimentoÎncă nu există evaluări