Documente Academic

Documente Profesional

Documente Cultură

Sika - 42 Grout

Încărcat de

Bill MurrayDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Sika - 42 Grout

Încărcat de

Bill MurrayDrepturi de autor:

Formate disponibile

Product Data Sheet

Edition 06.2010/v1

CSC Master FormatTM 03 63 00

Sikadur® 42 Grout Pak Multi-Flo

Sikadur® 42 Grout Pak Multi-Flo

Pre-Proportioned, Epoxy Base Plate, Grouting System

Description Sikadur® 42 Grout-Pak Multi-Flo, is a three-component, solvent-free, moisture-insensitive,

epoxy grouting system to seat base plates.

Where to Use Seat base plates for light and heavy machinery.

Advantages ■ Ready-to-mix, pre-proportioned kits.

■ Moisture insensitive.

Construction

■ Corrosion and impact resistant.

■ Stress and chemical resistant.

■ High compressive strength.

■ High vibration resistance.

■ The versatility of Sikadur® 42 Grout Pak Multi-Flo allows for an aggregate resin ratio of:

6:1 for a pourable consistency, 5:1 for a flowable consistency.

■ Ministry of Transport Québec acceptance.

Technical Data

Packaging

Component A 13.49 kg (29.7 lb) 6.75 kg (14.9 lb)

Component B 4.34 kg (9.6 lb) 2.17 kg (4.8 lb)

Component C 4 x 26.75 kg (59 lb) bag 2 x 26.75 kg (59 lb) bag

Yield 6:1 - 56.6 L per kit (2 ft3) 6:1 - 28.3 L per kit (1 ft3)

Colour Concrete Grey

Shelf Life 2 years in original unopened packaging. Store dry at 5 to 32°C

(41 to 89°F). Condition product at 20 to 30°C (68 to 86°F) before using.

Mix Ratio Fluid consistency depends on the aggregate to resin ratio. If a greater flow

is required for the larger unit of 56.6 L (2 ft3) yield, reduce aggregate by

approx. half to two thirds of one of the four bags. Therefore: Use 3.3 to

3.5 bags of component C for a 5:1 - flowable consistency. Use 4 bags of

component C for a 6:1 - pourable consistency.

If a greater flow is required for the smaller unit of 28.3 L (1 ft3) yield, reduce

aggregate by approx. one third to one quarter of one of the two bags.

Therefore: Use 1.65 to 1.75 bags of component C for a 5:1 - flowable

consistency. Use 2 bags of component C for a 6:1 - pourable consistency.

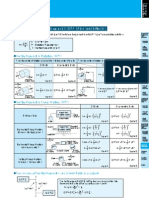

Properties at 23°C (73°F) and 50% R.H.

Compressive Strength ASTM C579, MPa (psi)

Ratio 6:1 5:1

5°C (41°F)* 23°C (73°F)* 38°C 5°C (41°F)* 23°C (73°F)* 38°C

(100°F)* (100°F)*

16 hrs - - - - 31 (4498) 43 (6239)

1 day - 37 (5368) 63 (9141) 3 (435) 41 (5949) 51 (7400)

3 days - - - 45 (6529) 71 (10 302) 64 (9286)

7 days 70 (10 157) 95 (13 784) 90 (13 059) 88 (12 768) 90 (13 059) 77 (11 172)

28 days 96 (13 929) 103 (14 945) 96 (13 929) 106 (15 380) 105 (15 235) 85 (12 333)

*Product cured and tested at temperatures indicated

Ratio 6:1 5:1

Tensile Strength ASTM C307, MPa (psi)

14 days 12.5 (1813) 12 (1741)

Flexural Strength ASTM C580, MPa (psi)

14 days 28 (4062) 31.5 (4570)

Tangent Modulus of Elasticity in Bending ASTM C580, GPa (psi)

14 days 14.7 (21.3 x 105) 12.9 (18.7 x 105)

Coefficient of Thermal Expansion 3.29 x 10-5/°C 3.6 x 10-5 /°C

ASTM C531 (1.83 x 10-5/°F) (2.0 x 10-5/°F)

Bond Strength ASTM C882 Modified, MPa (psi)

14 days (to concrete) 28 (4062) 20 (2902)

Water Absorption ASTM C413

7 days (2 hrs boil) 0.08% 0.05%

Sikadur® 42 Grout Pak Multi-Flo

3-435

03 63 00 epoxy Grouting

How to Use

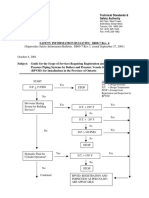

Surface Note: For optimum results when grouting in critical items of equipment, it is recommended that

Preparation the surface preparation requirements of the latest edition of Chapter 5, API Recommended

Practice 686 be followed. This document is the “Recommended Practices for Machinery

Installation and Installation Design” published by the American Petroleum Institute. Surface

and base plate contact area must be clean and sound. It may be dry or damp, but free of

standing water. Remove dust, laitance, oils, grease, curing compounds, impregnations,

waxes, foreign particles, coatings, and disintegrated materials by mechanical means, i. e.

chipping with a chisel, sandblasting. Sandblast metal base plates to a commercial white finish

(SP-10) for maximum adhesion. Apply grout immediately to prevent re-oxidizing.

Forming - The consistency of the epoxy grout system requires the use of forms to contain the

material around the base plates. In order to prevent leakage or seepage, all forms must be

sealed. Apply polyethylene film or wax to all forms to prevent adhesion of the grout. Prepare

form work to maintain more than 100 mm (4 in) liquid head to facilitate placement. A grout

box equipped with an inclined trough attached to the form will enhance the grout’s flowability

and minimize air encapsulation.

Mixing Mix the entire contents of components A and B in the component A pail for 3 minutes with

a paddle attached to a low speed drill (200 - 250 rpm). Place the mixed epoxy into an

appropriate mixer. Slowly add the contents of component C depending on flow required and

mix until uniformly blended (approx. 5 minutes). When mixing the first batch of the epoxy

Construction

adhesive grout system in a clean and dry mixer, withhold 10 kg (22 lb) of component C to

charge the mixer. Mixed grout should be kept agitated just prior to placement.

Application Pour the mixed grout into the prepared forms from one or two sides only, to eliminate air

entrapment. Maintain the liquid head to ensure intimate contact to the base plate. Place

sufficient epoxy grout in the forms to rise slightly above the underside [3 mm (1/8 in)] of the

base plate. The minimum void depth beneath the base should be 25 mm (1 in). Where the

void beneath the base plate is greater than 150 mm (6 in), place the epoxy grout in successive

150 mm (6 in) lifts or less, once the preceding lift has cooled.

Clean Up Sweep into appropriate containers. Dispose of in accordance with applicable local regulations.

Uncured material can be removed with Sika Equipment Cleaner. Cured material can only be

removed mechanically.

Limitations ■ Minimum substrate temperature: 16°C (61°F).

■ Grouting material must be stored in an area with an ambient temperature between 20 and

30°C (68 and 86°F) for a minimum of 48 hours before using.

■ Do not thin with solvents. Solvents will prevent proper cure.

■ Material is a vapour barrier after cure.

■ Minimum grout thickness: 25 mm (1 in).

■ Maximum grout thickness: 150 mm (6 in) per lift.

■ Component C must be kept dry.

■ For bolt grouting applications contact Sika Canada Technical Service.

■ For proper seating, allow grout to rise above the bottom [3 mm (1/8 in)] of the base plate.

■ Do not batch. Mix complete units only.

■ Cold ambient, substrate or material temperatures will inhibit the curing and flow

characteristics of Sikadur® 42 Grout Pak.

■ Do not subject cured epoxy grout to sudden temperature changes especially during early

curing stages.

■ Contact Sika Canada Technical Service for control joint spacing on large base plate

grouting projects.

Caution Component A - Irritant - Prolonged contact to skin may cause irritation. Avoid eye contact.

Component B - Irritant - Contact with skin may cause severe burns. Avoid eye contact.

Component C - Contains silica. Avoid breathing dust. Product is a strong sensitizer. Use

of safety goggles and chemical resistant gloves recommended. Avoid breathing material.

Use adequate ventilation. Use of a NIOSH/MSHA organic vapour respirator recommended.

Consult product label for additional information.

First Aid In case of skin contact, wash with soap and water. For eye contact, flush immediately

with plenty of water for at least 15 minutes. Contact a physician. For respiratory problems,

transport victim to fresh air. Remove contaminated clothing and wash before re-use.

For more information, consult Sika Material Safety Data Sheet.

KEEP OUT OF REACH OF CHILDREN

FOR INDUSTRIAL USE ONLY

The information, and in particular, the recommendations relating to the application and end-use of Sika products, are given in

good faith based on Sika’s current knowledge and experience of the products when properly stored, handled and applied under

normal conditions, within their shelf life. In practice, the differences in materials, substrates and actual site conditions are such that

no warranty in respect of merchantability or of fitness for a particular purpose, nor any liability arising out of any legal relationship

whatsoever, can be inferred either from this information, or from any recommendations, or from any other advice offered. The

proprietary rights of third parties must be observed. All orders are accepted subject to our current terms of sale and delivery. Users

should always refer to the most recent issue of the Product Data Sheet for the product concerned, copies of which will be supplied

on request or can be accessed in the Internet under www.sika.ca.

Sika Canada Inc. Ontario Alberta 1-800-933-SIKA

601 Delmar Avenue 6915 Davand Drive 18131–114th Avenue N.W. www.sika.ca

Pointe-Claire, QC H9R 4A9 Mississauga, ON L5T 1L5 Edmonton, AB T5S 1T8

Tel.: 514-697-2610 Tel.: 905-795-3177 Tel.: 780-486-6111 An ISO 9001 certified company

Fax: 514-697-3087 Fax: 905-795-3192 Fax: 780-483-1580 Pointe-Claire : ISO 14001 certified EMS

Sikadur® 42 Grout Pak Multi-Flo

3-435

03 63 00 epoxy Grouting

S-ar putea să vă placă și

- Sikadur®-42 Grout Pak Multi-Flo: Pre-Proportioned, Epoxy Base Plate, Grouting SystemDocument2 paginiSikadur®-42 Grout Pak Multi-Flo: Pre-Proportioned, Epoxy Base Plate, Grouting SystemnedÎncă nu există evaluări

- Sikatop 123 Plus: Polymer-Modified, Cementitious, Non-Sag Mortar, Plus Migrating Corrosion InhibitorDocument2 paginiSikatop 123 Plus: Polymer-Modified, Cementitious, Non-Sag Mortar, Plus Migrating Corrosion InhibitorMarkÎncă nu există evaluări

- Sikadur 42 Gorut Palk LE - CaDocument2 paginiSikadur 42 Gorut Palk LE - Carobert benavidesÎncă nu există evaluări

- Sikadur®-42 Grout Pak LE: Pre-Proportioned, Precision Epoxy Grouting SystemDocument2 paginiSikadur®-42 Grout Pak LE: Pre-Proportioned, Precision Epoxy Grouting Systemraunak upadhyayaÎncă nu există evaluări

- Sika® M-Bed® Standard: Non-Shrink, Gassing, Cementitious GroutDocument2 paginiSika® M-Bed® Standard: Non-Shrink, Gassing, Cementitious Groutraunak upadhyayaÎncă nu există evaluări

- SikaAnchorFix3001 PdsDocument4 paginiSikaAnchorFix3001 PdssaulolmÎncă nu există evaluări

- Sikadurcrackfix CADocument2 paginiSikadurcrackfix CAlaust69Încă nu există evaluări

- Sikacrete08SCC PdsDocument2 paginiSikacrete08SCC PdsPatrick PlamondonÎncă nu există evaluări

- Data Sheet Mortero (Grout) Epóxico Chockfast Red PDFDocument2 paginiData Sheet Mortero (Grout) Epóxico Chockfast Red PDFDaniel Puello RodeloÎncă nu există evaluări

- Sikadur®-31 SBA Normal SetDocument2 paginiSikadur®-31 SBA Normal Setkvemanak9733Încă nu există evaluări

- Dri-Pak Precast GroutDocument2 paginiDri-Pak Precast GroutTim_CÎncă nu există evaluări

- Sika - AG GroutDocument4 paginiSika - AG GroutBill MurrayÎncă nu există evaluări

- Technical Data: Plastic Steel Putty (A)Document4 paginiTechnical Data: Plastic Steel Putty (A)francisÎncă nu există evaluări

- Characterisation of Dissolving Pulp Using Designed NIR and NMRDocument17 paginiCharacterisation of Dissolving Pulp Using Designed NIR and NMRJaqueline SilvaÎncă nu există evaluări

- SikaGrout 112 - Pds en PDFDocument2 paginiSikaGrout 112 - Pds en PDFabegaa aberaÎncă nu există evaluări

- SikaGrout212HP Pds PDFDocument3 paginiSikaGrout212HP Pds PDFraunak upadhyayaÎncă nu există evaluări

- SikagroutDocument4 paginiSikagroutpatricia ann belarteÎncă nu există evaluări

- Pds CPD Sikadur35HiModLV UsDocument2 paginiPds CPD Sikadur35HiModLV UsBudhi KurniawanÎncă nu există evaluări

- Sikadur - 23 - Lo-Modgel-Pick Proof Epoxy SealantDocument4 paginiSikadur - 23 - Lo-Modgel-Pick Proof Epoxy SealantDavid RiceÎncă nu există evaluări

- Interprime 820Document4 paginiInterprime 820Trịnh Minh KhoaÎncă nu există evaluări

- Datasheet Chockfast RedDocument2 paginiDatasheet Chockfast RedAlexander0% (1)

- Rheological Study On Mixing Temperatures For Modified BindersDocument10 paginiRheological Study On Mixing Temperatures For Modified BindersSri RamyaÎncă nu există evaluări

- Krystol Repair Grout™: Technical Data SheetDocument2 paginiKrystol Repair Grout™: Technical Data SheetYatsen Jepthe Maldonado SotoÎncă nu există evaluări

- Fundamentals of Chemical Engineering Thermodynamics 1st Edition Dahm Solutions Manual DownloadDocument75 paginiFundamentals of Chemical Engineering Thermodynamics 1st Edition Dahm Solutions Manual DownloadEarl Blevins100% (26)

- Sika Repair Grout 223Document2 paginiSika Repair Grout 223Bill MurrayÎncă nu există evaluări

- Duralprep A.C.: Bonding Agent and Anti-Corrosion CoatingDocument2 paginiDuralprep A.C.: Bonding Agent and Anti-Corrosion Coatingaandueza_1Încă nu există evaluări

- Pds CPD Sikadur CrackFix UsDocument2 paginiPds CPD Sikadur CrackFix UsReab SimanthÎncă nu există evaluări

- Final Project PPT (MB)Document72 paginiFinal Project PPT (MB)Aashka BhattÎncă nu există evaluări

- Use of Brick Dust, Fly Ash and Cement Kiln Dust As A Replacement of Fine Aggregate in Self Compacting ConcreteDocument7 paginiUse of Brick Dust, Fly Ash and Cement Kiln Dust As A Replacement of Fine Aggregate in Self Compacting ConcretehakÎncă nu există evaluări

- Tnemec (Data Sheet) 46h-413Document2 paginiTnemec (Data Sheet) 46h-413PubcrawlÎncă nu există evaluări

- ECE 4215 Pavement Analysis Design Worked ExamplesDocument8 paginiECE 4215 Pavement Analysis Design Worked ExamplesdantezÎncă nu există evaluări

- Tds CPD SikaGrout312 UsDocument2 paginiTds CPD SikaGrout312 Usikusokos6594100% (3)

- CA9311 Desothane HS Advanced Performance CoatingsDocument7 paginiCA9311 Desothane HS Advanced Performance CoatingsAbhinandan JainÎncă nu există evaluări

- MasterFlow - 410 v1Document2 paginiMasterFlow - 410 v1Anonymous XVEucVMsEÎncă nu există evaluări

- Sikatoparmatec110epocem Pds PDFDocument2 paginiSikatoparmatec110epocem Pds PDFRio CahyantoÎncă nu există evaluări

- Sikaflex®-2c SL: Two-Component, Self-Levelling, Polyurethane Elastomeric SealantDocument3 paginiSikaflex®-2c SL: Two-Component, Self-Levelling, Polyurethane Elastomeric SealantRay GongÎncă nu există evaluări

- SikaAnchorFix2Arctic PdsDocument4 paginiSikaAnchorFix2Arctic PdsDragoș SturzoiuÎncă nu există evaluări

- Quakebond J333Sr: The Infrastructure InnovatorsDocument2 paginiQuakebond J333Sr: The Infrastructure Innovatorskhoirul ramadhanÎncă nu există evaluări

- Experiment No. 11 Fabricating Concrete Specimen For Tests: Referenced StandardDocument5 paginiExperiment No. 11 Fabricating Concrete Specimen For Tests: Referenced StandardRenÎncă nu există evaluări

- Sikafloor®-161: Product Data SheetDocument5 paginiSikafloor®-161: Product Data SheetashayshaÎncă nu există evaluări

- Experiment No. 7 Fabricating Concrete Specimen For TestsDocument8 paginiExperiment No. 7 Fabricating Concrete Specimen For TestsMeriann May Sacayan DivinagraciaÎncă nu există evaluări

- Masterflow 870 TdsDocument3 paginiMasterflow 870 TdsemilÎncă nu există evaluări

- Discussions, Conclusion and Recommendations 5.1. Discussions and ConclusionDocument3 paginiDiscussions, Conclusion and Recommendations 5.1. Discussions and ConclusionWai Yann ZawÎncă nu există evaluări

- HTR Grout: Product DescriptionDocument2 paginiHTR Grout: Product Descriptionmcdermott22Încă nu există evaluări

- Product: Chocking & Anchor Bolt Setting CompoundDocument2 paginiProduct: Chocking & Anchor Bolt Setting CompoundFajri AnnamlaÎncă nu există evaluări

- Sikadur 52: Advanced, Very-Low-Viscosity, Moisture-Tolerant Epoxy Injection AdhesiveDocument2 paginiSikadur 52: Advanced, Very-Low-Viscosity, Moisture-Tolerant Epoxy Injection Adhesivehendri sukrisnoÎncă nu există evaluări

- NS Grout PDFDocument2 paginiNS Grout PDFRenjithÎncă nu există evaluări

- Shrinkage TestDocument12 paginiShrinkage TestAlsonChinÎncă nu există evaluări

- Sikadur 52Document2 paginiSikadur 52JessiÎncă nu există evaluări

- Crystic Ve671Document2 paginiCrystic Ve671M Taufik WijayaÎncă nu există evaluări

- Technical Data: Plastic Steel 5-Minute Putty (SF)Document4 paginiTechnical Data: Plastic Steel 5-Minute Putty (SF)Hoàng DũngÎncă nu există evaluări

- 256 UkDocument4 pagini256 UkBùi Văn TấnÎncă nu există evaluări

- 37-Materials Research-Replacement of Elastic Recovery (AASHTO T301) and Force Ductility (AASHTO 300) Tests by DSR-Based TestsDocument56 pagini37-Materials Research-Replacement of Elastic Recovery (AASHTO T301) and Force Ductility (AASHTO 300) Tests by DSR-Based TestsMohammed BoucherbaÎncă nu există evaluări

- Mechanical Properties of Gridcore Panels (FPL Spaceboard) Made From Compositions of Recycled Corrugated, Newsprint and KenafDocument8 paginiMechanical Properties of Gridcore Panels (FPL Spaceboard) Made From Compositions of Recycled Corrugated, Newsprint and Kenafgemesh83Încă nu există evaluări

- Liquid Epoxy Coating (3M)Document5 paginiLiquid Epoxy Coating (3M)Thamaraikani ManiÎncă nu există evaluări

- Perma-Glaze Series G435: Product ProfileDocument2 paginiPerma-Glaze Series G435: Product ProfileR. Raziel Vergara Z.Încă nu există evaluări

- 08 - Analisis Del Lugar Geometrico de La RaicesDocument1 pagină08 - Analisis Del Lugar Geometrico de La RaicesNorbert HernándezÎncă nu există evaluări

- SikaGrout 328Document4 paginiSikaGrout 328Jun ZhuÎncă nu există evaluări

- GRP and Buildings: A Design Guide for Architects and EngineersDe la EverandGRP and Buildings: A Design Guide for Architects and EngineersÎncă nu există evaluări

- Basic Fracture Mechanics: Including an Introduction to FatigueDe la EverandBasic Fracture Mechanics: Including an Introduction to FatigueÎncă nu există evaluări

- Use of Atlantium Uv Technology As Means of Control For Bio Fouling Ais Invasive Mussels - Whitepaperpdf.renderDocument12 paginiUse of Atlantium Uv Technology As Means of Control For Bio Fouling Ais Invasive Mussels - Whitepaperpdf.renderBill MurrayÎncă nu există evaluări

- The Abcs of Small Hydro Upgrade and Automation: Industry ApplicationDocument8 paginiThe Abcs of Small Hydro Upgrade and Automation: Industry ApplicationAde YD SaputraÎncă nu există evaluări

- Improvement of Efficiency Prediction ForDocument11 paginiImprovement of Efficiency Prediction ForMobile LegendÎncă nu există evaluări

- Pedoman Perilaku PLNDocument11 paginiPedoman Perilaku PLNAbdul AzimÎncă nu există evaluări

- USA Customs Chapter 98Document117 paginiUSA Customs Chapter 98jpcoteÎncă nu există evaluări

- CompleteMG1 1998rev3Document596 paginiCompleteMG1 1998rev3Bill MurrayÎncă nu există evaluări

- Kapl Turb Inc93Document16 paginiKapl Turb Inc93Bill MurrayÎncă nu există evaluări

- Chapter 9Document19 paginiChapter 9Bill MurrayÎncă nu există evaluări

- MOD-025 Standard Mapping 061511Document7 paginiMOD-025 Standard Mapping 061511Bill MurrayÎncă nu există evaluări

- NERC - MOD-025-1 - Verification of Generator Gross and Net Reactive Power CapabilityDocument3 paginiNERC - MOD-025-1 - Verification of Generator Gross and Net Reactive Power CapabilityBill MurrayÎncă nu există evaluări

- Contents and Forward MG 1Document53 paginiContents and Forward MG 1aderezoÎncă nu există evaluări

- Nema MG1Document76 paginiNema MG1Rajmohan100% (4)

- Pa Stand Reliability Standards MOD-025-2Document20 paginiPa Stand Reliability Standards MOD-025-2abdulkadir aliÎncă nu există evaluări

- Ip PDFDocument1 paginăIp PDFecruz_yhwhÎncă nu există evaluări

- Ansi or Nema Mg1-1998Document596 paginiAnsi or Nema Mg1-1998cuervohijoguachoÎncă nu există evaluări

- Contents and Forward MG 1Document53 paginiContents and Forward MG 1aderezoÎncă nu există evaluări

- Pa - Stand - Reliability Standards - MOD-025-RFC-01Document14 paginiPa - Stand - Reliability Standards - MOD-025-RFC-01Bill MurrayÎncă nu există evaluări

- Implementation Plan: Project 2007-09 Generator VerificationDocument3 paginiImplementation Plan: Project 2007-09 Generator VerificationBill MurrayÎncă nu există evaluări

- Forging MillitaryDocument39 paginiForging MillitaryKatie RamirezÎncă nu există evaluări

- WEG Synchronous Motors Pedestal Type Brushless 240E Manual EnglishDocument72 paginiWEG Synchronous Motors Pedestal Type Brushless 240E Manual EnglishBill MurrayÎncă nu există evaluări

- Safety Excellence: Supplier Code of ConductDocument10 paginiSafety Excellence: Supplier Code of ConductBill MurrayÎncă nu există evaluări

- SSPC ChartDocument2 paginiSSPC ChartajuhaseenÎncă nu există evaluări

- Mat - No. 1.1181, DIN Ck35, AISI 1035: Designation by StandardsDocument2 paginiMat - No. 1.1181, DIN Ck35, AISI 1035: Designation by StandardsBill MurrayÎncă nu există evaluări

- Roister OLD Fashioned: Buy The BookDocument1 paginăRoister OLD Fashioned: Buy The BookBill MurrayÎncă nu există evaluări

- Supersedes Safety Information Bulletin: SB00-7 Rev.3, Issued September 27, 2001Document3 paginiSupersedes Safety Information Bulletin: SB00-7 Rev.3, Issued September 27, 2001Bill MurrayÎncă nu există evaluări

- Greaseless Bushing PDFDocument122 paginiGreaseless Bushing PDFthavisiÎncă nu există evaluări

- GD2 CalculationDocument1 paginăGD2 CalculationbahramhooÎncă nu există evaluări

- Greaseless Bushing PDFDocument122 paginiGreaseless Bushing PDFthavisiÎncă nu există evaluări

- 30 - 1979 - Factors Influencing Power LossDocument8 pagini30 - 1979 - Factors Influencing Power LossBill MurrayÎncă nu există evaluări

- Starbucks Progressive Web App: Case StudyDocument2 paginiStarbucks Progressive Web App: Case StudyYesid SuárezÎncă nu există evaluări

- El TontoDocument92 paginiEl TontoRobertÎncă nu există evaluări

- ERBS UPDATE John Doe ProceedingDocument3 paginiERBS UPDATE John Doe ProceedingtpeppermanÎncă nu există evaluări

- A Sample Script For Public SpeakingDocument2 paginiA Sample Script For Public Speakingalmasodi100% (2)

- Beer Lambert'S Law: Dr. Swastika Das Professor of ChemistryDocument19 paginiBeer Lambert'S Law: Dr. Swastika Das Professor of ChemistryShabanaÎncă nu există evaluări

- Written Report in Instructional PlanningDocument6 paginiWritten Report in Instructional PlanningRose Aura HerialesÎncă nu există evaluări

- Saes T 883Document13 paginiSaes T 883luke luckyÎncă nu există evaluări

- Overview of Incorporation in CambodiaDocument3 paginiOverview of Incorporation in CambodiaDavid MÎncă nu există evaluări

- A Quantitative Method For Evaluation of CAT Tools Based On User Preferences. Anna ZaretskayaDocument5 paginiA Quantitative Method For Evaluation of CAT Tools Based On User Preferences. Anna ZaretskayaplanetalinguaÎncă nu există evaluări

- New - BMP3005 - ABF - Assessment Brief - FDocument5 paginiNew - BMP3005 - ABF - Assessment Brief - Fmilka traykovÎncă nu există evaluări

- Acronyms and AbbreviationsDocument875 paginiAcronyms and AbbreviationsLacky KrishnanÎncă nu există evaluări

- Name: Mercado, Kath DATE: 01/15 Score: Activity Answer The Following Items On A Separate Sheet of Paper. Show Your Computations. (4 Items X 5 Points)Document2 paginiName: Mercado, Kath DATE: 01/15 Score: Activity Answer The Following Items On A Separate Sheet of Paper. Show Your Computations. (4 Items X 5 Points)Kathleen MercadoÎncă nu există evaluări

- Image Hosting SitesDocument16 paginiImage Hosting SitesstudentÎncă nu există evaluări

- Silapathikaram 3Document37 paginiSilapathikaram 3gavinilaaÎncă nu există evaluări

- Grade 10 Module 1 Performing Roughing in Activities For Communication and DistributDocument26 paginiGrade 10 Module 1 Performing Roughing in Activities For Communication and DistributNelshane JohnÎncă nu există evaluări

- ФО Англ.яз 3клDocument135 paginiФО Англ.яз 3клБакытгуль МендалиеваÎncă nu există evaluări

- MSDS Charcoal Powder PDFDocument3 paginiMSDS Charcoal Powder PDFSelina VdexÎncă nu există evaluări

- Tso C197Document6 paginiTso C197rdpereirÎncă nu există evaluări

- 120 Câu Tìm Từ Đồng Nghĩa-Trái Nghĩa-Dap AnDocument9 pagini120 Câu Tìm Từ Đồng Nghĩa-Trái Nghĩa-Dap AnAlex TranÎncă nu există evaluări

- Capital Structure and Leverage: Multiple Choice: ConceptualDocument53 paginiCapital Structure and Leverage: Multiple Choice: ConceptualArya StarkÎncă nu există evaluări

- Bankers ChoiceDocument18 paginiBankers ChoiceArchana ThirunagariÎncă nu există evaluări

- Pell (2017) - Trends in Real-Time Traffic SimulationDocument8 paginiPell (2017) - Trends in Real-Time Traffic SimulationJorge OchoaÎncă nu există evaluări

- TOR AND SCOPING Presentation SlidesDocument23 paginiTOR AND SCOPING Presentation SlidesSRESTAA BHATTARAIÎncă nu există evaluări

- Acc 106 Account ReceivablesDocument40 paginiAcc 106 Account ReceivablesAmirah NordinÎncă nu există evaluări

- USA Nozzle 01Document2 paginiUSA Nozzle 01Justin MercadoÎncă nu există evaluări

- Presentation No. 3 - Songs and ChantsDocument44 paginiPresentation No. 3 - Songs and Chantsandie hinchÎncă nu există evaluări

- CCNP SWITCH 300-115 - Outline of The Official Study GuideDocument31 paginiCCNP SWITCH 300-115 - Outline of The Official Study GuidehammiesinkÎncă nu există evaluări

- 24 Inch MonitorDocument10 pagini24 Inch MonitorMihir SaveÎncă nu există evaluări

- Basler Electric TCCDocument7 paginiBasler Electric TCCGalih Trisna NugrahaÎncă nu există evaluări

- Ch04Exp PDFDocument17 paginiCh04Exp PDFConstantin PopescuÎncă nu există evaluări