Documente Academic

Documente Profesional

Documente Cultură

Biogas Production and Utilization

Încărcat de

Wijetunga SomasiriDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Biogas Production and Utilization

Încărcat de

Wijetunga SomasiriDrepturi de autor:

Formate disponibile

AEN 3200 Farm Practice Course

Biogas Production and Utilization

CONTENT

1. Introduction

1.1 What is biogas?

1.2 Composition of biogas

1.3 Calorific value of biogas

1.4 What can biogas do?

1.5 Why do we need biogas?

2. Is there any Potential to Produce Biogas in Sri Lanka?

2.1 Livestock byproducts

2.2 Municipal solid wastes

2.3 Human excreta

2.4 Kitchen wastes

2.5 Abattoirs

2.6 Agricultural byproducts

2.7 Industrial wastes

3. Important Definitions…

3.1 Anaerobic digestion (degradation)

3.2 Methanogenesis

3.3 Biomethanation

3.4 Organic Matter

4. History of Biogas

5. How is Biogas Produced?

5.1 Microbial process of biogas production

5.2 Microbes involved in anaerobic digestion

5.2.1 Hydrolytic fermentative microorganisms

5.2.2 Acidogenic fermentative microorganisms

5.2.3 Methanogenic fermentative microorganisms

6. Factors Affecting Biomethanation

6.1 Important factors

6.1.1 Anaerobiosis

6.1.2 Temperature

6.1.3 pH

6.1.4 Substrate composition

6.1.5 C/N ratio

6.1.6 Micronutrients

6.1.7 Toxins and inhibitors

6.1.8 Hydraulic retention time

6.1.9 Total solids

6.2 Essential requirements for anaerobic digestion

7. Biogas Production

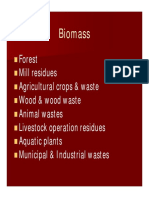

7.1 Compounds that can produce biogas

7.2 Raw materials suitable for biomethanation

7.3 Degradability of organic compounds

S Wijetunga Page 1 7/27/2011

AEN 3200 Farm Practice Course

8. Digester for Biogas Production

8.1 Parts of a digester

8.1.1 Digester

8.1.2 Gasholder

8.1.3 Piping system

8.1.4 Inlet and outlet

8.2 Types of digesters

8.2.1 Based on origin

8.2.2 Based on dome

8.2.3 Based on the way of putting feeding materials

9. Utilization of Biogas

9.1 Major uses of biogas

9.1.1 Biogas for cooking

9.1.2 Biogas for lighting

9.1.3 Biogas for engines

9.2 Treatment of biogas

9.3 Storage of biogas

10. Design of a Biogas Plant

11. Advantages and Environmental Aspects of Anaerobic Digestion

11.1 Advantages of anaerobic digestion

11.2 Environmental aspects of biogas technology

11.3 Uses of digested slurry

References

S Wijetunga Page 2 7/27/2011

AEN 3200 Farm Practice Course

1. Introduction

Biogas production has several advantages in terms of economically as well as

environmentally. Therefore, it has to be very important to know about production and

utilization of this environmentally friendly technology. This manual explains the most

of important aspects of biogas production and utilization.

1.1 What is biogas?

Biogas is a mixture of gases produced by microorganisms under anaerobic

degradation (digestion) of organic water. Major component of biogas is methane.

Methane is a combustible gas and it can be used for energy generation.

Composition of biogas

Methane (CH4) 50% - 70%

Carbon dioxide (CO2) 25% - 40%

Various other gases (H2S, NH3, H2O vapour) 0% - 5%

In addition to above gases N2, CO, O2, and H2 slight concentrations occasionally

present in biogas.

Biogas is often named according to its origin. Biogas is named as landfill gas when

they originate from landfill sites and named as sewage gas when they originate from

sewage sludge.

1.3 Calorific value of biogas

The calorific value of biogas varies according to its percentage of methane since

methane is the major component of biogas that can produce energy. Other

constituents do not produce energy and they absorb energy, which are produced by

the combustion of biogas.

The calorific value of pure methane is 36000kJ/m3. Each 10% of methane can

change the calorific value by 3600kJ/m3. For example, calorific value of biogas

containing of 70% of methane is 25200kJ/m3. The actual calorific value of biogas is a

function of its methane percentage, pressure and temperature. The actual values are

very important parameter for the performance of the engines, which are running on

biogas.

1.4 What can biogas do?

It can easily be used as an energy source especially for cooking, lighting, generating

electricity and motive power. In addition, digested material, which comes out from

the digesters, can be used as organic manure and there are various beneficial

effects to environment in biogas production.

1.5 Why do we need biogas?

Production of biogas is a process of generation of renewable energy and a process

of waste management as well.

S Wijetunga Page 3 7/27/2011

AEN 3200 Farm Practice Course

Energy is very important for the development of a country. With the development, the

demand for energy is also increasing. And also increase of population makes high

demand on energy. Therefore, we have to spend lot of money for importing the

petroleum since Sri Lanka do not have fossil fuel. Although we use biomass for

major energy source, lots of petroleum fuels are needed for industries and to

generate electricity. The energy sources and their contribution and the sectors of

energy usage and their percentages are given below.

Sources of Energy Contribution %

Biomass 70

Petroleum 25

Hydropower 05

Consumption Category Consumption %

Domestic 65

Industry 13

Other 22

Table 01: Sources of energy and consumption

Almost all the biomass energy is used for household purposes, especially cooking.

The limited amount of biomass is used for industries such as bricks & tile, tea,

rubber, coconut, etc. Use of biomass as an energy source is compelled to increase

deforestation. Therefore, use of biogas as an energy source for household purposes

reduce the deforestation of the country.

In year 2000, cost of petroleum imports was Rs 67187 million and it is considerably

high when compared with national income. Considerable amount of petroleum

(basically LP gas) is also used for cooking and it can be replaced by biogas. As such

the use of biogas save the national income, which is needed to import petroleum

fuels.

Uses of firewoods in unventilated kitchens create health problems in housewives due

to inhalation of unidentified substances in smokes that are produced by burning of

biomass. But biogas burners do not produce other gases than carbon dioxide.

Therefore, use of biogas improves the health of the housewives.

Methane is a green house gas by which increase the global temperature 25 times

more than carbon dioxides does. As such production of methane is not

environmentally friendly and it can cause to increase global temperature. The

estimated anthropogenic green house effect is 15% from methane and 60% from

carbon dioxide. The atmospheric methane concentration is increasing at a rate of

0.8-1.0 % per year. The almost all methane emissions are from low land paddy

fields, ruminant excreta and landfill sites. Ruminant excreta naturally produce

methane and it increases the methane concentration in the atmosphere. But if we

can produce methane from animal excreta in control condition and it can be used for

energy purposes. Then methane emission to atmosphere is reduced and decreases

the global worming. Lowland paddy cultivation is also one reason to increase

methane emission to atmosphere. It has been found that emission of methane from

paddy cultivation varies from 20-150Tg per year. And also researches showed that

methane emission from paddy fields is higher after harvesting due to degrading of

S Wijetunga Page 4 7/27/2011

AEN 3200 Farm Practice Course

straw at the field. Therefore, if we can use straw for biogas production methane

emission can be reduced and useful energy could be generated. In the same way,

the organic wastes, which are a large part of land filling, can be used for biogas

production and it will also reduce the emission of methane to the atmosphere.

Conventional energies such as petroleum, coal and LP gases are not unlimited. The

estimated recovable years for petroleum, coal and gases are 43, 232 & 65 years

respectively. Therefore, it is beneficial to find out good sources of renewable

energies for our requirements. In considering Sri Lanka almost all hydropower

capabilities has already been used and wind and biomass energy sources, as

renewable energy is a good option.

S Wijetunga Page 5 7/27/2011

AEN 3200 Farm Practice Course

Is there any Potential to Produce Biogas in Sri Lanka?

The biogas production basically depends on the availability of substrates that can go

through anaerobic digestion. Since Sri Lanka is an agricultural country there are so

many good sources of substrates.

2.1 Livestock byproducts

Cattle, buffalo, pig and poultry are the major groups of livestock that can produce

good substrates for biogas production. In 1995 statistics shows that cattle, buffalo,

pigs and poultry population in the country is 1704000, 764000, 87000 and 9573000

in numbers, respectively. Therefore, production potential of biogas in Sri Lanka is

very high. Cattle and buffalo rearing in open space, especially dry zone farmers, is

the major problem for collecting of cow dung that badly affect to the biogas

production. Use of total available animal excreta can generate 27782400MJ of

energy per day (@ 252MJ per cubic meter of biogas). This value is equivalent to

86.82MW of electricity.

2.2 Municipal solid wastes

In most town areas the waste disposal is a big problem. The urban wastes contain

more than 80% of organic wastes, which can easily be used for biogas production.

This helps to make pleasant and healthier environment in urban areas.

The total availability of solid wastes in Sri Lanka is about 2425MT/day (Ministry of

environment, 1996). The production rate may vary with population growth rate and

economic changes. As a guide value, waste production in low-income countries is

0.4kg/person/day; middle-income countries 0.5-0.9kg/person/day and industrialized

countries 0.7-1.8kg/person/day.

The amount of organic wastes that can be obtained from municipal solid wastes in

Sri Lanka is about 1940T/day (if organic fraction of MSW is 0.8). The energy

potential that could be generated from MSW through biogas production is 101.5MW

of electricity equivalent.

2.3 Human excreta

Human excreta are good source but production of biogas using human wastes is not

a culturally accepted in Sri Lanka. And handling is also a problem. By diverting toilet

outlet directly to digester can prevent handling practice. Digested wastes coming

from digester do not have any harmful organisms and they all were destroyed due to

high temperature in the digester.

Total potential of biogas production is about 518000m3/day, which is equivalent to

40.8MW of electricity.

2.4 Kitchen wastes

Kitchen wastes could also easily be used for biogas production but available amount

of wastes in a single kitchen is very small and they only do not enough for biogas

production. However, kitchen wastes generated from hostels, hospitals, factories,

etc., can easily be used for biogas generation. The biogas production rate is 93L/kg

S Wijetunga Page 6 7/27/2011

AEN 3200 Farm Practice Course

with a 30 days retention time from a conventional Indian type digester. The methane

content is observed as 58%.

2.5 Abattoirs

Abattoirs produce a variety of wastes such as blood, soft offal, meat, tallow, bone

meal, etc., and liquid effluents at cleaning operations. These fractions could also be

used but potential is not exactly known.

2.6 Agricultural by products

Lots of agricultural by products can be used for biogas production. Since Sri Lanka

cultivates rice, the rice straw can be used as substrates for biogas production. It is

estimated that the rice straw production is about 2000000MT per annum. Most of this

straw is burnt removing vast amount of nutrients from the field. However, use of rice

straw as a raw material for biogas has several benefits, energy generation and

production of enriched manure as well as avoiding of releasing methane from paddy

fields by uncontrolled anaerobic digestion.

Potential energy generation from rice straw is about 64MW electricity equivalent (use

of 100% of straw).

2.7 Industrial wastes

Wastes and wastewater coming from industries such as beverages, food, milk,

sugar, rubber, coconut, etc., can be used. The potential of energy generation from

these sectors are high.

S Wijetunga Page 7 7/27/2011

AEN 3200 Farm Practice Course

3. Important Definitions…

3.1 Anaerobic digestion (degradation)

Anaerobic digestion is the process by which organic matter is transformed into

methane or reduced organic components such as ethanol, lactic acid etc, by the

microorganism in the absence of oxygen (air). This is a microbial process.

3.2 Methanogenesis

Methanogenesis is a biological process by which organic matter is transformed into

methane by microorganisms in the absence of air.

3.3 Biomethanation

When Methanogenesis process is housed in a reactor to create a technological

process, it is known as biomethanation.

3.4 Organic matter

Organic matter is the compound containing carbon atoms usually in chain. In other

words, matter made essentially from carbon linked together. Organic matter forms

the better part of living organisms.

S Wijetunga Page 8 7/27/2011

AEN 3200 Farm Practice Course

4. History of Biogas

Anecdotal (Unpublished) evidence indicates that biogas was used for heating bath

water in Persia during the 16th Century BC.

Benjamin Franklin described as early as 1764 that he was able to light a large

surface of shallow muddy late in New Jersy.

Alexander Volta was the first researcher describing the formation of inflammable

gases in (low temperature) marshes and lake sediments scientifically. His paper

was published in Italy in 1776. The importance of these findings was fully

recognized by the scientific community and his letters were translated into German

after two years (1778). Therefore, Volta is considered as the inventor of biogas.

In 1804, Dalton gave the correct chemical formula for methane.

In 1875, Popoff found that river sediments could produce biogas at temperature as

low as 6°C and with increasing of temperature up to 50°C the gas production was

stimulated. He also observed that the composition of biogas did not change with

temperature.

The first digestion plant was built at leper colony in Bombay, India in 1859.

Gayon, a pupil of Pasteur, recoded a success in his experiments with animal manure

in 1883-84. In same period, Louis Pasteur concluded that anaerobic manure

fermentation might supply gas for heating and illumination.

Based on the findings that higher temperatures stimulate the biogas formation,

heating systems were developed to increase the digester temperature. In between

1914 and 1921, Imhoff and Blunk took patents for heating devices (heat exchangers)

to increase the temperature in the digester.

In 1936, Bushwell made his basic experiments on manure digestion in combination

with most possible types of organic waste and he became the father of co-digestion.

The first full scale agricultural biogas installation developed in 1938 by Isman and

Descellion in Algeria.

Towards the end of the Second World War when the fuel was limited, anaerobic

digestion of liquid manure and sewage sludge became quite popular

France, Germany are operating biogas plants, specially large size plants, with higher

technical standard mainly on sewage works. Half of gas was utilized to run engines.

Today biogas production has become a standard technology in wastewater

treatment and upgrading of biowaste from household and agriculture. The

development of the last 20 years allows not only low cost gas production but also it’s

S Wijetunga Page 9 7/27/2011

AEN 3200 Farm Practice Course

upgrading and efficient – utilization in gas engines to produced electricity and fuel

vehicles.

In the field of biogas production (anaerobic digestion) from wastes the India and

China are recognized as world leaders. The period from 1973 – 1985 showed the

rapid and worldwide development of simple AD systems for methane production as

an energy source. In 1973, India, China and South East Asia rapidly and massively

expended their AD units to answer their increased energy cost. The both countries

have large number of small size biogas digesters for supplying the energy needs in

especially rural people.

S Wijetunga Page 10 7/27/2011

AEN 3200 Farm Practice Course

5. How is Biogas Produced?

Biogas is produced by microorganisms when they are degrading (digesting) of

organic substances under anaerobic condition.

5.1 Microbial process of biogas production

In fact, no known microbe can produce methane (major component of biogas) other

than

• Acetate

• Carbon dioxide & Hydrogen

• Methanol

• Formate

• Carbon monoxide and

• Some methylated amines.

Therefore, any organic matter should be converted to one or more of above

substances before produce the methane. There are three distinct groups of bacteria

that can involve in the process of anaerobic digestion. Together with these three

groups of bacteria finally organic matter converted to biogas and digested material,

which is almost different from initial material. And some instances, indigestible

material can also be seen in the digested material.

5.2 Microbes involved in anaerobic digestion

Three groups of bacteria involved in anaerobic digestion are,

i. Hydrolytic fermentative microorganisms. (Hydrolysis or liquefaction)

ii. Acetogenic fermentative bacteria. (Acedogenesis)

iii. Methanogenic bacteria (Methanogenesis)

5.2.1 Hydrolytic fermentative microorganisms

These groups of microorganisms can hydrolyze high molecular substances in to low

molecular substances, for example, proteins to amino acid, polysaccharides to oligo

and monosaccharides, and lipids to free fatty acids. Process performed by these

microorganisms is called as Hydrolysis or liquefaction.

5.2.2 Acetogenic fermentative microorganisms

Acetogenic bacteria obtain their energy from the oxidation of organic acids, alcohols

and volatile acids with more than two carbon atoms, for example, caproate,

butyrate and propionate. End products of hydrolysis process are converted to

volatile fatty acids, H2, CO2, NH3, ethanol, and methanol. The process

performed by microorganism is called as Acedogenesis.

5.2.3 Methanoganic fermentative microorganisms

Methanogenic bacteria are the ultimate group in the process of anaerobic digestion.

They produce the most reduced form of carbon, namely, methane. A detailed

scheme for break down of organic compounds is given in the following diagram.

Approximately 70% of the methane is formed from VFA, 30% form H 2, CO2 by

S Wijetunga Page 11 7/27/2011

AEN 3200 Farm Practice Course

methanogenic bacteria. The process performed by these groups of microorganism is

referred as Methane formation.

According to above three groups of bacteria process of biogas production could be

divided into three steps

o Hydrolysis

o Fermentation

o Methane formation.

Figure 01: Flow sheet of methanogenesis

S Wijetunga Page 12 7/27/2011

AEN 3200 Farm Practice Course

Factors Affecting Biomethanation

6.1 Important factors

Several factors are governing the methanogenesis process in anaerobic digestion

process. Important factors are briefly explained in the following sections.

6.1.1 Anaerobiosis (anaerobic condition)

Methanogenesis is a strict anaerobic process. The major groups of bacteria actively

engaged in methanogenesis will die in the present of O 2. But some researchers

have found some aerobic facultative bacteria in the digesters. These bacteria do not

have any role in the main degradative reactions of the digestion but they may have

some role in sugar fermentation. Most probably, these bacteria may use the oxygen

in the system, reducing the system, to be suitable for the growth of the

methanogenic bacteria.

6.1.2 Temperature

Methane is formed in nature over a wide range of temperatures. Three different

temperature varies are distinguished

• Psychrophilic temperature - 10 - 25oC

• Measophilic temperature - 30 - 37oC

• Thermophilic temperature - 50 - 65oC

In low temperatures gas production rate as well as the amount of gas production is

low and in high temperatures biogas production is high. In most cases, measophilic

temperature range is used. The measophilic digesters could be converted to

thermophilic or vise versa.

However, the change should be in smoothly (slow change). The sudden

temperature changes badly affects to the digester activities and slow or stop the gas

production. To convert the measophilic process to thermophilic process, it will take

10-20 days.

Thermophilic digestion process has several advantages. These are

Rapid metabolic activity, help to

- Reduce the retention time

- Increasing the loading rate

- Small digester volume

- Increase rate of methane production (1.5 times faster than

measophilic).

High temperature, helps to

- Kill the pathogenic organisms

- Improve dewaterability.

Low temperature, psychrophilic, waste digestion is slower than measophilic and

thermophilic digestion.

S Wijetunga Page 13 7/27/2011

AEN 3200 Farm Practice Course

6.1.3 pH

A pH value between 6.5 and 7.7 has been found to be optimum for the process.

Methanogenesis beyond the range of 6.5 – 8.0 pH has been found to be less yield of

biogas

6.1.4 Substrate composition

Depending on the composition of the substrate (feedstock), the rate and amount of

gas production and digesting process rate will vary. If we have the composition of

the substrate, it is possible to calculate the amounts of gas, which may be produced

on the basis of a simple carbon balance.

Theoretical yield of biogas (m3/kg is destroyed) from various compounds of organic

matter are 0.886 (carbohydrates), 1.535 (fat), and 0.587 (proteins) with methane

content of 50, 70 and 84% respectively.

C/N ratio

Nitrogen is essential for cell growth and it can controls the pH by releasing the NH 3

from Nitrogenous compounds.

The optimum range of C/N ration for methane production is 25:1 to 30:1. This shows

that bacteria consume carbon 25 to 30 times faster than Nitrogen. Therefore,

optimum ratio of C/N is essential for smooth operation of digester. The C/N ratios of

important feeds stocks are given in the following table.

Organic Substrate Carbon (dry wt %) Nitrogen (dry wt %) C/N Ratio

Straw (rice) 42 0.63 67:1

Fallen leaves 41 1.0 41:1

Stalks (corn) 40 0.75 53:1

Weeds 14 0.54 27:1

Sheep excreta 16 0.55 29:1

Cattle dung 7.3 0.29 25:1

Horse excreta 10 0.42 24:1

Swine excreta 7.8 0.65 13:1

Human faeces 2.5 0.85 3:1

Table 02: Composition of different raw materials

The different substrates can be mixed together to achieve the proper C/N ratio for

anaerobic digestion. If we have various raw materials, they can be mixed up to get

desired C/N ratio. Following example clearly show the method of calculating

required amount of nitrogen sources to get desired C/N ratio of law nitrogen raw

materials.

Example: Calculate the quantity of urea (46% of N) required to make the 1000kg

of rice straw for biogas digester with C/N, 30:1.

Rice straw contains carbon, 42% and nitrogen, 0.63%. The urea (CO(NH 2)2)

contains nitrogen, 46% and carbon, 20%. Required amount of urea can be

calculated as follows.

S Wijetunga Page 14 7/27/2011

AEN 3200 Farm Practice Course

42 20

(Amount of C in Straw) ×1000 + (Amount of C in Urea) ×x

30 100 100

(Required C/N ratio) =

1 0.63 46

(Amount of N in Straw) ×1000 + (Amount of N in Urea) ×x

100 100

Re qured amount of Nitrogen is about 16 .75 kg

6.1.5 Micronutrients

In addition to nitrogen, the phosphorous is also essential for the better growth of

microorganisms. The ratio of C:P of 100-200 is said to be optimum. Micronutrients

such as Nickel (100 nM) Cobalt (50nM) and Molybdenum (50 nM) are important.

Molybdenum may enhance the joint effect of Nickel and Cobolt. Iron (2nm) and

Copper (4nm) are necessary for enhancing the performance of the digestion

process.

Toxins and inhibitors

It has been found that metal irons exert a toxic effect they exceed the required

concentration. If they are in the digester more than tolerable limit, it should be

diluted by adding water and regularly flushed out.

--

SO 4 500 ppm

Cyanide <25 mg/L

Detergent compounds 20-40 ppm

Sodium chloride 40 000 ppm

Ammonia (Not NH+4 ) 1500 - 3000 ppm

Copper 100 mg/L

Chromium 200 mg/L

Nickel 200-500 mg/L

Sodium 3500-5500 mg/L

Potassium 2500-4500 mg/L

Calcium 2500-4500 mg/L

Magnesium 1000-1500 mg/L

Hydraulic retention time (HRT)

Hydraulic Retention Time expresses the volume of fluids in the reactor per volume of

fluid passing into and out of the reactor on a daily basis. It indicates the contact time

allowed between the substrate and microorganisms in the system. Maintaining

option retention time is an important for efficient conversion of organic matter to

methane.

Use of long retention time would result inefficient use of digestion capacity. The

substrates for microorganisms are not sufficient and their growth is slow down.

Short retention time is not sufficient for microorganisms to degrade the whole

substrate. The retention time may very depending on the composition of the

substrate. For example, cellulose material required 10 days for digestion and for

lignocellulose material is non degradable even at 30 days. In most cases 30-40

days of retention time is suitable.

6.1.6 Total solids

S Wijetunga Page 15 7/27/2011

AEN 3200 Farm Practice Course

Total solid content of the substrate is very important in biogas production. The

optimal total solid level for biogas production was observed as 10%. But

considerable gas production can be obtained up to 30% of solid level. The increase

of solid level leads to reduce the gas production. To obtained desirable amount of

biogas production from higher total solid levels, long duration of retention times

should be practiced.

When we are using animal excreta (specially cow dung) and green refuse, 1:1 ratio

of water to substrate could be practiced as a general value. Approximate total solid

contents of several substrates are given below.

Substrates Total Solid %

Water hyacinth 11

Plant wastes 75

Grasses 30-80

Poultry manure (fresh) 35

Poultry manure (dry) 90

Pig manure 14

Human faeces 27

News papers 93

Cow dung 20-25

Table 03: Total solids in different raw materials

6.2 Essential requirements for anaerobic digestion

pH near neutral

C/N 25 – 30 / 1

Organic substrates of digestion

Total solids in the substrates (10% is best but up to 30% is possible)

Free from toxic compounds

Initial material to initiate the digestion process (inoculums), in most cases

cow dung (ruminant fluid) or sewage sludge or digested material from an

anaerobic digester could be used.

7. Biogas Production

S Wijetunga Page 16 7/27/2011

AEN 3200 Farm Practice Course

7.1 Compounds that can produce biogas

There are several compounds, which can be easily anaerobically degraded. The

following table shows the compound for biogas production and its anaerobic

biodegradability, biogas yields and percentage of methane in the biogas.

Compounds Anaerobic bio Bio gas yield Methane

degradability (m3/kg COD destroyed) (%)

Sugars Excellent

Starch Excellent 0.79 50

Cellulose Poor – good

Proteins Excellent 0.96 53

Fats/Lipids Excellent 1.43 71

Volatile Fatty Acids Excellent 0.75 50

(Short chain with two (for Acetic Acid)

to five “C” atoms)

Table 04:Rate of biogas production in different compounds

7.2 Raw materials suitable for Biomethanation

1. Agricultural wastes: Plant residues (straws, husks, cobs, hulls, etc) and

Animal byproducts (horse, cattle, goat, sheep, pig, poultry, etc)

2. Agro industrial wastes (Bagasses, coir mill wastes, etc)

3. Forestry and forest product industries (leaves, twigs, sawdust,

wood wastes)

4. Energy crops: Agricultural crops and aquatic weeds

(Salvinia, Water Hyacinth)

cipal Bio waste: Municipal solid waste, sewage sludge sewage including industrial effluent

6. Other wastes such as petrochemical, organic chemical, leather, soap,

etc.

7. Food industrial wastes (milk, fruit, vegetable processing)

7.3 Degradability of organic compounds

Compound Duration

Lignin Hardly Noticeable

Cellulose Several weeks

Hemi cellulose

Fat A few days

Proteins

Low molecular sugars

Volatile Fatty Acids A few hours

Alcohols

Table 05: Degradability of different compounds

8. Digester for Biogas Production

S Wijetunga Page 17 7/27/2011

AEN 3200 Farm Practice Course

8.1 Parts of a digester

Biogas Unit and Plant are other names for biogas digester. The biogas plant consists

of basically four parts

The digester where organic matter is digested

The gas holder where the biogas is collected and stored

Piping system which helps to transport of biogas to the place where

its use.

Inlet and outlet for feeding the feedstock and removing the digested

material

8.1.1 Digester

The digester is a tank, normally circular in shape and it is normally constructed

underground. The digester should be entirely air light to prevent the entering of

oxygen to the digester and leaving out of biogas produced from the digester. It also

should be waterproof. The digester should meet followings also;

• Absolutely leak proof for liquid and gas

• Strong enough to withstand slurry pressure

• Resistance to corrosion

• Heat insulation

• Provisions for fittings such as gas outlet, inlet, outlet, etc,.

8.1.2 Gasholder

There are two types of gasholders namely fixed dome type and floating dome type.

In fixed dome type, the biogas accumulates in the dome over the digester slurry.

The slurry in the digester serves as a reversible displacement medium. The biogas

accumulating in the dome pushes out a portion of the slurry into a higher auxiliary

compartment. The digester slurry floor back into the dome by gravity as the biogas

is consumed. In floating done type, the inverted tank is placed over the digester tank

and the gas released from the digester tank accumulates in the inverted tank over

the slurry.

8.1.3 Piping system

The piping system helps to transport the biogas where it is used. PVC based pipes

are the most suitable pipes for gas transportation. Metal-based pipes may be

corroded since H2S and water vapour are present in the biogas.

8.1.4 Inlet and outlet

Inlet is used to feed the feeding material to the digester. In most cases, before

diverting the feeding material, they are mixed with water. Digested materials come

out from the digester through outlet.

8.2 Types of digesters

There are several types of digesters, fabricated by the scientist in various countries

specially China, India, Vietnam, Taiwan, German, etc. These digesters could be

categorized into groups depending on the country where it is constructed, types of

the dome and the way of putting the feeding material in to digester.

S Wijetunga Page 18 7/27/2011

AEN 3200 Farm Practice Course

8.2.1 Based on origin

China type (fixed dome type)

Indian (Floating dome)

Vietnam/Taiwan (The bag digesters is essentially a long cylinder

made of PVC), Inlet, outlet and gas outlet pipes are attached to the

bag. The construction cost is very much less compare to other

digesters.

8.2.2 Based on the dome

o Fixed dome: This digester has been developed in china. The

biogas accumulates in the upper portion of the digester. The pressure of the

gas is varied depending on the consumption. The digester is constructed to

maintain the pressure of the gas equal or below 120 cm of water. The

retention time for both cow and pig manure normally is 35-40 days. The total

solid concentration of the feeding material is about 7 – 10 %. The

construction of digester is somewhat difficult and skilled masonry labour is

required.

o Floating dome: Floating dome types has been developed in

India in 1950. The produced gas accumulates in a tank, which was placed on

the slurry in inverted position. The digesters are designed for 30,40,55 days

retention times. The gasholder (drum) was originally made of milled steel, until

fiberglass reinforced plastic was introduced successful, to overcome the

problem of corrosion. The pressure of the gas available depends on the

weight of the gasholder per unit area, and usually varies between 4-10cm of

water pressure. This pressure is sufficient to carry the gas up to a length of 20

to 100 m depend on the size.

8.2.3 Based on the way of putting feeding materials

o Batch System: A digester is loaded periodically with designed

quantity of waste material, water and initial material (inoculums or activated

sludge) to initiate the microbial activity in the digester. The daily gas

production increases initially thereafter, it starts falling down, after use over a

period. When quantity of gas decreases below the rated capacity, the digester

is unloaded and recharged with fresh material.

If the raw material (waste material) contains total solids more than 10%, the

system is referred as dry batch system. The researches have shown that total

solid up to 32% could be used for dry batch fermentation. In batch systems,

the biogas production is initially increasing and after some period, (depending

on the feeding material) the production will be reduced. Therefore, uniform

gas production cannot be achieved using this system.

o Continuous system: The continuous digesters are more suitable

for regularly and sufficiently available wastes, which can be mixed with water

homogeneously to form liquid slurry, such materials are cattle dung human

and animal excreta or the materials, which can flow after digestion.

A fixed amount of waste is charge into the biogas plant daily and gas

production from its digester is constant and equal to gas produced from the

S Wijetunga Page 19 7/27/2011

AEN 3200 Farm Practice Course

daily charge. The daily effluent from the digester is equal to daily feed

material.

9. Utilization of Biogas

S Wijetunga Page 20 7/27/2011

AEN 3200 Farm Practice Course

9.1 Major uses of biogas

The biogas could be used to obtain thermal energy, mechanical energy and

electrical energy. The thermal energy is required for cooking, lighting, boiling of

water, bakery industry, Ironing, etc. The mechanical energy is required for water

pumping, running of engines, etc. Electric energy (electricity) could be generated by

coupling a generator to an engine, which is running in biogas.

9.1.1 Biogas for cooking

In Sri Lanka, very large amount of energy is used for cooking. Almost all biomass

energy is used for cooking. Biomass utilization for cooking easily could be replaced

by adopting the use of biogas for cooking.

Pure methane burns in a mixture of 91% air and 9% methane. The biogas, however,

needs approximately 93% air to burn completely. For this reason, the normal LPG

burners used commonly in the houses are not fit for biogas. Special burners with

bigger holes have been designed for use biogas as fuel. The bigger holes enable to

draw higher percentages of air from the atmosphere, needed for efficient burning of

the biogas with the correct air an biogas mixture, the flame temperature can reach as

high as 8000C. Since the pressure of the biogas is normally low (less than 35cm)

the bigger holes is essential to provide sufficient amount of gas to the burning point.

The biogas burner should be designed to work at 7-10cm of water column. Generally

about 0.25-0.35m3 of biogas is required for cooking for a person per day.

To ensure that the flame does not “lift off”, the ratio of the total area of burner parts to

the area of the injector orifice should be between 80 and 200:1.

9.1.2 Biogas for lighting

The lamp with a mantle could be used for lighting purposes. The biogas consumption

for lighting is about 0.15 m3 per hour for 100-candle power mantle lamp (equivalent

to 60W).

9.1.3 Biogas for engines

Biogas can be used as a fuel in stationary and mobile engines to supply motive

power, pump water, drive machinery (ex: threshers, grinders) or generate electricity.

Both, spark and compression engines could be operated in biogas. The spark

engines are easily modified to run on biogas by using a gas carburetor. Ignition

system need not be altered, other than minor timing adjustment. Spark ignition

engines can run entirely on biogas after starting on petrol and initial heating. The

biogas supply pipe is attached to air manifold between air cleaner and carburetor.

After the engine is run on petrol for 5 to 10 minutes the biogas supply valve is

opened slowly and petrol supply valve closed simultaneously. In two-stroke cycle

engine the lubrication is done by adding lubricant with fuel, which become difficult,

therefore, these engines cannot be converted to biogas.

In the diesel engines the engine is usually started with pure diesel fuel and the

biogas increased gradually until it comprises around 20% of fuel intake with 80%

biogas, engine performance is good and 20% more hose power is delivered the with

diesel alone. Approximately 0.43m3 of biogas is required for running a one-horse

power engine for hour. Electricity also could be produced using biogas. Normally

0.75 m3 of Biogas is required to produce 1kwh

S Wijetunga Page 21 7/27/2011

AEN 3200 Farm Practice Course

Thermal efficiency is very low in engines running on biogas, about 25-30%.

Therefore, extra amount of thermal energy could be used to heat the digester or for

space heating of animal sheds, green houses and buildings.

9.2 Treatment of biogas

The raw biogas produced in a digester is normally treated in order to remove water

H2S, dust & CO2. The choice of cleaning method employed and the compounds to be

removed depends on the type of end use of the gas. If biogas is used for any

purpose, the water removal is essential. Simple arrangements could be employed in

the gas distribution system to trap water in the biogas.

By removing the H2O in the biogas, quality of flames both burners and lamps could

be improved. Hydrogen sulfide and water removed is essential when biogas is used

in engines. Removing H2S and water could prevent damaging to the engines by

corrosion. CO2 removal is employed when a high quality gas is required. This can

be the case when the biogas is to be used as a substitute for natural gas or when

sensitive equipment is used.

H2S removal using iron oxide pellets is one method. In this technique, in which the

gas is led through a box of pellets, the iron oxide pellets reacts with the H 2S in the

biogas according to the following reaction

Fe2O3 + 3H2S → Fe2S3 + 3H2O

Regeneration of the iron pellets is done with oxygen

2Fe2O3 + 3O2 → 2Fe2O3 + 6S

Normally two boxes of pellets are installed in the gas line; one box is loaded whereas

the other is regenerated. When the iron pellets are completely covered with sulfide,

the pellets are replaced. H2S could be removed by absorption of H 2S in water or

organic solvents. High consumption of water limits the use of this method. Chemical

absorption with a diluted sodium hydroxide and iron chloride solutions are also

employed to remove the H2S. By removing the CO2, biogas energy volume of biogas

could be increased. And petrol and diesel engines works properly if the CH4 in the

biogas more than 90-95%. Presence of CO2 in the biogas when biogas is used as

fuel for vehicles, lower the output power, take up space in the storage cylinders and

freezing at valves are major problems. Therefore, all or most of CO2 should be

removed when biogas is used for vehicles or engines.

9.3 Storage of biogas

Biogas could be compressed for the use of vehicles. However, it has to be utilized

energy to compress the biogas. Therefore, for small biogas plants, it is not

economically viable. Biogas cannot be liquefied easily because the boiling point of

methane is very much less. It is about -1620C. Methane is the major components in

the biogas.

10. Design of a Biogas Plant

S Wijetunga Page 22 7/27/2011

AEN 3200 Farm Practice Course

The biogas plants are designed based on type of waste material available for

digestion and the quantity of gas required. The gas requirements for various

purposes are given below.

Purpose Gas requirement

Cooking 0.25 m3 per person per day

Lighting 0.12-0.15 m3 per hour per lamp

Driving engines 0.75 m3 per kWh

Table 06: Gas requirement for various purposes

Source Manure Gas/kg/day Retention Time Total Solids

/day (kg) (m3) (days) (%)

Cattle 10 0.036 30-45 14-25

Buffalo 15 0.036 30-45 14-25

Pig 2.25 0.078 45-55 18-27

Chicken 0.18 0.062 30-45 20-30

Adult Human 0.4 0.070 45-55 17-20

Table 07: Waste materials and their gas generations

Based on the above information such as waste material available, their gas

productions rate, retention time, gas requirement for cooking, lighting etc, the biogas

digesters could be designed. In the case of straw, one kilogram of straw

approximately can produce 1L of biogas per day but this may vary with the retention

time.

According to the number of animals that farmer having, the gas production from the

wastes, which is produced by excreta of the animals, could be calculated. And also

number of family members and their gas requirement decide the total gas

requirement for the family.

Now it is easy to find out which is less, total amount of gas produced form available

quantity of waste or the quantity of gas required per day. Then, it can be found the

limiting parameter for determining the volume the digester. That means, if gas

consumption is less than gas production, the volume of digester will be decided by

the amount of gas consumption. If the gas production is less than gas consumption,

the volume of gas digester will be decided by the gas production. Which is less, it will

decide the digester size (volume).

Example: Farmer having six members is going to construct a biogas unit. He has

five cows and two buffaloes. Design a biogas unit for the farmer. The biogas unit

should be able to provide gas for cooking for the family and for lighting of two lamps

for 2 hours.

First, it has to be calculated the gas production and gas consumption.

S Wijetunga Page 23 7/27/2011

AEN 3200 Farm Practice Course

Gas production:

No. Of animals are seven (five cows, two buffaloes)

Amount of excreta (cow dung) per day is 70 Kg.

Total gas production is 2.52 m3/day (70 x 0.036)

Gas consumption:

For cooking, the gas requirement is (0.25 x 6) 1.5 m3

The gas requirement for lighting two lamps for three hrs is (0.15 x 2 x 2) 0.6m3

Total gas consumption is 2.1 m3 /day

The digester could be designed based on the gas production as well as gas

consumption. But the size of the digester would be large when digester is designed

in considering the gas production and hence the cost of construction is high. When

the digester is designed based on gas consumption, the size of the digester would

be small compared to the digester built based on gas production. Since the gas

consumption is less than gas production, the digester is designed based on gas

consumption. Hence, the cost of construction would be less and it is the suitable

size. Therefore, the design of the digester should be done based on, gas

consumption in this case.

Total gas consumption is 2.1 m3 /day

Required amount of raw material (Cow dung) is 58.3kg(2.1/0.036) and it could be

considered as 60Kg.

Normally, before feed the raw material to the digester the raw materials should be

mixed with water to make the desired level of total solids in the raw materials. The

amount of total solids (TS) in the raw materials for better anaerobic digester and

biogas production is about 10%. That mean, the 90% of water is required for

digestion. Researches now have shown considerable biogas production even at

30% of total solid concentrations. However, in the design of a biogas unit, TS

concentration should be considered as 10%.

Normally, cow dung has about 14 – 25 % of TS. By mixing cow dung with water at

1:1 ratio, the desired TS concentration can be achieved. Therefore, the amount of

water that has to be applied is 60kg.

The weight of total feeding material is about 120 Kg. (60kg cow dung + 60kg of

water).

Now it has to be calculated the volume of the digester. If the density of cow dung

water mixture digester is about 1080kg/m3 the volume of the mixture is about 0.111

m3 (120/1080). This amount of mixture of raw materials can produce gas for one-

day requirement for the family. The retention time for the cow dung in tropical

condition is about 40 days.

The total volume of the digester (feeding compartment) is 4.44 m3 ((120x40)/1080).

Retention time is the average time a unit volume of feeding material (liquid) remains

S Wijetunga Page 24 7/27/2011

AEN 3200 Farm Practice Course

in a digester (vessel) operated a continuous way. It means, the cow dung water

mixture is in the digester and produce gas for about 40 days.

Normally, volume of the dome (basically this space is for storage of gas) is about ¼

of the volume of the feeding material. Therefore total volume is 5.55m3

3

(4.44/4+4.444=5.55m ).

Actual volume should be more than 10% of the theoretical volume. Therefore actual

volume of the digester would be about (5.55 x 10/100 + 5.55) = 6.105) 6.0m3.

Therefore, the total volume of the digester is about 6m3. Using following simple

equations, the dimensions of the digester can be found.

Figure 02: Sketch of the digester

capacity 6

(A) Diameter of the digester = 3 =3 3 = 2.38 m

0.447 0.447

diameter 2.38

(B) Height of the dome = = = 0.47 m

5 5

diameter

(C) Height of the cylindrical part = x 2 = 0.95 m

5

diameter

(D) Depth of bottom = = 0.29 m

8

Total height = 0.50+0.95+0.30=1.75m

S Wijetunga Page 25 7/27/2011

AEN 3200 Farm Practice Course

11. Advantages and Environmental Aspects of Anaerobic

Digestion

11.1 Advantage of Anaerobic digestion

Produces large amount of methane gas which could be used as energy

source

Digested materials (out come of the digester) are almost odorless

Digested material has good fertilizer value and can be used as soil

conditioners

Reduces organic content of waste materials by 30-80% and produce an

established sludge (slurry) for ultimate disposal

Weed seed are destroyed and pathogens are either destroyed or greatly

reduced in number

Rodents and flies are not attracted to the end product of the process

Provide a sanitary method for disposal of human and animal wastes

Helps conserve scare local energy resources such as forests

Produce valuable source of energy and it could be used for cooking

purposes and make smoke free environment in the kitchen

11.2 Environmental aspects of biogas technology

The use of biogas technology in the agricultural sector is influenced by environment,

social (income, establishing and employment) and hygienic issues. In the following

the only environmental aspects of biogas technology in the agriculture are

discussed.

1. Anaerobic treatment of animal manure with co-substrates increases the quality of

the digested manure: It will improve the handling of manure and increased yield.

In addition, the range of application possibilities and the acceptance by farmers in

increased. Many farmers have observed yield, after using digested manure,

increase of 2 to 3% compared to untreated manure. By co-fermentation, nutritive

value of crops could be easily increased.

2. Anaerobically treated manure increases the range of application possibilities in

terms of time, crops and housing: Digested manure has high content of

Ammonium Nitrogen. The increased ammonia content of digested manure

combined with a slightly increased pH causes a higher risk of ammonia loss in

treated manure compared to untreated manure. Therefore, digested manure

must be handled more carefully. The loss of N (NH 3 commissions) could be

prevented by injecting the digested manure to the soil or by cover the manure.

NH3 and NH4 are changed with pH. At lower pH, due to high concentration of H+,

the NH3 is converted to NH4, which cannot evaporate. However, in high pH levels,

NH3 is high and it has high evaporation capacity.

Undigested manure most probably has phytotoxic compounds, which creates

necroses and scleroses on the plant leaves. Through anaerobic digestion,

phytotoxic acids are degraded and dry matter content is decreased. Therefore,

digested manure can be applied to a growing field, which usually has a high

demand for nutrients. Odor causing substances are also degraded in the same

way and therefore anaerobic digestion produces odorless digested material.

S Wijetunga Page 26 7/27/2011

AEN 3200 Farm Practice Course

3. Reduction of weed seeds: The AD process lowers the ability of seeds to

germinate.

4. Improvement and stabilization of soil fertility: Organic fertilizer and mineral

fertilizer differentiate in not only nutrient content, composition and variance but

also in qualitative aspects, while, organic fertilizer contributes directly to the

humus for making process of the soil, mineral fertilized does not. Lack of humus

alternately results in desertification. A productive soil system needs a balance

between incoming humus and degrading of humus. Manure, compost or any

organic fraction will increase or stabilize the humus level in the soil. During AD

process, most of the low molecular substances (less than 1000g/Mol) are

degraded, while lignin substances still contributes to the humus pool of the soil.

5. Reduction of pollutants: Organic compounds can be reduced through the

anaerobic treatment process. Tests have shown that organic carbon compound,

mainly resulting from the use of pesticides, can be degraded. (trichlormethane,

tetrachlormethane, 2-4D,etc).

6. Contribution to the water resource protection: Since the increased ammonia

content in the digested manure an accelerated plant up take occurs. Roots

prefer, NH3 than nitrate, if they are available at same time. When NH3 is more

and faster absorbed by the plants it cannot be transformed into nitrate and

leached downward in direction of the ground water level. Thus, ground water

pollution through nitrate is prevented.

7. Contribution to the climate change protection: Methane is the second most

important greenhouse gas in the world, with a global worming potential of 25

times higher than CO2. It has been estimated that CH4 emissions from

agriculture contributes about 33% to the global green house effect. About 7%

alone result from animal excrement, which is similar to 20-30 million tones of

methane per year. Through anaerobic treatment of animal excretion, a

renewable source of energy is generated. It has an important duel climatic effect.

• The use of renewable energy reduces the CO2 emission through a reduction

of the demand for fossil fuel.

Coal Heavy mineral oil Mineral oil Gas

0.33 0.28 0.26 0.20

Table 08: CO2 emissions different fuels kg/kwh

• At the same time, the process can diminish uncontrolled methane generation

by capturing methane as biogas.

Smaller agricultural biogas plants reduce the use of forest resources for

household energy purposes and thus slow down deforestation, soil degradation,

and resulting natural catastrophes (disasters) like flooding or desertification.

Nitrous Oxide has high global worming potential. It has found the anaerobic

digestion reduce the Nitrous oxide emissions also.

S Wijetunga Page 27 7/27/2011

AEN 3200 Farm Practice Course

8. Biogas composition and emissions after burning in comparison with other fuels

are given in the following table and it shows that biogas has clear emissions after

burning.

Pollutants SO2 NOX Dust CO2 BaP*

kg/TJ kg/TJ kg/TJ g/TJ g/TJ

Mineral Oil 140 90 20 90 1

Gas 3 90 2 70 -

Coal 300 180 20 100 3000

Wood industry 100 64 100 130 13

(Efficient

burning)

Wood private 30 60 100 300 -

(Inefficient)

Straw 170 340 200 300 -

Biogas 3 50 3 50 -

(*Cancer causing substance, Benzo (a) Pyren)

Table 09: Emissions after burning of different fuels

9. Resource protection, an appropriate technology: Fossil fuels are limited and

contribute to the greenhouse effect. Biogas is renewable and can help to reduce

the climate change a well as support the protection and conservation of limited

resources. Gases as fuel have one big advantage in computing to other fuels.

There is no need for refining and processing of the fuel, and the exhaust usually

does not need an expensive and sophisticated clearing facility.

10. Reduction of waste disposal: AD contributes strongly to a closed nutrient cycle

system, where nutrients are not lost but reused in the agriculture. At the same

time, energy is generated. Therefore, participation of the agricultural sector is

and should be a major and important step in a sound waste management.

11.3 Use of digested slurry

Digested slurry could be used as a feed for fish.

Digested slurry could be used for substrates for mushroom production.

Valuable organic fertilizer with valuable micronutrients

Digested manure could be easily handled since there is no odour.

Slurry could be used as insecticide for insect pests

References

Ajith de alwis (2001).Study on the potential of biogas in Sri Lanka. ITDG South Asia.

Anonymous, (2000). Annual report, central Bank of Sri Lanka.

Anonymous, (1998). National Environmental action plan 1998 – 2001. Ministry of forestry &

Environment, Sampathpaya, Baththaramulla, Sri Lanka.

Bardiya, N., Somayaji, P. & Knanna,S. (196). Bio methanation of Banana peel and

pineapple waste. Bioresource Technology,58, 73-76.

Mathur,A.N. and Rathore, N.S. (1992). Biogas management and utilization, Himanshu

publications,5k51,Ram singh K1 Badi, Sector 11, Udaipur(Rajasthan).

S Wijetunga Page 28 7/27/2011

S-ar putea să vă placă și

- 1.1 Introduction To Biogas: Electrical DepartmentDocument38 pagini1.1 Introduction To Biogas: Electrical DepartmentYogesh KhairnarÎncă nu există evaluări

- Bio GasDocument24 paginiBio GasMohit PunaniÎncă nu există evaluări

- Bio Gas From Distillery Spent WashDocument40 paginiBio Gas From Distillery Spent WashGerlane Paiva100% (4)

- Biogas Project ReportDocument69 paginiBiogas Project ReportKetan V. JoshiÎncă nu există evaluări

- Thesis Biogas Production Using Anaerobic Bio Dig Ester From CADocument55 paginiThesis Biogas Production Using Anaerobic Bio Dig Ester From CAApocolyse100% (2)

- Renewable Energy: Presented By: Jatin Meghlan Piyush Singh ChiraghDocument26 paginiRenewable Energy: Presented By: Jatin Meghlan Piyush Singh Chiraghjaazsingh100% (1)

- Biogas Plant - Food WastesDocument33 paginiBiogas Plant - Food Wastesayman1111167% (3)

- Handbook On Bio Gas and Its ApplicationsDocument10 paginiHandbook On Bio Gas and Its Applicationsawhk2006Încă nu există evaluări

- Biogas Power PlantDocument7 paginiBiogas Power PlantShailesh Sankdasariya100% (1)

- BiogasDocument420 paginiBiogasNagireddy Venkat Suresh100% (1)

- Project Report For Biomass BriquettingDocument73 paginiProject Report For Biomass BriquettingPrakhar SharmaÎncă nu există evaluări

- Waste To EnergyDocument31 paginiWaste To EnergyMichaelCoffeeBÎncă nu există evaluări

- 1.0 Project Background: WWW - Gam-Rd - Co.inDocument17 pagini1.0 Project Background: WWW - Gam-Rd - Co.inljsflj alsfjoiÎncă nu există evaluări

- Waste To Energy PlantDocument35 paginiWaste To Energy PlantZerlyn JoebeÎncă nu există evaluări

- Biogas From Human Waste HandbookDocument164 paginiBiogas From Human Waste Handbookazim_niaziÎncă nu există evaluări

- 4601423133391success Story of Biomethanation Projects-Dr - Bharat B NagarDocument16 pagini4601423133391success Story of Biomethanation Projects-Dr - Bharat B Nagarpuja MangalÎncă nu există evaluări

- Design and Fabrication of An Anaerobic DigesterDocument9 paginiDesign and Fabrication of An Anaerobic DigesterAZOJETE UNIMAIDÎncă nu există evaluări

- Basic Biogas DigesterDocument7 paginiBasic Biogas DigesterOpen Knowledge and Education Book ProgramsÎncă nu există evaluări

- Bio GasDocument4 paginiBio GasSaroj Kumar0% (1)

- Types of Biogas PlantDocument72 paginiTypes of Biogas PlantParth PatelÎncă nu există evaluări

- CDM Project On Briquettes ManufacturingDocument2 paginiCDM Project On Briquettes ManufacturingShanky JainÎncă nu există evaluări

- Biomass Energy LectureDocument9 paginiBiomass Energy LectureRishant YadavÎncă nu există evaluări

- Sector Handbook BiogasDocument39 paginiSector Handbook BiogasMann HumanÎncă nu există evaluări

- Renewable Biomass Fuel As "Green Power" Alternative For Sugarcane Milling in The PhilippinesDocument9 paginiRenewable Biomass Fuel As "Green Power" Alternative For Sugarcane Milling in The Philippinesencourage36Încă nu există evaluări

- Biogas Revolution Secrets Biogas PlansDocument16 paginiBiogas Revolution Secrets Biogas PlanslimlerianÎncă nu există evaluări

- Biogas Consultants ContractorsDocument8 paginiBiogas Consultants ContractorsuemaaplÎncă nu există evaluări

- Detailed Project Report For Biogas Power PlantDocument132 paginiDetailed Project Report For Biogas Power PlantShubham Jain100% (2)

- Proposal Biogas RohulDocument13 paginiProposal Biogas RohulIman SatriaÎncă nu există evaluări

- Thesis 6Document48 paginiThesis 6manoj100% (1)

- Development and Evaluation of A Fixed Dome Plug Flow Anaerobic DigesterDocument11 paginiDevelopment and Evaluation of A Fixed Dome Plug Flow Anaerobic DigesterAryadharma PrasetyoÎncă nu există evaluări

- Biogas PlantDocument17 paginiBiogas PlantHussein El Zikry0% (1)

- E101-3155 Package BoilersDocument12 paginiE101-3155 Package BoilersLuis Bravo SotoÎncă nu există evaluări

- Biogas Plant ConstructionDocument27 paginiBiogas Plant ConstructionAnkit Anurag NaikÎncă nu există evaluări

- Design of Biogas DigestersDocument22 paginiDesign of Biogas DigestersSharath Chandra100% (5)

- Process Simulation and Design of Biogas Plant Using Food Waste As FeedstockDocument27 paginiProcess Simulation and Design of Biogas Plant Using Food Waste As FeedstockInternational Journal of Innovative Science and Research Technology0% (1)

- Biogas Generation A Study: By: Madhav Mohan Bsc. Physics (Hons.) Ii Year Roll Number: 1815052Document17 paginiBiogas Generation A Study: By: Madhav Mohan Bsc. Physics (Hons.) Ii Year Roll Number: 1815052Madhav Mohan100% (1)

- Small Scale Ethanol PlantDocument15 paginiSmall Scale Ethanol PlantPedroC NERVÎncă nu există evaluări

- Biomass Briquette: Aramco Project ProposalDocument5 paginiBiomass Briquette: Aramco Project ProposalHeartwell Bernabe Licayan100% (1)

- Future Perspectives of Biomass Torrefaction: Review of The Current State-Of-The-Art and Research DevelopmentDocument17 paginiFuture Perspectives of Biomass Torrefaction: Review of The Current State-Of-The-Art and Research DevelopmentKaiba SetoÎncă nu există evaluări

- A Report On Biomass Preprocessing and MheDocument12 paginiA Report On Biomass Preprocessing and MheHarshil LimbaniÎncă nu există evaluări

- Biomass Gasification Report Final-SubmittedDocument103 paginiBiomass Gasification Report Final-SubmittedLeandro Baran100% (2)

- Waste To EnergyDocument9 paginiWaste To Energyherb089Încă nu există evaluări

- Energy Recovery From WasteDocument31 paginiEnergy Recovery From WasteSyed UmerÎncă nu există evaluări

- Biomass Energy in PhilippinesDocument58 paginiBiomass Energy in PhilippinesMichael Vince Arugay TulauanÎncă nu există evaluări

- USAID Briquetting Feasibility Study SudanDocument95 paginiUSAID Briquetting Feasibility Study SudanFood CatÎncă nu există evaluări

- Paul GreeneDocument27 paginiPaul GreeneLiuJaluÎncă nu există evaluări

- Running A Biogas Programme PDFDocument199 paginiRunning A Biogas Programme PDFparamjeetÎncă nu există evaluări

- Bio CNG PDFDocument39 paginiBio CNG PDFpriyank sharmaÎncă nu există evaluări

- GTZ - Biogas Plants - 1993Document24 paginiGTZ - Biogas Plants - 1993Kroya HunÎncă nu există evaluări

- Design, Construction and Maintenance of A Biogas GeneratorDocument23 paginiDesign, Construction and Maintenance of A Biogas GeneratorOxfamÎncă nu există evaluări

- Waste To EnergyDocument37 paginiWaste To EnergyCheng PasionÎncă nu există evaluări

- BIOGAS in GHANA Subsector Analysis BiogasDocument38 paginiBIOGAS in GHANA Subsector Analysis BiogasIndraw100% (1)

- BiomassDocument36 paginiBiomassGábor MátyásiÎncă nu există evaluări

- Design, Construction and Testing of A Biogas Reactor For Production of Biogas Using Cassava Peel and Cow Dung As BiomassDocument11 paginiDesign, Construction and Testing of A Biogas Reactor For Production of Biogas Using Cassava Peel and Cow Dung As BiomassAZOJETEÎncă nu există evaluări

- Biogas ProductionDocument57 paginiBiogas ProductionMmaduekwe JanefrancesÎncă nu există evaluări

- How To Setup Bio Gas PlantDocument5 paginiHow To Setup Bio Gas PlantMunish BansalÎncă nu există evaluări

- Production of Ammonia by Biomass GasificationDocument220 paginiProduction of Ammonia by Biomass GasificationAdeel ArifÎncă nu există evaluări

- Assignment: Name Class Subject Topic Reg No# Submitted ToDocument12 paginiAssignment: Name Class Subject Topic Reg No# Submitted ToAli AyanÎncă nu există evaluări

- Biogas in India Potential and IntegratioDocument12 paginiBiogas in India Potential and IntegratioUTHSO NANDYÎncă nu există evaluări

- Biogas IntroductionDocument75 paginiBiogas IntroductionRohan JindalÎncă nu există evaluări

- PV Cell CharaDocument40 paginiPV Cell CharaBlessy JoyÎncă nu există evaluări

- Tabla Cargas Grua F4C-892Document4 paginiTabla Cargas Grua F4C-892Juan Carlos Callas GarayÎncă nu există evaluări

- Isv5 0-Web PDFDocument2 paginiIsv5 0-Web PDFperulapiaÎncă nu există evaluări

- DNV Maritime Forecast 2050 2021-WebDocument82 paginiDNV Maritime Forecast 2050 2021-WebДмитрий Ганжа100% (1)

- MF1547Electric Panel PDFDocument24 paginiMF1547Electric Panel PDFAhmad Ali NursahidinÎncă nu există evaluări

- A Study of Integrated Choke Characteristic For EMI Filter DesignDocument4 paginiA Study of Integrated Choke Characteristic For EMI Filter DesignDiego GutierrezÎncă nu există evaluări

- P&id LegendDocument1 paginăP&id Legendkamal arabÎncă nu există evaluări

- Product Manual 36641 (Revision H) : Governor Oil Heat Exchanger For PG & EG GovernorsDocument10 paginiProduct Manual 36641 (Revision H) : Governor Oil Heat Exchanger For PG & EG GovernorsMussardÎncă nu există evaluări

- Miller 652 and 812 Owners Manualo278aj - MilDocument44 paginiMiller 652 and 812 Owners Manualo278aj - MilrobertoarellanocastiÎncă nu există evaluări

- Physics Thermal Chemical Current MCQDocument5 paginiPhysics Thermal Chemical Current MCQAyan GhoshÎncă nu există evaluări

- Essentials of Radio Wave PropagationDocument215 paginiEssentials of Radio Wave Propagation9177811805100% (7)

- Learning Module No. 4 - Aircraft Air Conditioning and Pressurization SystemDocument36 paginiLearning Module No. 4 - Aircraft Air Conditioning and Pressurization SystemDavidSamsonÎncă nu există evaluări

- 1 s2.0 S002236972200364X MainDocument16 pagini1 s2.0 S002236972200364X MainFatima NÎncă nu există evaluări

- Presentation Mahmud Totonji DarwishDocument13 paginiPresentation Mahmud Totonji DarwishMahmoud ToutounjyÎncă nu există evaluări

- Transformers and Rectifiers IndiaDocument26 paginiTransformers and Rectifiers IndiaPravesh RaoÎncă nu există evaluări

- Slope Efficiency: Threshold Above Current Input in Increase Power Output Optical in IncreaseDocument34 paginiSlope Efficiency: Threshold Above Current Input in Increase Power Output Optical in IncreaseRIzwanaÎncă nu există evaluări

- 12 Chapter 5Document46 pagini12 Chapter 5kharisÎncă nu există evaluări

- Portal Frame ConstructionDocument2 paginiPortal Frame Constructionriz2010Încă nu există evaluări

- Asme Ea-3-2009 (R2019)Document23 paginiAsme Ea-3-2009 (R2019)Jesus Rodriguez100% (1)

- 2 - Cable Lugs CatalogDocument36 pagini2 - Cable Lugs CatalogSanjay GandhiÎncă nu există evaluări

- Catalogo de Partes Compresor Ingersoll Rand PDFDocument34 paginiCatalogo de Partes Compresor Ingersoll Rand PDFHarold Joel Zurita LinaresÎncă nu există evaluări

- Peugeot 306 Cabriolet Roof OperationDocument3 paginiPeugeot 306 Cabriolet Roof OperationKenneth NelsonÎncă nu există evaluări

- MES ManualDocument122 paginiMES ManualDenis AlfinÎncă nu există evaluări

- Effects of Mass Transfer On Heat and Mass Transfer Characteristics Between Water Surface and AirstreamDocument11 paginiEffects of Mass Transfer On Heat and Mass Transfer Characteristics Between Water Surface and AirstreamPiterÎncă nu există evaluări

- EFuel ReportDocument52 paginiEFuel ReportMassimiliano ZocchiÎncă nu există evaluări

- Air Circuit Breakers For The 21st Century: Catalogue No.'00-P55EDocument4 paginiAir Circuit Breakers For The 21st Century: Catalogue No.'00-P55EAsif ShahÎncă nu există evaluări

- Dipen Baroda Follo-Up SheetDocument92 paginiDipen Baroda Follo-Up Sheetanon-272209100% (1)

- Presentation Material BalanceDocument101 paginiPresentation Material BalanceSharizada KanapiyevaÎncă nu există evaluări

- BMW - Us X1 - 2015Document66 paginiBMW - Us X1 - 2015Alex PaunaÎncă nu există evaluări

- A Novel High-Gain DC-DC Converter Applied in Fuel Cell VehiclesDocument13 paginiA Novel High-Gain DC-DC Converter Applied in Fuel Cell Vehiclesrock starÎncă nu există evaluări