Documente Academic

Documente Profesional

Documente Cultură

RB Biscuit Co Funding Request

Încărcat de

Jerome Naves TayawaDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

RB Biscuit Co Funding Request

Încărcat de

Jerome Naves TayawaDrepturi de autor:

Formate disponibile

RB BISCUIT CO.

ENTERPRISE ENHANCEMENT PLAN

&

FUNDING REQUEST

Small Business Corporation

InWent

Center for Small Entrepreneurs

September 2008

RG BISCUIT CO.

1. Executive Summary

RB Biscuit Co. is an offshoot of a previous business in the hard biscuit

industry. The proponent and main owner, Roque Belgado, had

previously been in the native hard biscuit business for 8 years.

However, because of certain circumstances the business was closed

down. Looking for a new partner, Belgado, was able to restart the

business under RB Biscuit Co.

The new company just produce one product, Paborita. It is a native

hard biscuit, circular in shape with a diameter of approximately 1¼

inches and around half an inch thick. It is baked in a brick oven thus

giving it a very distinct taste. RB Biscuit Co. prides itself that the taste

of its Paborita is 1 to 2 notches higher than competition. The hard

biscuit is packed at 12 pcs. per plastic pack. Each pack is sold at a

very affordable price of P10.00.

RB Biscuit Co. is located in Sta. Rosa Laguna. Its Paborita biscuit is

now sold in the provinces of Laguna, Batangas and Cavite, and in

Metro Manila. The company sells to snack food wholesalers in public

markets. The wholesalers, in turn, sell to retailers (sari-sari stores and

vendors), who then sells to the consuming public. In Metro Manila, RB

Biscuit Co. has a distributor who covers the whole of the National

Capital Region.

Over the past 2 years, Belgado has been able to grow RB Biscuit Co. to

a sales volume of over P8 million by tapping its old customers. Market

demand is growing but the company is unable to serve the

requirement because of lack of working capital.

RB Biscuit Co. plans to make a bold move to increase production and

sales from the current 3,000 bags per month to 5,600 bags per month

in the next 12 months. At the 3,000 bag level, production is only at

50%-60% capacity. RB Biscuit Co. would like to operate at the

maximum capacity of 5,800 bags per month on one shift. Except for

direct material costs, other expenses of the company will not

drastically increase by scaling up production from 3,000 bags per

month to 5,600 bags per month within the next 12 months. Thus RB

Biscuit Co. foresees increasing profits from P0.16 million per annum at

present to P1.25 million in the next 12 months.

Further, RB Biscuit Co. has targeted to increase production and sales to

11,000 bags per month to generate sales of P30 million in three years.

This can be done by increasing production, opening new markets, and

Sample Enterprise Enhancement Plan 2

RB Biscuit Co.

introducing a new product. The key to RB Biscuit Co.’s realization of its

3-year goal is increasing capacity immediately. But lack of funds is the

stumbling block. As such, RB Biscuit Co. is trying to secure a P500,000

loan to be used for working capital to scale up production.

2. Business Concept

Native biscuits started from the local “panaderya” or bakery. These

panaderyas started with baking breads such as pan de sal, pan de

limon, etc. To maximize use of the oven, the panaderyas or bakeries

started developing other baked food and snack items such as

ensaymada, pan de coco, monay, etc. These further expanded to

baking of hard native biscuits such as galletas, paborita, ogoy or ogoy-

ogoy, apas, etc.

Over time and with the intention of focusing on a market niche,

bakeries concentrated on just certain products. Some bakeries

completely stopped making bread and just baked various cookies and

biscuits. Because of financial constraints many small bakeries decided

to produce one or two products only. These small bakeries grew in

number. But this generated some positive effects. With just producing

a limited number of products, the bakery was able to improve the

quality of the product. And with its expertise in just baking and selling

a few products, these small bakeries were able to lower their costs and

ultimately the selling price.

RB Biscuit Co. is one of these small bakeries currently producing just

one product, Paborita, a hard biscuit.

3. Description of the Business

RB Biscuit Co. is an offshoot from a previous business. Roque Belgado

and his cousin, Joselito Villania, started a hard biscuit bakery business

in 1998 in Sta Rosa, Laguna. The bakery was set up in the lot owned

by Joselito Villania.

They produced basically two kinds of hard biscuits only, Paborita and

Ogoy-Ogoy (or Ogoy). Paborita is a circular biscuit around 1½ inches

in diameter and about half an inch thick. Ogoy-ogoy is a rectangular

biscuit ½ inch wide, around 2 inches long and half an inch thick and

topped with brown sugar. Both Paborita and Ogoy are snack foods

enjoyed by children and adults alike.

The hard biscuit business of Belgado and Villania grew. From Sta.

Rosa, Laguna, the cousins started distributing the biscuits to other

Laguna towns and then to neighboring provinces, reaching up to Metro

Sample Enterprise Enhancement Plan 3

RB Biscuit Co.

Manila. Villania was responsible for production, while Belgado handled

marketing. The biscuits were sold in volume to wholesalers, who in

turn sell the biscuits to retailers such as sari-sari stores or vendors.

The hard biscuits the pair baked tasted very good which is the reason

for its growth. The secret to the good taste, aside from the mixture,

was in the baking. While most of the biscuit makers now use LPG

ovens, Belgado & Villania still baked their biscuits in a brick oven which

gives it a very distinct taste.

In 2004, Villania became very sick. He could not oversee production

properly and as the months past he fell deep into debt. With

production being erratic, the business started incurring losses. Finally

in 2005, the cousins agreed to shut down the business.

Seeing the potential of the business, Belgado started looking for other

partners. He felt that with his seven years in the business and with

properly trained staff he can handle already both production and

marketing. Belgado was able to convince a long-time friend, Rodolfo

Santiago to invest in the business. Santiago infused some capital and

agreed to lend the business a loan.

In 2007, Belgado and Santiago set-up and registered RB Biscuit Co. It

was decided to just make the Paborita biscuit first and just expand as

the years go by. Belgado hired a good baker and kneader to ensure

that the taste of the previous Paborita biscuit is replicated. He then

visited all their former wholesalers and distributors, was able to

convince them and was able to get orders. He also started opening up

new markets. The company now sells the Paborita biscuit in Laguna,

Batangas and Cavite. The company has a distributor who was given

the right to solely distribute the product in Metro Manila.

The Paborita is packed in plastic bags at 12 pcs. per pack. It is then

packed in big plastic bags at 30 packs per bag. The biscuit is sold to

wholesalers at P7.50 per pack or P225 per bag. The biscuit is sold

retail at P10.00 per pack.

The bakery is operating only at around 50%-60% capacity. Belgado

sees that the company can sell in other municipalities and even

possibly move south east to Quezon and Bicol areas. The company

plans to increase production by 40% within the next 12 months.

4. Vision of the Business

In three years, RB Biscuit Co. sees itself to be delivering hard biscuits

from Metro Manila, through the Southern Tagalog region and then into

Sample Enterprise Enhancement Plan 4

RB Biscuit Co.

the Bicol area. It will retain its distribution method of selling to

wholesalers in public markets or assigning distributors in certain

localities. This way it does not need to maintain its own extensive

sales force.

RB Biscuit Co. also intends to increase the number of biscuits it

produces. Aside from the Paborita, the company intends to produce

already the Ogoy-ogoy. The baking process is basically the same. The

only difference is that brown sugar is sprinkled on the Ogoy-ogoy prior

to baking.

RB Biscuit Co. is targeting to increase its sales volume from the current

P8 million to P30 million in three years, with a net income objective of

P2.6 million. The company sees the potential for growth especially in

these hard times. Because of rising costs of most products, consumers

are now more “Peso”-conscious. They are looking for cheaper

products and substitutes but which will give them almost the same

value and satisfaction. RB Biscuit Co. projects that , as long as wheat

flour prices do not drastically increase, it can maintain its low selling

price. With its good taste and low price, RB Biscuit Co. projects that its

sales will continually increase.

To be able to realize this 3-year vision of RB Biscuit Co. it needs to

expand operations at once. However, currently RB Biscuit Co. does not

have enough funds to purchase additional equipment and for the

needed increased working capital. As such, the company is trying on

securing a P500,000 loan from a financial institution. When the

business increases its production and sales capacity, the cash flow will

be very positive as will be shown at the latter part of this Enterprise

Enhancement Plan. However, in order to be able to achieve this

positive cash flow, additional funds have to be infused to be able to

scale up production immediately.

5. Marketing Plan

RB Biscuit Co. is duplicating the business model employed by Belgado

and Villania in their previous partnership. This has proven to be

successful before, and the company does not see problems in

replicating the previous business.

a. Product

Although the facilities of RB Biscuit Co. can produce a variety of

biscuits, it decided to just produce one product first, the Paborita

hard biscuit. The reasons for this move are:

Sample Enterprise Enhancement Plan 5

RB Biscuit Co.

- the company’s production staff has already mastered the

process;

- the company does not have the facilities to produce the more

expensive biscuits; and

- the company is targeting the bigger C-D-E market.

However, RB Biscuit Co. sees that it is now time to produce also

Ogoy-ogoy. The mixture and baking process of both Paborita

and Ogoy-ogoy is basically the same.

Paborita is a circular biscuit around 1½ inches in diameter and

about half an inch thick. Ogoy-ogoy is an elongated biscuit ½

inch wide, around 2 inches long and half an inch thick and

sprinkled at the top with brown sugar.

The biscuits are packed at 12 pcs. per pack. Then 30 packs are

placed in a big plastic bag. These are sold in bags to wholesalers

and retailers. The company does not sell by the pack.

Both products will be positioned as a cheap yet delicious snack

food. Previous feedback received that it was good with coffee or

soft drinks.

There are over a dozen bakeries making Paborita, but most of

these do not distribute the product extensively. In the Metro

Manila and Southern Tagalog area, RB Biscuit Co.’s main

competitors are Zee Bakery in Batangas, Pedro Co from Mindoro

and Variety Snacks from Bulacan.

Zee Bakery and Pedro Co sells a variety of bakery products aside

from the hard biscuits. Variety Snacks produces only hard

biscuits. Zee Bakery and Pedro Co uses an LGP oven and RB

Biscuit Co. does not see them as much of a threat in terms of

taste and quality of the biscuit. Variety Snack uses a brick oven,

but feedback from wholesalers in the public markets, the

perception is that RB Biscuit Co.’s Paborita tastes better.

Another major difference between RB Biscuit Co.’s Paborita and

that of Variety Snacks is the size of the product and packaging.

Variety Snacks’ Paborita is larger at around 2 inches. Further, RB

Biscuit Co.’ packs Paborita in 50 grams, while Variety Snacks

packs their biscuit in 80 grams.

b. Price

Sample Enterprise Enhancement Plan 6

RB Biscuit Co.

The Paborita and Ogoy-ogoy biscuits of RB Biscuit Co. shall be

retailed at P10.00 per pack. The recommended pricing scheme

is as follows:

For Wholesalers

Per Pack Per Bag

Factory price 7.50 225.00

Wholesaler’s mark-up .75 22.50

Price to retailers 8.25 247.50

Retailer’s mark-up 1.75 52.50

Retail Price 10.00 300.00

For Distributors

Per Pack Per Bag

Factory price 7.50 225.00

Distributor’s mark-up .25 7.50

Price to wholesaler 7.75 232.50

Wholesaler’s mark-up .50 15.00

Price to retailers 8.25 247.50

Retailer’s mark-up 1.75 60.00

Retail Price 10.00 300.00

The retail prices of RB Biscuit Co.’s competitors are as follows:

- Zee Bakery - P8.00/pack (50 grams)

- Pedro Co - P10.00/pack (50 grams)

- Variety Snacks - P15.00/pack (80 grams)

RB Biscuit Co. does not assess Zee Bakery and Pedro Co as

serious threats because of product quality. Their biscuits are

baked in LPG ovens and the taste is not as good as biscuits

baked in a brick oven. Variety Snack is more of the major

competitor. Effectively Variety Snack’s biscuit costs P0.1875 per

piece, while that of RB Biscuit Co. is P0.20 per piece. However, it

is assessed that it would be lighter for a consumer to shed off

P10 for a snack versus P15. Thus, RB Biscuit Co. decided that it

will not match Variety Snack’s packaging size.

c. Place

RB Biscuit Co. does not sell retail to the general public. Instead

the Paborita is sold in bags of 30 packs to wholesalers and

distributors. In the provinces of Laguna, Batangas and Cavite,

Sample Enterprise Enhancement Plan 7

RB Biscuit Co.

there are wholesalers in public markets. There is no exclusivity

for a wholesaler. Thus in a public market there can be more than

one wholesaler of the Paborita. If a particular wholesaler asks for

exclusivity, RB Biscuit Co. assesses the potential of the particular

market and gives the wholesaler a weekly quota.

Retailers, such as sari-sari stores and snacks vendors, buy the

biscuit from the wholesaler also on a per bag basis. The retailers

then sell directly to the public.

In Sta. Rosa, Laguna, retailers can buy directly from the company

at the factory price of P225/bag pick-up. This does not affect the

wholesalers in Sta. Rosa, Laguna because the biscuits are

delivered to the wholesalers, whereas the retailer has to spend

for transportation to pick up the bags of biscuits.

For Metro Manila, a distributor was assigned. The distributor has

exclusive rights to sell in Metro Manila. RB Biscuit Co. does not

sell to the wholesalers in the public markets in Metro Manila. The

distributor in Metro Manila distributes to the wholesalers at his

own expense. Aside from the Paborita of RB Biscuit Co., the

distributor also carries various snack food items.

d. Promotion

The company does not do any promotion. The wholesalers are

requested to tell retailers to tell the consumers to just serve the

Paborita in replacement for sandwiches in funerals and

gatherings. It comes out cheaper.

6. Sales Plan

Currently, RB Biscuit Co.’s monthly sales volume is only 3,000 bags.

The brick oven and production capacity can produce a maximum of

5,824 bags per month in one 8-hour shift. The potential maximum

production capacity of RB Biscuit Co. is 17,471 bags per month

operating at three shifts. At P225 per bag, maximum potential sales of

RB Biscuit Co. is P3.9 million per month or P47 million per year.

At its current production volume, RB Biscuit Co.’s profits is only

P160,000 per year. However, at full capacity, profitability can be as

high as P3.4 million per year. ANNEX A shows the Sales and Costs Plan

for RB Biscuit Co.’s current production and sales volume of 3,000 bags

per month. ANNEX B shows the profitability picture at a production

and sales volume of 5,824 bags per month.

Sample Enterprise Enhancement Plan 8

RB Biscuit Co.

This is the sales objective of RB Biscuit Co., to increase sales from the

current 3,000 bags of Paborita per month to 5,600 bags per month on

a combination of Paborita and Ogoy-ogoy for the first year.

The oven is currently being used at only 50%-60% capacity. At

present, there are only 5-8 baking cycles per day, whereas the oven

can be run for 14-16 baking cycle per 8-hour day. There is still a lot of

oven capacity to accommodate the projected 40% increase in

production. Thus there will be no major investment required.

The production staff of RB Biscuit Co. are paid on a daily basis based

on an 8-hour work, even if there are only 5-8 baking cycles per day.

The workers are paid the full 8 hours wages but effectively providing

only 4 hours of work. Thus the increase in production capacity will also

not drastically increase production staff salaries and wages.

RB Biscuit Co. has an ambitious plan of producing and selling 11,000

bags per month of Paborita and Ogoy-ogoy in three years. This will

result in a annual sales volume of P30 million. ANNEX C details the

sales expansion program of RB Biscuit Co. for the next three years.

7. Production

To produce Paborita, wheat flour, sugar, yeast and a little cooking oil is

mixed in a heavy duty, industrial-type mixer. The Paborita mixture is

allowed to set for a few minutes then is passed to the kneader so that

the desired consistency is reached for the whole mixture. The Paborita

mixture passes through the kneader a number of times then laid on

the cutting table. A cutting die is used so that in one cut 192 pcs. are

made. The excess mixture is sent back to the kneader.

The formed Paborita rounds are then laid out on baking trays. The

baking trays match the cutting dies such that each baking tray

accommodates 192 pcs. A little cooking oil is wiped on the baking

trays prior to laying of the Paborita rounds.

The trays are then placed in the brick oven for baking. The oven can

accommodate 30 trays in one baking cycle. The Paborita is then baked

for 20 minutes. Wood is used as fuel and this gives RB Biscuit Co.’s

Paborita a distinctive taste. The mixer, the person who operates the

mixer, is also the baker.

When baked, the Paborita are placed in biscuit bins were it is cooled

then packed in small plastic packs at 12 pcs. per pack. The Paborita

packs are then placed in a big plastic bag at 30 packs per bag. The

Paborita bags are then stored for the next delivery.

Sample Enterprise Enhancement Plan 9

RB Biscuit Co.

ANNEX D shows the Business Process Workflow of the Paborita

business.

8. Business Requirements

a. Staffing and Costs

The Production Section of the business shall have a total of 9

employees. The Production Supervisor and 8 workers.

The Administration and Sales Section is headed by Gina Belgado,

the wife of Roque Belgado. She has a staff of 5 employees.

Roque Belgado is President of the company.

The staffing compliment of the business and the salary schedule

is shown in ANNEX E.

The staff costs will not drastically increase even if production in

increased from 3,000 bags per month to 5,600 bags per month.

Actually the current production staff is overpaid. Actual work

done is only about 4-5 hours but they are still paid for an 8-hour

day.

b. Business Organization

The organizational structure of RB Biscuit Co. is very simple and

lean. This is shown below.

President

Roque Belgado

Administration & Sales Manager Production Supervisor

Gina Belgado Jose Icayan

Secretary/ Admin Clerk Mixer/ Baker

Bookkeeper Kneader/ Cutter

Driver / Sales Assistant Kneader

Delivery Helper Packers (3)

Sample Enterprise Enhancement Plan 10

RB Biscuit Co.

Utility Sealer/ Packer

Stockman/ Bagger

Roque Belgado, as President, has general management

responsibility. Though the Sales function is directly under the

Administration & Sales Manager, Roque Belgado shall be deeply

involved in Marketing. He will principally be responsible for

opening new markets.

Gina Belgado, the Administration and Sales Manager, shall be

responsible for the office.

Jose Icayan, who was the baker in the previous bakery of Belgado

with his cousin, will be responsible for production.

c. Equipment

The company‘s equipment and other assets, exclusive of the

land, are enumerated in ANNEX F, including the value for each.

The critical equipment for RB Biscuit Co. is the brick oven. The

oven structure itself is good for 10 years. However, every 3-5

years the brick lining have to be replaced depending on the use

of the oven and this is a substantial investment. The current

oven’s bricks are still good for another 2 years.

d. Space Requirement

The bakery, where RB Biscuit Co. is presently operating, was the

facility used when Belgado and Villania were still partners.

Belgado offered to buy the land and the bakery within the

property. The loan provided by Rodolfo Santiago was used to

buy the land and all the physical structures, including the brick

oven.

The bakery layout is shown in ANNEX G.

The lot still has some empty and unused space. If business

demand increases drastically, the bakery can be expanded with

the construction of another brick oven.

e. Other Costs

Sample Enterprise Enhancement Plan 11

RB Biscuit Co.

The Projected Other Costs (operating costs) of the business for

the next 12 months is shown in ANNEX H. The major operating

expenses are power, gas/delivery and taxes & licenses. In the

direct material costings, the water used as direct material is for

the biscuit mixture. The water in Other Costs is for equipment &

facilities washing and human cleansing use.

f. Business Inputs

The projected raw material (business inputs) requirements for

the next 12 months are enumerated in ANNEX I. The raw

material requirements are based on the increasing production

during the year. The major raw material component is the wheat

flour and the wood used as fuel in the brick oven.

g. Material Costs

The costs of the business inputs enumerated in (f) above is

shown in ANNEX J.

h. Depreciation

The depreciation computation of the company’s physical assets

is shown in the depreciation table in ANNEX K.

i. Interest Cost

The company has a P1.5 million loan from Rodolfo Santiago. This

carries an interest of 15% per annum and payable over a 3-year

period. Twenty one (21) amortizations have already been paid

by RB Biscuit Co. and only 15 months remain. The interest costs

and amortization computation table for the next 12 months is

shown in ANNEX L.

8. Sales and Costs Plan

The Sales and Costs Plan (or Projected Income Statement) of RB Biscuit

Co. for the next 12 months is shown in ANNEX M. Based on the Sales

and Costs Plan, the company is targeting to increase production and

sales to 5,600 bags per month of Paborita and Ogoy-ogoy. The

projected revenues for the next 12 months is P14 million which will

earn a projected net profit of around P1.25 million. This is expected to

be realized with almost all expenses not drastically increasing except

for direct materials.

9. Cash Flow Plan

Sample Enterprise Enhancement Plan 12

RB Biscuit Co.

The Cash Flow Plan for the next 12 months is shown in ANNEX N.

Based on the cash flow plan, the business will not experience funds

problem for its operations provided that it can scale up production and

sales immediately with the infusion of around P500,000 in funds.

The achievement of the cash flow plan, aside from increasing sales, is

based on collection efficiency. The company has not really

experienced major collection problems, mainly because of its one-

up/one-down delivery and collection policy. Products delivered on the

first week have to be paid by the next delivery. If the client does not

pay for the previous weeks’ orders, the products for the second week

are not given to him.

10. Conclusion - Intent

Based on the evaluation of the market, the business has potential to

generate more profits. However, this is premised on scaling up

production and sales immediately. Clients’ demand has been

increasing but RB Biscuit Co. lacks the funds to be able to increase

production at once. Other wholesalers in current public markets that

the company serves have been asking that RB Biscuit Co. also deliver

to them. Further, the company assesses that it can penetrate other

public markets in other municipalities or cities.

Secondly, the company plans to start making a second product, the

Ogoy-ogoy biscuit. The technology for producing Ogoy-ogoy is

basically the same as in the Paborita production. Further, since RB

Biscuit Co. already has the distribution set-up for its Paborita, the

Ogoy-ogoy will just piggy-back on this distribution system.

It is the intention of RB Biscuit Co. to borrow P500,000 to fund this

expansion program. Given the funds, the company can immediately

scale up production and serve the increasing market. Once the

increased sales are realized, RB Biscuit Co. will be very cash positive as

shown in the Cash Flow Plan. The main reason it is experiencing cash

flow problems is because it is operating below capacity. Once

production capacity is optimized, then much cash will flow in.

ANNEX O shows the amortization table for a P500,000 loan at an

interest of 12% p.a. and payable over a 2-year period. RB Biscuit Co.’s

Cash Flow Plan shows that the company can easily pay for the monthly

installments of P23,000. Further, the sales and costs plan also shows

that it can absorb the interest on the loan.

Sample Enterprise Enhancement Plan 13

RB Biscuit Co.

RB Biscuit Co. knows that it can grow and expand. All it needs is a

little credit facility to move forward.

Sample Enterprise Enhancement Plan 14

RB Biscuit Co.

ANNEX A

RB BISCUIT CO.

SALES & COSTS PLAN - PABORITA - CURRENT OPERATIONS

Month

1 2 3 4 5 6 7 8 9 10 11 12 Annual

Sales:

Quantity-Paborita (bags) 3,000 3,000 3,000 3,000 3,000 3,000 3,000 3,000 3,000 3,000 3,000 3,000 36,000

Quantity-Ogoy-ogoy (bags) 0 0 0 0 0 0 0

Wholesale Price per Bag 225 225 225 225 225 225 225 225 225 225 225 225

TOTAL SALES 675,000 675,000 675,000 675,000 675,000 675,000 675,000 675,000 675,000 675,000 675,000 675,000 8,100,000

Direct Material Costs - Paborita 303,941 303,941 303,941 303,941 303,941 303,941 303,941 303,941 303,941 303,941 303,941 303,941 3,647,293

Direct Material Costs - Ogoy-ogoy - - - - - - 0

Direct Labor Costs 55,453 55,453 55,453 55,453 55,453 55,453 55,453 55,453 55,453 55,453 55,453 55,453 665,440

TOTAL DIRECT COSTS 359,394 359,394 359,394 359,394 359,394 359,394 359,394 359,394 359,394 359,394 359,394 359,394 4,312,733

GROSS MARGIN 315,606 315,606 315,606 315,606 315,606 315,606 315,606 315,606 315,606 315,606 315,606 315,606 3,787,267

Indirect Costs

Staff Costs 73,213 73,213 73,213 73,213 73,213 73,213 73,213 73,213 73,213 73,213 73,213 73,213 878,560

Other Costs 60,500 60,500 60,500 60,500 60,500 60,500 60,500 60,500 60,500 60,500 60,500 60,500 726,000

Depreciation 154,873 154,873 154,873 154,873 154,873 154,873 154,873 154,873 154,873 154,873 154,873 154,873 1,858,480

TOTAL INDIRECT COSTS 288,587 288,587 288,587 288,587 288,587 288,587 288,587 288,587 288,587 288,587 288,587 288,587 3,463,040

NET PROFIT BEFORE

FINANCING 27,019 27,019 27,019 27,019 27,019 27,019 27,019 27,019 27,019 27,019 27,019 27,019 324,227

Interest Costs 9,373 8,840 8,301 7,754 7,201 6,641 6,074 5,500 4,919 4,331 3,735 3,131 75,801

NET PROFIT FROM OPERATIONS 17,646 18,179 18,718 19,265 19,818 20,378 20,945 21,519 22,100 22,688 23,284 23,887 248,426

Provision for Income Tax 6,176 6,363 6,551 6,743 6,936 7,132 7,331 7,532 7,735 7,941 8,149 8,361 86,949

NET PROFIT 11,470 11,816 12,167 12,522 12,881 13,245 13,614 13,987 14,365 14,747 15,135 15,527 161,477

Sample Enterprise Enhancement Plan 15

RB Biscuit Co.

ANNEX B

RB BISCUIT CO.

SALES & COSTS PLAN - PABORITA - ONE-SHIFT MAXIMUM CAPACITY

Month

1 2 3 4 5 6 7 8 9 10 11 12 Annual

Sales:

Quantity-Paborita (bags) 5,824 5,824 5,824 5,824 5,824 5,824 5,824 5,824 5,824 5,824 5,824 5,824 69,888

Quantity-Ogoy-ogoy

(bags) 0 0 0 0 0 0 0

Wholesale Price per Bag 225 225 225 225 225 225 225 225 225 225 225 225

1,310, 1,310, 1,310, 1,310, 1,310, 1,310, 1,310, 1,310, 1,310, 1,310, 1,310, 1,310, 15,724,80

TOTAL SALES 400 400 400 400 400 400 400 400 400 400 400 400 0

Direct Material Costs - 397,2 397,2 397,2 397,2 397,2 397,2 397, 397, 397, 397, 397, 397,

Paborita 46 46 46 46 46 46 246 246 246 246 246 246 4,766,952

Direct Material Costs - Ogoy-

ogoy - - - - - - 0

Direct Labor Costs 76,662 76,662 76,662 76,662 76,662 76,662 76,662 76,662 76,662 76,662 76,662 76,662 919,944

473, 473, 473, 473, 473, 473, 473, 473, 473, 473, 473, 473,

TOTAL DIRECT COSTS 908 908 908 908 908 908 908 908 908 908 908 908 5,686,896

836, 836, 836, 836, 836, 836, 836, 836, 836, 836, 836, 836, 10,037,90

GROSS MARGIN 492 492 492 492 492 492 492 492 492 492 492 492 4

Indirect Costs

92,9 92,9 92,9 92,9 92,9 92,9 92,9 92,9 92,9 92,9 92,9 92,9

Staff Costs 11 11 11 11 11 11 11 11 11 11 11 11 1,114,928

108, 108, 108, 108, 108, 108, 108, 108, 108, 108, 108, 108,

Other Costs 208 208 208 208 208 208 208 208 208 208 208 208 1,298,496

189, 189, 189, 189, 189, 189, 189, 189, 189, 189, 189, 189,

Depreciation 073 073 073 073 073 073 073 073 073 073 073 073 2,268,880

390, 390, 390, 390, 390, 390, 390, 390, 390, 390, 390, 390, 4,682,30

TOTAL INDIRECT COSTS 192 192 192 192 192 192 192 192 192 192 192 192 4

NET PROFIT BEFORE 446, 446, 446, 446, 446, 446, 446, 446, 446, 446, 446, 446, 5,355,60

FINANCING 300 300 300 300 300 300 300 300 300 300 300 300 0

9,3 8,8 8,3 7,7 7,2 6,6 6,0 5,5 4,9 4,3 3,7 3,1 75,80

Interest Costs 73 40 01 54 01 41 74 00 19 31 35 31 1

NET PROFIT FROM 436, 437, 437, 438, 439, 439, 440, 440, 441, 441, 442, 443, 5,279,79

OPERATIONS 927 460 999 546 099 659 226 800 381 969 565 169 9

Sample Enterprise Enhancement Plan 16

RB Biscuit Co.

152, 153, 153, 153, 153, 153, 154, 154, 154, 154, 154, 155, 1,847,93

Provision for Income Tax 925 111 300 491 685 881 079 280 483 689 898 109 0

284, 284, 284, 285, 285, 285, 286, 286, 286, 287, 287, 288, 3,431,8

NET PROFIT 003 349 700 055 414 778 147 520 898 280 667 060 69

Sample Enterprise Enhancement Plan 17

RB Biscuit Co.

ANNEX C

RB BISCUIT CO.

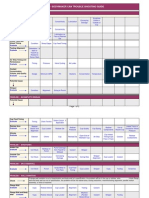

CUSTOMERS & SALES

Year 1 Target Sales - Year 2 Target Sales - Year 3 Target Sales –

PABORITA Current Sales - PABORITA PABORITA PABORITA PABORITA

Pri Pri

Bag Bag Pric Bag Bag Pric Bag Bag ce/ Bag ce/

CUSTOMERS / s/ s/ e/ Sales/ s/ s/ e/ Sales/ s/ s/ Ba Sales/ s/ Bags Ba Sales/

OUTLETS Wk Mo Bag Mo. Wk Mo Bag Mo. Wk Mo g Mo. Wk / Mo g Mo.

LAGUNA LAGUNA

Sta. Rosa 10 40 22 90, Sta. Rosa 22 117,00

1 (factory) 0 0 5 000 1 (factory) 120 480 225 108,000 130 520 5 0 140 560 225 126,000

6 24 22 54, 22

2 Biñan 0 0 5 000 2 Biñan 70 280 225 63,000 80 320 5 72,000 90 360 225 81,000

8 32 2 72, 22

3 Cabuyao 0 0 25 000 3 Cabuyao 90 360 225 81,000 100 400 5 90,000 110 440 225 99,000

8 32 2 72, 22

4 Calamba 0 0 25 000 4 Calamba 90 360 225 81,000 100 400 5 90,000 110 440 225 99,000

4 16 2 36, San 22

5 San Pablo 0 0 25 000 5 Pablo 50 200 225 45,000 60 240 5 54,000 70 280 225 63,000

Los 22

6 Baños 20 80 225 18,000 30 120 5 27,000 40 160 225 36,000

22

7 Alaminos 20 80 225 18,000 30 120 5 27,000 40 160 225 36,000

Total- 3 1,4 Total- 1,84 2,12 477,00 2,40

Laguna 60 40 Laguna 460 0 414,000 530 0 0 600 0 540,000

BATANGA BATANG

S AS

Batangas

Batangas 9 36 2 81, & Lipa 22 108,00

6 & Lipa City 0 0 25 000 8 City 100 400 225 90,000 120 480 5 0 130 520 225 117,000

Sto. 6 24 2 54, Sto. 22

7 Tomas 0 0 25 000 9 Tomas 70 280 225 63,000 80 320 5 72,000 90 360 225 81,000

2 8 2 18, 1 22

8 Tanauan 0 0 25 000 0 Tanauan 30 120 225 27,000 30 120 5 27,000 40 160 225 36,000

1 22

1 San Juan 0 225 0 20 80 5 18,000 30 120 225 27,000

1 22

2 Ibaan 0 225 0 20 80 5 18,000 30 120 225 27,000

Total- 17 68 Total- 1,08 243,00 1,28

Batangas 0 0 Batangas 200 800 180,000 270 0 0 320 0 288,000

Sample Enterprise Enhancement Plan 18

RB Biscuit Co.

CAVITE CAVITE

4 16 2 36, 1 22

9 Carmona 0 0 25 000 3 Carmona 50 200 225 45,000 60 240 5 54,000 70 280 225 63,000

1 4 16 2 36, 1 22

0 GMA 0 0 25 000 4 GMA 50 200 225 45,000 60 240 5 54,000 70 280 225 63,000

1 Trece 2 8 2 18, 1 Trece 22

1 Martires 0 0 25 000 5 Martires 30 120 225 27,000 40 160 5 36,000 50 200 225 45,000

1 2 8 2 18, 1 22

2 Silang 0 0 25 000 6 Silang 30 120 225 27,000 40 160 5 36,000 50 200 225 45,000

1 22

7 Naic 10 40 225 9,000 20 80 5 18,000 30 120 225 27,000

1 22

8 Indang 10 40 225 9,000 20 80 5 18,000 30 120 225 27,000

1 22

9 Alfonso 10 40 225 9,000 20 80 5 18,000 30 120 225 27,000

Total- 15 48 Total- 1,04 234,00 1,32

Cavite 0 0 Cavite 190 760 171,000 260 0 0 330 0 297,000

METRO METRO

MANILA MANILA

1 Jun 10 40 2 90, 2 Jun 22 135,00

3 Villania 0 0 25 000 0 Villania 120 480 225 108,000 150 600 5 0 180 720 225 162,000

MINDOR

O

2 22

1 Calapan 0 225 0 0 5 0 30 120 225 27,000

2 Puerto 22

2 Galera 0 225 0 0 5 0 30 120 225 27,000

Total

-Mindoro 0 0 0 0 0 0 60 240 54,000

QUEZON

2 22

3 Sariaya 10 40 225 9,000 20 80 5 18,000 30 120 225 27,000

2 22

4 Tiaong 10 40 225 9,000 20 80 5 18,000 30 120 225 27,000

2 Candelar 22

5 ia 10 40 225 9,000 20 80 5 18,000 30 120 225 27,000

2 22

6 Lucena 10 40 225 9,000 20 80 5 18,000 30 120 225 27,000

Total-

Quezon 40 160 36,000 80 320 72,000 120 480 108,000

CAMARINES

NORTE

Sample Enterprise Enhancement Plan 19

RB Biscuit Co.

2 Sta. 22

7 Elena 0 225 0 20 80 5 18,000 30 120 225 27,000

2 22

8 Labo 0 225 0 20 80 5 18,000 30 120 225 27,000

2 22

9 Daet 0 225 0 20 80 5 18,000 30 120 225 27,000

Total-

Cam

Norte 0 0 0 60 240 54,000 90 360 81,000

7 3,0 675, 1,0 4,0 1,3 5,4 1,215, 1,7 6,80 1,530,

TOTAL 80 00 000 TOTAL 10 40 909,000 50 00 000 00 0 000

ANNUAL SALES - 8,100, 10,908 14,580 18,360

PABORITA 000 ,000 ,000 ,000

Current Sales - OGOY- Year 1 Target Sales-OGOY- Year 2 Target Sales- Year 3 Target Sales-OGOY-

OGOY-OGOY OGOY OGOY OGOY-OGOY OGOY

Pri Pri

Bag Bag Pric Bag Bag Pric Bag Bag ce/ Bag ce/

CUSTOMERS / s/ s/ e/ Sales/ s/ s/ e/ Sales/ s/ s/ Ba Sales/ s/ Bags Ba Sales/

OUTLETS Wk Mo Bag Mo. Wk Mo Bag Mo. Wk Mo g Mo. Wk / Mo g Mo.

LAGUNA LAGUNA

Sta. Rosa Sta. Rosa 22

1 (factory) 1 (factory) 50 200 225 45,000 70 280 5 63,000 90 360 225 81,000

22

2 Biñan 2 Biñan 30 120 225 27,000 50 200 5 45,000 60 240 225 54,000

22

3 Cabuyao 3 Cabuyao 30 120 225 27,000 50 200 5 45,000 60 240 225 54,000

22

4 Calamba 4 Calamba 30 120 225 27,000 50 200 5 45,000 60 240 225 54,000

San 22

5 San Pablo 5 Pablo 20 80 225 18,000 30 120 5 27,000 40 160 225 36,000

Los 22

6 Baños 0 225 0 20 80 5 18,000 30 120 225 27,000

22

7 Alaminos 0 225 0 20 80 5 18,000 30 120 225 27,000

Total- Total- 1,16 261,00 1,48

Laguna Laguna 160 640 144,000 290 0 0 370 0 333,000

BATANGA BATANG

S AS

Sample Enterprise Enhancement Plan 20

RB Biscuit Co.

Batangas

Batangas & Lipa 22

6 & Lipa City 8 City 50 200 225 45,000 70 280 5 63,000 90 360 225 81,000

Sto. Sto. 22

7 Tomas 9 Tomas 30 120 225 27,000 40 160 5 36,000 50 200 225 45,000

1 22

8 Tanauan 0 Tanauan 20 80 225 18,000 30 120 5 27,000 40 160 225 36,000

1 22

1 San Juan 0 225 0 10 40 5 9,000 20 80 225 18,000

1 22

2 Ibaan 0 225 0 10 40 5 9,000 20 80 225 18,000

Total- Total- 144,00

Batangas Batangas 100 400 90,000 160 640 0 220 880 198,000

CAVITE CAVITE

1 22

9 Carmona 3 Carmona 20 80 225 18,000 30 120 5 27,000 40 160 225 36,000

1 1 22

0 GMA 4 GMA 20 80 225 18,000 30 120 5 27,000 40 160 225 36,000

1 Trece 1 Trece 22

1 Martires 5 Martires 20 80 225 18,000 30 120 5 27,000 40 160 225 36,000

1 1 22

2 Silang 6 Silang 20 80 225 18,000 30 120 5 27,000 40 160 225 36,000

1 22

7 Naic 0 225 0 10 40 5 9,000 20 80 225 18,000

1 22

8 Indang 0 225 0 10 40 5 9,000 20 80 225 18,000

1 22

9 Alfonso 0 225 0 10 40 5 9,000 20 80 225 18,000

Total- Total- 135,00

Cavite Cavite 80 320 72,000 150 600 0 220 880 198,000

METRO METRO

MANILA MANILA

1 Jun 2 Jun 22

3 Villania 0 Villania 60 240 225 54,000 80 320 5 72,000 120 480 225 108,000

MINDOR

O

2 22

1 Calapan 0 225 0 0 5 0 30 120 225 27,000

2 Puerto 22

2 Galera 0 225 0 0 5 0 30 120 225 27,000

Total

-Mindoro 0 0 0 0 0 60 240 54,000

Sample Enterprise Enhancement Plan 21

RB Biscuit Co.

QUEZON

2 22

3 Sariaya 0 225 0 10 40 5 9,000 20 80 225 18,000

2 22

4 Tiaong 0 225 0 10 40 5 9,000 20 80 225 18,000

2 Candelar 22

5 ia 0 225 0 10 40 5 9,000 20 80 225 18,000

2 22

6 Lucena 0 225 0 10 40 5 9,000 20 80 225 18,000

Total-

Quezon 0 0 0 40 160 36,000 80 320 72,000

CAMARINES

NORTE

2 Sta. 22

7 Elena 0 225 0 10 40 5 9,000 20 80 225 18,000

2 22

8 Labo 0 225 0 10 40 5 9,000 20 80 225 18,000

2 22

9 Daet 0 225 0 10 40 5 9,000 20 80 225 18,000

Total-

Cam

Norte 0 0 0 30 120 27,000 60 240 54,000

1,6 3,0 675,00 1,1 4,52 1,017,

TOTAL TOTAL 400 00 360,000 750 00 0 30 0 000

ANNUAL SALES - OGOY- 4,320,0 8,100, 12,204

OGOY 00 000 ,000

1,4 5,6 2,1 8,4 2,8 11,3

GRAND TOTAL - BAGS 10 40 00 00 30 20

GRAND TOTAL - MONTHLY 1,269,0 1,890, 2,547,

SALES 00 000 000

GRAND TOTAL - ANNUAL 15,228, 22,680 30,564

SALES 000 ,000 ,000

Sample Enterprise Enhancement Plan 22

RB Biscuit Co.

ANNEX D

RB BISCUIT CO.

BUSINESS PROCESS WORKFLOW

Planning:

Prod Plan

Marketing Purchasing

Delivery Collection

Cutting & Packing &

Mixing Kneading Lay out Baking Packaging

Production / OperatIons

Administration / Management

Sample Enterprise Enhancement Plan 23

RB Biscuit Co.

ANNEX E

STAFF COSTS

STAFF REQUIREMENT STAFF COSTS

SSS, PH, PI

Basic Salary 13th Total Salary Total Salary

No. Designation Qualification (12% of

Per Month Month Pay Per Month Per Year

Basic)

Production Staff

1 Production Supv. 12,000 1,440 1,000 14,440 173,280

2 Mixer/Baker 10,000 1,200 833 12,033 144,400

3 Kneader/Cutter 7,800 936 650 9,412 112,944

4 Asst. Kneader 6,500 780 542 7,848 94,172

5 Packers (3) 15,600 1,872 1,300 18,798 225,576

6 Sealer/Packer 5,720 686 477 6,909 82,909

7 Stockman/Bagger 5,980 718 498 7,222 86,663

TOTAL 76,662 919,944

Administration & Marketing Staff

1 President 30,000 3,600 2,500 36,100 433,200

2 Admin & Sales Mgr. 20,000 2,400 1,667 24,067 288,800

3 Sec/Admin Clerk 7,280 874 607 8,786 105,435

4 Bookkeeper 7,280 874 607 8,786 105,435

5 Utility 5,720 686 477 6,909 82,909

6 Driver/Sales 6,500 780 542 7,848 94,172

7 Delivery Asst. 5,200 624 433 6,283 75,400

TOTAL 98,779 1,185,351

TOTAL STAFF COSTS 175,441 2,105,295

Sample Enterprise Enhancement Plan 24

RB Biscuit Co.

ANNEX F

EQUIPMENT

ADDITIONAL EQUIPMENT

CURRENT NEEDED

Type of Qt Unit Qt Unit

Equipment Specifications y Cost Cost y Cost Cost

PRODUCTION

50 kg cap., single offset

Mixer rotary blade, 2 Hp 43, 43,0

motor, 220v, 1Ø 1 000 00

50 kg cap., single roller

Kneading Machine type, 1 Hp motor, 220v, 5 5

1Ø 1 0,000 0,000

Cutting dies - Stainless Steel, 1.25"Ø 3 1 40

Paborita per out, 12x16 outs 4 8,000 2,000 4 0,000 ,000

Stainless Steel,

Cutting dies -

0.5"x2.0" per out, 32

Ogoy-ogoy

24"x11", 256 outs 4 8,000 ,000

Brick Type, wood fired,

Brick Oven 12' x 12' oven area, 3 8 8

levels 1 0,000 0,000

Oven Paddle

Wood, 12' long 2 800 1,600

3'x8', stainless steel 1 1

Kneading Table

tabletop 1 2,000 2,000

4'x8', enameled

Packing Table

tabletop 1 8,000 8,000

15"x20", 5 levels,

Tray Carts square mech, w/ caster 9 50

wheels 20 4,500 0,000 10 5,000 ,000

33,0 7 21,0

Baking Trays

18" x 24", Aluminum 60 550 00 30 00 00

2'x2'x1', enameled

Biscuit Bin sheets, w/ caster 2 20

wheels 5 4,000 0,000 4 5,000 ,000

Induction type, 12", 17,0 17,0

Sealing Machine

foot-triggered 1 00 00

386,

Sub-Total 600 163,000

STORAGE ROOM

Storage Rack Constructed on 3 sides 25, 25,0

of storage room. 1 000 00

1, 1,8

Push cart

Heavy duty type 1 800 00

26,

Sub-Total 800

SALES

Isuzu closed van, 280, 280,0

Delivery Van

second hand 1 000 00

1, 1,8

Push cart

Heavy duty type 1 800 00

281,8

Sub-Total 00

ADMINISTRATION

Airconditioning 16, 16,0

unit Window type, 1.5 Hp 1 000 00

16,

Sub-Total 000

FURNITURE & FIXTURES

1, 2,6

Executive Table

2 300 00

1,6

Clerical Table

2 800 00

Sample Enterprise Enhancement Plan 25

RB Biscuit Co.

1,4

Office chairs

4 350 00

Conference Table 3, 3,5

& 4 chairs 1 500 00

1,0

Visitors Chairs

4 250 00

6, 6,0

Filing Cabinet

1 000 00

16,

Sub-Total 100

727,

TOTAL

300 163,000

Sample Enterprise Enhancement Plan 26

RB Biscuit Co.

ANNEX G

BAKERY LAYOUT

Open Space for Future Expansion

Wash

Area Brick Oven

Packing Table

Tray Carts

Kneading & Cutting

Table

Driveway

Biscuit Bin

Kneader Mixer

Racks

Office Storage Room

Racks

Racks

Sample Enterprise Enhancement Plan 27

RB Biscuit Co.

ANNEX H

OTHER COSTS

Month

Inputs 1 2 3 4 5 6 7 8 9 10 11 12 Annual

20,00 20,00 20,00 20,00 20,00 20,00 20,00 20,00 20,00 20,00 240,00

Power 20,000 20,000 0 0 0 0 0 0 0 0 0 0 0

5,00 5,00 5,00 5,00 5,00 5,00 5,00 5,00 5,00 5,00 5,00 5,00 60,00

Water 0 0 0 0 0 0 0 0 0 0 0 0 0

30,00 30,00 30,00 30,00 30,00 30,00 30,00 30,00 30,00 30,00 30,00 30,00 360,00

Gas / Delivery 0 0 0 0 0 0 0 0 0 0 0 0 0

8,00 8,00 8,00 8,00 8,00 8,00 8,00 8,00 8,00 8,00 8,00 8,00 96,00

Transportation 0 0 0 0 0 0 0 0 0 0 0 0 0

5,00 5,00 5,00 5,00 5,00 5,00 5,00 5,00 5,00 5,00 5,00 5,00 60,00

Repairs & Maintenance 0 0 0 0 0 0 0 0 0 0 0 0 0

22,50 22,50 22,50 23,40 23,40 23,40 24,30 24,30 24,30 25,38 25,38 25,38 286,74

Taxes & Licenses 0 0 0 0 0 0 0 0 0 0 0 0 0

4,00 4,00 4,00 4,00 4,00 4,00 4,00 4,00 4,00 4,00 4,00 4,00 48,00

Office Supplies 0 0 0 0 0 0 0 0 0 0 0 0 0

5,00 5,00 5,00 5,00 5,00 5,00 5,00 5,00 5,00 5,00 5,00 5,00 60,00

Representation 0 0 0 0 0 0 0 0 0 0 0 0 0

5,00 5,00 5,00 5,00 5,00 5,00 5,00 5,00 5,00 5,00 5,00 5,00 60,00

Miscellaneous 0 0 0 0 0 0 0 0 0 0 0 0 0

104,50 104,50 104,50 105,40 105,40 105,40 106,30 106,30 106,30 107,38 107,38 107,38 1,270,74

Total 0 0 0 0 0 0 0 0 0 0 0 0 0

Sample Enterprise Enhancement Plan 28

RB Biscuit Co.

ANNEX I

BUSINESS INPUTS

Quantity Per Month Per Year

1 2 3 4 5 6 7 8 9 10 11 12

Production/sales – Paborita

3.700 3.700 3.700 3,800 3,800 3,800 3,900 3,900 3,900 4,040 4,040 4,040

(bags)

Inputs Price/Unit

Wheat Flour (kg) 32.00/kg 6,167 6,167 6,167 6,333 6,333 6,333 6,500 6,500 6,500 6,733 6,733 6,733 77,200

Wheat Flour Knead 32.00/kg

(kg) 987 987 987 1,013 1,013 1,013 1,040 1,040 1,040 1,077 1,077 1,077 12,352

White Sugar (kg) 42.00/kg 370 370 370 380 380 380 390 390 390 404 404 404 4,632

Cooking Oil (li) 86.84/li 62 62 62 63 63 63 65 65 65 67 67 67 772

Yeast (gm) 0.7/gm 1,233 1,233 1,233 1,267 1,267 1,267 1,300 1,300 1,300 1,347 1,347 1,347 15,440

Water (li) 1.05/li 1,850 1,850 1,850 1,900 1,900 1,900 1,950 1,950 1,950 2,020 2,020 2,020 23,160

Plastic Bag-small (pcs) 0.25/pc 111,0 111,0 111,0 114,0 114,0 114,0 117,0 117,0 117,0 121,2 121,2 121,2 1,389,60

00 00 00 00 00 00 00 00 00 00 00 00 0

Plastic Bag-big (pcs) 1.20/pc 123 123 123 127 127 127 130 130 130 135 135 135 1,544

Label (pcs) 0.15/pc 111,0 111,0 111,0 114,0 114,0 114,0 117,0 117,0 117,0 121,2 121,2 121,2

00 00 00 00 00 00 00 00 00 00 00 00 1,389,600

Wood (cum) 400/cum 185 185 185 190 190 190 195 195 195 202 202 202 2,316

Production/sales – Ogoy-ogoy

1,300 1,300 1,300 1,400 1,400 1,400 1,500 1,500 1,500 1,600 1,600 1,600

(bags)

Inputs Price/Unit

Wheat Flour (kg) 32.00/kg 2,167 2,167 2,167 2,333 2,333 2,333 2,500 2,500 2,500 2,667 2,667 2,667 29,000

Wheat Flour Knead 32.00/kg

(kg) 347 347 347 373 373 373 400 400 400 427 427 427 4,640

White Sugar (kg) 42.00/kg 130 130 130 140 140 140 150 150 150 160 160 160 1,740

Brown Sugar (kg) 38.00/hg 520 520 520 560 560 560 600 600 600 640 640 640 6,960

Cooking Oil (li) 86.84/li 22 22 22 23 23 23 25 25 25 27 27 27 290

Yeast (gm) 0.7/gm 433 433 433 467 467 467 500 500 500 533 533 533 5,800

Water (li) 1.05/li 650 650 650 700 700 700 750 750 750 800 800 800 8,700

Plastic Bag-small (pcs) 0.25/pc 39,00 39,00 39,00 42,00 42,00 42,00 45,00 45,00 45,00 48,00 48,00 48,00

0 0 0 0 0 0 0 0 0 0 0 0 522,000

Plastic Bag-big (pcs) 1.20/pc 43 43 43 47 47 47 50 50 50 53 53 53 580

Label (pcs) 0.15/pc 39,00 39,00 39,00 42,00 42,00 42,00 45,00 45,00 45,00 48,00 48,00 48,00

0 0 0 0 0 0 0 0 0 0 0 0 522,000

Sample Enterprise Enhancement Plan 29

RB Biscuit Co.

Wood (cum) 400/cum 65 65 65 70 70 70 75 75 75 80 80 80 870

Sample Enterprise Enhancement Plan 30

RB Biscuit Co.

ANNEX J

MATERIAL COSTS

Material Costs Per Month Per Year

1 2 3 4 5 6 7 8 9 10 11 12

Production/sales 3.700 3.700 3.700 3,800 3,800 3,800 3,900 3,900 3,900 4,040 4,040 4,040 46,320

Inputs - Paborita

Wheat Flour 197,3 197,3 197,3 202,6 202,6 202,6 208,0 208,0 208,0 215,4 215,4 215,4

33 33 33 67 67 67 00 00 00 67 67 67 2,470,400

Wheat Flour (Kneading) 31,5 31,5 31,5 32,4 32,4 32,4 33,2 33,2 33,2 34,4 34,4 34,4

73 73 73 27 27 27 80 80 80 75 75 75 395,264

White Sugar 15,5 15,5 15,5 15,9 15,9 15,9 16,3 16,3 16,3 16,9 16,9 16,9

40 40 40 60 60 60 80 80 80 68 68 68 194,544

Cooking Oil 5,3 5,3 5,3 5,5 5,5 5,5 5,6 5,6 5,6 5,8 5,8 5,8

55 55 55 00 00 00 45 45 45 47 47 47 67,042

Yeast 8 8 8 8 8 8 9 9 9 9 9 9

63 63 63 87 87 87 10 10 10 43 43 43 10,808

Water 1,9 1,9 1,9 2,0 2,0 2,0 2,0 2,0 2,0 2,1 2,1 2,1

47 47 47 00 00 00 53 53 53 26 26 26 24,379

Plastic Bag (small) 27,7 27,7 27,7 28,5 28,5 28,5 29,2 29,2 29,2 30,3 30,3 30,3

50 50 50 00 00 00 50 50 50 00 00 00 347,400

Plastic Bag (big) 1 1 1 1 1 1 1 1 1 1 1 1

48 48 48 52 52 52 56 56 56 62 62 62 1,853

Label 16,6 16,6 16,6 17,1 17,1 17,1 17,5 17,5 17,5 18,1 18,1 18,1

50 50 50 00 00 00 50 50 50 80 80 80 208,440

Wood 74,0 74,0 74,0 76,0 76,0 76,0 78,0 78,0 78,0 80,8 80,8 80,8

00 00 00 00 00 00 00 00 00 00 00 00 926,400

Total Paborita 4,692,850

Production/sales 1,300 1,300 1,300 1,400 1,400 1,400 1,500 1,500 1,500 1,600 1,600 1,600 17,400

Inputs – Ogoy-ogoy

69,3 69,3 69,3 74,6 74,6 74,6 80,0 80,0 80,0 85,3 85,3 85,3

Wheat flour 33 33 33 67 67 67 00 00 00 33 33 33 928,000

11,0 11,0 11,0 11,9 11,9 11,9 12,8 12,8 12,8 13,6 13,6 13,6

Wheat flour used in kneading 93 93 93 47 47 47 00 00 00 53 53 53 148,480

5,4 5,4 5,4 5,8 5,8 5,8 6,3 6,3 6,3 6,7 6,7 6,7

White sugar 60 60 60 80 80 80 00 00 00 20 20 20 73,080

19,7 19,7 19,7 21,2 21,2 21,2 22,8 22,8 22,8 24,3 24,3 24,3

Brown sugar 60 60 60 80 80 80 00 00 00 20 20 20 264,480

Cooking oil 1,8 1,8 1,8 2,0 2,0 2,0 2,1 2,1 2,1 2,3 2,3 2,3 25,184

Sample Enterprise Enhancement Plan 31

RB Biscuit Co.

82 82 82 26 26 26 71 71 71 16 16 16

3 3 3 3 3 3 3 3 3 3 3 3

Yeast 03 03 03 27 27 27 50 50 50 73 73 73 4,060

6 6 6 7 7 7 7 7 7 8 8 8

Water 84 84 84 37 37 37 89 89 89 42 42 42 9,158

9,7 9,7 9,7 10,5 10,5 10,5 11,2 11,2 11,2 12,0 12,0 12,0

Plastic Bag (small) 50 50 50 00 00 00 50 50 50 00 00 00 130,500

Plastic Bag (big) 52 52 52 56 56 56 60 60 60 64 64 64 696

5,8 5,8 5,8 6,3 6,3 6,3 6,7 6,7 6,7 7,2 7,2 7,2

Label 50 50 50 00 00 00 50 50 50 00 00 00 78,300

26,0 26,0 26,0 28,0 28,0 28,0 30,0 30,0 30,0 32,0 32,0 32,0

Wood 00 00 00 00 00 00 00 00 00 00 00 00 348,000

Total Ogoy-ogoy 2,027,338

TOTAL 6,720,188

Sample Enterprise Enhancement Plan 32

RB Biscuit Co.

ANNEX K

DEPRECIATION TABLE

CURRENT ADDITIONAL EQUIPMENT NEEDED

Yrs. Yrs.

Of Annual Unit Of Annual

Investment Item Value Use Depreciation Total Qty Cost Value Use Dep'n

PRODUCTION

Mixer 43,000 5 8,600

Kneading Machine 50,000 5 10,000

Cutting dies - Paborita 32,000 3 10,667

Cutting dies - Ogoy-ogoy - 4 10,000 40,000 3 13,333

Brick Oven 80,000 10 8,000

Oven Paddle 1,600 2 800

Kneading Table 12,000 5 2,400

Packing Table 8,000 5 1,600

Tray Carts 90,000 5 18,000 10 5,000 50,000 5 10,000

Baking Trays 33,000 5 6,600 30 700 21,000 5 4,200

Biscuit Bin 20,000 3 6,667 4 5,000 20,000 3 6,667

Sealing Machine 17,000 5 3,400

76,733 34,200

STORAGE ROOM

Storage Rack 25,000 5 5,000

Push cart 1,800 5 360

5,360

SALES

Delivery Van 330,000 5 66,000

Push cart 1,800 5 360

66,360

ADMINISTRATION

Airconditioning unit 16,000 5 3,200 3,200

FURNITURE & FIXTURES

Executive Table 2,600 5 520

Clerical Table 1,600 5 320

Office chairs 1,400 5 280

Conference Table & 4

chairs 3,500 5 700

Visitors Chairs 1,000 5 200

Filing Cabinet 6,000 5 1,200

3,220

TOTAL 154,873 131,000 34,200

Sample Enterprise Enhancement Plan 33

RB Biscuit Co.

ANNEX L

INTEREST COSTS

Month

Product 1 2 3 4 5 6 7 8 9 10 11 12

FAMILY LOAN:

Principal

Interest rate

Interest cost

Installment

BANK LOAN

Principal 500,00 481, 462, 443, 424, 405, 385, 366, 346, 326, 306, 285,

0 463 741 832 733 444 962 285 411 338 065 589

Interest rate 12% 12% 12% 12% 12% 12% 12% 12% 12% 12% 12% 12%

Interest cost 5,0 4, 4, 4, 4, 4, 3, 3, 3, 3, 3, 2,

00 815 627 438 247 054 860 663 464 263 061 856

Installment 23,537 23,537 23,537 23,537 23,537 23,537 23,537 23,537 23,537 23,537 23,537 23,537

OTHER LOANS

Principal 749,82 707,20 664,04 620,34 576,10 531,30 485,94 440,02 393,52 346,44 298,78 250,51

6 1 3 6 2 5 9 5 7 8 1 8

Interest rate 15% 15% 15% 15% 15% 15% 15% 15% 15% 15% 15% 15%

Interest cost 9, 8, 8, 7, 7, 6, 6, 5, 4, 4, 3, 3,

373 840 301 754 201 641 074 500 919 331 735 131

Installment 51,998 51,998 51,998 51,998 51,998 51,998 51,998 51,998 51,998 51,998 51,998 51,998

TOTALS

DEBT SERVICE

Installment 75,535 75,535 75,535 75,535 75,535 75,535 75,535 75,535 75,535 75,535 75,535 75,535

Interest cost 14, 13, 12, 12, 11, 10, 9, 9, 8, 7, 6, 5,

373 655 928 193 449 696 934 163 383 594 795 987

Sample Enterprise Enhancement Plan 34

RB Biscuit Co.

Sample Enterprise Enhancement Plan 35

RB Biscuit Co.

ANNEX M

SALES AND COSTS PLAN

Month

1 2 3 4 5 6 7 8 9 10 11 12 Annual

Sales:

Paborita (bags) 3,700 3,700 3,700 3,800 3,800 3,800 3,900 3,900 3,900 4,040 4,040 4,040 46,320

Ogoy-ogoy (bags 1,300 1,300 1,300 1,400 1,400 1,400 1,500 1,500 1,500 1,600 1,600 1,600 17,400

Wholesale Price per

Bag 225 225 225 225 225 225 225 225 225 225 225 225

1,125,0 1,125,0 1,125,0 1,170,0 1,170,0 1,170,0 1,215,0 1,215,0 1,215,0 1,269,0 1,269,0 1,269,0 14,337,

TOTAL SALES 00 00 00 00 00 00 00 00 00 00 00 00 000

Direct Material Costs- 374,8 374,8 374,8 384,9 384,9 384,9 395,1 395,1 395,1 409,3 409,3 409,3 4,692,8

Paborita 61 61 61 92 92 92 23 23 23 07 07 07 50

Direct Material Costs- 151,4 151,4 151,4 163,1 163,1 163,1 174,7 174,7 174,7 186,4 186,4 186,4 2,027,3

Ogoy-ogoy 68 68 68 19 19 19 71 71 71 22 22 22 38

Direct Labor Costs 76,662 76,662 76,662 76,662 76,662 76,662 76,662 76,662 76,662 76,662 76,662 76,662 919,944

602,9 602,9 624,7 624,7 624,7 646,5 646,5 646,5 672,3 672,3 672,3 7,640,1 11,952,

Total Direct Cost 90 90 73 73 73 56 56 56 91 91 91 32 351

522,0 522,0 522,0 545,2 545,2 545,2 568,4 568,4 568,4 596,6 596,6 596,6 6,696,8

GROSS MARGIN 10 10 10 27 27 27 44 44 44 09 09 09 68

Indirect Costs

98,77 98,77 98,77 98,77 98,77 98,77 98,77 98,77 98,77 98,77 98,77 1,185,3

Staff Costs 9 9 9 9 9 9 9 8,779 9 9 9 9 51

104,5 104,5 104,5 105,4 105,4 105,4 106,3 106,3 106,3 107,3 107,3 107,3 1,270,7

Other Costs 00 00 00 00 00 00 00 00 00 80 80 80 40

15,75 15,75 15,75 15,75 15,75 15,75 15,75 15,75 15,75 15,75 15,75 15,75

Depreciation 6 6 6 6 6 6 6 6 6 6 6 6 189,073

TOTAL INDIRECT 219,0 219,0 219,0 219,9 219,9 219,9 220,8 220,8 220,8 221,9 221,9 221,9 2,645,

COSTS 35 35 35 35 35 35 35 35 35 15 15 15 165

NET PROFIT BEFORE 302,9 302,9 302,9 325,2 325,2 325,2 347,6 347,6 347,6 374,6 374,6 374,6 4,051,

FINANCING 74 74 74 91 91 91 09 09 09 93 93 93 704

14,37 13,65 12,92 12,19 11,44 10,69 9,93 9,16 8,38 7,59 6,79 5,98 123,

Interest Costs 3 5 8 3 9 6 4 3 3 4 5 7 150

Sample Enterprise Enhancement Plan 36

RB Biscuit Co.

NET PROFIT FROM 288,6 289,3 290,0 313,0 313,8 314,5 337,6 338,4 339,2 367,0 367,8 368,7 3,928,

OPERATIONS 01 20 46 99 43 96 75 46 26 99 98 06 554

Provision for Income 101,0 101,2 101,5 109,5 109,8 110,1 118,1 118,4 118,7 128,4 128,7 129,0 1,374,

Tax 10 62 16 85 45 08 86 56 29 85 64 47 994

187,5 188,0 188,5 203,5 203,9 204,4 219,4 219,9 220,4 238,6 239,1 239,6 2,553,

NET PROFIT 91 58 30 14 98 87 89 90 97 15 34 59 560

Sample Enterprise Enhancement Plan 37

RB Biscuit Co.

ANNEX N

CASH FLOW PLAN

1 2 3 4 5 6 7 8 9 10 11 12

, , ,

Cash at the Beginning of 533, 675, 816, 972, 128,30 1,283, 453,35 622,72 1,791, 1,978, 2,164,4

1 the month 53,908 093 027 706 634 2 707 1 5 826 256 07

1,125, 1,125, 1,125, 1,170, 1,170, 1,170, 1,215, 1,215, 1,215, 1,269, 1,269, 1,269,0

2 Cash in from sales 000 000 000 000 000 000 000 000 000 000 000 00

500,00

3 Any other cash in 0

1,678, 1,658, 1,800, 1,986, 2,142, 2,298, 2,498, 2,668, 2,837, 3,060, 3,247, 3,433,4

4 TOTAL CASH IN 908 093 027 706 634 302 707 351 725 826 256 07

5 Cash out for direct costs

526,3 526, 526, 548, 548, 548, 569, 569, 569, 595, 595, 595,7

- Direct Materials 28 328 328 111 111 111 894 894 894 729 729 29

- Direct Labor 76,662 76,662 76,662 76,662 76,662 76,662 76,662 76,662 76,662 76,662 76,662 76,662

Total Cash Out for 602,99 602,99 602,99 624,77 624,77 624,77 646,55 646,55 646,55 672,39 672,39 672,39

Direct Costs 0 0 0 3 3 3 6 6 6 1 1 1

6 Cash out for indirect costs

98, 98, 98, 98, 98, 98, 98, 98, 98, 98, 98, 98,7

- Staff Costs 779 779 779 779 779 779 779 779 779 779 779 79

104, 104, 104, 105, 105, 105, 106, 106, 106, 107, 107, 107,

- Other Costs 500 500 500 400 400 400 300 300 300 380 380 380

- Loan Installment 75,535 75,535 75,535 75,535 75,535 75,535 75,535 75,535 75,535 75,535 75,535 75,535

Total Cash Out for 278, 278, 278, 279, 279, 279, 280, 280, 280, 281, 281, 281,

Indirect Costs 814 814 814 714 714 714 614 614 614 694 694 694

101, 101, 101, 109, 109, 110, 118, 118, 118, 128, 128, 129,

7 Any other cash out - Taxes 010 262 516 585 845 108 186 456 729 485 764 047

- 163,

Equipment 000 -

264, 101, 101, 109, 109, 110, 118, 118, 118, 128, 128, 129,

Total Any Other Cash Out 010 262 516 585 845 108 186 456 729 485 764 047

8 TOTAL CASH OUT 1,145, 983, 983, 1,014, 1,014, 1,014, 1,045, 1,045, 1,045, 1,082, 1,082, 1,083,

Sample Enterprise Enhancement Plan 38

RB Biscuit Co.

815 066 321 072 332 596 356 626 899 570 849 132

Cash at the end of the 533, 675, 816, 972, 1,128, 1,283, 1,453, 1,622, 1,791, 1,978, 2,164, 2,350,2

9 month 093 027 706 634 302 707 351 725 826 256 407 74

Sample Enterprise Enhancement Plan 39

RB Biscuit Co.

ANNEX O

INTEREST & INSTALLMENT ON NEW LOAN

BANK LOAN

Loan Amount 500,000 500,000

Interest Rate 12% 0.01

Period 24 24

Amortization ($23,536.74) 23,537

Period 0 1 2 3 4 5 6 7 8 9 10 11 12

Start Balance 500,000 481,463 462,741 443,832 424,733 405,444 385,962 366,285 346,411 326,338 306,065 285,589

Amortization 23,537 23,537 23,537 23,537 23,537 23,537 23,537 23,537 23,537 23,537 23,537 23,537

Interest 5,000 4,815 4,627 4,438 4,247 4,054 3,860 3,663 3,464 3,263 3,061 2,856

Principal 18,537 18,722 18,909 19,098 19,289 19,482 19,677 19,874 20,073 20,273 20,476 20,681

End Balance 500,000 481,463 462,741 443,832 424,733 405,444 385,962 366,285 346,411 326,338 306,065 285,589 264,908

Period 13 14 15 16 17 18 19 20 21 22 23 24

Start Balance 264,908 244,020 222,924 201,616 180,096 158,360 136,407 114,234 91,840 69,221 46,377 23,304

Amortization 23,537 23,537 23,537 23,537 23,537 23,537 23,537 23,537 23,537 23,537 23,537 23,537

Interest 2,649 2,440 2,229 2,016 1,801 1,584 1,364 1,142 918 692 464 233

Principal 20,888 21,097 21,308 21,521 21,736 21,953 22,173 22,394 22,618 22,845 23,073 23,304

End Balance 244,020 222,924 201,616 180,096 158,360 136,407 114,234 91,840 69,221 46,377 23,304 0

Sample Enterprise Enhancement Plan 40

RB Biscuit Co.

S-ar putea să vă placă și

- Zabala - 02 Laboratory Exercise 1 PastryDocument6 paginiZabala - 02 Laboratory Exercise 1 PastryKylle Justin ZabalaÎncă nu există evaluări

- Compression Molding and Injection MoldDocument23 paginiCompression Molding and Injection MoldKodhansÎncă nu există evaluări

- Pet Stores in The US Industry ReportDocument32 paginiPet Stores in The US Industry ReportJonathan TamÎncă nu există evaluări

- How Pet Foods Are ManufacturedDocument2 paginiHow Pet Foods Are ManufacturedABÎncă nu există evaluări

- Injection Molding ProcessDocument12 paginiInjection Molding ProcessImane El BouchehatiÎncă nu există evaluări

- I/ Reading 1 1. What Is Plastic Injection Molding?Document5 paginiI/ Reading 1 1. What Is Plastic Injection Molding?Hieu Nguyen TrungÎncă nu există evaluări

- Types of Planning (FOM) FinalDocument17 paginiTypes of Planning (FOM) FinalAbhijeet SinghÎncă nu există evaluări

- IngredientsDocument14 paginiIngredientsLiezaÎncă nu există evaluări

- Leather: Classification of Animal SkinDocument12 paginiLeather: Classification of Animal Skinprottoy8787Încă nu există evaluări

- Lecture 1 - Introduction To Food IngredientsDocument22 paginiLecture 1 - Introduction To Food IngredientsVanessa LimÎncă nu există evaluări

- Eclipse Airheat Burners: Ah-Ma SeriesDocument22 paginiEclipse Airheat Burners: Ah-Ma Seriescarlosloucao100% (1)

- ERT 426 Food Engineering Semester 1 Academic Session 2017/18Document32 paginiERT 426 Food Engineering Semester 1 Academic Session 2017/18nas radziÎncă nu există evaluări

- 3A - Extruder ComponentsDocument26 pagini3A - Extruder ComponentsMuhd Khairul Amri100% (1)

- Gelatin Alternatives For The Food IndustryDocument5 paginiGelatin Alternatives For The Food Industrymdsanchezo8373Încă nu există evaluări

- US5635237Document11 paginiUS5635237gabriela ruizÎncă nu există evaluări

- Baking HandbookDocument165 paginiBaking HandbookCarlos NeyÎncă nu există evaluări

- ExtrusionDocument12 paginiExtrusionNitesh YadavÎncă nu există evaluări

- Food Safety and Hygiene LayoutDocument9 paginiFood Safety and Hygiene LayoutJann Kerky100% (1)

- Blowmolding 120209032429 Phpapp01Document16 paginiBlowmolding 120209032429 Phpapp01luan_baÎncă nu există evaluări

- Blow Molding Machine ProcessDocument4 paginiBlow Molding Machine Processuocmogiandi_a100% (1)

- Compression Molding Is A Method ofDocument4 paginiCompression Molding Is A Method ofsathishpantaloonÎncă nu există evaluări

- The Blow Molding ProcessDocument4 paginiThe Blow Molding Processabi lashÎncă nu există evaluări

- Classification o F ExtruderDocument25 paginiClassification o F ExtruderSaman Waheed100% (1)

- Instant NoodlesDocument18 paginiInstant NoodlesTrần Tú LinhÎncă nu există evaluări

- Measurement of Meat TextureDocument5 paginiMeasurement of Meat TexturesitinurhanizaÎncă nu există evaluări

- Physical and Chemical Changes ExperimentDocument3 paginiPhysical and Chemical Changes ExperimentCj RamosÎncă nu există evaluări

- MeatDocument19 paginiMeatbhaskarÎncă nu există evaluări

- Ice Cream Overrun & Its Affect On The Characteristics of Ice CreamDocument12 paginiIce Cream Overrun & Its Affect On The Characteristics of Ice CreamTamaraÎncă nu există evaluări

- Manufacturing Process of Potato FlakesDocument5 paginiManufacturing Process of Potato FlakesandreaÎncă nu există evaluări

- Catalogo PDFDocument28 paginiCatalogo PDFjose.figueroa@foseco.comÎncă nu există evaluări

- Brochure Quality Confectionery - Eng - May 11Document8 paginiBrochure Quality Confectionery - Eng - May 11bikal_sthÎncă nu există evaluări

- Bakery Industry Conveyor and Processing Belts: Habasit - Solutions in MotionDocument20 paginiBakery Industry Conveyor and Processing Belts: Habasit - Solutions in MotionMarlonÎncă nu există evaluări

- Overview EHEDG Guidelines by Topics 2018 04Document3 paginiOverview EHEDG Guidelines by Topics 2018 04cahyaniÎncă nu există evaluări

- Complete Processing Lines For Extruded Pet FoodDocument13 paginiComplete Processing Lines For Extruded Pet FoodденисÎncă nu există evaluări

- Prepared Foods - June 2019Document140 paginiPrepared Foods - June 2019stupearlÎncă nu există evaluări

- Lecture Notes 1Document21 paginiLecture Notes 1Châu An NguyễnÎncă nu există evaluări

- DSM Enzymes For Biscuits Crackers Wafers PDFDocument19 paginiDSM Enzymes For Biscuits Crackers Wafers PDFOrhan AvurÎncă nu există evaluări

- Guide To Rotational Moulding - BeallDocument11 paginiGuide To Rotational Moulding - BeallBhaveshÎncă nu există evaluări

- C R C Critical Reviews in Food Science and NutritionDocument62 paginiC R C Critical Reviews in Food Science and NutritionR Joel ColqueÎncă nu există evaluări

- Vulc Catalogue2004 2005 EnglDocument107 paginiVulc Catalogue2004 2005 EnglAbraham HuacasiÎncă nu există evaluări

- Market Research Com 2206981Document302 paginiMarket Research Com 2206981Don OchoaÎncă nu există evaluări

- Ice Cream ManufacturingDocument55 paginiIce Cream ManufacturingVân Anh NguyenÎncă nu există evaluări

- 8 Bakey TechnologyDocument103 pagini8 Bakey TechnologyPawan CoomarÎncă nu există evaluări

- SDM Project (Dog Food)Document14 paginiSDM Project (Dog Food)Robbie K RajanÎncă nu există evaluări

- TroubleshootingDocument2 paginiTroubleshootingVan Khanh HuynhÎncă nu există evaluări

- Tortilla Processing Parameters - DesiderioDocument148 paginiTortilla Processing Parameters - DesiderioKarlo GoričkiÎncă nu există evaluări

- About Rotational MoldingDocument7 paginiAbout Rotational MoldingPatel DarshanÎncă nu există evaluări

- New insights on the urease activity range for soybean meal: a worldwide opportunity for the poultry industryDocument9 paginiNew insights on the urease activity range for soybean meal: a worldwide opportunity for the poultry industryBánvésố KiếmtiềnmuaôtôÎncă nu există evaluări

- 3 - Shortenings - Science and TechnologyDocument41 pagini3 - Shortenings - Science and TechnologyJulesÎncă nu există evaluări

- Effect of Sugars On The BiscuitDocument8 paginiEffect of Sugars On The BiscuitlpuntyÎncă nu există evaluări

- Group 7 Oat MilkDocument35 paginiGroup 7 Oat MilkHarfizzie FatehÎncă nu există evaluări

- Inorganic BindersDocument4 paginiInorganic Bindersadeniyi-sam100% (1)

- Troubleshooting Cast FilmDocument6 paginiTroubleshooting Cast FilmgredmirÎncă nu există evaluări

- What is Gelatin? The Protein Derived from CollagenDocument10 paginiWhat is Gelatin? The Protein Derived from CollagenMihai SebastianÎncă nu există evaluări

- JP Tropical Foods Quality Summit Reviewing Factors that Impact Fried Snack Food Shelf LifeDocument17 paginiJP Tropical Foods Quality Summit Reviewing Factors that Impact Fried Snack Food Shelf LifeFloreid100% (1)

- High Shear MixerDocument8 paginiHigh Shear MixerantiquekÎncă nu există evaluări

- Extrusion Problems Solved Food Pet FoodDocument1 paginăExtrusion Problems Solved Food Pet FoodLisandro ForteagaÎncă nu există evaluări

- Original Laguna Buko Pie Maker Looks to GrowDocument3 paginiOriginal Laguna Buko Pie Maker Looks to Growaccounting prob100% (2)

- Bisk Farm's journey from losses to becoming second largest biscuit brand in East IndiaDocument12 paginiBisk Farm's journey from losses to becoming second largest biscuit brand in East Indiadeb_banrjeeÎncă nu există evaluări

- Company ProfileDocument3 paginiCompany ProfileJenalyn OmnesÎncă nu există evaluări

- 1618 Office Solutions, IncDocument4 pagini1618 Office Solutions, IncJerome Naves TayawaÎncă nu există evaluări

- PAGCOR Casino Regulatory Manual for Entertainment City LicenseesDocument366 paginiPAGCOR Casino Regulatory Manual for Entertainment City LicenseesPaige Lim100% (2)

- 2015 Download Cover forAFS PDFDocument1 pagină2015 Download Cover forAFS PDFJerome Naves TayawaÎncă nu există evaluări

- Report in FinMaDocument18 paginiReport in FinMaJerome Naves TayawaÎncă nu există evaluări

- MeowDocument1 paginăMeowJerome Naves TayawaÎncă nu există evaluări

- Advertisement and Sales Management B Com Sem 6 MCQ PDFDocument23 paginiAdvertisement and Sales Management B Com Sem 6 MCQ PDFDrAbhishek Saraf60% (5)

- Computer Hardware WholesalersDocument2 paginiComputer Hardware WholesalersBruno Halfeld DutraÎncă nu există evaluări

- 2021 Cmci Annex ADocument48 pagini2021 Cmci Annex AArjay AletaÎncă nu există evaluări

- Scribd IncDocument1 paginăScribd InckmingsÎncă nu există evaluări

- E-Business & E-Commerce: Key Differences and TypesDocument31 paginiE-Business & E-Commerce: Key Differences and Typespatrick deveraÎncă nu există evaluări

- Chapter 1:-Introduction: Advertising Is CommunicationDocument51 paginiChapter 1:-Introduction: Advertising Is CommunicationsouvikÎncă nu există evaluări

- Fairdeal AppliancesDocument12 paginiFairdeal Appliancesaman bansalÎncă nu există evaluări

- 611B - ImcDocument20 pagini611B - ImcRushi100% (1)

- TX Drayage CarriersDocument75 paginiTX Drayage CarriersjaneÎncă nu există evaluări

- FinalDocument52 paginiFinalhitesh_shihoraÎncă nu există evaluări

- 2023 3PL SOI ReportDocument29 pagini2023 3PL SOI Reportmohammad100% (1)

- Global Business - Unit 4Document86 paginiGlobal Business - Unit 4GauravTiwariÎncă nu există evaluări

- Dashen Obsidya Industrial and Trading PLCDocument25 paginiDashen Obsidya Industrial and Trading PLCHilinaÎncă nu există evaluări

- Network Marketing Success Va PDFDocument103 paginiNetwork Marketing Success Va PDFJoao Paulo Moura100% (1)

- BluespaDocument70 paginiBluespaOndrej ProtopapasÎncă nu există evaluări

- SABECODocument28 paginiSABECO김수영Încă nu există evaluări

- Aakash Balaji FinalDocument43 paginiAakash Balaji FinalMeet PrajapatiÎncă nu există evaluări

- Marketing Management SyllabusDocument316 paginiMarketing Management SyllabusTazyn RahmanÎncă nu există evaluări

- MKT202 Group Report (Group 6)Document11 paginiMKT202 Group Report (Group 6)Al Amin Miajee 2031545630Încă nu există evaluări

- Higher Colleges of Technology: Project Cover Sheet (30%)Document7 paginiHigher Colleges of Technology: Project Cover Sheet (30%)AhmedÎncă nu există evaluări

- Case Study Amazon Chapter 8Document5 paginiCase Study Amazon Chapter 8Linh LêÎncă nu există evaluări

- Module 3. Services Marketing (Quality Service Management)Document11 paginiModule 3. Services Marketing (Quality Service Management)MARITONI MEDALLAÎncă nu există evaluări

- Marketing Management: Bba Iii Sem Ritesh SharmaDocument69 paginiMarketing Management: Bba Iii Sem Ritesh Sharmaaman mittalÎncă nu există evaluări

- Marketing 12th Edition Lamb Solutions ManualDocument26 paginiMarketing 12th Edition Lamb Solutions Manualchristopherbrownfpoqagcisz100% (29)

- Sell Out With Live Selling PagesDocument8 paginiSell Out With Live Selling PagesSandra WuÎncă nu există evaluări

- International Distribution Channel: Submitted by Vaibhav Deshmukh 62071 Prachi Parab 62095 Rajesh Chaudhari 62066Document24 paginiInternational Distribution Channel: Submitted by Vaibhav Deshmukh 62071 Prachi Parab 62095 Rajesh Chaudhari 62066Vaibhav DeshmukhÎncă nu există evaluări

- Maruti Project ReportDocument85 paginiMaruti Project ReportChirag Thakwani93% (14)

- Gujarat Technological University: Syllabus For New MBA Program Effective From Academic Year 2011-12Document23 paginiGujarat Technological University: Syllabus For New MBA Program Effective From Academic Year 2011-12poojaÎncă nu există evaluări

- Unit 4 MarketingDocument125 paginiUnit 4 MarketingDanish KhanÎncă nu există evaluări

- Understanding FinanceDocument29 paginiUnderstanding FinanceMadeline Chloe PlataÎncă nu există evaluări