Documente Academic

Documente Profesional

Documente Cultură

Winders: The Complete Guide For Paper Mills and Converters by Jan Gronewold

Încărcat de

HemantTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Winders: The Complete Guide For Paper Mills and Converters by Jan Gronewold

Încărcat de

HemantDrepturi de autor:

Formate disponibile

Winders: The Complete Guide for Paper Mills and Converters

By Jan Gronewold

This comprehensive new book serves as a complete winder training, applications, and product

buying guide. This helpful text shows readers how to analyze, select, implement, and improve a

winding operation. By describing and illustrating the various types of winders, the book can help

readers determine the best winding method for their particular materials.

Contents include:

• Understanding the Basics

• The Plateaus of Winding

• From reels to converting slitter-rewinders

• Features, functions, benefits, and limitations

• Winder Types by Concept and Industry

• From center to center-surface winding

• Winder Classifications and Selection Criteria

• Winding methods and tools applied

• Value-added controls

This valuable industry resource will be useful to everyone involved in the winder process area,

including engineers, production managers, maintenance managers, and other technical and

production staff. Winder manufacturers and industry consultants will also find this unique book

very useful.

1998. 186 pages, soft cover

Item Number 0101R274

TABLE OF CONTENTS

CHAPTER 1: ACKNOWLEDGEMENTS, FOREWORD, AWARENESS

Words of gratitude....................................................................................3

About this book........................................................................................3

About this industry ...................................................................................4

History of papermaking and printing .........................................................5

Awareness and selection focus ..................................................................6

Summary of objectives..............................................................................7

CHAPTER 2: UNDERSTANDING THE BASICS

Materials, their properties and behavior................................................... 11

The process of winding........................................................................... 25

Page 1 of 3

The basic TNT tools of winding (tension, nip, and torque) ...................... 28

Understanding nip................................................................................... 34

Understanding torque ............................................................................. 41

Torque ................................................................................................... 44

The holding forces that affect roll structure............................................. 48

Unwinding, slitting, spreading................................................................. 51

Slitting.................................................................................................... 55

Spreading ............................................................................................... 66

Spreading tools include........................................................................... 68

Types of operations ................................................................................ 73

CHAPTER 3: THE PLATEAUS OF WINDING

Pure center winding ................................................................................ 79

Center winding with gap (gap winding)................................................... 80

Center winding with nipped lay-on roll (contact winding) ....................... 81

Simplex center-surface winding............................................................... 81

Duplex center-surface winding................................................................ 82

The tools of center-surface winding ........................................................ 83

Differential winding ................................................................................ 84

Single-drum winding with multiple individual rewind stations.................. 85

Pure surface winders............................................................................... 86

Large single-drum winders, vertical two-drum winders, belted

three-drum winders, air-injection winders................................................ 88

Conventional reels .................................................................................. 89

CHAPTER 4: WINDER TYPES BY CONCEPT AND INDUSTRY

Terminology ........................................................................................... 95

Reel........................................................................................................ 96

Rereeler.................................................................................................. 99

Two-drum winder................................................................................. 100

Single-drum winder .............................................................................. 108

Large converting duplex slitter-rewinder............................................... 112

Small converting duplex slitter-rewinder ............................................... 115

Converting simplex slitter-rewinder....................................................... 118

Turret winder (with roll changer) .......................................................... 120

Dual turret slitter-rewinder ................................................................... 122

Modified converting reel with in-line slitting ......................................... 124

Counter-roll winder .............................................................................. 126

Other winder types ............................................................................... 128

Innovations........................................................................................... 132

CHAPTER 5: WINDER CLASSIFICATIONS AND SELECTION CRITERIA

Winding methods and tool applied ........................................................ 139

Winder geometry and configuration ...................................................... 141

Drive applications ................................................................................. 143

Degree of automation ........................................................................... 145

Design concepts.................................................................................... 148

Value-added controls............................................................................ 149

Customer/grade specific features/upgrades............................................ 157

Web and roll handling ........................................................................... 158

CHAPTER 6: CONCLUSION

Consistent uniformity............................................................................ 165

Which winder, winding tool and roll support for which material ............ 167

CHAPTER 7: APPENDIXES

Appendix A: Universal unwind/winder questionnaire............................. 171

Appendix B: Additional tension charts .................................................. 174

Appendix C: Fundamentals of electricity, energy, motors, and torque.... 175

Appendix D: Abbreviations................................................................... 177

Appendix E: SI conversion table ........................................................... 178

Appendix F: Equipment suppliers.......................................................... 179

Appendix G: References ....................................................................... 183

S-ar putea să vă placă și

- Incompressible Flow Turbomachines: Design, Selection, Applications, and TheoryDe la EverandIncompressible Flow Turbomachines: Design, Selection, Applications, and TheoryÎncă nu există evaluări

- Oregon WMR300 PDFDocument15 paginiOregon WMR300 PDFsibo100% (1)

- Drivepower 2nded 161024201601Document20 paginiDrivepower 2nded 161024201601Eduardo GuidoÎncă nu există evaluări

- Modelling and Control of A Gas Pressure Reduction SystemDocument339 paginiModelling and Control of A Gas Pressure Reduction SystemErick Renzo Hidalgo OrtegaÎncă nu există evaluări

- (Mark Anthony Richard Gunston) Microwave Transmiss (B-Ok - Xyz) PDFDocument297 pagini(Mark Anthony Richard Gunston) Microwave Transmiss (B-Ok - Xyz) PDFMoysés LicáÎncă nu există evaluări

- AC Servo System: SDA Series 100W 3.5KWDocument22 paginiAC Servo System: SDA Series 100W 3.5KWSunil Kumar YelisettyÎncă nu există evaluări

- Energy in Steady Flow-Part 4Document35 paginiEnergy in Steady Flow-Part 4shazaib aliÎncă nu există evaluări

- Electric Power System Components - Transformers and Rotating MachinesDocument485 paginiElectric Power System Components - Transformers and Rotating MachinesYH TAnÎncă nu există evaluări

- Intro To Mathematical Programming MITDocument228 paginiIntro To Mathematical Programming MITCloud neuronÎncă nu există evaluări

- Rseec 2016 06.10.2016 PDFDocument341 paginiRseec 2016 06.10.2016 PDFJicheng PiaoÎncă nu există evaluări

- Tension Control and Winder Application GuideDocument7 paginiTension Control and Winder Application GuideSachuuÎncă nu există evaluări

- jhtp5 22Document58 paginijhtp5 22Erick MartinezÎncă nu există evaluări

- Broadband TransformersDocument6 paginiBroadband TransformersKSÎncă nu există evaluări

- Foundation Product CatalogDocument68 paginiFoundation Product Catalogapi-279886039Încă nu există evaluări

- TA0262 Instruction Manual RevisedDocument39 paginiTA0262 Instruction Manual RevisedMarlon BenjaminÎncă nu există evaluări

- Course Code Course Name Course Structure Ececc05 Signal and Systems 3-1-0 L-T-PDocument2 paginiCourse Code Course Name Course Structure Ececc05 Signal and Systems 3-1-0 L-T-PSuvdeep NayakÎncă nu există evaluări

- Vintageshifi PDFDocument125 paginiVintageshifi PDFRobertas PutinasÎncă nu există evaluări

- Medium Steam Sterilizers - Azteca AC Series PDFDocument2 paginiMedium Steam Sterilizers - Azteca AC Series PDFDurban Chamber of Commerce and Industry0% (1)

- Kohler 101Document4 paginiKohler 101MGRilloÎncă nu există evaluări

- Mie10170 Drts XX User-Manual Rev1.33Document512 paginiMie10170 Drts XX User-Manual Rev1.33Slobodan SavicÎncă nu există evaluări

- E51325 Rev 2 - 546dp Sensor PDFDocument2 paginiE51325 Rev 2 - 546dp Sensor PDFMajidÎncă nu există evaluări

- Noise Generation in Dynamic Wireless Power TransferDocument4 paginiNoise Generation in Dynamic Wireless Power TransferChristian DavidÎncă nu există evaluări

- Power Supply Module1 To PLCDocument6 paginiPower Supply Module1 To PLCchiranjeeviÎncă nu există evaluări

- Double Tuned AmplifierDocument1 paginăDouble Tuned AmplifierAnbarasan RamamoorthyÎncă nu există evaluări

- (George C. Chryssis) High Frequency Switching Powe PDFDocument151 pagini(George C. Chryssis) High Frequency Switching Powe PDFJesus BarraganÎncă nu există evaluări

- GalvanometerDocument8 paginiGalvanometerAnkit ChauhanÎncă nu există evaluări

- Circuit Theory I-LEC Mohamed MegahedDocument137 paginiCircuit Theory I-LEC Mohamed MegahedHussien HassanÎncă nu există evaluări

- Fluke+PM6685,+PM6685R+Prog +Frequency+Counter PDFDocument94 paginiFluke+PM6685,+PM6685R+Prog +Frequency+Counter PDFtaryoÎncă nu există evaluări

- Smart x835 DatasheetDocument4 paginiSmart x835 DatasheetBeni SetiawanÎncă nu există evaluări

- Armature WindingDocument20 paginiArmature Windingk rajendra100% (1)

- Solutions Manual Microelectronic Circuits Analysis and Design 2nd Edition Rashid PDFDocument10 paginiSolutions Manual Microelectronic Circuits Analysis and Design 2nd Edition Rashid PDFAsta EfiÎncă nu există evaluări

- Fulltext 7499Document239 paginiFulltext 7499Jenn QuintoÎncă nu există evaluări

- LabviewDocument28 paginiLabviewchrist9088100% (1)

- DEE - 310 - NotesDocument41 paginiDEE - 310 - NotesAlfred K ChilufyaÎncă nu există evaluări

- Transformer Type & TutorialDocument106 paginiTransformer Type & TutorialHasan Basyaria100% (1)

- Air Circuit Breaker (ACB) 3WT SeriesDocument2 paginiAir Circuit Breaker (ACB) 3WT SeriesThilinaÎncă nu există evaluări

- LCL Filter DesignDocument8 paginiLCL Filter DesignAlex RochaÎncă nu există evaluări

- 6.measurement of Micro Feature of A Product (Thread of A Bolt) in A Profile Projector Metrology MeasurementLab - ME594Document9 pagini6.measurement of Micro Feature of A Product (Thread of A Bolt) in A Profile Projector Metrology MeasurementLab - ME594selvaram baluÎncă nu există evaluări

- User ManualDocument258 paginiUser ManualEdwin GiraldoÎncă nu există evaluări

- LLUE 310 - ManualDehydrator300L300hpaenglischDocument16 paginiLLUE 310 - ManualDehydrator300L300hpaenglischTechnical Digicel100% (1)

- Design, Control and Application of Modular Multilevel Converters For HVDC Transmission SystemsDocument50 paginiDesign, Control and Application of Modular Multilevel Converters For HVDC Transmission SystemsrajeshÎncă nu există evaluări

- Reaction Force in Pelton TurbinesDocument8 paginiReaction Force in Pelton TurbinesNazakat HussainÎncă nu există evaluări

- Power System Analysis Exercise I Load Flow Computation in PowerworldDocument5 paginiPower System Analysis Exercise I Load Flow Computation in Powerworldeddy martinezÎncă nu există evaluări

- Digital Storage Oscilloscope: ADS1000 C SeriesDocument5 paginiDigital Storage Oscilloscope: ADS1000 C Seriesel_frÎncă nu există evaluări

- Solucionario Signal Processing FirstDocument216 paginiSolucionario Signal Processing Firstmakey23Încă nu există evaluări

- Welded Joint Design 3rd EditionDocument155 paginiWelded Joint Design 3rd EditionDiÎncă nu există evaluări

- Brochure Syrige Pump 5BDocument2 paginiBrochure Syrige Pump 5BDaniel ParÎncă nu există evaluări

- Fourier Transform PairsDocument5 paginiFourier Transform PairsSwati100% (1)

- Etekcity ZAP 3L Remote Power OutletDocument28 paginiEtekcity ZAP 3L Remote Power OutletMacraméÎncă nu există evaluări

- Tutorial 7Document9 paginiTutorial 7tutulkarÎncă nu există evaluări

- Practice Problems - Synch - MachinesDocument3 paginiPractice Problems - Synch - MachinesBea DucaoÎncă nu există evaluări

- Electromagnetic - Disk - Brake RDocument70 paginiElectromagnetic - Disk - Brake RPrints BindingsÎncă nu există evaluări

- Field Effect Transistors PDFDocument102 paginiField Effect Transistors PDFanjanaÎncă nu există evaluări

- Thyrotronic (Russian) (1.1 MB)Document8 paginiThyrotronic (Russian) (1.1 MB)brobataÎncă nu există evaluări

- Laboratory Report Electronic MotorsDocument11 paginiLaboratory Report Electronic MotorsChloe JonesÎncă nu există evaluări

- Tutorials On MachinesDocument2 paginiTutorials On Machinesjenniferi_7Încă nu există evaluări

- Sem V Bee 502power ElectronicsDocument111 paginiSem V Bee 502power ElectronicsnazibÎncă nu există evaluări

- Three Phase InverterDocument11 paginiThree Phase InverterseethahereÎncă nu există evaluări

- AGC Automatic Gen-Set Controller: Designer'S Reference HandbookDocument183 paginiAGC Automatic Gen-Set Controller: Designer'S Reference Handbookchichid2008Încă nu există evaluări

- DeignDocument80 paginiDeignAnilÎncă nu există evaluări

- Paramount Health Services & Insurance Tpa Private Limited: Deficiency Letter Without PrejudiceDocument2 paginiParamount Health Services & Insurance Tpa Private Limited: Deficiency Letter Without PrejudiceHemantÎncă nu există evaluări

- Why A Variable Speed Drive?: ABB Industry OyDocument6 paginiWhy A Variable Speed Drive?: ABB Industry OyHemantÎncă nu există evaluări

- Open-And Closed-Loop Control: ABB Industry OyDocument12 paginiOpen-And Closed-Loop Control: ABB Industry OyHemantÎncă nu există evaluări

- Sca178832019 GJHC240640422019 2 20122019Document1 paginăSca178832019 GJHC240640422019 2 20122019HemantÎncă nu există evaluări

- 113 Children Money Back PlanDocument14 pagini113 Children Money Back PlanHemantÎncă nu există evaluări

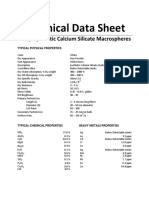

- Technical Data Sheet: Tisil / Synthetic Calcium Silicate MacrospheresDocument1 paginăTechnical Data Sheet: Tisil / Synthetic Calcium Silicate MacrospheresHemantÎncă nu există evaluări

- Notice No 3 Revised Admission Process ScheduleDocument1 paginăNotice No 3 Revised Admission Process ScheduleHemantÎncă nu există evaluări

- Course Update: Flow ChartsDocument20 paginiCourse Update: Flow ChartsHemantÎncă nu există evaluări

- Why I Killed The Mahatma - Understanding Godse's Defence PDFDocument198 paginiWhy I Killed The Mahatma - Understanding Godse's Defence PDFHemant100% (5)

- From The Restoration To The Augustan AgeDocument17 paginiFrom The Restoration To The Augustan AgeNicolò PiccioniÎncă nu există evaluări

- DirectDocument6 paginiDirectRoshaan AhmadÎncă nu există evaluări

- Little Red Riding HoodDocument3 paginiLittle Red Riding HoodcitraÎncă nu există evaluări

- A Syntactic Analysis of A Pakistani Poem in EnglishDocument19 paginiA Syntactic Analysis of A Pakistani Poem in EnglishSarang KhanÎncă nu există evaluări

- Matt Stuart: Alles, Was Das Leben Bieten KannDocument2 paginiMatt Stuart: Alles, Was Das Leben Bieten KannCilouÎncă nu există evaluări

- Teoria CríticaDocument121 paginiTeoria CríticaRenata CarvalhoÎncă nu există evaluări

- English Poetry and Drama Terms For ShakespeareDocument22 paginiEnglish Poetry and Drama Terms For ShakespeareChuii MuiiÎncă nu există evaluări

- Directing Great Television Sample PDFDocument34 paginiDirecting Great Television Sample PDFMichael Wiese Productions100% (3)

- Tolkien's Catholic Imagination LectureDocument37 paginiTolkien's Catholic Imagination Lectureblackpetal1Încă nu există evaluări

- Syed Shamsul Haque 2012 6Document21 paginiSyed Shamsul Haque 2012 6shahadat08Încă nu există evaluări

- F - Peng - Pendidikan Jasmani Olahraga Dan Kesehatan - XII IPS 1Document30 paginiF - Peng - Pendidikan Jasmani Olahraga Dan Kesehatan - XII IPS 1agustianÎncă nu există evaluări

- Rasmussen Experiencing ArchitectureDocument50 paginiRasmussen Experiencing ArchitectureEma AbreuÎncă nu există evaluări

- Ndebele Paintings - The Alain Guisson Legacy: South African Contemporary ArtDocument27 paginiNdebele Paintings - The Alain Guisson Legacy: South African Contemporary ArtIvory PlatypusÎncă nu există evaluări

- Decodable Book Directions-4 1 1 1 - 3-6Document3 paginiDecodable Book Directions-4 1 1 1 - 3-6api-479279934Încă nu există evaluări

- Honors & Awards: 66th National Film AwardsDocument4 paginiHonors & Awards: 66th National Film AwardsVISHAL JALANÎncă nu există evaluări

- Developmental Milestone of Preschool AgeDocument3 paginiDevelopmental Milestone of Preschool AgeJessa Mae BacuganÎncă nu există evaluări

- Gilead: Zirna Sikul Leh Isua ZuiDocument4 paginiGilead: Zirna Sikul Leh Isua ZuiCK LalropuiaÎncă nu există evaluări

- The T Programming Language: A Dialect of LispDocument1 paginăThe T Programming Language: A Dialect of LispPep DizÎncă nu există evaluări

- Literature Review Outline HarvardDocument5 paginiLiterature Review Outline Harvardaflrpjser100% (1)

- The Scum Villain's Self-Saving System - Ren Zha Fanpai Zijiu Xitong Vol. 1 PDFDocument302 paginiThe Scum Villain's Self-Saving System - Ren Zha Fanpai Zijiu Xitong Vol. 1 PDFRameesha Saddiqa100% (3)

- SKF Shortlisted List 2022 BatchDocument6 paginiSKF Shortlisted List 2022 Batchsai ChaitanyaÎncă nu există evaluări

- What Do You Know of Jerome K. Jerome and His Place in English Literature?Document2 paginiWhat Do You Know of Jerome K. Jerome and His Place in English Literature?Мария ШутакÎncă nu există evaluări

- English Notes Keeping QuietDocument5 paginiEnglish Notes Keeping QuietSanjanaÎncă nu există evaluări

- Clever Home Unite Distress Marriage Early: Worksheet One ScanningDocument3 paginiClever Home Unite Distress Marriage Early: Worksheet One ScanningDamary Bueno100% (1)

- Rizal Assignment Noli and El FiliDocument3 paginiRizal Assignment Noli and El FiliKhevin AlvaradoÎncă nu există evaluări

- MIDTERM EXAMINATION IN GE-9 RizalDocument5 paginiMIDTERM EXAMINATION IN GE-9 Rizalcesar pabilonaÎncă nu există evaluări

- Wassup BruhhhDocument2 paginiWassup BruhhhYuno UmeharaÎncă nu există evaluări

- Blood Relation Sheet 2Document3 paginiBlood Relation Sheet 2Yogi JiÎncă nu există evaluări

- Exercise - Narrative Text (Genre Analyzing)Document2 paginiExercise - Narrative Text (Genre Analyzing)solikin sudibyoÎncă nu există evaluări

- End Rhyme and Internal Rhyme WorksheetDocument1 paginăEnd Rhyme and Internal Rhyme WorksheetJesus_loves_Lara67% (3)