Documente Academic

Documente Profesional

Documente Cultură

Sea Transportation

Încărcat de

Mark Samsel Rohan0 evaluări0% au considerat acest document util (0 voturi)

228 vizualizări8 paginiA number of cases is known in which big cranes, tanks, etc. Are fabricated in a workshop with access to a quay and then loaded on a barge and transported complete to the client. The wind and wave loadings during the transport depend on the transportation route as well as the season. In the design of the structure, the loads in the sea transportation situation will in many cases give the critical load cases.

Descriere originală:

Titlu original

SeaTransportation

Drepturi de autor

© Attribution Non-Commercial (BY-NC)

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentA number of cases is known in which big cranes, tanks, etc. Are fabricated in a workshop with access to a quay and then loaded on a barge and transported complete to the client. The wind and wave loadings during the transport depend on the transportation route as well as the season. In the design of the structure, the loads in the sea transportation situation will in many cases give the critical load cases.

Drepturi de autor:

Attribution Non-Commercial (BY-NC)

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

228 vizualizări8 paginiSea Transportation

Încărcat de

Mark Samsel RohanA number of cases is known in which big cranes, tanks, etc. Are fabricated in a workshop with access to a quay and then loaded on a barge and transported complete to the client. The wind and wave loadings during the transport depend on the transportation route as well as the season. In the design of the structure, the loads in the sea transportation situation will in many cases give the critical load cases.

Drepturi de autor:

Attribution Non-Commercial (BY-NC)

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 8

Nordic Steel Construction Conference "95

Sea Transportation of Complete Structures

Jens Lilleore and Helge Skov Pedersen, ISC A/S Consulting Engineers,

Denmark

Summary

The present paper describes the planning and design procedure for sea transport of complete

structures on barges from the early planning till the transport is completed. It describes the

loading conditions and design procedure and gives examples of sea transport

Introduction

In the last decades the development of heavy lift cranes, onshore as well as offshore, and

flexible trailers with high capacity has lead to prefabrication of bigger and heavier construc-

tions in the workshops for transport and installation of complete structures.

From the offshore sector sea transport of complete platform structures and topside structures

is well-known, and the advantages by fabricating the complete structure onshore are obvious.

In recent years sea transport of complete structures and spans has proved to be effective and

feasible also for the bridge construction.

Many heavy industries, as for example power plants, with easy or direct access to quay may

consider the advantages and profit from the seaside delivery of a complete built up section

when new projects are planned.

‘A number of cases is known in which big cranes, tanks, etc. are fabricated in a workshop

with access to a quay and then loaded on a barge and transported complete to the client.

The advantages of using sea transport in such projects are:

- Higher quality by fabricating the structures in a permanent workshop.

= Shorter construction time due to better production facilities.

- Competitive prices by fabrication in a workshop with idle capacity.

Selection of construction method and the sizes of workshop-fabricated sections are determined

by transport possibilities, However, the position of the structure on the barge is given by the

selection of transport method from the workshop to the barge and from the barge to the site.

In the design of the structure, the loads in the sea transportation situation will in many cases

give the critical load cases.

The wind and wave loadings during the transport depend on the transportation route as well

as the season. For instance transport in Oeresund will give an operational wave height of

H, < 0.5 m, whereas the significant wave height for the Halmstad region is Hy < 1.5 m, when

choosing the same possibility for completion.

When choosing climatic loads reliable meteorological data and weather forecasts will

determine the transport loads completely.

The sea transport and transport method must be planned at an early stage in order to make an

optimum design with respect to transport loads and transport methods.

It is very important that the planning of the sea transport is included in a project from the

early beginning as the sea transport might lead to some modification and/or reinforcement of

a structure.

Early planning will result in a safe tansport which minimises the risk of failure, which

normally means total loss of the structure. In the past large cranes have been lost from barges

in the Biscaya, the North Sea and the Baltic Sea.

Planning

‘A clear distinction between planning, loading and design is not possible as they are strongly

intertwined. This is why a sea transportation project will always be an interactive process.

The preliminary investigation is very important because apparently insignificant factors may

result in large expenses and at worst the failure of the structure.

Planning of sea transports requires clarification of a number of aspects.

= Possible unloading harbours inclusive of. contact to harbour authorities.

- Possible transport routes inclusive of distress harbour

= Possible loading and unloading methods

= Onshore transport

- Verification of environments (Weather window principle)

= Choice of barge

- Verification of accelerations (Motion response analysis)

= Stability analysis

- Ballast calculations

Preparation of operational manuals for the transport

= Meteorological assistance during the transport

= Insurance of the transport

= Approvement by Marine Warranty Surveyor

- Classification of barge in case of major modifications

- Design of sea fastening, mooring and ramps

- Stipulation of towing pull for the tugs

- Loading and towing manual

= Design basis for the construction which had to be transported

- Estimate of cost for the total transport

= Risk analysis

The size of the barge must be found and the market for barge hire must be checked at an

early stage in order to find available barge dimensions in the planned period.

If the structure which had to be transported is sensible to the motions, the barge can be

ballasted or it can be an advantage to chose a barge of a larger dimension than needed in

order to reduce the size of acceleration,

Loading conditions

The feasibility of the project depends entirely on the weather. Therefore it is important to

determine a weather window for the operation, or several in case of safe stops along the way

‘A weather window is a period of time in which it is possible to predict with certainty that the

loads will not exceed the conditions laid out in the design.

The weather window is determined by factors such as time of year. sea lane, possible distress

habour and frequent wind/wave direction.

Cost ean be reduced by planning the transport in the summer period and by choosing

favorable environmental loads. However, this can lead to a critical transport in case of for

instance a delay in the project. If the season of the transport is unknown, the transport loads

‘must be based on yearly environmental loads.

The loads on a construction during sea transport is

- Dead load of the structure

- Wind load

- Splash on the structure

- Accelerations due to the barge motion in the waves

The movement of a barge can be described by the following:

Rotations ‘Translations

Roll (Rotation about the longitudinal axis) Surge (Longitudinal movement)

Pitch (Rotation about the transversal axis) Sway (Perpendicular movement)

Yaw (Rotation about the vertical axis) Heave (Vertical movement)

As the resulting acceleration forces increase with the distance from the rotation axis it is

important to place the sensitive items above the center of the barge and as low above the

deck as possible. The rotation axis for each rotation is situated between the center of gravity

for the barge inclusive of deck load and the center of buoyancy.

It might be noted that any elevations above the deck level due to secondary items will require

heavy seafastening constructions due to the large horizontal acceleration forces.

In many cases the loading on the structure is estimated by simple formulas for the move-

ment, In the Danish North Sea area the following motion parameter has been used.

Roll; amplitude 20° with a period of 10 sec.

Pitch amplitude 12,5° with a period of 10 sec.

Heave : 02xg

Loadcase ; Roll + Heave or Pitch + Heave

It shall be noted that the above practice will lead to a conservative design.

There are no easy design rules for transportation by barge. A motion response analysis for the

actual transport is necessary if a consensus knowledge of the actual loads are desired. Luckily

wave data for many sea lanes are available and the analysis can be carried out by using an

advanced finite element programme like GTSTRUDL.

Loads on the structure during loading and unloading inclusive of onshore transport have to be

considered.

In this situation the structure will often have unfavourable support conditions compared to a

permanent situation and the sea transport conditions.

In the specific situation it might be evaluated if the loads during the sea transport and land

transport will have any consequences with respect to the lifetime of the structures due to

fatigue.

Design

The design will typically include design of the following main items:

Onshore Transport

- Transport equipment

- Transport route

- Analysis and reinforcement of structure,

Load Ouv/In

= Transport equipment

= Ballast calculation

= Moring analysis

= Analysis and reinforcement of structure.

Sea transportation

= Stability analysis

- Towing

~ Sea fastening of the structure

- Design of the structure.

Stability Analysis

The stability analysis is carried out on the basis of different rules published by the classifica-

tion companies, for example Lloyd’s rules for mobile offshore units.

These rules will not be discussed in here, but it is a fairly simple analysis which should be

carried out at an early stage.

Towing

The towing analysis is primarily carried out in order to determine which tug force to use in

order to uphold a given speed. The results come from the Motion Response Analysis, or

alternatively experiences from former towings may be used.

Sea fastening

Sea fastening is the structure that safely ties the structure to the barge, and the design

includes a local check-up of the barge.

If the standard load tables of the barge cannot be used, then a new calculation of the barge

and a subsequent classification is required. This operation is very costly and should therefore

be considered carefully.

Design of Structure

In the permanent situation a structure has to be designed according to the local codes with

respect to loading.

For the sea transport the design loads are given on basis of a Motion Response Analysis.

For the onshore transport, loads from local codes and experience from previous transport are

to be used.

The safety loads for the static as well as the fatigue analysis will however, always be

according to local codes.

Onshore Transport

The choice of onshore transport from the workshop to the barge and from the barge to the

site depends on the structure and the transport distance, and finally also whether it is a one

time operation or repetitive operations.

In case of one-off operations over long distances, it is often favourable to use flexible selfpro-

pelled platform trailers. The height of trailers are 1.5 m to 2 m which raises the structure

above the barge deck and requires heavy seafastening.

If the distance is shorter skidding on rails can be used.

The structure can either be equipped with PTEE plates with low friction or with roller skate

An alternative is to use aerofoil plates which require relative plane and close surfaces as

smooth concrete or steel plates. The advantage is the distribution on the load over a large area

which leads to a low pressure.

The critical point in the onshore transport is in all cases the pass from land to the the barge.

For the last mentioned equipment the ballasting during load out is sensitive, however less

critical if platform trailers are used.

If the structure is constructed in a dry dock with large crane capacity, the structure can be

lifted while the dock is filled and the barge positioned below the structure.

Examples of Sea Transport

In the following three examples of sea transport will be described.

Transport of Coal Cranes

The two cranes were built in Aalborg harbor and transported 200 km to the "Coal Landing

pier” by the power plant "Asnasverrket". The cranes were transported complete with the crane

booms erected in horizontal positions. The height of the structure and the relatively high

waves justify a thorough investigation of the transport.

For a number of elements the transportation load case was most critical and the cranes were

temporarily braced. The barge was equipped with rails and the cranes were loaded on and off

on their own wheels.

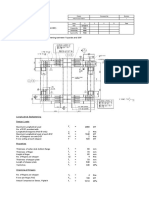

Fig. 1. Coal cranes during transport crossing "Kattegat"

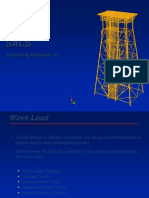

Transport of Gantry Crane

The possibility of transporting a big crane with a weight of 7200 tonnes from Malmé to

Copenhagen was investigated

As the cost for dismantling and reassembling of the crane legs exceed the expenses for whole

transportation of the complete crane structure, the last was chosen.

A solution with one large barge was rejected due to

~ Special large barges are not normally available.

~The height of the barge compared with the water depth required elevation of the crane

by 2 m above the final level.

~ Expenses due to reinforcement of barge deck for installation of crane rails.

Each leg of the crane is supported by means of 2 barges with rigid connections

The connection between the legs is established by 3 barges hinged to each other, which was

less expensive than purpose-made beam connections.

The solution with the hinged standard barges was possible due to the shallow water.

wor

Fig. 2. Cantry crane loaded on connected barges.

Transport of Bridge Sections

When a bridge is planned the erection method is naturally a part of the design. Bridges

crossing waterways will normally be mounted from the seaside. The transport shown is one

proposal for erection of the Oresund bridge. The large barge will increase the stability, but the

main issue for the size is to keep a very small draft which is required due to the water depth

by the coasts.

ELEVATION

Fig. 3. Bridge section transported in installation height.

References

Hilmer Jung Larsen & Kjeld Thomsen

“Transport og montage af store stilkonstruktioner"

ISC Bulletin No. 30, December 1991

S-ar putea să vă placă și

- Bollard Pull CalculationDocument1 paginăBollard Pull CalculationMark Samsel Rohan100% (2)

- Star Plate Design With Sector Tubular MODIFIEDDocument14 paginiStar Plate Design With Sector Tubular MODIFIEDparvej0% (1)

- Jacket Weighing ProcedureDocument14 paginiJacket Weighing ProcedureBolarinwaÎncă nu există evaluări

- 8E.3 - Barge - Deflection - Sea - TransDocument11 pagini8E.3 - Barge - Deflection - Sea - TransSiva ShankarÎncă nu există evaluări

- Grillage Seafastening DesignExampleDocument66 paginiGrillage Seafastening DesignExampleeÎncă nu există evaluări

- Longitudinal Strength Analysis of Barge Kreuz 282 During CPP2 JacketDocument106 paginiLongitudinal Strength Analysis of Barge Kreuz 282 During CPP2 JacketSanieBurhan100% (3)

- Leg Penetration Analysis AD-G34-1041-R2658 - Seafox 8 LPA at Zulf 246-251Document8 paginiLeg Penetration Analysis AD-G34-1041-R2658 - Seafox 8 LPA at Zulf 246-251SinojKumarMalipronÎncă nu există evaluări

- Design of Lifting LugDocument7 paginiDesign of Lifting Luga_toups100% (1)

- PP00011 Pdi DS Cal 00007 - C03Document96 paginiPP00011 Pdi DS Cal 00007 - C03Olanrewaju Tope100% (1)

- 8E.2 - Evaluation - Barge - MotionDocument7 pagini8E.2 - Evaluation - Barge - MotionSiva ShankarÎncă nu există evaluări

- SEA - TRANS - REACTION PAU-106-104B - Preliminary IssueDocument4 paginiSEA - TRANS - REACTION PAU-106-104B - Preliminary IssueUMER AZIQÎncă nu există evaluări

- BP Angelin Project: Jacket Loadout Analysis ReportDocument48 paginiBP Angelin Project: Jacket Loadout Analysis ReportDhanu PadhuÎncă nu există evaluări

- Jacket Lifting COG ShiftDocument6 paginiJacket Lifting COG ShiftLit Phen TuÎncă nu există evaluări

- Miscellaneous Calculations: 1 Sea Transport Forces On CargoDocument4 paginiMiscellaneous Calculations: 1 Sea Transport Forces On CargoAgarry EmmanuelÎncă nu există evaluări

- DFGHJ PDFDocument3 paginiDFGHJ PDFGaneshÎncă nu există evaluări

- 109002-TSP-417 Specification For Landfall Construction and Pipeline Pull-InDocument41 pagini109002-TSP-417 Specification For Landfall Construction and Pipeline Pull-InMohd. Fadhil JamirinÎncă nu există evaluări

- Lifting Analysis Report - Mahadi KurniawanDocument31 paginiLifting Analysis Report - Mahadi KurniawanDian SasÎncă nu există evaluări

- SL-ELT-PR-WPS1-4105-C1-S1 Topside Load Out ProcedureDocument142 paginiSL-ELT-PR-WPS1-4105-C1-S1 Topside Load Out Proceduresaeed ghafooriÎncă nu există evaluări

- Seafastening Manual For The Carriage of Anode Cages On Seagoing Vessels Rev. 3Document17 paginiSeafastening Manual For The Carriage of Anode Cages On Seagoing Vessels Rev. 3JackÎncă nu există evaluări

- PE-PP-10-1-F3 Rev. 7.0 PLNG SSI Check List Confirmation ListDocument22 paginiPE-PP-10-1-F3 Rev. 7.0 PLNG SSI Check List Confirmation ListLuis Enrique LavayenÎncă nu există evaluări

- Transportation Analysis Dynamic Forces Calculation: + Roll Heave (Load Case 101)Document2 paginiTransportation Analysis Dynamic Forces Calculation: + Roll Heave (Load Case 101)Booraj DuraisamyÎncă nu există evaluări

- Stopperwith-Face-Plate-Rev-1.0-SI-Units-www.thenavalarch.com_Document6 paginiStopperwith-Face-Plate-Rev-1.0-SI-Units-www.thenavalarch.com_Karthik36100% (2)

- Boatlanding and Riser Protecter Design-3Document16 paginiBoatlanding and Riser Protecter Design-3samiransmitaÎncă nu există evaluări

- Offshore General Introduction AnalysisDocument28 paginiOffshore General Introduction AnalysisOkolo Obinna100% (3)

- Jacket Design ProcedureDocument59 paginiJacket Design Procedurebhagyalaxmi50% (2)

- Lifting COG Shift DDTL-IfR SouthDocument6 paginiLifting COG Shift DDTL-IfR Southvovancuong8Încă nu există evaluări

- Topside Seafastening.002Document6 paginiTopside Seafastening.002Sai SushankÎncă nu există evaluări

- Skew Load Lift AnalysisDocument3 paginiSkew Load Lift AnalysisBolarinwadeÎncă nu există evaluări

- Mudmat Bearing CapacityDocument11 paginiMudmat Bearing CapacityMathew Simon100% (1)

- DANA-Technical Note (TN)Document8 paginiDANA-Technical Note (TN)Samsul Imran BahromÎncă nu există evaluări

- Full Specs PNGMH02721 - REV2-design Basis PDFDocument765 paginiFull Specs PNGMH02721 - REV2-design Basis PDFNag Raj100% (1)

- Collapse Analysis 1Document13 paginiCollapse Analysis 1samiransmitaÎncă nu există evaluări

- 0013-nd Rev 8.1 28-Jun-16 Guidelines For Load-Outs PDFDocument38 pagini0013-nd Rev 8.1 28-Jun-16 Guidelines For Load-Outs PDFMark InnesÎncă nu există evaluări

- Sacs-Basics PDFDocument113 paginiSacs-Basics PDFanilÎncă nu există evaluări

- Nave TehniceDocument181 paginiNave TehniceGeoGeorgianaÎncă nu există evaluări

- PT Gunanusa Utama Fabricators: Calculation SheetDocument29 paginiPT Gunanusa Utama Fabricators: Calculation SheetRiandi HartartoÎncă nu există evaluări

- RPT - DNV Recommended Practice (DNV-RP-C205) Environmental Conditions & LoadsDocument1 paginăRPT - DNV Recommended Practice (DNV-RP-C205) Environmental Conditions & Loadsjdkelley0% (1)

- H0a C03al A1Document2 paginiH0a C03al A1iw2fualÎncă nu există evaluări

- KOM Loadout InterfaceDocument49 paginiKOM Loadout InterfaceNguyen Dinh Ngoc Duy100% (1)

- DNV-OS-H206 Transport and Installation of Subsea ObjectsDocument54 paginiDNV-OS-H206 Transport and Installation of Subsea ObjectsPatranÎncă nu există evaluări

- Mathcad - Dog Plate CalculationDocument4 paginiMathcad - Dog Plate CalculationAkhmad Syahroni100% (1)

- Sample Cleat For 20Ft SeafasteningDocument2 paginiSample Cleat For 20Ft SeafasteningMohd Reza MohsinÎncă nu există evaluări

- EGP3-01.22 Transportation of Cargo by Barge or ShipDocument32 paginiEGP3-01.22 Transportation of Cargo by Barge or ShipMathias OnosemuodeÎncă nu există evaluări

- 05-1 - EPC-SV-ALE-N-CA-10006 - Rev B2 Barge Deck Strength Check PDFDocument63 pagini05-1 - EPC-SV-ALE-N-CA-10006 - Rev B2 Barge Deck Strength Check PDFBill BenÎncă nu există evaluări

- Lifting Analysis TK. Flolift 200 PDFDocument35 paginiLifting Analysis TK. Flolift 200 PDFAhmed HossamÎncă nu există evaluări

- SACS - Moving LoadsDocument4 paginiSACS - Moving LoadsBolarinwaÎncă nu există evaluări

- 7234 M RP 1002 Ver C0100 PDFDocument601 pagini7234 M RP 1002 Ver C0100 PDFbaskaran ayyapparaj100% (1)

- SACS Software Offshore Structures Design Rev1Document2 paginiSACS Software Offshore Structures Design Rev1Boonme ChinnaboonÎncă nu există evaluări

- GLND Guidelines For Loadouts 0013-ND - 7Document37 paginiGLND Guidelines For Loadouts 0013-ND - 7Milandro Lou AcuzarÎncă nu există evaluări

- Offshore Fixed Platform Design In-Place Analysis: Pbt750@mun - CaDocument60 paginiOffshore Fixed Platform Design In-Place Analysis: Pbt750@mun - CaJOSE LUIS GUTIERREZ GARCIAÎncă nu există evaluări

- Collapse Analysis 2Document15 paginiCollapse Analysis 2samiransmitaÎncă nu există evaluări

- SL-ELT-AN-WPS1-4114-C2-S1 Topside Lift Analysis & Report PDFDocument633 paginiSL-ELT-AN-WPS1-4114-C2-S1 Topside Lift Analysis & Report PDFsaeed ghafoori100% (1)

- Quayside Mooring Analysis - Floatel Triumph at Kemaman (P30049-MA-REV 0) (2095)Document35 paginiQuayside Mooring Analysis - Floatel Triumph at Kemaman (P30049-MA-REV 0) (2095)cliff1234Încă nu există evaluări

- 02-Lifting Operation Planning Checklist - Lifting Freon Bottle To E-House Roof TopDocument6 pagini02-Lifting Operation Planning Checklist - Lifting Freon Bottle To E-House Roof TopImam Saja DechÎncă nu există evaluări

- Appendix e (Sacs Output)Document6 paginiAppendix e (Sacs Output)Tran Van DaiÎncă nu există evaluări

- Boatlanding and Riser Protecter Design-2Document15 paginiBoatlanding and Riser Protecter Design-2samiransmitaÎncă nu există evaluări

- Jacket Topside Transportation Sea Fastening InstallationDocument5 paginiJacket Topside Transportation Sea Fastening InstallationMermaid co100% (1)

- Offshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsDe la EverandOffshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsÎncă nu există evaluări

- Ageing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityDe la EverandAgeing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityÎncă nu există evaluări

- Ports and Harbor EngineeringDocument11 paginiPorts and Harbor EngineeringRyan MinaÎncă nu există evaluări

- Offshore Cargo HandlingDocument51 paginiOffshore Cargo HandlingAnonymous n5yCH2SÎncă nu există evaluări

- L4-Platform Installation (Compatibility Mode)Document37 paginiL4-Platform Installation (Compatibility Mode)Laxmi Kant PrasadÎncă nu există evaluări

- GSF Development Driller IDocument2 paginiGSF Development Driller IMark Samsel RohanÎncă nu există evaluări

- The Catenary PDFDocument5 paginiThe Catenary PDFChandra PrakashÎncă nu există evaluări

- Guidelines For Converting Between Various Wind Averaging Period in Tropical Cyclones PDFDocument60 paginiGuidelines For Converting Between Various Wind Averaging Period in Tropical Cyclones PDFnikhilgarg_gjuÎncă nu există evaluări

- Norsok Standard M-501: Rev. 5, June 2004Document24 paginiNorsok Standard M-501: Rev. 5, June 2004Nelson Matos100% (1)

- 80 Ton AHTS Specification Rev 0Document81 pagini80 Ton AHTS Specification Rev 0Mark Samsel RohanÎncă nu există evaluări

- Bending StiffnessDocument6 paginiBending StiffnessMark Samsel RohanÎncă nu există evaluări

- 80 Ton AHTS Specification Rev 0Document81 pagini80 Ton AHTS Specification Rev 0Mark Samsel RohanÎncă nu există evaluări

- Os c106 - 2009 10Document26 paginiOs c106 - 2009 10Mark Samsel RohanÎncă nu există evaluări

- Anode CalculationsDocument3 paginiAnode CalculationsMark Samsel RohanÎncă nu există evaluări