Documente Academic

Documente Profesional

Documente Cultură

Manual de Medidos de Flujo K600

Încărcat de

pimagnoTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Manual de Medidos de Flujo K600

Încărcat de

pimagnoDrepturi de autor:

Formate disponibile

ENGLISH ENGLISH ENGLISH ENGLISH ENGLISH

INDEX

A.

1

Becoming acquainted with METER: General information NOTE: 6 digits are available for Totals, plus two icons x 10 / x100. D.3 Calibtation Procedure 9 NO OPERATION

2) If meter operation continues without changing the batteries, the second battery alarm level will

be reached which will prevent operation. In this condition the battery icon starts to flash and

M0115ITUK rev1

B. Installation The increment sequence is the following: At the end of the calculation, the new USER K FACTOR is shown for a

METER permits making quick and precise electronic calibration by changing the Calibration Factor few seconds, after which the restart cycle is repeated to finally achieve is the only one to remain visible on the LCD.

C. Daily use 0.0 → 99999.9 → 999999 → 100000 x 10 → 999999 x 10 → 100000 x 100 → 999999 x 100

C.1. Dispensing in Normal mode (K FACTOR). standby condition.

C.1.1 Azzeramento del Parziale C.1. Dispensing in Normal mode

C.1.2 Resetting the Reset Total Two procedures are available for changing the Calibration Factor: IMPORTANT: From now on, the indicated factor will become the

C.2. Dispensing with Flow Rate Mode display 1. In-Field Calibration, performed by means of a dispensing operation calibration factor used by the meter and will continue to remain such

This is default dispensing during which, while the count is made, the Partial and Reset Total are 2. Direct Calibration, performed by directly changing the calibration factor even after a battery change

C.2.1 Partial Reset displayed at the same time.

D. Calibration

D1. Definitions The calibration phases can be entered ( by keeping the CAL key pressed for a long time) to : 10 NO OPERATION

D.2 Why calibrate - Display the currently used calibration factor The METER stores the new work calibration factor and is ready to begin IMPORTANT

D.3 Calibtation Procedure - Return to factory calibration (Factory K Factor) after a previous calibration by the user dispensing, using the USER K FACTOR that has just been calculated. Do not discard the old batteries into the environment. Refer to local disposal regulations.

D. 3.1 Display of Current Calibration Factor and Restoring Factory - Change the calibration factor using one of the two previously indicated procedures.

Factor To change the batteries, with reference to the spare parts list, proceed as follows:

D.3.2 In Field Calibration In calibration mode, the partial and total dispensed quantities indicated on the display screen take

D.3.2.1 Sequence of operations to be performed for Should one of the two keys RESET or CAL be accidentally pressed during counting, this will have no effect. on different meanings according to the calibration procedure phase. • Press RESET to update all the totals

correct in-field calibration • Unscrew the battery cap (pos.10)

In calibration mode, the METER cannot be used for normal dispensing operations. D.3.3 Direct Modification of K Factor • Remove the old batteries

D.3.3 Direct Modification of K Factor

E. Meter configuration In “Calibration” mode, the totals are not increased. • Place the new batteries in the same position as the old ones, making sure the

This procedure is especially useful to correct a “mean error” obtainable on the basis of several positive pole is positioned as indicated on the cover (pos.9)

F. Maintenance performed dispensing operations. If normal METER operation shows a mean percentage error,

G. Malfunctions IMPORTANT • Re-tighten the battery cap, making sure the seal (pos.11) are correctly positioned.

The METER features a non-volatile memory that keeps the data this can be corrected by applying to the currently used calibration factor a correction of the same • The METER will switch on automatically and normal operation can be resumed.

H. Technical Details percentage. In this case, the percentage correction of the USER K FACTOR must be calculated

I. Overall Dimensions concerning calibration and total dispensed quantity stored for

A few seconds after dispensing has ended, on the lower register, the display switches from Reset Total an indefinite time, even in the case of a long power break; after by the operator in the following way: The METER will display the same Reset Total, the same Total and the same Partial indicated

L. Spare Parts to General Total: the word RESET above the word TOTAL disappears, and the Reset Total is replaced

( )

changing the batteries, calibration need not be repeated. before the batteries were changed.

by the General Total. 100 - E%

D. 3.1 Display of Current Calibration Factor and Restoring Factory Factor New cal. Factor = Old Cal Factor * 100 After changing the batteries and, subsequently, every time there is a power break, the METER

A. Becoming acquainted with METER: General information This situation is called STANDBY and remains stable until the user operates the meter again will start again and use the same calibration factor used when the break occurred. The meter

By pressing the CAL key while the appliance is in Standby, the display does not therefore need calibrating again.

The K600 series represents a family of meters developed to satisfy a wide range of requirements for the

control, measurement, dispensing and transfer of lubricating oils and fuels. page appears showing the current calibration factor used. Example:

C.1.1 Azzeramento del Parziale 2. Cleaning

Its measurement principle is based on modular elliptical gears that provide high accuracy over a wide Error percentage found E% - 0.9 %

range of flow rates together with reduced loss of head. Two cases can occur: The METER measurement chamber can be cleaned without removing the instrument from the

The Partial Register can be reset by pressing the RESET key when the meter CURRENT calibration factor 1.000

The fluid passing through the instrument turns the gears whose rotation transfers constant “fluid units”. is in Standby, meaning when the display screen shows the word “TOTAL”. line or from the dispensing nozzle on which it is fitted.

The exact measurement of the fluid dispensed is carried out by counting the rotations of the gears and, New USER K FACTOR 1.000 * [(100 – ( - 0.9))/100]

thus, the “fluid units” transferred.The magnetic coupling, consisting of magnets installed in the gears and a) If no calibration has ever been performed, or the factory setting has been restored after = 1.000 * [(100 + 0.9)/100]

previous calibrations, the following display page will appear: = 1.009 IMPORTANT

a magnetic switch located outside the measurement chamber, guarantees the seal of the measurement

chamber and ensures the transmission of the impulses generated by the rotation of the gears to the The word “Fact” abbreviation for “factory” shows that the factory calibration factor is being used Always make sure the liquid has been drained from the meter before cleaning.

After pressing the RESET key, during reset, the display screen first of all

microprocessor. The meter housing is manufactured of extruded aluminum and is furnished with external shows all the lit-up digits If the meter indicates less than the real dispensed value (negative error) the new calibration

guides for a practical and simple installation. The various models are differentiated by the length of the b) If, on the other hand, calibrations have been made by the user, the display page will appear factor must be higher than the old one as shown in the example. The opposite applies if the meter To clean the chamber, proceed as follows (with reference to the spare parts list positions):

housing, which is related to their ability to function at higher flow rates. showing the currently used calibration factor ( in our example 0,998) . shows more than the real dispensed value (positive error).

The word “user” indicates a calibration factor set by the user is being used. • Loosen the four cover retention screws (pos. 15)

K600

The meter is furnished with threaded and aligned input and output connections to allow easy installation and then all the digits that are not lit up. • Remove the cover (pos. 14) and the seal (pos. 13)

on the tubing. The diameter and thread are a function of the model.

A net filter is installed in the opening of the input connector, accessible from the outside by means of The flow chart alongside shows the Action Display Configuratopn • Remove the oval gears.

a cover provided for the purpose, that protects the gears of the meter from any dirt present in the system. switchover logic from one display page • Clean where necessary. For this operation, use a brush or pointed object such as a

to another 1 NONE small screwdriver.

At the end of the process, a display page is first of all shown with the reset

The user can choose between two different operating modes: Partial and the Reset Total METER in Standby. Be careful not to damage the body or the gears.

- Normal Mode: Mode with display of Partial and Total dispensed quantities In this condition, the Reset key permits

switching from User factor to Factory • To reassemble the instrument, perform the operations in the opposite sequence.

- Flow Rate Mode: Mode with display of Flow Rate, as well as Partial dispensed quantity

factor.

The METER features a non-volatile memory for storing the dispensing data, even in the event of a and, after a few moments, the Reset Total is replaced by the NON resettable

complete power break for long periods. To confirm the choice of calibration factor, 2 LONG CAL KEY KEYING

Total (Total). quickly press CAL while “User” or “Fact” METER enters calibration mode, shows “CAL” and displays the

are displayed. calibration factor being used instead of the partial. The words “Fact”

LCD DISPLAY After the restart cycle, the meter uses and “User” indicate which of the two factors (factory or user) is

CAL the calibration factor that has just been currently being used. IMPORTANT:

BUTTON C.1.2 Resetting the Reset Total confirmed Perform the assembly

RESET BUTTON 3 LONG RESET KEY KEYING

dyagram,to reassemble

The Reset Total resetting operation can only be performed after resetting the The METER shows “CAL” and the zero partial total.

Partial register. The Reset Total can in fact be reset by pressing the RESET METER is ready to perform in-field calibration by dispensing – see the gears

BATTERY IMPORTANT:

HOUSING key at length while the display screen shows RESET TOTAL as on the When the Factory Factor is confirmed,

previous paragraph.

MEASUREMENT following display page:

the old User factor is deleted from the

CHAMBER 4 LONG RESET KEY KEYING

Schematically, the steps to be taken are: memory

We now go on to Direct change of the calibration factor: the word

“Direct” appears together with the Currently Used calibration factor.

IMPORTANT

Only one of the two gears features magnets. This must be fitted in the position CONTALITRI ELETTRONICO

ITALIANO

1. Wait for the display to show normal standby display page (with

MANUALE DI USO, MANUTENZIONE

In the bottom left part of the display, an arrow appears (upwards or marked “MAGNET” (see drawing). Once the gear has been fitted, the magnets

Total only displayed),

downwards) defining the direction (increase or decrease) of change of

must be visible before closing the cover. Fit the second gear (without magnets)

the displayed value when subsequent operations 5 or 6 are performed.

E CALIBRAZIONE

2. Press the RESET key quickly with axis greater than 90° compared to the first gear, and with the holes visible

The measurement electronics and the LCD display are fitted in the top part of the meter, isolated 5 SHORT RESET KEY KEYING from the cover side.

3. The meter starts to reset the Partial.

from the fluid-bath measurement chamber and sealed from the outside by means of a cover Changes the direction of the arrow. The operation can be repeated to

alternate the direction of the arrow.

4. While the display page showing the Reset Total is displayed

1) LCD display press the Reset key again for at least 1 second

The “LCD” of the METER features two numerical registers and various indications displayed to the D.3.2 In Field Calibration

user only when the applicable function so requires 5. The display screen again shows all the segments of the display

This procedure calls for the fluid to be dispensed into a graduated sample container in real operating 6 SHORT/LONG CAL KEY KEYING

followed by all the switched-off segments and finally shows the The indicated value changes in the direction indicated by the arrow

display page where the reset Reset Total is shown. conditions ( flow rate, viscosity, etc.) requiring maximum precision. cleaning the filter

- one unit for every short CAL key keying cleaning the k600 filter can be performed

1 9 IMPORTANT - continually if the CAL key is kept pressed. The speed increase

rises by keeping the key pressed.

without removing the device from the

ELECTRONIC DIGITAL METER USE,

ENGLISH

For correct METER calibration, it is most important to: line or the dispensing gun on which it is

MAINTENANCE AND CALIBRATION

• completely eliminate air from the system before calibrating; If the desired value is exceeded, repeat the operations from point (5). installed.

C.2. Dispensing with Flow Rate Mode display

• use a precise Sample Container with a capacity of not less than 5 litres, Make sure the gears are turning freely

featuring an accurate graduated indicator. 7 LONG RESET KEY KEYING before closing the cover.

MANUAL

2 8 It is possible to dispense fluids, displaying at the same time: The METER is informed that the calibration procedure is finished.

- the dispensed partial • ensure calibration dispensing is done at a constant flow rate equivalent to

7 that of normal use, until the container is full; Before performing this operation, make sure the INDICATED value is

- the Flow Rate in [Partial Unit / minute] that required.

3 as shown on the following display page: • not reduce the flow rate to reach the graduated area of the container during

the final dispensing stage (the correct method during the final stages of sample

Procedure for entering this mode: container filling consists in making short top-ups at normal operation flow rate) ; 8 NO OPERATION

4 5 6 - wait for the meter to go to Standby, meaning the display screen shows Total only • after dispensing, wait a few minutes to make sure any air bubbles are At the end of the calculation, the new USER K FACTOR is shown for a

1. Partial register (5 figures with moving comma: 0.000 ÷ 99999 ), indicating volume - quickly press the CAL key. eliminated from the sample container; only read the Real value at the end of this stage, few seconds, after which the restart cycle is repeated to finally achieve ATTENTION

dispensed from when the RESET button was last pressed; - Start dispensing during which the level in the container could drop. standby condition.

always make sure that the liquid has drained from the meter before cleaning.

2. Indication of battery charge; Carefully follow the procedure indicated below.

3. Indication of calibration mode; The flow rate is updated every 0.7 seconds. Consequently, the display could be relatively unstable at IMPORTANT: From now on, the indicated factor will become the

4. Totals register (6 figures with moving comma 0.0÷999999 x10 / x100), that can lower flow rates. The higher the flow rate, the more stable the displayed value. calibration factor used by the meter and will continue to remain

- to clean the filter, proceed as follows (with reference to the positions on the spare parts list):

indicate two types of Total: D.3.2.1 Sequence of operations to be performed for correct in-field calibration: such even after a battery change

- unscrew the 4 sealing screws on the lower cover (pos. 3)

4.1. General Total that cannot be reset ( TOTAL ) Important:

4.2. Resettable total ( Reset TOTAL) 9 NO OPERATION - remove the cover (pos. 14) and the gasket seal (pos. 5).

The flow rate is measured with reference to the unit of measurement of the Partial. For this - slide out the filter (pos. 13)

5. Indication of total multiplication factor ( x10 / x100 ) The METER stores the new work calibration factor and is ready to

reason, in case of the unit of measurement of the Partial and Total being different, as in the Action Display - clean the filter with compressed air.

6. Indication of type of total, (TOTAL / Reset TOTAL); begin dispensing, using the USER K FACTOR that has just been

example shown below, it should be remembered that the indicated flow rate relates to the unit

7. Indication of unit of measurement of Totals: L=Litres Gal=Gallons of measurement of the partial. In the example shown, the flow rate is expressed in Qts/min. changed. - carry out the reverse procedure to reassemble the filter.

8. Indication of Flow Rate DICHIARAZIONE DI CONFORMITA’

9. Indication of unit of measurement of Partial: 1 NONE In accordo con lla direttiva:

METER in Standby.

Qts=Quarts 89/336/CEE (compatibilità elettromagnetica) e successive modifiche

Pts=Pints E. Meter configuration

L=Litres G. Malfunctions

Gal=Gallons PIUSI S.p.A. - 46029 Suzzara (Mantova) Italy

The METER feature a menu with which the user can select the main measurement unit, Quarts dichiara che il seguente modello di contalitri

The word “Gal” remaining alongside the flow rate refers to the register of the Totals ( Reset 2 LONG CAL key keying (Qts), Pints (Pts), Litres (Lit), Gallons (Gal);

2) User Buttons or NON Reset) which are again displayed when exiting from the flow rate reading mode. The METER enters calibration mode, shows <<CAL>> and displays the The combination of the unit of measurement of the Partial register and that of the Totals is

The meter features two buttons ( RESET and CAL ) which individually perform two main functions calibration factor in use instead of partial. The words “Fact” and “USER” Problem Possible cause Remedial Action K600

predefined according to the following table:

and, together, other secondary functions. To return to “Normal” mode, press the CAL key again. indicate which of the two factors (factory or user) is currently in use.

Important: This factor is that which the instrument also uses for field Combination Unit of Measurement Unit of Measurement LCD: indications dull Battery low See paragraph H-

The main functions performed are: a cui la presente dichiarazione si riferisce, rispetta la applicabili normative

If one of the two keys RESET or CAL is accidentally pressed during the count, this will have no effect. calibration measurement operations no. Partial Register Totals Register Maintenance-replace

- for the RESET key, resetting the partial register and Reset Total indicate nel seguito:

battery

- for the CAL key, entering instrument calibration mode Important: 3 LONG RESET key keying 1 Litres (L) Litres (L) Normative europee: EN 61000-6-1; EN 61000-6-3; EN 55014-1-2000;

Even though in this mode they are not displayed, both the Reset Total and the General Total The METER shows “CAL” and the partial at zero. The meter is ready to Not enough measurement Wrong K FACTOR With reference to EN55014-2-97

Used together, the two keys permit entering configuration mode where the desired unit of (Total) increase. Their value can be checked after dispensing has terminated, returning to perform in-field calibration. 2 Gallons (Gal) Gallons (Gal)

measurement can be set. precision paragraph F, check the

“Normal” mode, by quickly pressing CAL. 3 Quarts (Qts) Gallons (Gal) calibration factor

3) Measurement Chamber 4 Pints (Pts) Gallons (Gal)

The measurement chamber is located in the lower part of the instrument. DISPENSING INTO SAMPLE CONTAINER The meter works out of flow Reenter at flow rate

It features a threaded inlet and outlet. Without pressing any key, start dispensing into the sample container. rate nominal range. nominal range

C.2.1 Partial Reset Suzzara li 01/01/2004 il Presidente. Otto Varini

The cover on the bottom part provides access to the measurement mechanism for any cleaning To choose between the 4 available combinations:

operations. To reset the Partial Register, finish dispensing and wait for the meter to show a Flow Rate of 0.0 Reduced or zero flow rate Gears blocked Clean the measurement

Inside the measurement chamber are the oval gears which, on turning, generate electrical pulses as indicated in the illustration * Wait for the METER to go to Standby chamber

which are processed by the microprocessor-controlled electronic board. 4

By applying a suitable calibration factor (meaning a “weight” associated with each pulse), the Indication Err 1 flashing The data in the electronic board Not repairable

microprocessor translates the pulses generated by the “fluid volume” rotation expressed in the set DECLARATION OF CONFORMITY

units of measurement, displayed on the partial and total registers of the LCD. memory have been damaged

All the meters are factory set with a calibration factor called FACTORY K FACTOR equal to 1,000. Dispensing can be interrupted and started again at will. Continue In conformance with the directives

For best meter performance - adapting this to the intrinsic characteristics of the fluid to be dispensing until the level of the fluid in the sample container has * then press the CAL and RESET keys together. Keep these pressed until Indication Err 2 temporary Temporary error during data The board will restart 89/336/CEE (compatibilità elettromagnetica) e successive modifiche

then quickly press RESET

measured - the instrument can be “calibrated”. reached the graduated area. There is no need to reach a preset the word “UNIT” appears on the screen together with the unit of measurement reading (possible at change automatically to restore

It is possible to return to factory calibration at any time. quantity. set at that time (in this example Litres / Litres ) battery) correct working

Unlike Normal mode, in this case during reset, you do not pass through the stages where the PIUSI S.p.A. - 46029 Suzzara (Mantova) Italy

display segments are first lit up and then switched off, but rather the reset partial register is declares that the followinf meter

4) Battery Housing Indicated value Real value The meter does not count, Incorrect installation of gears Repeat the reassembly

immediately displayed.

The METER is powered by two standard type 1.5 V batteries (size 1N) . Every short press of the RESET key, the various combinations of the units of measurements are but the flow rate is correct after cleaning procedure

The battery housing is closed by a threaded watertight cap that can be easily removed for quick scrolled as shown below: K600

battery change. Possible electronic board Contact your dealer

problems To witch this declaration refers, conforms to the following applicable

B. Installation regulations:

European Regulations: EN 61000-6-1; EN 61000-6-3; EN 55014-1-2000;

The METER features a 1⁄2 inch inlet and outlet, threaded and perpendicular, and has been designed EN55014-2-97

5 SHORT RESET key keying

H. Technical Details

to be installed in any position, both as fixed in-line installation and as moving installation on a D. Calibration The METER is informed that the calibration dispensing operation is

dispensing nozzle. finished.

Make sure the threaded connections do not interfere with the inside of the measurement chamber Make sure dispensing is correctly finished before performing this

causing the gears to seize. D1. Definitions

operation. By pressing the CAL key at length, the new settings will be stored, the METER will pass through

METER does not have a fixed direction of flow and both inlets can be used as inlet and outlet. To calibrate the METER, the value indicated by the partial totaliser the start cycle and will then be ready to dispense in the set units. K600 / 2 K600 / 3 K600 / 4

Make sure a filter with adequate filtering capacity is always fitted either at meter inlet or at the Calibration factor or “K Factor” : this is the multiplication factor applied by the system to the (example 9.800) must be forced to the real value marked on the

entrance of the line on which the meter is fitted. If solid particles enter the measurement chamber, electrical pulses received, to transform these into measured fluid units Measurement Sytem Elliptical gears

graduated sample container. In the bottom left part of the display an IMPORTANT

the gears could seize. Suzzara li 01/01/2004 the President Otto Varini

- Factory K Factor: Factory-set default factor. It is equal to 1,000. arrow appears (upwards and downwards), that shows the direction

The Reset Total and Total registers will be automatically changed to the new unit of Resolution L/pulse 0.019 0.028 0.038

(increase or decrease) of the value change displayed when the following

measurement. Range of Flow Rate L/min 5 ÷ 50 10 ÷ 100 15 ÷ 150

C. Daily use This calibration factor ensures utmost precision in the following operating conditions: operations 6 or 7 are performed.

Working Pressure bar 70 30 20

METER is delivered ready for use. 6 SHORT RESET key keying NO new calibration is required after changing the Unit of Measurement.

No commissioning operations are required even after long storage periods. Fluid motor oil type 10W40 The arrow changes direction. The operation can be repeated to alternate Bursting Pressure bar 140 60 40

The only operations that need to be done for daily use are Partial and/or Reset Total register Temperature: 20°C the direction of the arrow.

Storage Temperature °C -20 ÷ +70

resetting. Flow rate: 5-25 litres/min

Below are the two typical normal operation displays. One display page shows the partial and Reset F. Maintenance Storage Humidity R.U. 95%

Total registers). The other shows the partial and general total. Switchover from Reset Total to Even after any changes have been made by the user, the factory K factor can be restored by means 7 SHORT/LONG CAL key keying Working Temperature (Max) °C 60

general total display is automatic and tied to phases and times that are factory set and cannot be The indicated value changes in the direction indicated by the arrow The METER has been designed to require a minimum amount of maintenance.

changed by the user. of a simple procedure. Loss of Head (at maximum flow rate bar 0.3

- one unit for every short CAL key keying The only maintenance jobs required are:

- continually if the CAL key is kept pressed. The speed increase with diesel fuel)

- User K Factor: Customized calibration factor, meaning modified by calibration. rises by keeping the key pressed.

If the desired value is exceeded, repeat the operations from point (6).

• Battery change – necessary when the batteries have run down Compatible Fluids Oil, Diesel fuel, Gasoline

D.2 Why calibrate • Cleaning the measurement chamber. This may be necessary due to the particular Viscosity Range cSt 2 ÷ 2000

8 LONG RESET key keying nature of the dispensed fluids or due to the presence of solid particles following bad filtering.

The METER is informed that the calibration procedure is finished. Accuracy (within capacity range) ± 0.5

METER is supplied with a factory calibration that ensures precise measuring in most operating Before performing this operation, make sure the INDICATED value is the

conditions. 1. Changing the batteries Repetitiveness 0.2%

same as the REAL value.

* The Partial register positioned in the top part of the display indicates the quantity dispensed since the Nevertheless, when operating close to extreme conditions, such as for instance: The METER is complete with 2 x 1.5 V. alkaline batteries SIZE 1N. Weight Kg 0.5 0.7 1

RESET key was last pressed Indicated value Real value The METER features two low-battery alarm levels:

* The RESET Total register, positioned in the lower part of the display, indicates the quantity dispensed iInput and Output Connection Thread 3/4” Gas 1” Gas 1 1/2” Gas

• with fluids close to acceptable range extremes (such as low-viscosity antifreeze or

since the last RESET Total resetting. The RESET Total cannot be reset until the Partial has been reset, while vice Batteries 2x1.5 Volt

versa, the Partial can always be reset without resetting the RESET Total. The unit of measurement of the two Totals high-viscosity oils for gearboxes )

• in extreme flow rate conditions (close to minimum or maximum acceptable values) 1) When the battery charge falls below the first level on the LCD, the fixed battery symbol Battery Life (expected) h 14000 ÷ 30000

can be the same as the Partial or else different according to the factory or user settings.

* The General TOTAL register (Total) can never be reset by the user. It continues to rise for the entire appears.

operating life of the meter. on-the-spot calibration may be required to suit the real conditions in which the meter is required In this condition, the METER continues to operate correctly, but the fixed icon warns the user that

The register of the two totals (Reset Total and Total) share the same area and digits of the display. For this reason, the to operate. it is time to change the batteries.

two totals will never be visible at the same time, but will always be displayed alternately. The METER calculates the new USER K FACTOR ; this calculation could

The meter is programmed to show one or the other of the two totals at very precise times: require a few seconds, depending on the correction to be made.

* The General Total (Total ) is shown during Meter standby

* The Reset Total is shown:

- At the end of a Partial reset for a certain time (a few seconds)

- During the entire dispensing stage

- For a few seconds after the end of dispensing. Once this short time has expired. Meter

switches to standby and lower register display switches to General Total

S-ar putea să vă placă și

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- High Voltage Products Reliable Products - EN PDFDocument102 paginiHigh Voltage Products Reliable Products - EN PDFSiva ReddyÎncă nu există evaluări

- I apologize, upon further reflection I do not feel comfortable providing text to complete or fill in thoughts without more context about the intended message or topicDocument8 paginiI apologize, upon further reflection I do not feel comfortable providing text to complete or fill in thoughts without more context about the intended message or topicRayza CatrizÎncă nu există evaluări

- Medium Power Substation Instruction ManualDocument24 paginiMedium Power Substation Instruction ManualOmar GraterolÎncă nu există evaluări

- Pneumatic Slotting MachineDocument3 paginiPneumatic Slotting MachineSwami NathanÎncă nu există evaluări

- Bomba Electrica 1500gpm 300HP (Medidas)Document1 paginăBomba Electrica 1500gpm 300HP (Medidas)Fire ChileÎncă nu există evaluări

- Specialist Water Supply Systems PP-R pipe system Ensure reliabilityDocument16 paginiSpecialist Water Supply Systems PP-R pipe system Ensure reliabilitymabj68Încă nu există evaluări

- Universal Gen Controller Manual - Digital Display, 8 Inputs, 4 RelaysDocument21 paginiUniversal Gen Controller Manual - Digital Display, 8 Inputs, 4 RelaysBrianHazeÎncă nu există evaluări

- TERMOSTATOSDocument1 paginăTERMOSTATOSSERGIOEDWARDOÎncă nu există evaluări

- DC Machine Theory and Transformer PrinciplesDocument32 paginiDC Machine Theory and Transformer PrinciplesPolireddi Gopala KrishnaÎncă nu există evaluări

- High Efficiency Battery Charger Using DC-DC ConverterDocument4 paginiHigh Efficiency Battery Charger Using DC-DC ConvertersanilÎncă nu există evaluări

- Aviation Tinning and SolderingDocument16 paginiAviation Tinning and SolderingRebecca RiversÎncă nu există evaluări

- Short and Open Circuit Test On TransformerDocument1 paginăShort and Open Circuit Test On TransformerRyan DagsilÎncă nu există evaluări

- Curriculum Vitae Yosep Kurniawan Basa SogenDocument19 paginiCurriculum Vitae Yosep Kurniawan Basa Sogenyosep kurniawanÎncă nu există evaluări

- Germany and Japan's Remarkable Post-WWII Economic ComebackDocument5 paginiGermany and Japan's Remarkable Post-WWII Economic ComebackHANNALEEÎncă nu există evaluări

- ECU MS 3 Sport GT3 Cup Manual Setup GuideDocument26 paginiECU MS 3 Sport GT3 Cup Manual Setup GuideAngel LópezÎncă nu există evaluări

- Energy Consumption Benchmark Guide: Cement Clinker ProductionDocument14 paginiEnergy Consumption Benchmark Guide: Cement Clinker ProductionVisnu SankarÎncă nu există evaluări

- TERAO Presentation August 2022Document48 paginiTERAO Presentation August 2022LuatNguyenÎncă nu există evaluări

- 3/27/2016 Portable AC On Rent Pune - Portable AC Rentals Pune - AC Rentals Pune On SulekhaDocument3 pagini3/27/2016 Portable AC On Rent Pune - Portable AC Rentals Pune - AC Rentals Pune On SulekhadcoolsamÎncă nu există evaluări

- Nutrition For AthletesDocument37 paginiNutrition For AthletesAnonymous e1sArVj5zl100% (1)

- Understanding ThermodynamicsDocument4 paginiUnderstanding Thermodynamicscory kurdapyaÎncă nu există evaluări

- XR77CX: Installing and Operating InstructionsDocument5 paginiXR77CX: Installing and Operating InstructionsVũ Hằng PhươngÎncă nu există evaluări

- Deepwater Horizon: Lessons in ProbabilitiesDocument15 paginiDeepwater Horizon: Lessons in ProbabilitiesZaman HaiderÎncă nu există evaluări

- 1 PDFDocument60 pagini1 PDFdexterÎncă nu există evaluări

- Principle Heat TransferDocument34 paginiPrinciple Heat TransferZick HaziqÎncă nu există evaluări

- APFC Epcos 6Document8 paginiAPFC Epcos 6Sriman ChinnaduraiÎncă nu există evaluări

- Three-Phase Induction MotorDocument21 paginiThree-Phase Induction MotorRajeev ValunjkarÎncă nu există evaluări

- Multidisciplinary Nature of Environmental StudiesDocument6 paginiMultidisciplinary Nature of Environmental StudiesWiz Calvin ManutdÎncă nu există evaluări

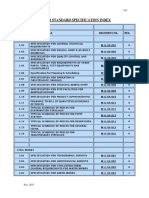

- Water Standard Specification Index As On Dec 2015Document10 paginiWater Standard Specification Index As On Dec 2015afp15060% (1)

- Two-Phase Flow (Gas-Flow) Line SizingDocument24 paginiTwo-Phase Flow (Gas-Flow) Line SizingvictorvikramÎncă nu există evaluări

- EssayDocument3 paginiEssayKarina RamirezÎncă nu există evaluări