Documente Academic

Documente Profesional

Documente Cultură

6 X 28 Extra-Flow Product Data Sheet: Membrane Characteristics

Încărcat de

Donatas BertasiusDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

6 X 28 Extra-Flow Product Data Sheet: Membrane Characteristics

Încărcat de

Donatas BertasiusDrepturi de autor:

Formate disponibile

6 x 28 EXTRA-FLOW PRODUCT DATA SHEET

Membrane Characteristics

Cartridge Configuration Extra-Flow with center baffle

3

Liquid Flow Guidelines 1-11 m /hr (5-50 gpm)

Membrane Type X50 Fiber X40 Fiber

Recommended for CO2 Recommended for O2

removal from liquid and other removal from liquid and other

gas transfer applications gas transfer applications

Membrane/Potting Material Polypropylene/Epoxy

Typical Membrane Surface Area 2

42 m (452 ft )

2

764.5 mm

(30.10 in)

Priming Volume (approximate) X50 Fiber X40 Fiber

Shellside 6.7 liters (1.8 gal) 6.7 liters (1.8 gal)

Lumenside 2.6 liters (0.7 gal) 2.3 liters (0.6 gal)

Pressure Guidelines

1009.4 mm

(39.74 in)

168.3 mm

(6.63 in) X50 Fiber X40 Fiber

Maximum Shellside LIQUID 5-25° C, 7.2 bar 5-25° C 8.3 bar

Working Temperature/Pressure (41-77° F, 105 psig) (41-77° F, 105 psig)

60° C, 2.1 bar 70° C, 2.1 bar

(140° F, 30 psig) (158° F, 30 psig)

If no vacuum is used, 1.05 bar (15 psig) can be added to pressures above.

Maximum Applied Gas Pressure 4.1 bar (60 psig)

Max applied gas pressure is for integrity testing at ambient temperatures. Normal operating pressures are typically

lower.

See Operating Guide for complete temp/pressure limits for housings and membrane. Note: Liquid pressure should

always exceed gas pressure.

Housing Options and Characteristics

Material ABS

Flange Connections

Shellside 2 inch class 150 raised face flange per ANSI B16.5

(Wetted surface) 50A at 10K flat face flange per JIS B2238

Lumenside 1 inch class 150 raised face flange per ANSI B16.5

25A at 10K flat face flange per JIS B2238

Weight

Dry 10.4 kg. (23 lbs.)

Liquid full (shellside) 17.1 kg. (37.7 lbs.)

All dimensions are nominal values

Shipping weight without

16.8 kg. (37 lbs.)

mounting kit

Shipping weight with

19.1 kg. (42 lbs.)

mounting kit

Regulatory

Meets RoHS threshold limits. Complies with the PED 97/23/EC and is manufactured with sound engineering practice.

CFR Title 21 compliant with non alcoholic liquids at ambient temperatures.

6 x 28 EXTRA-FLOW PRODUCT DATA SHEET

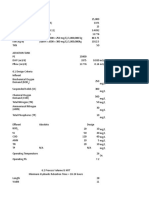

Water Flow Rate (gpm) Water Flow Rate (gpm)

0 10 20 30 40 50 0 10 20 30 40 50

100

% Dissolved Oxygen Removal

100

Free CO2 Removal %

2 contactors

90 1 contactor 90

2 contactors

1 contactor

80 80

70 70

60 60

50 50

0 2.3 4.5 6.8 9.1 11.4 0 2.3 4.5 6.8 9.1 11.4

3 3

Water Flow Rate (m /hr) Water Flow Rate (m /hr)

Water Flow Rate (gpm)

Cartridge Specifications

0 10 20 30 40 50 Characteristics Test Conditions Specifications

20 1.37

Shellside water flow:

Pressure Drop (psi)

Performance

Pressure Drop (bar)

27 gpm, 20°C (68°F) 88%

15 1.03 02 Removal Lumenside N2 Flow: 1 scfm minimum

10 0.67 Pressure Drop, Shellside water flow: 5.26 psi

psi maximum 27 gpm, 20°C (68°F) maximum

5 0.34

Curves represent nominal values. Characteristics may change under different

0 0 operating conditions.

0 2.3 4.5 6.8 9.1 11.4

Test condition O2 Removal with X40 membrane at 20ºC: N2 Combo mode, vacuum

75 mm Hg, N2 sweep: 0.05 scfm.

3

Water Flow Rate (m /hr)

Test condition CO2 Removal with X50 membrane at 20ºC: Air Combo mode,

air sweep: 0.25 G/L, vacuum: 150 torr

This product is to be used only by persons familiar with its use. It must be maintained within the stated limitations. All sales are subject to Seller’s terms and conditions.

Purchaser assumes all responsibility for the suitability and fitness for use as well as for the protection of the environment and for health and safety involving this product.

Seller reserves the right to modify this document without prior notice. Check with your representative to verify the latest update. To the best of our knowledge, the information

contained herein is accurate. However, neither Seller nor any of its affiliates assumes any liability whatsoever for the accuracy or completeness of the information contained

herein. Determination of the suitability of any material and infringement of any third party rights, including patent, trademark, or copyright rights, are the sole responsibility of

the user. Users of any substance should satisfy themselves by independent investigation that the material can be used safely. We may have described certain hazards, but

we cannot guarantee that these are the only hazards that exist. Nothing herein shall be construed as a recommendation or license to use any information that conflicts with

any patent, trademark or copyright of Seller or others. Please read our Operating Manuals carefully before installing and using these modules.

THE INFORMATION CONTAINED HEREIN AND SELLER’S PRODUCTS ARE PROVIDED "AS IS" WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESSED OR

IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR ANY PARTICULAR PURPOSE OR USE, OR NON-

INFRINGEMENT OF INTELLECTUAL PROPERTY. IN NO EVENT SHALL SELLER BE LIABLE FOR ANY SPECIAL, INCIDENTAL, INDIRECT, OR CONSEQUENTIAL

DAMAGES OF ANY KIND, OR ANY DAMAGES WHATSOEVER RESULTING FROM THE USE OF INFORMATION CONTAINED HEREIN AND SELLER’S PRODUCTS.

Liqui-Cel, SuperPhobic, MiniModule, and MicroModule, are registered trademarks of Membrana-Charlotte, A Division of Celgard, LLC.

Copyright © 2010 Membrana – Charlotte All rights reserved. (D67_Rev.14_6-10)

Membrana - Charlotte Membrana GmbH Japan Office

A Division of Celgard, LLC Oehder Strasse 28 Shinjuku Mitsui Building, 27F

13800 South Lakes Drive 42289 Wuppertal 1-1, Nishishinjuku 2-chome

Charlotte, North Carolina 28273 Germany Shinjuku-ku, Tokyo 163-0427

www.liqui-cel.com

USA Phone: +49 202 6099 - 658 Japan

Phone: (704) 587 8888 Phone: +49 6126 2260 - 41 Phone: 81 3 5324 3361

Fax: (704) 587 8585 Fax: +49 202 6099 - 750 Fax: 81 3 5324 3369

S-ar putea să vă placă și

- 14 X 28 Extra-Flow Product Data Sheet: Cartridge CharacteristicsDocument2 pagini14 X 28 Extra-Flow Product Data Sheet: Cartridge CharacteristicsDmitry BÎncă nu există evaluări

- Liqui-Cel EXF-10x28 Data Sheet LC-1031Document2 paginiLiqui-Cel EXF-10x28 Data Sheet LC-1031LuisAngelCordovadeSanchezÎncă nu există evaluări

- Liqui Cel EXF Series 10x28 DatasheetDocument2 paginiLiqui Cel EXF Series 10x28 Datasheetwongpengchiong7205Încă nu există evaluări

- 3m Liqui Cel Exf 14x28 Series Membrane Contactorlc 1032 PDFDocument2 pagini3m Liqui Cel Exf 14x28 Series Membrane Contactorlc 1032 PDFDsy Tratamiento de AguaÎncă nu există evaluări

- UF IntegraTec P Series PES IO MB 40 OP PDS 45 D04377 enDocument2 paginiUF IntegraTec P Series PES IO MB 40 OP PDS 45 D04377 enSomogyi ÁgiÎncă nu există evaluări

- HF 745 / HF 748 Series: in Line High Pressure FiltersDocument24 paginiHF 745 / HF 748 Series: in Line High Pressure FilterssitnikovsÎncă nu există evaluări

- HF 650 Series: in Line Medium Pressure Spin-On FiltersDocument24 paginiHF 650 Series: in Line Medium Pressure Spin-On FilterssitnikovsÎncă nu există evaluări

- HFU 2020AN Specification Sheet - 20181004Document1 paginăHFU 2020AN Specification Sheet - 20181004Parvinder KaurÎncă nu există evaluări

- HF 725 Series: in Line High Pressure FiltersDocument16 paginiHF 725 Series: in Line High Pressure FilterssitnikovsÎncă nu există evaluări

- Especificaciones Bomba Graco Modelo 515Document1 paginăEspecificaciones Bomba Graco Modelo 515Bryan GuerreroÎncă nu există evaluări

- HF 735 Series: in Line High Pressure FiltersDocument20 paginiHF 735 Series: in Line High Pressure FilterssitnikovsÎncă nu există evaluări

- HF 760 - HF 761 Series: in Line High Pressure FiltersDocument28 paginiHF 760 - HF 761 Series: in Line High Pressure FilterssitnikovsÎncă nu există evaluări

- EV58-34 Vented Directional ElementDocument2 paginiEV58-34 Vented Directional ElementcaiÎncă nu există evaluări

- Data Sheet: Hfc-227Ea Clean Agent Impulse Valve Storage ContainersDocument3 paginiData Sheet: Hfc-227Ea Clean Agent Impulse Valve Storage ContainersFrancisco TorrealbaÎncă nu există evaluări

- UF IntegraTec P Series PES IO MB 60 OP PDS 45 D04374 enDocument2 paginiUF IntegraTec P Series PES IO MB 60 OP PDS 45 D04374 enSomogyi ÁgiÎncă nu există evaluări

- Relief Valves RH4 SeriesDocument6 paginiRelief Valves RH4 SerieslorenzoÎncă nu există evaluări

- HF 620 / HF 625 Series: Suction and Return in Line Spin-On FiltersDocument32 paginiHF 620 / HF 625 Series: Suction and Return in Line Spin-On FilterssitnikovsÎncă nu există evaluări

- Mini Gaskleen High-Flow Filter Assemblies: DescriptionDocument2 paginiMini Gaskleen High-Flow Filter Assemblies: Description3DP HelloÎncă nu există evaluări

- TDS 00201 C PDFDocument4 paginiTDS 00201 C PDFJohan VillarrealÎncă nu există evaluări

- Sprayjet SeriesDocument6 paginiSprayjet Seriestris khanÎncă nu există evaluări

- AJI20020 Ajax Integral Engine Compressor DPC 2202 r0 WebDocument2 paginiAJI20020 Ajax Integral Engine Compressor DPC 2202 r0 WebJavier TisalemaÎncă nu există evaluări

- HF 525 Series: Tank Mounted Return and Suction Line FiltersDocument16 paginiHF 525 Series: Tank Mounted Return and Suction Line FilterssitnikovsÎncă nu există evaluări

- HIDRAULICA MPJ9-08 24 - 11 - 17 - Hoyo 16'' at 550'Document1 paginăHIDRAULICA MPJ9-08 24 - 11 - 17 - Hoyo 16'' at 550'alfonzitoÎncă nu există evaluări

- Series 5100: Texsteam Gas/Pneumatic Driven Injection PumpDocument18 paginiSeries 5100: Texsteam Gas/Pneumatic Driven Injection PumpNajem A. SakorÎncă nu există evaluări

- AFV Sizing DN100 Arseal 150422Document1 paginăAFV Sizing DN100 Arseal 150422FrancoÎncă nu există evaluări

- Hydraulic HRK10 PDFDocument4 paginiHydraulic HRK10 PDFRamiro Rojas MachucaÎncă nu există evaluări

- Iv 10501Document3 paginiIv 10501Brian MirandaÎncă nu există evaluări

- Katalog PROFLUID OIL AND GASDocument16 paginiKatalog PROFLUID OIL AND GASGigiÎncă nu există evaluări

- 9341 PID 404 00 WIJ 06 Rev00Document2 pagini9341 PID 404 00 WIJ 06 Rev00GbengaÎncă nu există evaluări

- Perbandinganteknis SPBG CompressorsDocument6 paginiPerbandinganteknis SPBG CompressorsdedynovandiÎncă nu există evaluări

- Sand Filters Datasheet PDFDocument2 paginiSand Filters Datasheet PDFJamesStenhouseÎncă nu există evaluări

- HPK02Document4 paginiHPK02Tan CkÎncă nu există evaluări

- 13284D - (04feb2022)Document5 pagini13284D - (04feb2022)pedro peñaÎncă nu există evaluări

- SBR Design CalculationsDocument26 paginiSBR Design Calculationsn_zeinoun78% (9)

- Dispositivos e Interfases de Oxigenoterapia BTSDocument5 paginiDispositivos e Interfases de Oxigenoterapia BTSgonzalo osorioÎncă nu există evaluări

- Hydraulic WorksheetDocument4 paginiHydraulic WorksheetMiguel RodriguezÎncă nu există evaluări

- HF 710 Series: in Line Medium Pressure FiltersDocument4 paginiHF 710 Series: in Line Medium Pressure FilterssitnikovsÎncă nu există evaluări

- High Pressure Full Flow Bi-Directional FilterDocument7 paginiHigh Pressure Full Flow Bi-Directional FilterOscar NavarroÎncă nu există evaluări

- Sherwin-Williams Primer E67BC1704 20141007 PDFDocument2 paginiSherwin-Williams Primer E67BC1704 20141007 PDFLorenzo RodriguezÎncă nu există evaluări

- Sherwin-Williams Primer E67BC1704 20141007Document2 paginiSherwin-Williams Primer E67BC1704 20141007lorenzordzrmzÎncă nu există evaluări

- Pisgsfeoilxpxdcaoaa 02 enDocument8 paginiPisgsfeoilxpxdcaoaa 02 enJumaidi AbdyÎncă nu există evaluări

- DDP 1 4 - 400 P 260111 enDocument5 paginiDDP 1 4 - 400 P 260111 enCommunications ShipyardÎncă nu există evaluări

- Excavator CX210D LRDocument7 paginiExcavator CX210D LRKyle LuoÎncă nu există evaluări

- (23ago2022)Document5 pagini(23ago2022)Pedro Alfredo Peña CastilloÎncă nu există evaluări

- HF 690 Series: in Line Medium Pressure FiltersDocument4 paginiHF 690 Series: in Line Medium Pressure FilterssitnikovsÎncă nu există evaluări

- CSM - Phase Separator Atm.Document2 paginiCSM - Phase Separator Atm.Ganesh ZambreÎncă nu există evaluări

- IV.1.38.01 Storage ContainersDocument3 paginiIV.1.38.01 Storage ContainersNestor RodriguezÎncă nu există evaluări

- Conventional Technology Gen Iii Technology - Rapidcap: Statistics: StatisticsDocument2 paginiConventional Technology Gen Iii Technology - Rapidcap: Statistics: StatisticsFirstface LastbookÎncă nu există evaluări

- Design CalculationsDocument26 paginiDesign CalculationsBhavin SolankiÎncă nu există evaluări

- Data Sheet: FK-5-1-12 CLEAN AGENT Impulse Valve Storage ContainersDocument3 paginiData Sheet: FK-5-1-12 CLEAN AGENT Impulse Valve Storage ContainersdavidÎncă nu există evaluări

- Ultra High Purity Water - Vaponics and Barnstead Compatible - Lowest Operating CostsDocument2 paginiUltra High Purity Water - Vaponics and Barnstead Compatible - Lowest Operating CostsTarekÎncă nu există evaluări

- PCT 267510 PDFDocument2 paginiPCT 267510 PDFMiguel VlntìnÎncă nu există evaluări

- DrillPipe, 80%, 2.875 OD, 0.362 Wall, EU, G-105.. XT26 (3.375 X 1.750)Document3 paginiDrillPipe, 80%, 2.875 OD, 0.362 Wall, EU, G-105.. XT26 (3.375 X 1.750)Luis Alberto García CórdovaÎncă nu există evaluări

- Eutectic 19400: Atomized Martensitic Stainless Steel Alloy PowderDocument2 paginiEutectic 19400: Atomized Martensitic Stainless Steel Alloy PowderYeison Piedrahita PérezÎncă nu există evaluări

- VSO Low Flow: Thermally Compensated Proportional ValveDocument6 paginiVSO Low Flow: Thermally Compensated Proportional Valvebiomed2083Încă nu există evaluări

- (DS - LF - 011 - 0111 Rev. 4A - 01-11) CARBOFLOW MX Filter CartridgesDocument2 pagini(DS - LF - 011 - 0111 Rev. 4A - 01-11) CARBOFLOW MX Filter CartridgesRyelfi SessimÎncă nu există evaluări

- Hypro Housing Fa-Mf3Document4 paginiHypro Housing Fa-Mf3Roberto Torres ArancibiaÎncă nu există evaluări

- En7613 5 03 19 - Fam25 - 95 PDFDocument8 paginiEn7613 5 03 19 - Fam25 - 95 PDFhamsterÎncă nu există evaluări

- En7613 5 03 19 - Fam25 - 95 PDFDocument8 paginiEn7613 5 03 19 - Fam25 - 95 PDFhamsterÎncă nu există evaluări

- Darco h2s 8 Ways BrochureDocument8 paginiDarco h2s 8 Ways BrochureDonatas BertasiusÎncă nu există evaluări

- DR 890 Colorimeter Procedures ManualDocument614 paginiDR 890 Colorimeter Procedures ManualArmin MajerÎncă nu există evaluări

- Steam and Water Analysis System (SWAS) An OverviewDocument16 paginiSteam and Water Analysis System (SWAS) An OverviewDonatas Bertasius100% (1)

- Doc316 53 01053Document8 paginiDoc316 53 01053Veronica BoydÎncă nu există evaluări

- 27 36Document6 pagini27 36Donatas BertasiusÎncă nu există evaluări

- Hach 8009 Zinc Ed 08Document6 paginiHach 8009 Zinc Ed 08Beth AlvaradoÎncă nu există evaluări

- Do Wi One ChangeDocument210 paginiDo Wi One ChangeDonatas BertasiusÎncă nu există evaluări

- Total Organic Carbon Measurement: Portable, Real-Time, ContinuousDocument8 paginiTotal Organic Carbon Measurement: Portable, Real-Time, ContinuousDonatas BertasiusÎncă nu există evaluări

- 2 Electrodes Conductivity Sensor K 0,01 3/4NPT Thread With TDocument1 pagină2 Electrodes Conductivity Sensor K 0,01 3/4NPT Thread With TDonatas BertasiusÎncă nu există evaluări

- Polymetron 9610 SC Online Silica Analyser: Lower Maintenance, Less DowntimeDocument2 paginiPolymetron 9610 SC Online Silica Analyser: Lower Maintenance, Less DowntimeDonatas BertasiusÎncă nu există evaluări

- Industrial Boiler Measurements: Conductivity / Total Dissolved Solids PH PhosphatesDocument3 paginiIndustrial Boiler Measurements: Conductivity / Total Dissolved Solids PH PhosphatesDonatas BertasiusÎncă nu există evaluări

- Industrial Boiler Measurements: Conductivity / Total Dissolved Solids PH PhosphatesDocument3 paginiIndustrial Boiler Measurements: Conductivity / Total Dissolved Solids PH PhosphatesDonatas BertasiusÎncă nu există evaluări

- POLYMETRON 9245 Sodium Analyser, 1-ch., Panel, STD., 0.01-10000 PPB NaDocument2 paginiPOLYMETRON 9245 Sodium Analyser, 1-ch., Panel, STD., 0.01-10000 PPB NaDonatas BertasiusÎncă nu există evaluări

- Injection and Sample Quills: Specifications & FeaturesDocument2 paginiInjection and Sample Quills: Specifications & FeaturesDonatas BertasiusÎncă nu există evaluări

- Hot FiltrationDocument8 paginiHot FiltrationDonatas BertasiusÎncă nu există evaluări

- Polymetron 9582 Dissolved Oxygen: User ManualDocument28 paginiPolymetron 9582 Dissolved Oxygen: User ManualDonatas BertasiusÎncă nu există evaluări

- Man Turbin No S Reika LV ImaiDocument8 paginiMan Turbin No S Reika LV ImaiDonatas BertasiusÎncă nu există evaluări

- 5 Epa As Course Coag and PPT Processes YujungchangDocument63 pagini5 Epa As Course Coag and PPT Processes YujungchangDonatas BertasiusÎncă nu există evaluări

- New Microsoft Office Word DocumentDocument3 paginiNew Microsoft Office Word DocumentDonatas BertasiusÎncă nu există evaluări

- Chemical Guidelines For Water / Steam CycleDocument47 paginiChemical Guidelines For Water / Steam CycleparatonerqÎncă nu există evaluări

- Beer Processing SolutionsDocument28 paginiBeer Processing SolutionsDonatas BertasiusÎncă nu există evaluări

- Cond CO2Document18 paginiCond CO2Donatas BertasiusÎncă nu există evaluări

- Ammonia StrippingDocument15 paginiAmmonia StrippingFaiqoh NahareyÎncă nu există evaluări

- Armeen 18 DDocument5 paginiArmeen 18 DDonatas BertasiusÎncă nu există evaluări

- GE Polyamine TechnologyDocument17 paginiGE Polyamine TechnologyDonatas BertasiusÎncă nu există evaluări

- Aminai KatiluoseDocument34 paginiAminai KatiluoseDonatas BertasiusÎncă nu există evaluări

- Imac Hp336 LDocument2 paginiImac Hp336 LDonatas BertasiusÎncă nu există evaluări

- AWT2009 Pres - Enviro Brom 20LDocument25 paginiAWT2009 Pres - Enviro Brom 20LDonatas BertasiusÎncă nu există evaluări

- Exploded ScorpionT 10Document1 paginăExploded ScorpionT 10Donatas BertasiusÎncă nu există evaluări

- 33 12 530 Adjusting BacklashDocument2 pagini33 12 530 Adjusting BacklashDonatas BertasiusÎncă nu există evaluări

- Environmental Risk Aug enDocument26 paginiEnvironmental Risk Aug enRuxandra TudorașcuÎncă nu există evaluări

- An Experimental Study of Lithium Ion Battery Thermal Management PDFDocument8 paginiAn Experimental Study of Lithium Ion Battery Thermal Management PDFAbid HussainÎncă nu există evaluări

- DNV 2009-1115 Recommended Failure Rates For Pipelines ReportDocument135 paginiDNV 2009-1115 Recommended Failure Rates For Pipelines Reportjiaolei9848Încă nu există evaluări

- Environmental Engineering - Civil Engineering - McGill UniversityDocument4 paginiEnvironmental Engineering - Civil Engineering - McGill Universityamrin jannatÎncă nu există evaluări

- Activated Carbon and Its ApplicationDocument16 paginiActivated Carbon and Its ApplicationErik Weeks100% (2)

- ACM Troubleshoot Guide by HoneywellDocument109 paginiACM Troubleshoot Guide by HoneywellLivsÎncă nu există evaluări

- Groundwater Exploration Using 1D and 2D Electrical Resistivity MethodsDocument10 paginiGroundwater Exploration Using 1D and 2D Electrical Resistivity Methodsrizal montazeriÎncă nu există evaluări

- Datasheet 400700 - Arsenic Test Kit enDocument2 paginiDatasheet 400700 - Arsenic Test Kit enMuchlas AkbarÎncă nu există evaluări

- DOSAGDocument4 paginiDOSAGmochales01Încă nu există evaluări

- 18 - Thesis - Solar Desalination Plant - 357 - 369 - 385 - 386Document55 pagini18 - Thesis - Solar Desalination Plant - 357 - 369 - 385 - 386Talha Malik100% (1)

- Design Proposal PresentationDocument15 paginiDesign Proposal PresentationTaliaÎncă nu există evaluări

- Envirn-Engg Iit KanpurDocument6 paginiEnvirn-Engg Iit KanpurNbisht25Încă nu există evaluări

- EPA NOI (Notice of Intent) Vessel General Permit - Clean Water ActDocument5 paginiEPA NOI (Notice of Intent) Vessel General Permit - Clean Water ActLakeMichiganFilesÎncă nu există evaluări

- ES ES Processwater GB 154 - Parameter & User ManualDocument9 paginiES ES Processwater GB 154 - Parameter & User ManualHuy TranÎncă nu există evaluări

- Basic Irrigation BookDocument300 paginiBasic Irrigation Bookhaithamelramlawi7503100% (3)

- Extended Abstract Abiyyu 2021Document6 paginiExtended Abstract Abiyyu 2021Dani Puji UtomoÎncă nu există evaluări

- Establishing A Conversion Factor Between Electrical Conductivity and Total Dissolved Solids in South African Mine WatersDocument11 paginiEstablishing A Conversion Factor Between Electrical Conductivity and Total Dissolved Solids in South African Mine WatersRceL AutomationÎncă nu există evaluări

- Blackwater EstuaryDocument7 paginiBlackwater EstuaryLauraÎncă nu există evaluări

- Eco-Friendly Technologies: A PresentationDocument51 paginiEco-Friendly Technologies: A Presentationrupeshpanda92Încă nu există evaluări

- Sea Transport of Liquid Chemicals in Bulk PDFDocument131 paginiSea Transport of Liquid Chemicals in Bulk PDFDiana MoralesÎncă nu există evaluări

- Material Safety Data Sheet: I. General InformationDocument7 paginiMaterial Safety Data Sheet: I. General InformationPemalang HockÎncă nu există evaluări

- Linking The Sdgs and Gri: LegendDocument41 paginiLinking The Sdgs and Gri: LegendricardocubagÎncă nu există evaluări

- Msds CuSO4.5H2ODocument6 paginiMsds CuSO4.5H2OFebrina Tri NarantiÎncă nu există evaluări

- (F 1.0) DensetsuKemononoAnaDocument57 pagini(F 1.0) DensetsuKemononoAnaJumper AnonÎncă nu există evaluări

- Thinner Gta220Document10 paginiThinner Gta220mohd zaim abd wahab100% (1)

- Aroma Oil MSDSDocument3 paginiAroma Oil MSDSsabuyexpress.worldwideÎncă nu există evaluări

- Manual de BatidoraDocument20 paginiManual de BatidoraAdrianMerchanÎncă nu există evaluări

- Spirit of Saturn PDFDocument4 paginiSpirit of Saturn PDFJoel ZtgÎncă nu există evaluări

- Fisher Scientific T, (M) Sdn. Bhd. MDocument3 paginiFisher Scientific T, (M) Sdn. Bhd. Mwongpengchiong7205Încă nu există evaluări

- Sambhar LakeDocument3 paginiSambhar LakeAditya BhandariÎncă nu există evaluări