Documente Academic

Documente Profesional

Documente Cultură

Principle of Operation

Încărcat de

mohdnaveedDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Principle of Operation

Încărcat de

mohdnaveedDrepturi de autor:

Formate disponibile

Types of 3-phase Induction Motors

The 3-phase induction motors are of three types depending upon the type of rotor

they employ namely

(i) Squirrel cage rotor

(ii) Wound rotor or slip-ring

(iii) Double squirrel cage rotor induction motors. The principle of operation is same

for all types of induction motors.

PRINCIPLE OF OPERATION

When the stator or primary winding of 3-phase induction motor is connected to a 3-

phase ac supply, a rotating magnetic field is established which rotates at

synchronous speed. The direction of revolution of this field will depend upon the

phase sequence of the primary currents and, therefore, will depend upon the order

of connection of the primary terminals to the supply. The direction of rotation of the

field can be reversed by interchanging the connection to the supply of any two leads

of a 3-phase induction motor. The number of magnetic poles of the revolving field

will be the same as the number of poles for which each phase of the primary or

stator winding is wound. The speed at which the field produced by the primary

currents will revolve is called the synchronous speed of the motor and is given by an

expression, Ns = 120f/P

Where f is supply frequency and P is the number poles on stator.

The revolving magnetic field produced by the primary currents sweeps across the

rotor conductors and thereby induces an emf in these conductors. Since the rotor

windng is either directly shorted or closed through some external resistance, the emf

induced in the secondary by the revolving field causdes a current to flow in the rotor

conductors whose direction is such as to oppose the cause which is producing

it. Because the cause producing the induced currents is the relative speed between

the rotating magnetic field and the stationary rotor conductors, therefore, they

circulate in such a way that a torque is produced in the rotor tending to cause it to

follow the rotating magnetic field and thus reducing the relative speed.

An induction motor cannot run at synchronous speed. If it were possible, by some

means, for the rotor to attain synchronous speed, the rotor would then be standstill

with the respect to the rotating flux. Then no emf would be induced in the rotor, no

rotor current would flow, and therefore, there would be no torque developed.

An introduction motor running on no-load will have a speed very close to

synchronous speed and, therefore, emf induced in the rotor winding will be very

small. As the mechanical load is applied to the motor shaft, the motor slows down,

the relative motion between the rotating magnetic field and the rotor increases

causing increase in rotor emf, rotor current and so in the torque developed. Thus the

motor meets the increased load.

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- PaccarServiceManual2005 2010Document189 paginiPaccarServiceManual2005 2010Eric Porter100% (19)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Review Review Review Review M M M M Ssss OHE OHE OHE OHEDocument61 paginiReview Review Review Review M M M M Ssss OHE OHE OHE OHETushar100% (2)

- Lab Manual Switchgear and Protection SapDocument46 paginiLab Manual Switchgear and Protection SapYash MaheshwariÎncă nu există evaluări

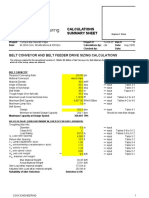

- Belt Conveyors With Shaft SizingDocument5 paginiBelt Conveyors With Shaft SizingRakhi Mor100% (2)

- Specs PyroLance L 1000 WG Sept 2015Document9 paginiSpecs PyroLance L 1000 WG Sept 2015Forum PompieriiÎncă nu există evaluări

- Gts-150 Operation Manual 08 VerDocument329 paginiGts-150 Operation Manual 08 VersunhuynhÎncă nu există evaluări

- American Wire Gauge (AWG)Document8 paginiAmerican Wire Gauge (AWG)Marija DjenicÎncă nu există evaluări

- LED Series ResistanceDocument10 paginiLED Series ResistanceKramyer Rabanillo100% (1)

- Weishaupt Valve Proving System VPS 504S2Document6 paginiWeishaupt Valve Proving System VPS 504S2diab ali100% (1)

- Mine Venting DuctDocument28 paginiMine Venting DuctSergej SchlegelÎncă nu există evaluări

- Bicycle Sprayer Machine: Major Project Report Submitted in Partial Fulfilment For The Award ofDocument24 paginiBicycle Sprayer Machine: Major Project Report Submitted in Partial Fulfilment For The Award ofashi ashiÎncă nu există evaluări

- Orbital X: Modular ProgramDocument48 paginiOrbital X: Modular Programshahrol effendy rodziÎncă nu există evaluări

- ML411A Solar Marine LanternDocument12 paginiML411A Solar Marine Lanternjetr19754106Încă nu există evaluări

- CONTRACT - JAP006-D73 132/11kV PALM, JUMEIRAH S/S (4 Nos) 11Kv Switchgear VT CalculationDocument6 paginiCONTRACT - JAP006-D73 132/11kV PALM, JUMEIRAH S/S (4 Nos) 11Kv Switchgear VT CalculationmadhavanÎncă nu există evaluări

- Brochure l45f t3 en 21 20000742 CDocument16 paginiBrochure l45f t3 en 21 20000742 CKonrad MatuszkiewiczÎncă nu există evaluări

- Technical Data: G2750SMU5Document3 paginiTechnical Data: G2750SMU5Wilman Elias Gutierrez RadaÎncă nu există evaluări

- List of Equipment: Procedures Manual On Utpras Unified TVET Program Registration and Accreditation SystemDocument3 paginiList of Equipment: Procedures Manual On Utpras Unified TVET Program Registration and Accreditation SystemRichardÎncă nu există evaluări

- Hazard Study 4 - Compress AirDocument12 paginiHazard Study 4 - Compress AirSaran rasayaÎncă nu există evaluări

- Rail Injector Girs12: FeaturesDocument2 paginiRail Injector Girs12: FeaturesAndrea VaccariÎncă nu există evaluări

- INIM Catalogo Incendio ENG Rev3.00 MediumRes PDFDocument76 paginiINIM Catalogo Incendio ENG Rev3.00 MediumRes PDFnedzadÎncă nu există evaluări

- Single PhasingDocument22 paginiSingle PhasingAakarsh Rastogi100% (2)

- Upmo, Ovcpd Uplb: The Electrical Services SectionDocument24 paginiUpmo, Ovcpd Uplb: The Electrical Services SectionMickiee OracionÎncă nu există evaluări

- Samsung ProRo4u TV Service ManualDocument174 paginiSamsung ProRo4u TV Service ManualAdrian AguilarÎncă nu există evaluări

- Various ToolRoomDocument18 paginiVarious ToolRoomToshang SharmaÎncă nu există evaluări

- Computer Systems ServicingDocument13 paginiComputer Systems ServicingLoli Gonzales ArtiagaÎncă nu există evaluări

- Capacitor Technologies Characterization Selection and Packaging For Next-Generation Power Electronics ApplicationsDocument11 paginiCapacitor Technologies Characterization Selection and Packaging For Next-Generation Power Electronics Applicationssueng666Încă nu există evaluări

- ZXM8 TPLDD120 600Document2 paginiZXM8 TPLDD120 600SOLUCIONES ENERGETICAS Y PROCESOS INNOVADORESÎncă nu există evaluări

- PSC LoadGuider Datasheet - 2020Document1 paginăPSC LoadGuider Datasheet - 2020Project Sales CorpÎncă nu există evaluări

- Airless TireDocument12 paginiAirless TireLaxmipriya SenapatiÎncă nu există evaluări

- Presentation PERU IEC Ex Brasil 2013-Set-18Document20 paginiPresentation PERU IEC Ex Brasil 2013-Set-18Oliver A. Chura QuispeÎncă nu există evaluări