Documente Academic

Documente Profesional

Documente Cultură

DCP Using H3PO4

Încărcat de

caprolactamclDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

DCP Using H3PO4

Încărcat de

caprolactamclDrepturi de autor:

Formate disponibile

F e e d i n g r e d i e n t s n e w s f r o m T e s s e n d e r l o G r o u p May 2006

Dicalcium phosphate:

The production makes the difference

This article describes two different methods that exist for the

production of dicalcium phosphate. The dicalcium phosphates that

result from these two processes differ significantly in terms of New dioxin legislation

composition, purity and, most importantly, phosphorus digestibility. p2

The most commonly used production method is known as P digestibility for pigs p3

the “wet acid” route in which rock phosphate is reacted with

sulphuric acid to produce phosphoric acid. After

High technological p5

concentration and purification to reduce the level of

undesirable elements, this phosphoric acid is reacted with a additives

calcium source such as quick lime or limestone to produce

dicalcium phosphate.

The insoluble fraction, consisting mainly of calcium fluoride,

is removed and the liquor is purified (see picture page 4).

Process chemistry Phosphoric acid route Because monocalcium phosphate is readily soluble in water

Phosphoric acid production it cannot be precipitated.

Ca10(PO4)6F2 + 10 H2SO4 Æ 6H3PO4 + 10CaSO4 + 2HF

Production of anhydrous dicalcium phosphate Process chemistry Hydrochloric acid route

H3PO4 + CaCO3 Æ CaHPO4 +CO2 +H2O Dissolution in hydrochloric acid

or Ca10(PO4)6F2 + 12 HCl Æ 3Ca(H2PO4)2 + 6CaCl2 + CaF2

H3PO4 + CaO Æ CaHPO4 + H2O

Saturation of monocalcium phosphate solution to produce

This phosphoric acid production process generates large dihydrated crystalline dicalcium phosphate

quantities of gypsum, which contains significant levels of Ca(H2PO4)2 + Ca(OH)2 Æ 2CaHPO4.2H2O

undesirable elements. As a consequence, apart from a few

exceptions, production in Western Europe is no longer

carried out and phosphoric acid has to be imported from

other regions.

The quality of the phosphoric acid, in terms of levels of

impurities or undesirable elements, can have a major effect

on the purity, composition and digestible phosphorus content

of the resulting dicalcium phosphate. Therefore, Tessenderlo

Group liaise closely with suppliers of feed grade phosphoric

acid to ensure that the quality of their products is strictly

controlled.

Processing for purity

Another method, which was first used by Tessenderlo

Group, is the dissolution of rock phosphate in hydrochloric

acid to deliver a very pure and crystalline dicalcium

phosphate. The process starts with the dissolution of finely

ground rock phosphate in diluted hydrochloric acid, resulting

in the formation of a monocalcium phosphate solution.

Microscopic view of crystalline dicalcium phosphate

(Aliphos Dical)

Aliphos Italphos Windmill

Therefore, additional calcium is added to saturate the liquor

and to change the molecular structure from monocalcium

phosphate into dicalcium phosphate. Dicalcium phosphate

crystals are precipitated and after filtration and drying the

resulting product is a very pure crystalline dihydrate

dicalcium phosphate that is sold as Aliphos® Dical.

Legislation on undesirable substances:

Advantages of Tessenderlo’s process dioxins and dioxin like PCBs

Dissolution is a gradual process, offering a number of On the 3rd of February a new Commission Directive

advantages for animal feeding applications: 2006/13/EC on undesirable substances in animal feed with

• The low temperature of the process prevents the regards to dioxins and dioxin-like PCBs was published. This

formation of biologically unavailable meta- and/or pyro- latest edition includes permitted maximum contents for a

phosphates group of 12 PCBs that exhibit similar toxicological properties

• As a crystallization process it ensures a very to dioxins and are therefore often termed ‘dioxin-like PCBs’.

predictable composition and a highly pure dicalcium According to this legislation, maximum contents for feed

phosphate, virtually free of undesirable elements materials of mineral origin, such as inorganic feed

• The hydrate structure is recognized to be nutritionally phosphates, are 1.0 ng WHO-PCDD/F-TEQ/kg for dioxins

beneficial as has been proven in several trials with a and 1.5 ng WHO-PCDD/F-TEQ/kg for the sum of dioxins and

wide range of animal species (see also the results of a dioxin like PCBs.

recent pig trial presented on page 3)

The results of the dioxin analyses performed during

In a later stage this crystalline dicalcium phosphate February 2006 on the inorganic feed phosphates of

dihydrate is used for the production of either monocalcium or Tessenderlo Group are published in the table below.

monodicalcium phosphate. The use of high quality dicalcium Analyses are performed at Carso France, an official

phosphate in these types of feed phosphates results in accredited laboratory. In line with our results of previous

chemically stable and pure products with a low content of years, the dioxin levels in all inorganic feed phosphates of

undesirable elements. Also the nutritional value of these Tessenderlo Group are well below the legal maximum

products (Aliphos® Monocal & Modical) is proven to be the content and the same is true for the sum of dioxins and

highest on the market. dioxin like PCBs.

Dioxins Dioxins +

Dioxin-like PCBs

(ng/kg) (ng/kg)

ALIPHOS DICAL 0.10 0.10

ALIPHOS MONOCAL 0.08 0.08

ALIPHOS MONOMAG 0.03 0.03

WINDMILL DICALPHOS 0.14 0.15

ALIPHOS MODICAL 0.03 0.04

WINDMILL MAGNUMPHOS 0.02 0.03

WINDMILL MONAMPHOS 0.05 0.07

ITALPHOS DICAL 0.06 0.08

ITALPHOS MONOCAL 0.03 0.06

ITALPHOS MODICAL 0.02 0.03

Dissolution tanks of finely ground rock phosphate with

diluted hydrochloric acid

Aliphos Italphos Windmill

New results on digestible phosphorus (P) content

of three types of feed phosphates for pigs

In 2005 Tessenderlo Group carried out a trial at the Agricultural Research Centre (FAL;

Braunschweig, Germany) to evaluate the P-digestibility of Italphos Dical, Aliphos Dical and Aliphos

Monomag using pigs. It is known from literature (CVB, 1990) that there are differences in digestible

P-content of DCP dihydrate (Aliphos Dical; DCP2H2O) compared to DCP anhydrate (Italphos Dical;

DCP0H2O). However, often no differentiation is made between the two chemically different products

and only one value for P-digestibility of around 70% has been assigned to all forms of DCP used in

pig feeding (DLG Information 1/1999). Aliphos Monomag, a calcium-magnesium phosphate (CaMgP)

was tested because no accurate P-digestibility figure exists for such a product.

Materials and methods Differences in dP-content caused by

The basal diet was a so-called semi-synthetic diet (GR) with a low P-content (less differences in feed phosphate

than 1.0 g calculated digestible P per kg DM). Phosphates were added to the base production

diet at a rate such that the total calculated digestible P did not exceed 2.0 g per kg Feed phosphates including dicalcium

DM (Table 1). phosphates (DCP), can be

manufactured by various methods. This

Table 1: Composition of the mixed feeds (g/kg) can result in products with different

GR DCP0H2O DCP2H2O Ca-Mg-P chemical compositions (see pages

Italphos Dical Aliphos Dical Aliphos Monomag 1&2). The purity of the raw materials

Corn starch 635.0 635.0 635.0 635.0 used in the processes but certainly the

Sugar beet pulp 150.0 146.0 145.5 144.5 different process conditions do have

Potato protein 85.0 85.0 85.0 85.0 major consequences for the digestibility

Albumen protein 65.0 65.0 65.0 65.0 of such products.

Cellulose 30.0 30.0 30.0 30.0 Aliphos Monomag is produced by

Soy oil 15.0 15.0 15.0 15.0 means of reacting a calcium source and

Vitamins / trace 5.0 5.0 5.0 5.0 a highly reactive magnesium oxide

elements (MgO) with feed grade phosphoric acid.

CaCO3 9.5 4.5 5.0 8.0 The resulting product is a homogeneous

NaCl 3.0 3.0 3.0 3.0 chemical complex of monocalcium and

Lysine-HCl 2.0 2.0 2.0 2.0 monomagnesium phosphate.

L-Tryptophane 0.5 0.5 0.5 0.5 The three phosphates investigated in

MgO -- 1.5 1.5 -- this trial were analysed according to a

Phosphate -- 7.5 7.5 7.0 method known as XRD-analysis. With

this method the composition of the

Both calcium and magnesium were added to the trial feeds to arrive at more or less product can be estimated. Aliphos Dical

the same levels in the trial diets to exclude any affect on P-digestibility. Twelve contained mainly dihydrate dicalcium

castrated males (hybrids “BHZP”) were used in the trial. Three balance trials were phosphate (CaHPO4.2H2O) as well as

carried out with these animals in the live weight range from 36.6±0.9 kg up to traces of dicalcium phosphate

61.6±1.2 kg in an incomplete Latin square arrangement (Table 2). anhydrate (CaHPO4). In contrast to this,

Italphos Dical contained mainly

Table 2: Design of the trial dicalcium phosphate anhydrate

Days Period GR Italphos Aliphos Aliphos (CaHPO4) together with CaCO3,

Dical Dical Monomag Ca(OH)2 and traces of CaO. Aliphos

Monomag is composed of monocalcium

1-7 Pre period Anim. 1-3 Anim. 4-6 Anim. 7-9 Anim. 10-12

phosphate Ca(H2PO4)2.xH20 and

8 14 Collection Anim. 1-3 Anim. 4-6 Anim. 7-9 Anim. 10-12

monomagnesium phoshate Mg(H2PO4)2

15-21 Pre period Anim. 4-6 Anim. 7-9 Anim. 10-12 Anim. 1-3

together with MgO and CaCO3.

22-28 Collection Anim. 4-6 Anim. 7-9 Anim. 10-12 Anim. 1-3

29-35 Pre period Anim. 7-12 Anim. 1-3 Anim. 4-6

36-42 Collection Anim. 7-12 Anim. 1-3 Anim. 4-6

Feedstuffs were analysed for crude nutrients and mineral elements. N, P, Ca and Continued on next page

Mg were analysed in faeces and urine. The P digestibility (dP) of the different feed

phosphates was calculated according the following formula:

DPtest feed (%)-DPGR (%) x (1-a)

DPfeed phosphate (%) = a

a = analysed P content of the feed phosphate (g/kg DM) x ratio of the test

component in test feed (kg/kg) / analysed P content of the test feed (g/kg DM)

Aliphos Italphos Windmill

Results

The analyses of the trial feeds are shown in Table 3.

The average feed intake of all animals in the whole trial Table 5: P-digestibility of the experimental diets and feed

period was 1503 ± 83 g/day. The average LW was 48.5 ± phosphates (%)

8.1 kg with an average live weight gain (LWG) of 590 ± 116 n dP diet dP

g/day. The results of the P-balance trial are shown in Table phosphate

4. GR 12 17 ± 13

Italphos Dical, DCP0H2O 8 55 ± 7 72.1

Table 3: Results of analyses of the trial feeds Aliphos Dical, DCP2H2O 5 60 ± 6 79.9

GR Italphos Aliphos Aliphos Aliphos Monomag, 9 65 ± 4 83.9

Dical Dical Monomag CaMgP

Ash (% DM) 3.4 3.2 3.8 3.6

Cr. Prot. (% DM) 15.8 15.7 15.3 15.6

Ca (g/kg DM) 5.59 5.52 6.15 5.61 Conclusion

P (g/kg DM) 0.76 1.99 2.01 1.91 Differences were found in P-digestibility between Italphos

Mg (g/kg DM) 0.53 1.10 1.23 1.12 Dical (DCP0H2O) and Aliphos Dical (DCP2H2O). The P-

ME (MJ/kg DM) 16.00 16.13 16.21 16.31 digestibility from Italphos Dical was 72%, however, DCP

dihydrate Aliphos Dical scored a much higher value of 80%.

Table 4: P intake and excretion per day These differences clearly reflect differences in chemical

n P intake P faeces P urine composition; anhydrous vs. dihydrate dicalcium phosphate.

mg mg mg This is also in line with previous studies for poultry where

GR 12 1036±59 854±116 20±3 similar differences between DCP2H2O (80%) and

Italphos Dical 8 2700±167 1213±171 17±2 DCP0H2O (70-75%) were found (Van der Klis and

Aliphos Dical 5 2628±99 1050±184 18±1 Versteegh, 1993; Potter et al, 1995; De Groote and

Aliphos 9 2550±147 884±132 16±2 Huyghebaert, 1997; etc).

Monomag“ The dP content of Aliphos Monomag was 84%, which is to

be expected for a product in which the greater part of the P

is found in the form of MCP (Aliphos Monocal), which has a

Table 5 shows the P-digestibilities of the experimental diets. 90% digestibility for pigs.

After subtracting the effect of the basal diet, the P-

digestibility of the different feed phosphates can be This article will be published in Kraftfutter Feed

calculated. Magazine, a European Feed Business Magazine.

Sedimentation of insoluble material out of the monocalcium phosphate liquor.

Aliphos Italphos Windmill

Tessenderlo Group enlarges the

range of high technological additives

Tessenderlo Group has cooperated closely with SODA Feed

Ingredients for about ten years in the commercialization of

coated acids and other products. The Micropearls of SODA

Feed Ingredients are already well known in Europe and the

range has been enlarged with the recent introduction of new

microencapsulated products. SODA Feed Ingredients’

research team has used its considerable knowledge and

expertise to develop Microcapsules or Micropearls which are a

combination of simple feed preservatives and essential oils.

This produces an excellent tool for the natural control of the ACIXOL

health and performance of animals through the feed.

In FORMAXOL, the REPAXOL is combined with formiate and

Production in EURHEMA citric acid through a fluid bed process. This combination has

SODA Feed Ingredients has many years’ experience in the the advantage of providing strong formic acid activity enhanced

manufacture of these products in its EURHEMA plant located by the effect of the essential oils.

in Cavriago Italy. This high technology plant has developed in

response to the demands of today’s feed industry. The ISO Extensive research

9001:2000 quality system was implemented several years ago Scientific publications have shown the benefits of the use of

and the plant introduced a full HACCP plan in early 2005. This ACIXOL and REPAXOL in broiler feeds (M. Lippens et al.,

was followed in March 2006 by FAMI-QS certification for the Arch. Geflügelk., 69(6).S. 261-266, 2005). In the figure below a

production of feed ingredient mixes which is equivalent to all calculation is made of the financial result in this trial. It shows

existing GMP systems for the feed industry today. Fully that the coated products give a 1.5% advantage over the

equipped to meet the high standards of the EU Feed Hygiene control group.

regulation, Soda FI developed a new range of products based Several field trials have demonstrated that the combination of

on their knowledge of the technology of encapsulation and these protected feed ingredients is also very effective in

their extensive experience gained through consultation with the piglets, pigs, sows and layers/breeders. Reports are available

pig and poultry industry on this subject. on request. Tessenderlo staff and the SODA FI technical

department are happy to advise you on how to achieve the

New Products most cost-effective solution.

The new range of products: REPAXOL, ACIXOL, and

FORMAXOL combine acids and essential oils in a high Your requests will be forwarded to the responsible people in

technological premix which allows their gradual release within your area or contact animalnutrition@tessenderlo.com

the digestive tract. The intelligent use of this combination of

101

ingredients gives pig and poultry growers the possibility of

addressing the challenges of today’s animal husbandry such

as suboptimal condition of the breeding animals (pigs, poultry 100

and rabbits) as well as maintaining performance in an era 100 100

where more ‘natural’ methods of animal production are often

99

demanded by the final consumer. These products also give the 99.20

feed compounder the possibility to work with products that are %

quite difficult to handle when used individually. 98 98.55

REPAXOL is a combination of essential oils and can be

efficiently used at low dosages (50 to 300 ppm) in all types of 97

animal feed. The essential oils are protected in a way that they

are heat stable. REPAXOL is used as an ingredient in two

other products of this range. In ACIXOL organic and inorganic 96

acids are combined by spray freezing with REPAXOL. The

synergy between the acids and the essential oils makes it an 95

ideal product for continuous use in pigs, poultry and turkey Negative control Avilamycin 10 AciXol 500 RepaXol 100

feeds.

Relative production cost of broilers (CLO-Melle Belgium, 2005)

Tessenderlo Group Feed Ingredients

Leading the world in feed phosphates

Tessenderlo Group

Troonstraat 130, B-1050 Brussels, Belgium

Tel: +32 2 639 1811 Fax: +32 2 639 1940

www.tessenderlogroup.com

animalnutrition@tessenderlo.com

S-ar putea să vă placă și

- Aqueous Solubility of Inorganic Compounds at Various TemperaturesDocument9 paginiAqueous Solubility of Inorganic Compounds at Various TemperaturesterrorfordÎncă nu există evaluări

- Weld Joint Geometry and Welding SymbolsDocument12 paginiWeld Joint Geometry and Welding Symbolsnavi91Încă nu există evaluări

- Aniline Separation From TolueneDocument41 paginiAniline Separation From ToluenecaprolactamclÎncă nu există evaluări

- Acid As Catalyst in Esterfication of Phthalic AnhydrideDocument5 paginiAcid As Catalyst in Esterfication of Phthalic AnhydridecaprolactamclÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Cadweld MS UsDocument12 paginiCadweld MS UsEfrain Melgarejo PinedaÎncă nu există evaluări

- Food Science: Using An Emulsifier To Create Homemade MayonnaiseDocument10 paginiFood Science: Using An Emulsifier To Create Homemade Mayonnaiseapi-350675057Încă nu există evaluări

- Obturating Materials Used For Pulpectomy in Primary Teeth A ReviewDocument9 paginiObturating Materials Used For Pulpectomy in Primary Teeth A ReviewMohammed SaeedÎncă nu există evaluări

- Bram Cor EQUIPO DE PRE TRATAMIENTO Biopharma Water SystemsDocument16 paginiBram Cor EQUIPO DE PRE TRATAMIENTO Biopharma Water SystemsYeimer MesaÎncă nu există evaluări

- 120131-Perforated Sheet Metal - IPRF - CD PDFDocument239 pagini120131-Perforated Sheet Metal - IPRF - CD PDFMisagh100% (1)

- ANSI-AWWA (American Water Works Association)Document1 paginăANSI-AWWA (American Water Works Association)Vaniya GoelÎncă nu există evaluări

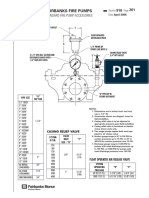

- Fire Pump AccessoriesDocument23 paginiFire Pump AccessoriesMuhammad ArslanÎncă nu există evaluări

- O - LEVEL CHEMISTRY WORKSHEETS - Reactions QuestionsDocument21 paginiO - LEVEL CHEMISTRY WORKSHEETS - Reactions QuestionsFahim Ahmed75% (4)

- Acids and Bases YMS X ALJDocument9 paginiAcids and Bases YMS X ALJFaqihah Syahindah Mohammed FiroozÎncă nu există evaluări

- Yellow Shoulder On TomatoDocument2 paginiYellow Shoulder On TomatoargikarÎncă nu există evaluări

- PH4211 Statistical Mechanics: Problem Sheet 2Document4 paginiPH4211 Statistical Mechanics: Problem Sheet 2Roy VeseyÎncă nu există evaluări

- Viscosity Flow Time RelationDocument7 paginiViscosity Flow Time Relationm_k_tripathyÎncă nu există evaluări

- Indian Chemical IndustryDocument3 paginiIndian Chemical IndustryRajat SahaiÎncă nu există evaluări

- Answers Chemistry, 12e (Brown, LeMay, Bursten, Murphy) Chapter 3, 4, & 10Document11 paginiAnswers Chemistry, 12e (Brown, LeMay, Bursten, Murphy) Chapter 3, 4, & 10Jose RiveraÎncă nu există evaluări

- Weekly Construction Report - 2011.10.15Document22 paginiWeekly Construction Report - 2011.10.15Farouq SHah100% (5)

- Chapter 12 Power Point 5e HPDocument83 paginiChapter 12 Power Point 5e HPsweetgirl_24_6_9630Încă nu există evaluări

- PaintDocument28 paginiPaintAnna KateurinaÎncă nu există evaluări

- 3 NsaidsDocument23 pagini3 NsaidsHagai MagaiÎncă nu există evaluări

- Nano Buble NozzleDocument4 paginiNano Buble Nozzlefajar123269733% (3)

- Lesson Plan Physical ScienceDocument7 paginiLesson Plan Physical ScienceRANDOLPH CABAOBASÎncă nu există evaluări

- Exp 10 Alkyl HalidesDocument18 paginiExp 10 Alkyl HalidesGeorge PiliposyanÎncă nu există evaluări

- C1081pe DM ValveDocument6 paginiC1081pe DM ValveAhmed Mohamed HassanÎncă nu există evaluări

- Organic ChemicalsDocument55 paginiOrganic ChemicalsjajajaÎncă nu există evaluări

- Metabolit SekunderDocument76 paginiMetabolit SekunderCempaka Kusuma DewiÎncă nu există evaluări

- Advanced Construction MaterialsDocument37 paginiAdvanced Construction MaterialsZara AliÎncă nu există evaluări

- 16 - OreOre Deposit Geology (John Ridley, 2013)Document3 pagini16 - OreOre Deposit Geology (John Ridley, 2013)Hugo Luis HuamaníÎncă nu există evaluări

- Water Quality AnalyzerDocument1 paginăWater Quality AnalyzerVictor BiacoloÎncă nu există evaluări

- 2015-08-20 St. Mary's County TimesDocument32 pagini2015-08-20 St. Mary's County TimesSouthern Maryland OnlineÎncă nu există evaluări

- Crude Distillation Unit: Atmospheric and Vacuum Crude TowersDocument5 paginiCrude Distillation Unit: Atmospheric and Vacuum Crude TowersLuz Angela Jaramillo CiprianÎncă nu există evaluări

- MeasureMaster Dual Chamber Orifice FittingDocument6 paginiMeasureMaster Dual Chamber Orifice FittingirfanÎncă nu există evaluări