Documente Academic

Documente Profesional

Documente Cultură

Hyundai Transys Knob Assy FR Seat H/Adj RH 88023-K3000 NNB/T9Y

Încărcat de

ubraghu0 evaluări0% au considerat acest document util (0 voturi)

44 vizualizări2 paginiTitlu original

LEVER - RH

Drepturi de autor

© © All Rights Reserved

Formate disponibile

XLSX, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca XLSX, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

44 vizualizări2 paginiHyundai Transys Knob Assy FR Seat H/Adj RH 88023-K3000 NNB/T9Y

Încărcat de

ubraghuDrepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca XLSX, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 2

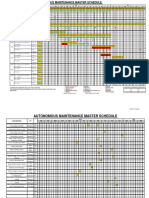

DOC NO : TRAI/PD/AWI/090

TOPRUN AUTOMOTIVE INDIA PVT LTD EO Number : QX1IU016

WORK INSTRUCTION EO Date : 26.04.2019

Machine Resin / Part Assembly / Subparts

Product

CUSTOMER: CAR MODEL DRIVE PART DESCRIPTION / PART NUMBER TONNAGE DESCRIPTION Item No Drier Temp Part Weight Assembly Part Description Item No Qty

Material NYLON PA6 TYP B1 INSERT 1

Grade LS 620 AI3

HYUNDAI KNOB ASSY FR SEAT H/ADJ RH Color NNB,T9Y As per As per

- AI3(5DR/4DR) - 350 T Control Control

TRANSYS 88023-K3000 NNB/T9Y Plan Plan

No Description / Explanation PICTURE / SKETCH

1 INJECTION MOLDING AND PUT IN INSERT AT MOLD

2 PICK THE PART FROM MACHINE AND KEPT IN THE TABLE

3 GATE POINT TRIM THE PART

4 100% VISUAL INSPECTION AT THE PART

5 DATE AND SHIFT CODE MENTION IN THE PART

6 PLACE IT IN THE PART FROM FG BIN (AS PER PACKING STD)

1. INJECTION MOLDING AND PUT IN 2. PICK THE PART FROM MACHINE AND

INSERT AT MOLD KEPT IN THE TABLE 3. GATE POINT TRIM THE PART

5.DATE AND SHIFT CODE MENTION IN 4.100% VISUAL INSPECTION AT THE

6.PLACE IT IN THE PART FROM FG THE PART PART

BIN (AS PER PACKING STD)

CAUTION POINTS Q-ALERT POINTS CAUTION AREAS

1 Every machine stop isolate the first 2 pcs for QA verifcation to setup

bin (yellow bin or trolley)

2 Confirmed rejects should be moved to red bin or trolley for QA Verification

3 Check all the caution points for flash, shortfill and any other defects

4 Any abnormalities or high rejection , escalate to supervisor Front side

5 Ensure Steel clip and brackt steel clip locking noise during assy

100% VISUAL INSPECTION FOR SINK

Preparation MARK, FLOW MARK, SHINING, 100% VISUAL INSPECTION FOR

PARTING LINE FLASH , WELD LINE, SHORT FILL, HOLE FLASH ISSUE

1 Arrange packaging cover as per lot qty COLOUR MISMATCH

2 Use Pen knife for deflashing

-

SAFETY GUARD

Rear side

00 QX1IU016-26.04.2019 RELEASED SOP Mr.Rajesh Mr.Satheesh Mr.Magesh

Rev History / Change of content Prepared By Reviewed By Approved By

DOC NO : TRAI/PD/AWI/090

TOPRUN AUTOMOTIVE INDIA PVT LTD EO Number : QX1IU016

WORK INSTRUCTION EO Date : 26.04.2019

Machine Resin / Part Assembly / Subparts

Product

CUSTOMER: CAR MODEL DRIVE PART DESCRIPTION / PART NUMBER TONNAGE DESCRIPTION Item No Drier Temp Part Weight Assembly Part Description Item No Qty

Material NYLON PA6 TYP B1 INSERT 1

Grade LS 620 MS213 42

HYUNDAI KNOB ASSY FR SEAT H/ADJ RH Color NNB,RBD As per As per

- SU2I - 350 T Control Control

TRANSYS 88023-BV000NNB/RBD Plan Plan

No Description / Explanation PICTURE / SKETCH

1 INJECTION MOLDING AND PUT IN INSERT AT MOLD

2 PICK THE PART FROM MACHINE AND KEPT IN THE TABLE

3 GATE POINT TRIM THE PART

4 100% VISUAL INSPECTION AT THE PART

5 DATE AND SHIFT CODE MENTION IN THE PART

6 PLACE IT IN THE PART FROM FG BIN (AS PER PACKING STD)

1. INJECTION MOLDING AND PUT IN 2. PICK THE PART FROM MACHINE AND

INSERT AT MOLD KEPT IN THE TABLE 3. GATE POINT TRIM THE PART

5.DATE AND SHIFT CODE MENTION IN 4.100% VISUAL INSPECTION AT THE

6.PLACE IT IN THE PART FROM FG THE PART PART

BIN (AS PER PACKING STD)

CAUTION POINTS Q-ALERT POINTS CAUTION AREAS

1 Every machine stop isolate the first 2 pcs for QA verifcation to setup

bin (yellow bin or trolley)

2 Confirmed rejects should be moved to red bin or trolley for QA Verification

3 Check all the caution points for flash, shortfill and any other defects

4 Any abnormalities or high rejection , escalate to supervisor Front side

5 Ensure Steel clip and brackt steel clip locking noise during assy

100% VISUAL INSPECTION FOR SINK

Preparation MARK, FLOW MARK, SHINING, 100% VISUAL INSPECTION FOR

PARTING LINE FLASH , WELD LINE, SHORT FILL, HOLE FLASH ISSUE

1 Arrange packaging cover as per lot qty COLOUR MISMATCH

2 Use Pen knife for deflashing

-

SAFETY GUARD

Rear side

00 QX1IU016-26.04.2019 RELEASED SOP Mr.Purushoth Mr.Satheesh Mr.Balaraghavan

Rev History / Change of content Prepared By Reviewed By Approved By

S-ar putea să vă placă și

- VIP Activity Plan & Status for Qavi BrothersDocument5 paginiVIP Activity Plan & Status for Qavi BrothersMurtaza AhmedÎncă nu există evaluări

- 6 Team Feasibility STUDDYDocument6 pagini6 Team Feasibility STUDDYkamalÎncă nu există evaluări

- A3Document1 paginăA3chavesierra20081 SierraÎncă nu există evaluări

- 16 Major Losses in ProductionDocument18 pagini16 Major Losses in ProductionAgung Chilmy FirdanaÎncă nu există evaluări

- Standard Work Chart: (NVA) (NVA) (NVA)Document2 paginiStandard Work Chart: (NVA) (NVA) (NVA)Carlos Manuel ParionaÎncă nu există evaluări

- Nabtesco - Annual Appraisal Sheet (For Manager & Above) 2021Document10 paginiNabtesco - Annual Appraisal Sheet (For Manager & Above) 2021Kiran AmboreÎncă nu există evaluări

- Audit MatrixDocument1 paginăAudit MatrixsivamandoÎncă nu există evaluări

- Tool Development PlanDocument3 paginiTool Development PlanTrivesh SharmaÎncă nu există evaluări

- Control Plan Ingersol RandDocument2 paginiControl Plan Ingersol Randrgrao85Încă nu există evaluări

- Standard Operating Procedure / Work Instructions / Visual AidsDocument3 paginiStandard Operating Procedure / Work Instructions / Visual AidsSwapnil BachhavÎncă nu există evaluări

- GM 1927 31a PDCA Wall ScorecardDocument10 paginiGM 1927 31a PDCA Wall ScorecardMostafa Abd ElalemÎncă nu există evaluări

- 5S Audit Plan vs Actual 2022Document7 pagini5S Audit Plan vs Actual 2022RajaVeluÎncă nu există evaluări

- Advanced quality planning worksheetDocument1 paginăAdvanced quality planning worksheetFernando MejíaÎncă nu există evaluări

- Flow DiagramDocument2 paginiFlow DiagramMiftah ZarkasiÎncă nu există evaluări

- Preventive Maintenance Checklist for Hardrock Attachments Pvt. LtdDocument1 paginăPreventive Maintenance Checklist for Hardrock Attachments Pvt. LtdSandeep KumarÎncă nu există evaluări

- Abnormal Situation Record for Manufacturing ChangesDocument2 paginiAbnormal Situation Record for Manufacturing ChangesPk NimiwalÎncă nu există evaluări

- LSAI SQA Manual FileDocument39 paginiLSAI SQA Manual FileSivakumar LÎncă nu există evaluări

- Past defect history details root cause analysis formatDocument10 paginiPast defect history details root cause analysis formatRahulÎncă nu există evaluări

- Control Plan For Lighting ProductDocument6 paginiControl Plan For Lighting ProductpapplionÎncă nu există evaluări

- 8 D For ShrinkageDocument6 pagini8 D For ShrinkageSachin KumbharÎncă nu există evaluări

- Form30TM Advanced Product Quality Planning-APQPDocument1 paginăForm30TM Advanced Product Quality Planning-APQPShinichi SuzukiÎncă nu există evaluări

- Chintamani Metal 4M Change SheetDocument6 paginiChintamani Metal 4M Change Sheetcmu qmsÎncă nu există evaluări

- MARATHAN MOTOR SOP Recruitment ProcedureDocument4 paginiMARATHAN MOTOR SOP Recruitment Procedurerishi gautamÎncă nu există evaluări

- FMEA - Quick Reference Guide: Actions Are Required: (By Priority)Document2 paginiFMEA - Quick Reference Guide: Actions Are Required: (By Priority)Igor PÎncă nu există evaluări

- Packaging Details: Vendor Name & AddressDocument4 paginiPackaging Details: Vendor Name & AddressPk NimiwalÎncă nu există evaluări

- Micro Turn Product (Blue Colour Tag) : RejectDocument2 paginiMicro Turn Product (Blue Colour Tag) : RejectSahil WadhwaÎncă nu există evaluări

- D10414410a Fmea MachiningDocument13 paginiD10414410a Fmea MachiningSuraj RawatÎncă nu există evaluări

- Bin CleaningDocument2 paginiBin CleaningRS MANIKANDANÎncă nu există evaluări

- Shutter Mag WiDocument1 paginăShutter Mag Wikiran vkÎncă nu există evaluări

- QAF-160 Supplier Quality Survey 3-5-18Document9 paginiQAF-160 Supplier Quality Survey 3-5-18Gábor MonokÎncă nu există evaluări

- Deviation Request: Deviation Request Is For Temporary Changes Only. Submission Is Only Valid With An 8D ReportDocument3 paginiDeviation Request: Deviation Request Is For Temporary Changes Only. Submission Is Only Valid With An 8D ReporttrungÎncă nu există evaluări

- APQP and PPAP ExplainedDocument3 paginiAPQP and PPAP ExplainedignaunaqÎncă nu există evaluări

- Control Plan m6 Flange NutDocument8 paginiControl Plan m6 Flange NutRANAÎncă nu există evaluări

- TEAM fEASIBILITYDocument2 paginiTEAM fEASIBILITYPk NimiwalÎncă nu există evaluări

- Dis 6 W 2 HDocument14 paginiDis 6 W 2 HBalachandar SathananthanÎncă nu există evaluări

- FEQ TemplateDocument5 paginiFEQ TemplateJackie van SchalkwykÎncă nu există evaluări

- WI-R&D-33 - Field Validation of ClutchDocument3 paginiWI-R&D-33 - Field Validation of ClutchDisha ShahÎncă nu există evaluări

- PFMEA Review - MOM FormatDocument2 paginiPFMEA Review - MOM FormatMASU BRAKE PADS QAÎncă nu există evaluări

- 01.SOP - Center BezelDocument2 pagini01.SOP - Center BezelRS MANIKANDANÎncă nu există evaluări

- GM Machining CP REV 03Document17 paginiGM Machining CP REV 03Suraj RawatÎncă nu există evaluări

- Exedy India Ltd. APQP Process DocumentsDocument3 paginiExedy India Ltd. APQP Process Documentssam1hi5Încă nu există evaluări

- pure cotton pvt ltd final inspection reportDocument4 paginipure cotton pvt ltd final inspection reportTarun PariharÎncă nu există evaluări

- AM FormatDocument73 paginiAM Formathisham_eyesÎncă nu există evaluări

- Boss Gears Attendance Training RecordDocument2 paginiBoss Gears Attendance Training RecordMohit SinghÎncă nu există evaluări

- D10414410A CP Rev 00Document21 paginiD10414410A CP Rev 00Suraj RawatÎncă nu există evaluări

- CAPA Incomplete Part MixDocument16 paginiCAPA Incomplete Part MixRohtash fastnerÎncă nu există evaluări

- Quality Manual: Organization ChartDocument2 paginiQuality Manual: Organization ChartmuthuselvanÎncă nu există evaluări

- Skill evaluation criteria for CED and chrome plating processesDocument1 paginăSkill evaluation criteria for CED and chrome plating processesDinesh KumarÎncă nu există evaluări

- Fr-scm-085 Packaging StandardDocument3 paginiFr-scm-085 Packaging StandardKaramjit SinghÎncă nu există evaluări

- APQP Guide Pre-U1aDocument241 paginiAPQP Guide Pre-U1aФедя ПлукчиÎncă nu există evaluări

- Efwe 2 e 4 GF 1 W 3Document1 paginăEfwe 2 e 4 GF 1 W 3BALACHANDAR SÎncă nu există evaluări

- 8D Report SummaryDocument9 pagini8D Report SummaryLukas LukasÎncă nu există evaluări

- 195 CasingDocument14 pagini195 Casingsasi10000Încă nu există evaluări

- First Production Part Inspection ReportDocument3 paginiFirst Production Part Inspection ReportwentropremÎncă nu există evaluări

- 1 - Supplier Rating - Including Premium Freight1Document1 pagină1 - Supplier Rating - Including Premium Freight1RAJESH DHOKALEÎncă nu există evaluări

- PDF Process Audit Vda 63Document9 paginiPDF Process Audit Vda 63Shahrazed ZineÎncă nu există evaluări

- Paretto (Defect Wise) FEB-2022Document2 paginiParetto (Defect Wise) FEB-2022Bangali SinghÎncă nu există evaluări

- 48 Point Ppap Check SheetDocument39 pagini48 Point Ppap Check SheetSanjay KumarÎncă nu există evaluări

- PFD and Pqcs of Can Rear BreakDocument16 paginiPFD and Pqcs of Can Rear BreakVikas KashyapÎncă nu există evaluări

- 1537 Minutes of MeetingDocument2 pagini1537 Minutes of MeetingubraghuÎncă nu există evaluări

- Kannada WordsDocument16 paginiKannada WordsubraghuÎncă nu există evaluări

- January 2019: Sunday Monday Tuesday Wednesday Thursday Friday SaturdayDocument1 paginăJanuary 2019: Sunday Monday Tuesday Wednesday Thursday Friday SaturdayVega AditamaÎncă nu există evaluări

- December 2021: Sunday Monday Tuesday Wednesday Thursday Friday SaturdayDocument1 paginăDecember 2021: Sunday Monday Tuesday Wednesday Thursday Friday SaturdayubraghuÎncă nu există evaluări

- Hyundai Transys Knob Assy FR Seat H/Adj RH 88023-K3000 NNB/T9YDocument2 paginiHyundai Transys Knob Assy FR Seat H/Adj RH 88023-K3000 NNB/T9YubraghuÎncă nu există evaluări

- Managing Change at Daejung Mo PartsDocument4 paginiManaging Change at Daejung Mo PartsubraghuÎncă nu există evaluări

- B515 TempDocument4 paginiB515 TempubraghuÎncă nu există evaluări

- Apqp - Layered Process Audit-1594636097 SAMPLE 4Document9 paginiApqp - Layered Process Audit-1594636097 SAMPLE 4ubraghuÎncă nu există evaluări

- January 2020 Calendar LandscapeDocument1 paginăJanuary 2020 Calendar LandscapeAmit ParchakeÎncă nu există evaluări

- Iso/Ts 16949 WorkshopDocument115 paginiIso/Ts 16949 WorkshopubraghuÎncă nu există evaluări

- Toprun Automotive India PVT LTD Work Instruction: Lever FR Seat Recl, LH/RH 88016/26-BV000 NNB/RBDDocument1 paginăToprun Automotive India PVT LTD Work Instruction: Lever FR Seat Recl, LH/RH 88016/26-BV000 NNB/RBDubraghuÎncă nu există evaluări

- SU2I Ins STDDocument10 paginiSU2I Ins STDubraghuÎncă nu există evaluări

- Apqp 2017Document124 paginiApqp 2017ubraghuÎncă nu există evaluări

- No: Trai/Pd/Mwi/71: Toprun Automotive India PVT LTDDocument2 paginiNo: Trai/Pd/Mwi/71: Toprun Automotive India PVT LTDubraghuÎncă nu există evaluări

- Complete Injection Molding Process: As Summarized in Fig. 1-2, Injection MoldDocument27 paginiComplete Injection Molding Process: As Summarized in Fig. 1-2, Injection MoldFedericoÎncă nu există evaluări

- Tuvnord Payment ScreenshotDocument1 paginăTuvnord Payment ScreenshotubraghuÎncă nu există evaluări

- Rubber Mixing Unit As A, Shift Incharge. Service Engineer-Furniture and Interior GroupDocument2 paginiRubber Mixing Unit As A, Shift Incharge. Service Engineer-Furniture and Interior GroupubraghuÎncă nu există evaluări

- Govt Jobs in IndiaDocument10 paginiGovt Jobs in IndialakshmilavanyaÎncă nu există evaluări

- Govt Jobs in IndiaDocument10 paginiGovt Jobs in IndialakshmilavanyaÎncă nu există evaluări

- Major Difference ISODocument1 paginăMajor Difference ISOubraghuÎncă nu există evaluări

- Book IRCTC ticket onlineDocument2 paginiBook IRCTC ticket onlineHimanshu GuptaÎncă nu există evaluări

- My Favourite Animal Is COW Reason: 1.giving Milk 2.harm Less 3.urine and Featal Have Medicinal Characteristic SDocument2 paginiMy Favourite Animal Is COW Reason: 1.giving Milk 2.harm Less 3.urine and Featal Have Medicinal Characteristic SubraghuÎncă nu există evaluări

- Book IRCTC ticket onlineDocument2 paginiBook IRCTC ticket onlineHimanshu GuptaÎncă nu există evaluări

- IATF 16949:2016 vs. ISO/TS 16949:2009 MatrixDocument26 paginiIATF 16949:2016 vs. ISO/TS 16949:2009 MatrixP.NAVEENAN50% (2)

- Ojt For Air CleaningDocument1 paginăOjt For Air CleaningubraghuÎncă nu există evaluări

- Q Alert GrindingDocument1 paginăQ Alert GrindingubraghuÎncă nu există evaluări

- Grinding Machine ParametterDocument19 paginiGrinding Machine ParametterubraghuÎncă nu există evaluări

- Thickness Gauge Usage Standard: SL - No OK Not Ok Not OkDocument1 paginăThickness Gauge Usage Standard: SL - No OK Not Ok Not OkubraghuÎncă nu există evaluări

- ISO/TS 16949 Quotation QuestionnaireDocument2 paginiISO/TS 16949 Quotation QuestionnaireubraghuÎncă nu există evaluări

- Manufacturing of Natural Fibre Reinforced Polymer Composites 2015Document393 paginiManufacturing of Natural Fibre Reinforced Polymer Composites 2015mohd asrofi muslim100% (1)

- Injection Molding Guide for Plastics ProfessionalsDocument33 paginiInjection Molding Guide for Plastics Professionalskemo_750252831Încă nu există evaluări

- KoDocument24 paginiKoAngelinaÎncă nu există evaluări

- DOJO CurriculumDocument47 paginiDOJO CurriculumGulshan SaxenaÎncă nu există evaluări

- Bakelite PF 31Document3 paginiBakelite PF 31dioguitomsolhaÎncă nu există evaluări

- Siddaganga Institute Technology: Injection MouldingDocument12 paginiSiddaganga Institute Technology: Injection MouldingPRAVEEN BOODAGOLIÎncă nu există evaluări

- (Speaking of Plastics Manufacturing Series) Fry, Bill-Working With Polyethylene-Society of Manufacturing Engineers (SME) (1999) PDFDocument42 pagini(Speaking of Plastics Manufacturing Series) Fry, Bill-Working With Polyethylene-Society of Manufacturing Engineers (SME) (1999) PDFEnrico Bruce GioloÎncă nu există evaluări

- Conformal Cooling 140217011257 Phpapp01 PDFDocument50 paginiConformal Cooling 140217011257 Phpapp01 PDFcute7707Încă nu există evaluări

- Hopelex Af 3100Document2 paginiHopelex Af 3100FarizÎncă nu există evaluări

- Ahmedabad and Gujarat Sample DataDocument20 paginiAhmedabad and Gujarat Sample DataPriya Shinde100% (1)

- SolidworksDocument4 paginiSolidworksSOLIDWORKS Indonesia - PT Arisma Data SetiaÎncă nu există evaluări

- Tesla Inc & Husky Injection PDFDocument2 paginiTesla Inc & Husky Injection PDFrcbcsk cskÎncă nu există evaluări

- Stavax ESR PH-ENDocument12 paginiStavax ESR PH-ENChetan SharmaÎncă nu există evaluări

- Mold Components 2020Document204 paginiMold Components 2020Shinichi SuzukiÎncă nu există evaluări

- Vydyne Processing GuideDocument84 paginiVydyne Processing GuideEmmaSiÎncă nu există evaluări

- Engel Robots: Precision automation for injection moldingDocument18 paginiEngel Robots: Precision automation for injection moldingAnonymous hxQ7PNOQÎncă nu există evaluări

- JSW Machinery LocationsDocument10 paginiJSW Machinery Locationsvantuan17792Încă nu există evaluări

- Arnitel cm551 - Inj MoldDocument6 paginiArnitel cm551 - Inj MoldHilman NetjibvuteÎncă nu există evaluări

- Sintex Part 2Document29 paginiSintex Part 2payalmalayÎncă nu există evaluări

- Sabic M80064SDocument2 paginiSabic M80064STungdinh NguyenÎncă nu există evaluări

- John Goff - Moulding MasterclassDocument100 paginiJohn Goff - Moulding MasterclassStarchyLittleOleMe100% (3)

- APS ThinsulatorsDocument3 paginiAPS ThinsulatorsBobbie RuckÎncă nu există evaluări

- Advanced Injection Mould Split Design TechniquesDocument175 paginiAdvanced Injection Mould Split Design TechniquesŠetkić SemirÎncă nu există evaluări

- Long Fiber CompoundsDocument14 paginiLong Fiber CompoundsspoorthiprasannaÎncă nu există evaluări

- A-Z of Plastics Manufacturing ProcessesDocument3 paginiA-Z of Plastics Manufacturing Processesrohitkhanna1180Încă nu există evaluări

- Injection Moulding - Quality Molded PartsDocument28 paginiInjection Moulding - Quality Molded PartsQuản Lê Đình100% (3)

- Iso 527-2-2012 PDF - PDF - International Organization For Standardization - Composite MaterialDocument42 paginiIso 527-2-2012 PDF - PDF - International Organization For Standardization - Composite Materialanapaula.raizerÎncă nu există evaluări

- Assignment IDocument23 paginiAssignment I016 ARUNACHALAM S R MÎncă nu există evaluări

- Moldex Product Inc.Document2 paginiMoldex Product Inc.Easy Write100% (1)

- Pu BayerDocument60 paginiPu BayercapitaotaylorÎncă nu există evaluări