Documente Academic

Documente Profesional

Documente Cultură

P74FA-9700 Pressure Switch Water

Încărcat de

rasengineeringDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

P74FA-9700 Pressure Switch Water

Încărcat de

rasengineeringDrepturi de autor:

Formate disponibile

PSC9626 European Refrigeration Controls Catalogue

Catalog Section 6

Product Bulletin P74

Issue 9712

Series P74

Differential Pressure Controls, without time delay

Introduction

These controls are designed to sense pressure

differences between two points and may be

used as operating or limit controls. Typical

applications are to detect flow across a chiller or

water cooled condenser, to detect flow in a A

heating system and sensing lube oil pressure

differential on refrigeration compressors.

Description

The P74 series of differential pressure switches

incorporate two opposing pressure elements

and an adjustable range setpoint spring with a

calibrated scale. The control switches at the

indicated setpoint on an increase in differential

pressure and switches back to the normal

position when the different pressure decreases

to the setpoint less the mechanical switching

differential.

P74 Differential Pressure Control

Note

These controls are designed for use only Adjustment

as operating controls. Where an operating The setpoint can be adjusted by the notched

control failure would result in personal cam A (see photo) located on the top of the

injury or loss of property it is the control. The switching differential can be

responsibility of the installer to add devices

or systems that protect against, or warn of, adjusted by turning a hexagonal nut on the

control failure. differential adjusting screw located inside the

control cover (adjustable differential models

only).

Feature and Benefits

❏ Heavy duty pressure elements. Withstands high overrun pressures.

❏ These controls may be used in Reduces the lube oil system cost.

combination with series P28

lube oil protection control on

two compressor, single motor

units.

© 1997 Johnson Controls Inc. Catalogue Section 6

Order No. PD-P74-E

P74

2 Issue 9712

Contact function

3 2 L2 L1

ρ< ρ<

M2 M1

1

Fig. 1a Fig. 1b

Type P74EA and P74FA Type P74DA

1 - 2 closes on increase of differential pressure. Contacts close on increase of differential

1 - 3 opens simultaneously. pressure.

Repair and replacement

Power elements may be replaced in the field. When contacting the supplier for a replacement

Other repairs are not possible. In case of an you should state the type/model number of the

improperly functioning control, please check control. This number can be found on the data

with your nearest supplier. plate or cover label.

Pressure connections

1 2

Fig.3

Style 13

Fig.4

Style 15

1. 90 cm capillary

2. 7/16"-20 UNF nut for

Fig.2 1/

4 "-18 NPT female

4" SAE flare tube

1/

Style 5

1. 7/16"-20 UNF male for

4" SAE flare tube

1/

Catalogue Section 6 © 1997 Johnson Controls Inc.

Order No. PD-P74-E

P74

Issue 9712 3

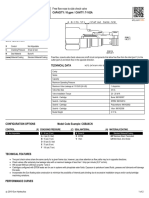

Type number selection table

Order number P74DA-9300 P74DA-9600 P74EA-9300 P74EA-9600

Range ∆ P (bar) 0.6/4.8 0.6/4.8 0.6/4.8 0.6/4.8

Switching differential (bar) 0.7/2 adj. 0.7/2 adj. 0.3 fix. 0.3 fix.

Medium Non-corrosive Non-corrosive Non-corrosive Non-corrosive

Refrigerant Refrigerant Refrigerant Refrigerant

Pressure connector (style) 5 13 5 13

Electrical rating 15(10) A 15(10) A 15(8) A 15(8) A

230 V ac 230 V ac 230 V ac 230 V ac

Contact function fig. 1b fig. 1b fig. 1a fig. 1a

Maximum bellows pressure 23 23 23 23

absolute (bar)

Maximum allowable diff. in 14 14 14 14

pressure between the bellows

(bar)

Pressure element material stainless stainless stainless stainless

steel/copper steel/copper steel/copper steel/copper

Order number P74EA-9700 P74FA-9700 P74FA-9701

Range ∆ P (bar) 0.6/4.8 0/1 2.0/8.0

Switching differential (bar) 0.3 fix. 0.1 fix. 0.7 fix.

Medium Ammonia or Non- Water Ammonia or Non-

corrosive corrosive

Refrigerant Refrigerant

Pressure connector (style) 15 15 15

Electrical rating 15(8) A 15(3) A 15(3) A

230 V ac 230 V ac 230 V ac

Contact function fig. 1a fig. 1a fig. 1a

Maximum bellows pressure 23 10 23

absolute (bar)

Maximum allowable diff. in 14 7 14

pressure between the bellows

(bar)

Pressure element material stainless steel tombac/ brass stainless steel

Note: 1 bar = 100 kPa ≈ 14.5 psi

© 1997 Johnson Controls Inc. Catalogue Section 6

Order No. PD-P74-E

P74

4 Issue 9712

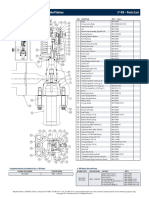

Dimensions (mm)

Ø44 83

51

8.5

27

83

25

44

29

8.5

39

A B D C

Ø44

101 48

Ø5 5

53

33

24

1.5

34

71

Fig. 5

A = Reset button

B = Mounting hole, Ø 5 mm

C = Mounting slot

D = 10 - 32 UNF2B

Catalogue Section 6 © 1997 Johnson Controls Inc.

Order No. PD-P74-E

P74

Issue 9712 5

Accessories (optional)

Fig. 6

Compression Coupling

Description Application Order number

Fits into style 15 pressure connectors For 6 mm copper or steel tubing CNR003N001R

For 8 mm copper or steel tubing CNR003N002R

Fig. 7 Fig. 8

Mounting bracket 90 cm Capillary with (2) flare nuts (1/4" SAE)

Order number 271-51 Order number SEC002N600

© 1997 Johnson Controls Inc. Catalogue Section 6

Order No. PD-P74-E

P74

6 Issue 9712

Notes

Catalogue Section 6 © 1997 Johnson Controls Inc.

Order No. PD-P74-E

P74

Issue 9712 7

Notes

© 1997 Johnson Controls Inc. Catalogue Section 6

Order No. PD-P74-E

P74

8 Issue 9712

Specifications

Types, ranges differentials See type number selection table

Media Ammonia (for special models), non-corrosive refrigerant or water

Pressure connections See type number selection

Maximum overrun See type number selection

pressure

Ambient temperature -30/+55 °C

limits

Material case Cold-rolled steel, zinc plated

cover Cold-rolled steel, painted

pressure element See type number selection

Protection IP30

Electrical rating See type number selection

Shipping weights ind. pack 1.2 kg

overpack 12 kg (10 pcs.)

Accessories (order Mounting bracket, Compression coupling, 90 cm capillary with two

separately) flare nuts. (For code numbers see page 5.)

Dimensions See dimension drawing.

The performance specifications are nominal and conform to acceptable industry standards. For applications at conditions beyond

these specifications, consult the local Johnson Controls office or representative. Johnson Controls shall not be liable for damages

resulting from misapplication or misuse of its products.

Johnson Controls International, Inc.

Headquarters: Milwaukee, WI, USA

European Headquarters: Westendhof 8, 45143 Essen, Germany

European Factories: Lomagna (Italy), Leeuwarden (The Netherlands) and Essen (Germany)

Branch Offices: Principal European Cities.

This document is subject to change Printed in Europe

Catalogue Section 6 © 1997 Johnson Controls Inc.

Order No. PD-P74-E

S-ar putea să vă placă și

- Technical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionDe la EverandTechnical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionÎncă nu există evaluări

- Abstract - Fatigue Behavior in Strain Cycling in The Low and Intermediate Cycle RangeDocument55 paginiAbstract - Fatigue Behavior in Strain Cycling in The Low and Intermediate Cycle RangeZarra FaktÎncă nu există evaluări

- Ebook t357 Block1 Part3-4 E2i1 n9780749252670 l1Document96 paginiEbook t357 Block1 Part3-4 E2i1 n9780749252670 l1Bobby extramoneyguyÎncă nu există evaluări

- In Elastic Buckling of Geometrically Imperfect TubesDocument16 paginiIn Elastic Buckling of Geometrically Imperfect TubesSiva RajÎncă nu există evaluări

- Technical Service Manual: Section TSM 144 1 of 10 Issue DDocument10 paginiTechnical Service Manual: Section TSM 144 1 of 10 Issue DHector_Cornejo_5673Încă nu există evaluări

- Active magnetic bearing design and characterization for high temperature applicationsDocument147 paginiActive magnetic bearing design and characterization for high temperature applicationsVijayTijareÎncă nu există evaluări

- 9 Power TrainDocument146 pagini9 Power TraineduamaÎncă nu există evaluări

- Dynamic structural models scalingDocument5 paginiDynamic structural models scalinggauravÎncă nu există evaluări

- Dynamic Analysis by Component Mode PDFDocument8 paginiDynamic Analysis by Component Mode PDFRodrigo GarayÎncă nu există evaluări

- Asme - PVP2005-71724Document11 paginiAsme - PVP2005-71724sagar1503Încă nu există evaluări

- Full Scale Experimental Analysis of Stress States in Sleeve Repairs of Gas Pipelines PDFDocument9 paginiFull Scale Experimental Analysis of Stress States in Sleeve Repairs of Gas Pipelines PDFzemog001100% (1)

- Notch SensitivityDocument7 paginiNotch SensitivityCheng PangÎncă nu există evaluări

- A 1028-03 Stainless Steel Bars For Compressor and Turbine AirfoilsDocument4 paginiA 1028-03 Stainless Steel Bars For Compressor and Turbine Airfoilsalucard375100% (1)

- Fundamentals of FatigueDocument54 paginiFundamentals of FatigueChristina HillÎncă nu există evaluări

- Barutzki PDFDocument9 paginiBarutzki PDFesutjiadiÎncă nu există evaluări

- Finite Element Analysis of Butterfly Valve Disc IJERTV2IS70790Document6 paginiFinite Element Analysis of Butterfly Valve Disc IJERTV2IS70790Aswaja313Încă nu există evaluări

- Solid Element Formulation OverviewDocument36 paginiSolid Element Formulation OverviewasdqwexÎncă nu există evaluări

- Determining Stress Intensity Factors Analytically and NumericallyDocument50 paginiDetermining Stress Intensity Factors Analytically and NumericallyAdnen Laamouri100% (1)

- Product Date Sheet - Swagelok BrocureDocument6 paginiProduct Date Sheet - Swagelok BrocurejulianpirahÎncă nu există evaluări

- 2017 Ijts Cavitating-Flow PDFDocument12 pagini2017 Ijts Cavitating-Flow PDFAdam AnugrahesaÎncă nu există evaluări

- Analysis of Friction Excited Vibration of Drum Brake SquealDocument11 paginiAnalysis of Friction Excited Vibration of Drum Brake SquealAnonymous PufNjgÎncă nu există evaluări

- Nanofluid in Heat Exchangers for Mechanical Systems: Numerical SimulationDe la EverandNanofluid in Heat Exchangers for Mechanical Systems: Numerical SimulationÎncă nu există evaluări

- Mean stress effects in fatigue of steels and aluminium alloysDocument17 paginiMean stress effects in fatigue of steels and aluminium alloysCarlos A CuencaÎncă nu există evaluări

- Limit Load SolutionsDocument131 paginiLimit Load SolutionsZaid KamardinÎncă nu există evaluări

- Eigenvalue buckling prediction analysisDocument9 paginiEigenvalue buckling prediction analysisMaria FlorÎncă nu există evaluări

- Ada 305006Document157 paginiAda 305006khudhayer1970Încă nu există evaluări

- Superlite: Superlite Asbestos Free Gp-150Document4 paginiSuperlite: Superlite Asbestos Free Gp-150blahblahÎncă nu există evaluări

- Investigations of Butterfly Control Valve Flow CharacteristicsDocument16 paginiInvestigations of Butterfly Control Valve Flow CharacteristicsKalimuthu Ps100% (1)

- Waves in Elastic Fluid-Filled TubesDocument13 paginiWaves in Elastic Fluid-Filled TubesNana LiuÎncă nu există evaluări

- An Insight Into Magneto Rheological DampersDocument239 paginiAn Insight Into Magneto Rheological DampersashutoshmanchandaÎncă nu există evaluări

- Fea SR CouplingsDocument67 paginiFea SR CouplingsAna Isabel Aguilar ReyesÎncă nu există evaluări

- Fatigue Life Prediction Models For Composites - A ReviewDocument8 paginiFatigue Life Prediction Models For Composites - A ReviewIJIERT-International Journal of Innovations in Engineering Research and TechnologyÎncă nu există evaluări

- Modern Developments in the Mechanics of ContinuaDe la EverandModern Developments in the Mechanics of ContinuaSalamon EskinaziÎncă nu există evaluări

- Watter Hammer HobasDocument35 paginiWatter Hammer HobasAnonymous 87xpkIJ6CFÎncă nu există evaluări

- Design Category and Service Class Selection For Below-the-Hook Lifting DevicesDocument5 paginiDesign Category and Service Class Selection For Below-the-Hook Lifting DevicesjdcervantesÎncă nu există evaluări

- Reliability-Based Bridge Assessment Using Risk-Ranking Decision AnalysisDocument9 paginiReliability-Based Bridge Assessment Using Risk-Ranking Decision AnalysissalmanÎncă nu există evaluări

- BradleyDocument247 paginiBradleythomas duncan eelesÎncă nu există evaluări

- Ch6 Thermal Stress Analysis Sp16Document34 paginiCh6 Thermal Stress Analysis Sp16Haidar YafieÎncă nu există evaluări

- Fracture MechanicsDocument174 paginiFracture Mechanicsroijen_pkÎncă nu există evaluări

- 17-7 PH Data BulletinDocument16 pagini17-7 PH Data Bulletinmeckup123Încă nu există evaluări

- 603 DDocument8 pagini603 DreluÎncă nu există evaluări

- Bladeless Wind TurbineDocument4 paginiBladeless Wind TurbineIJIERT-International Journal of Innovations in Engineering Research and TechnologyÎncă nu există evaluări

- Notch Chapter 7Document132 paginiNotch Chapter 7mre2006Încă nu există evaluări

- James F. Manwell, Jon G. McGowan, Anthony L. Rogers-Wind Energy Explained - Theory, Design and Application (2010)Document1 paginăJames F. Manwell, Jon G. McGowan, Anthony L. Rogers-Wind Energy Explained - Theory, Design and Application (2010)Josue Flores Barrios0% (1)

- Combination of Hydraulic Brake With Power Booster SystemDocument77 paginiCombination of Hydraulic Brake With Power Booster Systemjyani hitesh100% (1)

- DataGridView FAQDocument69 paginiDataGridView FAQyamanoblu100% (1)

- Creeps Analysis of ThermoplasticsDocument7 paginiCreeps Analysis of ThermoplasticsIgor AlarcónÎncă nu există evaluări

- Mil STD 1344aDocument129 paginiMil STD 1344aBillTrager100% (1)

- Torsion of BarsDocument33 paginiTorsion of Barskrishna kumar100% (1)

- B2 Stress IndexDocument12 paginiB2 Stress IndexParilla13Încă nu există evaluări

- Graficas Intercambiadores (NTU)Document269 paginiGraficas Intercambiadores (NTU)Junior RodriguezÎncă nu există evaluări

- 9/3/17 ME321: Advanced Mechanics of SolidsDocument21 pagini9/3/17 ME321: Advanced Mechanics of SolidsBrajesh kumarÎncă nu există evaluări

- (BS EN 12981 - 2005+A1 - 2009) - Coating Plants. Spray Booths For Application of Organic Powder Coating Material. Safety Requirements.Document54 pagini(BS EN 12981 - 2005+A1 - 2009) - Coating Plants. Spray Booths For Application of Organic Powder Coating Material. Safety Requirements.Simon ThaonÎncă nu există evaluări

- Reliability DistributionDocument16 paginiReliability DistributionJavier Alejandro Rodriguez MelgozaÎncă nu există evaluări

- Fatigue Crack Tolerance Design For Stainless Steel by Crack Growth Analysis-Grupo 3Document36 paginiFatigue Crack Tolerance Design For Stainless Steel by Crack Growth Analysis-Grupo 3sebastianÎncă nu există evaluări

- 2017 Rego CG500 PDFDocument96 pagini2017 Rego CG500 PDFSatyajit C DhaktodeÎncă nu există evaluări

- Thermal Fatigue Due To Statification in PipingDocument16 paginiThermal Fatigue Due To Statification in PipinghamadaniÎncă nu există evaluări

- Determination of Leakage Gap and Leakage Mass Flow of Flanged JointsDocument5 paginiDetermination of Leakage Gap and Leakage Mass Flow of Flanged Jointslcm3270% (1)

- Fatigue Design Procedures: Proceedings of the 4th Symposium of the International Committee on Aeronautical Fatigue held in Munich, 16–18 June 1965De la EverandFatigue Design Procedures: Proceedings of the 4th Symposium of the International Committee on Aeronautical Fatigue held in Munich, 16–18 June 1965E. GassnerÎncă nu există evaluări

- Turbulent Buoyant Jets and Plumes: HMT: The Science & Applications of Heat and Mass Transfer. Reports, Reviews & Computer ProgramsDe la EverandTurbulent Buoyant Jets and Plumes: HMT: The Science & Applications of Heat and Mass Transfer. Reports, Reviews & Computer ProgramsÎncă nu există evaluări

- Analysis and Design of Elastic Beams: Computational MethodsDe la EverandAnalysis and Design of Elastic Beams: Computational MethodsÎncă nu există evaluări

- 2006 Can-Am Outlander Max 400 H.O. XT ManualDocument164 pagini2006 Can-Am Outlander Max 400 H.O. XT Manualprotrek777Încă nu există evaluări

- MK IV Horizontal Sliding Door Replacement Parts GuideDocument48 paginiMK IV Horizontal Sliding Door Replacement Parts GuidevankarpÎncă nu există evaluări

- Advanced Power Electronics Corp.: AP0803GMT-HFDocument5 paginiAdvanced Power Electronics Corp.: AP0803GMT-HFAlexander TkachenkoÎncă nu există evaluări

- Diodes Inc - Library - Components - List PDFDocument5 paginiDiodes Inc - Library - Components - List PDFLuciaÎncă nu există evaluări

- Cub Cadet Parts Manual For Model 465 4x4 Utility Vehicle Efi SN 1i029z and AfterDocument6 paginiCub Cadet Parts Manual For Model 465 4x4 Utility Vehicle Efi SN 1i029z and Afterenid100% (50)

- Microprocessor 8086 by Nirvaan MahajanDocument14 paginiMicroprocessor 8086 by Nirvaan MahajanHallucinatory100% (1)

- AsdwDocument56 paginiAsdwsorcÎncă nu există evaluări

- Free-flow nose-to-side check valve technical detailsDocument2 paginiFree-flow nose-to-side check valve technical detailssnsnagarajanÎncă nu există evaluări

- Buell Ulisses Diagrama ElectricoDocument1 paginăBuell Ulisses Diagrama ElectricoHugo GonzalezÎncă nu există evaluări

- H16-22XM-12EC Empty Container Handlers Offer Class-Leading PerformanceDocument24 paginiH16-22XM-12EC Empty Container Handlers Offer Class-Leading PerformanceEjaz EjazÎncă nu există evaluări

- Hydraulic/Hydrostatic Schematic: S175 (S/N A3L520001 AND ABOVE)Document2 paginiHydraulic/Hydrostatic Schematic: S175 (S/N A3L520001 AND ABOVE)alexandrÎncă nu există evaluări

- Fischer FH II High Performance AnchorDocument5 paginiFischer FH II High Performance AnchorJaga NathÎncă nu există evaluări

- Etc Lmg-Ssc12a64Document10 paginiEtc Lmg-Ssc12a64Dubis EszterÎncă nu există evaluări

- The Brute' - Develops 300W Into 4 Ohms, 200W Into 8 Ohms!: Project 466Document6 paginiThe Brute' - Develops 300W Into 4 Ohms, 200W Into 8 Ohms!: Project 466Di CkyÎncă nu există evaluări

- CPU fan controller project uses PSOC for temperature-based speed controlDocument4 paginiCPU fan controller project uses PSOC for temperature-based speed controlmantoruleÎncă nu există evaluări

- Futek Hid Electronic SpecsDocument3 paginiFutek Hid Electronic SpecsAEEE100% (2)

- Normal Start Up ProcedureDocument8 paginiNormal Start Up ProceduremoronotoÎncă nu există evaluări

- PU360Document38 paginiPU360schservÎncă nu există evaluări

- Deutz Fahr Agrolux f50 f60 f70 f80 Workshop ManualDocument20 paginiDeutz Fahr Agrolux f50 f60 f70 f80 Workshop Manualmaya100% (33)

- Manual Valvula 3'' Titan RXDocument2 paginiManual Valvula 3'' Titan RXrolandÎncă nu există evaluări

- Application Note Gan Bias Circuit DesignDocument6 paginiApplication Note Gan Bias Circuit DesignAnonymous 3mJfZEÎncă nu există evaluări

- Shaper SlottingDocument34 paginiShaper SlottingAamer MohammedÎncă nu există evaluări

- MV Transformer Testing (7200DB1001Document4 paginiMV Transformer Testing (7200DB1001sulthanabdulÎncă nu există evaluări

- IRM-S01T Intelligent Temperature Sensor User Manual: 1 OverviewDocument1 paginăIRM-S01T Intelligent Temperature Sensor User Manual: 1 OverviewDavid MolinaÎncă nu există evaluări

- Basic Principles V2Document20 paginiBasic Principles V2Gautam PkÎncă nu există evaluări

- 8i845gvmrz Ac Rev.1.0Document34 pagini8i845gvmrz Ac Rev.1.0Cid santosÎncă nu există evaluări

- MS 1Document6 paginiMS 1afelipef27Încă nu există evaluări

- OM C5613 1 Turismo Veloce 800 Lusso RC SCS 18-20 USA SMLDocument472 paginiOM C5613 1 Turismo Veloce 800 Lusso RC SCS 18-20 USA SMLJulio VizueteÎncă nu există evaluări

- Gas Turbine Power PlantDocument7 paginiGas Turbine Power PlantYuvraj GogoiÎncă nu există evaluări