Documente Academic

Documente Profesional

Documente Cultură

Composting and Greenhouse

Încărcat de

Compost Heated GreenhousesDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Composting and Greenhouse

Încărcat de

Compost Heated GreenhousesDrepturi de autor:

Formate disponibile

`

The following text and references is from a resource packet

compiled by ATTRA in response to queries on compost-heating

of greenhouses. We field one or two dozen questions a year

on this topic.

If you need the printed literature that goes with it, send me your

full mailing address, phone number, and occupation.

In brief, compost-heating of greenhouse is feasible and it has

appeal for the small-scale operation that is focused on appropriate

technology and homesteading. From a future perspective where

bioshelters play a central role in a sustainable lifestyle, one

could say that this technology is pioneering. There is a book by

Anna Edey on the Solviva greenhouse that I highly recommend if

the bioshelter-style, solar greenhouse additionally integrated with

animal- and compost-heating appeals to you.

But for most commercial greenhouses, it would be a hassle in

comparison to heating with relatively inexpensive and clean-burning

natural gas. Of the alternative greenhouse designs, solar

greenhouses that are oriented for maximum solar collection, super

insulated, and equipped with special heat retention devices are still

among the most reliable and practical.

Fyi, ATTRA has a series of publications on greenhouse topics,

including Organic Greenhouse Vegetable Production, Solar Greenhouses,

Organic Potting Mixes, Disease-Suppressive Potting Mixes, IPM for

Greenhouse Crops, etc.

Steve Diver

ATTRA

http://www.attra.org

==================================================

Heating greenhouses with waste heat generated by thermophilic compost

was an idea that gained a lot of attention in the 1980s. The best

known example was the composting greenhouse project initiated in 1983

at the New Alchemy Institute (NAI) in Massachussetts, which began with

a 700 square foot prototype composting greenhouse.

In a composting greenhouse, heat and carbon dioxide are generated from

a manure-based compost contained in a special chamber attached to one

side of the greenhouse. As with any compost site, equipment access is

a basic requirement to facilitate the movement of vehicles, tractors,

and bucket loaders.

>From the mid- to late-80s, NAI published a number of research reports

and magazine articles about its on-going work with composting

greenhouses. Enclosed is the complete set of four articles published

on this topic in New Alchemy Quarterly between 1983 to 1989. These

articles contain blueprints, illustrations, photographs, and

descriptions of the composting greenhouse. Of special note are the

seven conclusions reached by the greenhouse team in the 1987 article,

plus the new findings reported in the 1989 article.

By 1987, NAI concluded there are considerable and significant problems

with the concept. These included (1):

* Composting greenhouses are a risky and experimental technology.

They should only be used in situations where both the greenhouse

composting businesses make sense separately at the same time.

* Composting is a challenge, since it is both art and science. The

small operation may not be able to afford specialized composting

equipment, resulting in substantially increased labor requirements.

* The composting component needs to be sized on the basis of its

carbon dioxide production. If the composting component is sized to

heat the greenhouse [in a mild climate like southern New England,

half a cubic yard of compost per square foot of greenhouse!], the

amount of carbon dioxide generated will be six times that needed for

optimal CO2-enriched atmospheres, and the amount of nitrogen released

will be fifty times that needed for optimal plant growth.

* When the composting component is sized on the basis of carbon

dioxide, the heat generated will be supplementary only, meeting

perhaps 15% of the energy needs. Excess nitrogen will still,

however, be a troublesome contaminant of the system at levels roughly

eight times greater than optimal. Nitrate levels are consistently

too high for safe production of cool season greens, due to

accumulation of nitrates in the vegetables.

However, in the 1989 article, NAI cited new design featuress that

promised to solve the ammonia problem. And, nitrates are not a

problem when greenhouses are only used to start vegetable seedlings

intended for field production.

In addition to the articles in New Alchemy Quarterly, NAI published

research reports and working papers on this topic. Although the

Institute ceased operations in 1991, NAI publications are available

through The Green Center, located at the site of the former Institute.

A listing of titles relating to work on composting greenhouses is

provided below. For current prices, contact:

The Green Center

237 Hatchville Rd.

East Falmouth, MA 02536

(508) 564-6301

Research Reports:

No. 3 Composting Greenhouse at New Alchemy Institute: A Report on Two

Years of Operation and Monitoring

Working Papers:

No. 4 Economics: Hydroponics vs. Composting Greenhouses

No. 16 Composting Greenhouse: Thermal Performance

No. 19 Nitrogen Dynamics in Composting Greenhouse

No. 29 Improved Composting Greenhouse Designs

The New Alchemy Institute was one of the premier alternative

technology centers in the 1970s and 80s. The Institute published

widely on appropriate technology, ecology, solar energy, bioshelters,

solar greenhouses, integrated pest management in greenhouses, organic

farming, and sustainable agriculture.

According to a notice from the Institute's Board of Directors upon

dissolution, New Alchemy publications will also be available through

The American Archives of Agriculture (AAA), located at Iowa State

University. On completion of cataloging, NAI's materials will be

available for on-site research as well as photocopying through

inter-library loan. Contact:

Ms. Anne Kenne

University Archivist and Acting Curator of AAA

Parks Library, Rm 403

Iowa State University

Ames, IA 50011

(515) 294-6672

In-vessel compost units, located in a nearby but separate location,

are an alternative to attached compost chamber on one side of the

greenhouse. In either case, capturing the heat of combustion and

distributing it to the greenhouse itself is a design feature that

needs attention. Options include wrapping the compost chamber with

recirculating water pipes, or using an air-to-water exchanger. The

heated water is then available for distribution through radiant

heating. Since root-zone heating (floor- and bench-heating) is an

established practice in the greenhouse industry, the technology

already exists to integrate this source of heat.

While the method proposed above is more experimental than proven, the

enclosed item from Biocycle magazine refers to one such system.

Quality of Compost

The operation of a compost-greenhouse facility has two inherent goals:

(1) heating the greenhouse via co-generation from a compost chamber,

and (2) the production of compost. Thus, compost end use (e.g.,

greenhouse production, potting mix, landscape industry, bagged sales)

and compost quality should both weigh in the decision-making process.

Good quality compost is recognized as a valuable soil treatment that

performs multiple functions: soil structure, crop fertility, soil

foodweb, natural disease suppression, etc. Thus, attention to the

composting process itself is rather important, and this means good

aerobic conditions (normally achieved by turning the pile when

windrows are used or through forced air when aerated static piles are

used) are critical.

Compost quality can be significantly improved by monitoring the pile

for temperature, carbon dioxide, pH, nitrites, nitrates, and sulfur,

and through the use of microbial inoculants. Compost biomaturity is

determined through a series of tests that indicate the level of humus

and biological activity.

Compost resources available from ATTRA includes the Farm-Scale

Composting Resource List, Compost Teas for Plant Disease,

Biodynamic Farming & Compost Preparation and related topics.

I hope these comments and enclosed materials are helpful.

Sincerely,

Steve Diver

Technical Specialist

References:

1)Fulford, Bruce. 1986. Composting Greenhouse at New Alchemy

Institute: A Report on Two Years of Operation and Monitoring.

Research Report No. 3, New Alchemy Institute.

2) Whitcomb, Carl E., Charlie Gray, and Billy Cavanaugh. 1985. A

floor heating top ventilating system for quonset greenhouses.

p.4-10. In: Nursery Research Field Day. Research Report

P-872. Agricultural Experiment Station, Oklahoma State University.

Enclosures:

Anon. 1991. Compost preheats water. Biocycle. July. p. 20.

Foulds, Chantal. 1992. Reducing costs, improving nutrient value.

Sustainable Farming. Winter. p. 6-8.

Fulford, Bruce. 1983. The composting greenhouse for commercial

regenerative agriculture. New Alchemy Quarterly. Winter/Number 14.

p. 4-5.

Fulford, Bruce. 1985. The compost story heats up. New Alchemy

Quarterly. Spring/Number 19. p. 19-20.

Fulford, Bruce. 1988. Composting in greenhouses for heat, CO2

enrichment, and nutrient economy. p. 337-346. In: Patricia Allen

and Debra Van Dusen (ed.) Global Perspectives on Agroecology and

Sustainable Agricultural Systems. Agroecology Program, University of

California, Santa Cruz.

Marshall, Norm. 1987. Composting greenhouse design update. New

Alchemy Quarterly. Fall/Number 29. p. 6-8.

Schonbeck, Mark. 1989. Composting greenhouse update. New Alchemy Quarterly. Summer/Number

36. p. 16-17.

Further Reading:

Compost Heating:

Anon. 1986. Heat with compost. Greenhouse Grower. Vol. 4, No. 12.

p. 50.

Floor Heating:

Roberts, Bill. 1991. Soil heating improves transplant production.

American Vegetable Grower. November. p. 40-42.

Solar-Floor Heating:

Roberts, W.J. et al. 1985. Energy Conservation for Commercial

Greenhouses. NRAES-3. Northeast Regional Agricultural Engineering

Service, Cornell University. p. 27-30.

Whitcomb, Carl E., Charlie Gray, and Billy Cavanaugh. 1984. The

"ideal" greenhouse for propagation. p. 4-8. In: Nursery Research

Field Day. Research Report P-855. Agricultural Experiment Station,

Oklahoma State University.

Whitcomb, Carl E., Charlie Gray, and Billy Cavanaugh. 1985. A floor

heating top ventilating system for quonset greenhouses. p. 4-10. In:

Nursery Research Field Day. Research Report P-872. Agricultural

Experiment Station, Oklahoma State University.

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Basu and Dutta Accountancy Book Class 12 SolutionsDocument14 paginiBasu and Dutta Accountancy Book Class 12 SolutionsGourab Gorai23% (30)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Designing A Compost-Heated Greenhouse To FosterDocument69 paginiDesigning A Compost-Heated Greenhouse To FosterCompost Heated Greenhouses100% (3)

- Berde Score Sheet TemplateDocument7 paginiBerde Score Sheet TemplateKRISSELLE TAYCO0% (1)

- Masters Degree Thesis For Educational ManagementDocument39 paginiMasters Degree Thesis For Educational ManagementJohn Bryan Aldovino100% (2)

- Composting Greenhouse Provide HotwaterDocument3 paginiComposting Greenhouse Provide HotwaterCompost Heated GreenhousesÎncă nu există evaluări

- Integrated Food-Waste Composting SystemDocument8 paginiIntegrated Food-Waste Composting SystemCompost Heated GreenhousesÎncă nu există evaluări

- The Composting Greenhouse by Bruce FulfordDocument24 paginiThe Composting Greenhouse by Bruce FulfordWyoming Native Plant Society100% (3)

- Composting and Thermal Energy SystemsDocument65 paginiComposting and Thermal Energy SystemsCompost Heated Greenhouses100% (3)

- Compost Thermal in Passive Solar GreenhouseDocument2 paginiCompost Thermal in Passive Solar GreenhouseCompost Heated Greenhouses100% (1)

- IBPS RRB Office Assistant Exam Pattern: Get Free Job Alerts in Your Email Click HereDocument9 paginiIBPS RRB Office Assistant Exam Pattern: Get Free Job Alerts in Your Email Click Hereहिमाँशु गंगवानीÎncă nu există evaluări

- Gender Inequality in The Philippine Labor MarketDocument41 paginiGender Inequality in The Philippine Labor MarketADBGADÎncă nu există evaluări

- Week 002-Module Political IdeologiesDocument4 paginiWeek 002-Module Political IdeologiesAlmirah MakalunasÎncă nu există evaluări

- 3 Steps To Find Your Hot Program Idea HPP Alina VincentDocument16 pagini3 Steps To Find Your Hot Program Idea HPP Alina VincentDebanik GhoshÎncă nu există evaluări

- Understanding Consumer Behaviour: © Macmillan Publishers India Ltd. 1Document12 paginiUnderstanding Consumer Behaviour: © Macmillan Publishers India Ltd. 1KavinÎncă nu există evaluări

- Melissa Fellman ResumeDocument1 paginăMelissa Fellman Resumeapi-300877369Încă nu există evaluări

- Bcsc009: Software Engineering: No. Content Teaching HoursDocument1 paginăBcsc009: Software Engineering: No. Content Teaching HoursAKSHIT VERMAÎncă nu există evaluări

- Entrepreneurship Development Institute of IndiaDocument7 paginiEntrepreneurship Development Institute of IndiaAnisha MarwahÎncă nu există evaluări

- Case Study Format 2021 2022Document12 paginiCase Study Format 2021 2022maryhamelnet rojasÎncă nu există evaluări

- Class Mural ProjectDocument1 paginăClass Mural ProjectarianamoonÎncă nu există evaluări

- Operations Strategy and Competitiveness: What Is Operation?Document6 paginiOperations Strategy and Competitiveness: What Is Operation?Mejidana, Rica Mae N.Încă nu există evaluări

- Care Routines ReferencesDocument2 paginiCare Routines Referencesapi-374587217Încă nu există evaluări

- The Institutional Foundations of Public Policy A Transactions Approach With Application To ArgentinaDocument26 paginiThe Institutional Foundations of Public Policy A Transactions Approach With Application To ArgentinaArmando MartinsÎncă nu există evaluări

- How Can Smes Effectively Implement The CSR Agenda: Kelompok 5Document21 paginiHow Can Smes Effectively Implement The CSR Agenda: Kelompok 5Vitha MasyitaÎncă nu există evaluări

- Word SmartDocument189 paginiWord SmartSmeeta Prasai0% (1)

- 0510 s11 QP 42Document8 pagini0510 s11 QP 42Veronica Simon OteroÎncă nu există evaluări

- Matias Dumas - PortfolioDocument12 paginiMatias Dumas - PortfolioMatias DumasÎncă nu există evaluări

- TDP NotesDocument29 paginiTDP NotesShivani NawaleÎncă nu există evaluări

- Circulatory SystemDocument3 paginiCirculatory SystemAbdurahmaan RaikarÎncă nu există evaluări

- Singapore High Speed Rail Project 2017Document14 paginiSingapore High Speed Rail Project 2017Jigisha VasaÎncă nu există evaluări

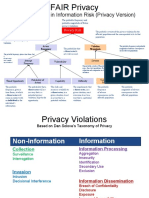

- Factor Analysis in Information Risk (Privacy Version)Document8 paginiFactor Analysis in Information Risk (Privacy Version)Otgonbayar TsengelÎncă nu există evaluări

- Final 2019sqyfergusonresume 5Document2 paginiFinal 2019sqyfergusonresume 5api-357486179Încă nu există evaluări

- 2nd Eco - Pelancongan Pulau (Malaysia)Document34 pagini2nd Eco - Pelancongan Pulau (Malaysia)Muhammad AsyrafÎncă nu există evaluări

- Intelligence Test: Three YearsDocument4 paginiIntelligence Test: Three YearsAnshuman TewaryÎncă nu există evaluări

- Community Health Nursing Notes (Second Year)Document6 paginiCommunity Health Nursing Notes (Second Year)anette katrinÎncă nu există evaluări

- Chapter 12 Quiz 1Document4 paginiChapter 12 Quiz 1joyceÎncă nu există evaluări

- Design Speed: Bill Gulick PEDocument12 paginiDesign Speed: Bill Gulick PEDiarra FallÎncă nu există evaluări