Documente Academic

Documente Profesional

Documente Cultură

Alcohol Sensor

Încărcat de

mygodspDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Alcohol Sensor

Încărcat de

mygodspDrepturi de autor:

Formate disponibile

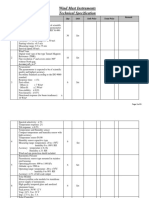

MQ303A Alcohol Sensor

Character

* High sensitivity

* Fast response and resume

* Long life and low cost

* Mini Size

Application

MQ303A is semiconductor sensor is for Alcohol detection,

It has good sensitivity and fast response to alcohol,

suitable for portable alcohol detector.

Configuration

Technical Data

Model No. MQ303A

Sensor Type Semiconductor

Standard Encapsulation Metal

Detection Gas Alcohol

Concentration 20-1000ppm Alcohol

Heater Voltage VH 0.9V ± 0.1V AC or DC

Loop Voltage Vc ≤6V DC

Load RL

Standard Adjustable

Resistance

Circuit

Heater

Conditions RH 4.5Ω ± 0.5 Ω(Room Tem.)

Resistance

Heater Current IH 120±20mA

Heater Power PH ≤ 140 mW

Sensor

PS ≤10 mW

Consumption

Sensing

Rs 4KΩ-400KΩ(in air)

Character Resistance

Rs(in air)/Rs(125ppm

Sensitivity S

Alcohol)≥3

Slope α 0.50 ± 0.15(R300ppm/R100ppm Alcohol)

Tem. Humidity 20℃±2℃;65%±5%RH

Vc:3.0 V±0.1 V DC ;

Condition Standard test circuit

VH: 0.9 V±0.1 V DC

Preheat time Over 48 hours

Sensing element of the semiconductor sensor is a

micro-ball, heater and metal electrode are inside,

and the sensing element is installed in

anti-explosion double 100 mesh metal case (see

the above)

Sensitivity Characteristics Influence of Temperature/Humidity

Fig.2 is the test circuit. You could get resistance Fig 3 is sensitivy of MQ303A, it reflects

change from voltage change on fixed or adjustable relations between resistance and gas

load resistance. Normally, it will take several concentration, resistance of the sensor

minutes preheating for sensor enter into stable reduce when gas concentration increases

working after electrified; oryou could give

2.2±0.2V high voltage for 5-10secs before test,

which make sensor easily stable.

Notification

1 Following conditions must be prohibited

1.1 Exposed to organic silicon steam

Organic silicon steam cause sensors invalid, sensors must be avoid exposing to silicon bond,

fixature, silicon latex, putty or plastic contain silicon environment

1.2 High Corrosive gas

If the sensors exposed to high concentration corrosive gas (such as H2Sz, SOX,Cl2,HCl etc), it will

not only result in corrosion of sensors structure, also it cause sincere sensitivity attenuation.

1.3 Alkali, Alkali metals salt, halogen pollution

The sensors performance will be changed badly if sensors be sprayed polluted by alkali metals salt

especially brine, or be exposed to halogen such as fluorin.

1.4 Touch water

Sensitivity of the sensors will be reduced when spattered or dipped in water.

1.5 Freezing

Do avoid icing on sensor’surface, otherwise sensor would lose sensitivity.

1.6 Applied voltage higher

Applied voltage on sensor should not be higher than stipulated value, otherwise it cause down-line or

heater damaged, and bring on sensors’ sensitivity characteristic changed badly.

1.7 Voltage on wrong pins

For 6 pins sensor, if apply voltage on 1、3 pins or 4、6 pins, it

will make lead broken, and without signal when apply on 2、4 pins

2 Following conditions must be avoided

2.1 Water Condensation

Indoor conditions, slight water condensation will effect sensors performance lightly. However, if water

condensation on sensors surface and keep a certain period, sensor’ sensitivity will be decreased.

2.2 Used in high gas concentration

No matter the sensor is electrified or not, if long time placed in high gas concentration, if will affect

sensors characteristic.

2.3 Long time storage

The sensors resistance produce reversible drift if it’s stored for long time without electrify, this drift is

related with storage conditions. Sensors should be stored in airproof without silicon gel bag with clean air.

For the sensors with long time storage but no electrify, they need long aging time for stbility before using.

2.4 Long time exposed to adverse environment

No matter the sensors electrified or not, if exposed to adverse environment for long time, such as

high humidity, high temperature, or high pollution etc, it will effect the sensors performance badly.

2.5 Vibration

Continual vibration will result in sensors down-lead response then repture. In transportation or

assembling line, pneumatic screwdriver/ultrasonic welding machine can lead this vibration.

2.6 Concussion

If sensors meet strong concussion, it may lead its lead wire disconnected.

2.7 Usage

For sensor, handmade welding is optimal way. If use wave crest welding should meet the following

conditions:

2.7.1 Soldering flux: Rosin soldering flux contains least chlorine

2.7.2 Speed: 1-2 Meter/ Minute

2.7.3 Warm-up temperature:100±20℃

2.7.4 Welding temperature:250±10℃

2.7.5 1 time pass wave crest welding machine

If disobey the above using terms, sensors sensitivity will be reduced.

S-ar putea să vă placă și

- MQ303B Manual (Ver1.3)Document7 paginiMQ303B Manual (Ver1.3)이상우Încă nu există evaluări

- Alcohol Sensor: ConfigurationDocument6 paginiAlcohol Sensor: ConfigurationNiranjan ReddyÎncă nu există evaluări

- MQ136 Semiconductor Sensor For Sulfur DioxideDocument3 paginiMQ136 Semiconductor Sensor For Sulfur DioxideHarold rochaÎncă nu există evaluări

- MQ137 Ammonia SensorDocument3 paginiMQ137 Ammonia Sensorkpkarthi80Încă nu există evaluări

- MQ131 PDFDocument3 paginiMQ131 PDFHarold rochaÎncă nu există evaluări

- MQ131 HenanHanweiDocument3 paginiMQ131 HenanHanweiEngr. Usman WaheedÎncă nu există evaluări

- MQ 131Document3 paginiMQ 131RogerÎncă nu există evaluări

- MQ137 (Ver1.4) - ManualDocument6 paginiMQ137 (Ver1.4) - ManualAleX KasperÎncă nu există evaluări

- MQ2 Data SheetDocument3 paginiMQ2 Data SheetPVPPP100% (2)

- Mp503 English PDFDocument7 paginiMp503 English PDFФлавио ПересÎncă nu există evaluări

- MQ3Document3 paginiMQ3George JosephÎncă nu există evaluări

- By ALLDATASHEETCOM - 2015 - DATASHEET SEARCH SITE WWW - ALLDATASHEET.COM (2) - AnnotatedDocument6 paginiBy ALLDATASHEETCOM - 2015 - DATASHEET SEARCH SITE WWW - ALLDATASHEET.COM (2) - AnnotatedPANJI BRAMMASTAÎncă nu există evaluări

- MQ138Document3 paginiMQ138Anbu OpsÎncă nu există evaluări

- MQ135 (Ver1.4) - ManualDocument7 paginiMQ135 (Ver1.4) - ManualPavankumar VijapurÎncă nu există evaluări

- MQ135 Semiconductor Sensor For Air Quality ControlDocument3 paginiMQ135 Semiconductor Sensor For Air Quality Controlubuntu 13.04Încă nu există evaluări

- For Detection of Odor and Air Contaminants: Applications: FeaturesDocument2 paginiFor Detection of Odor and Air Contaminants: Applications: FeaturesIvica ConicÎncă nu există evaluări

- MQ-7 Semiconductor Sensor For Carbon MonoxideDocument3 paginiMQ-7 Semiconductor Sensor For Carbon MonoxideChandrashekhar KulkarniÎncă nu există evaluări

- MQ 4Document3 paginiMQ 4Robin OhanyanÎncă nu există evaluări

- Datasheet MQ6Document3 paginiDatasheet MQ6Huitzilopoxtli GarciaÎncă nu există evaluări

- Manual: Flammable Gas SensorDocument7 paginiManual: Flammable Gas SensorWerliock MorlorumÎncă nu există evaluări

- DATAAEARDocument3 paginiDATAAEARMaruthi JacsÎncă nu există evaluări

- Especificaciones Tecnicas Mq-3Document2 paginiEspecificaciones Tecnicas Mq-3Oscar RMÎncă nu există evaluări

- MQ-9 DatasheetDocument3 paginiMQ-9 Datasheetshedboy71Încă nu există evaluări

- SENSORSDocument10 paginiSENSORSFaustin MailuÎncă nu există evaluări

- MQ-3 Datasheet SensorDocument2 paginiMQ-3 Datasheet SensorAfif AR100% (1)

- MQ306ADocument2 paginiMQ306AFarshad yazdiÎncă nu există evaluări

- TGS 842Document2 paginiTGS 842Cesar TemocheÎncă nu există evaluări

- Fis Gas Sensor Sb-12A-00: For Methane DetectionDocument2 paginiFis Gas Sensor Sb-12A-00: For Methane DetectionPABLO ANTONIO ESTEVEZ RUEDAÎncă nu există evaluări

- For The Detection of Carbon Monoxide: Applications: FeaturesDocument2 paginiFor The Detection of Carbon Monoxide: Applications: FeaturesFito PaezÎncă nu există evaluări

- 821 PDFDocument2 pagini821 PDFemrenormÎncă nu există evaluări

- Gas Sens MQ 306Document2 paginiGas Sens MQ 306Zia UllahÎncă nu există evaluări

- Wind Mast InstrumentsSpecDocument3 paginiWind Mast InstrumentsSpecHagosMebrahtuÎncă nu există evaluări

- Lampiran Tugas AkhirDocument35 paginiLampiran Tugas AkhirAsrief RizkiÎncă nu există evaluări

- H2,3,4N Temperature & Humidity TransmitterDocument2 paginiH2,3,4N Temperature & Humidity Transmittermohamed mansour100% (1)

- MQ 8Document2 paginiMQ 8Farshad yazdiÎncă nu există evaluări

- MQ 4Document2 paginiMQ 4api-3850017100% (1)

- 18.smoke SensorDocument6 pagini18.smoke SensorBRAGPW,Karimnagar 087Încă nu există evaluări

- ACTW-CAR ManualDocument12 paginiACTW-CAR ManualkongÎncă nu există evaluări

- TGS 244Document2 paginiTGS 244Tugino GinoÎncă nu există evaluări

- MQ 136 PDFDocument2 paginiMQ 136 PDFGerardo Guzman Correo100% (1)

- MQ 5Document2 paginiMQ 5api-3850017100% (2)

- Humidity Sensor: Type HCZ-H8Document4 paginiHumidity Sensor: Type HCZ-H8Rotaru Roxana MarianaÎncă nu există evaluări

- MQ 214Document2 paginiMQ 214api-3850017100% (1)

- Inc MDocument15 paginiInc MRajni ShelkeÎncă nu există evaluări

- MQ 3Document2 paginiMQ 3Farshad yazdiÎncă nu există evaluări

- Electrical Characterization of Organic Electronic Materials and DevicesDe la EverandElectrical Characterization of Organic Electronic Materials and DevicesÎncă nu există evaluări

- Electronics – From Theory Into Practice: Applied Electricity and Electronics DivisionDe la EverandElectronics – From Theory Into Practice: Applied Electricity and Electronics DivisionEvaluare: 5 din 5 stele5/5 (1)

- Electronics—From Theory Into Practice: Pergamon International Library of Science, Technology, Engineering and Social StudiesDe la EverandElectronics—From Theory Into Practice: Pergamon International Library of Science, Technology, Engineering and Social StudiesEvaluare: 5 din 5 stele5/5 (2)

- Automatic Controls for Heating and Air Conditioning: Principles and ApplicationsDe la EverandAutomatic Controls for Heating and Air Conditioning: Principles and ApplicationsEvaluare: 4 din 5 stele4/5 (2)

- Hall-Effect Sensors: Theory and ApplicationDe la EverandHall-Effect Sensors: Theory and ApplicationEvaluare: 5 din 5 stele5/5 (1)

- Nonlinear Electronics 1: Nonlinear Dipoles, Harmonic Oscillators and Switching CircuitsDe la EverandNonlinear Electronics 1: Nonlinear Dipoles, Harmonic Oscillators and Switching CircuitsÎncă nu există evaluări

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsDe la EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsEvaluare: 3.5 din 5 stele3.5/5 (6)

- A Guide to Electronic Maintenance and RepairsDe la EverandA Guide to Electronic Maintenance and RepairsEvaluare: 4.5 din 5 stele4.5/5 (7)

- Introduction to Power System ProtectionDe la EverandIntroduction to Power System ProtectionÎncă nu există evaluări

- Introduction to Power System ProtectionDe la EverandIntroduction to Power System ProtectionEvaluare: 5 din 5 stele5/5 (1)

- Angels On Assignment....... Roland BuckDocument72 paginiAngels On Assignment....... Roland BuckAgyeiwaa Opoku80% (5)

- ReportDocument106 paginiReportmygodspÎncă nu există evaluări

- Nayna PublishingDocument5 paginiNayna PublishingmygodspÎncă nu există evaluări

- Conveyor Belt RobotDocument120 paginiConveyor Belt Robotmygodsp100% (1)

- Eschatology IIIDocument151 paginiEschatology IIImygodspÎncă nu există evaluări

- 26.multiconverter Unified PowerDocument84 pagini26.multiconverter Unified PowermygodspÎncă nu există evaluări

- Conveyor Belt RobotDocument120 paginiConveyor Belt Robotmygodsp100% (1)

- Automatic Reconfiguration For Large-Scale Reliable Storage SystemsDocument13 paginiAutomatic Reconfiguration For Large-Scale Reliable Storage SystemsmygodspÎncă nu există evaluări

- AngelsOnAssignment 43pgDocument43 paginiAngelsOnAssignment 43pgmygodspÎncă nu există evaluări

- Cell CountingDocument5 paginiCell CountingmygodspÎncă nu există evaluări

- Literature Survey - Secure ComputingDocument6 paginiLiterature Survey - Secure ComputingmygodspÎncă nu există evaluări

- DelayDocument9 paginiDelaymygodspÎncă nu există evaluări

- AngelsOnAssignment 43pgDocument43 paginiAngelsOnAssignment 43pgmygodspÎncă nu există evaluări

- Erudite: !!! FREE Courses!!!Document2 paginiErudite: !!! FREE Courses!!!mygodspÎncă nu există evaluări

- Alarm System of Railway Gate Crossing Based On Gps and GSMDocument109 paginiAlarm System of Railway Gate Crossing Based On Gps and GSMmygodspÎncă nu există evaluări

- An Intelligent Vehicle Monitoring & Contorlling Using ArmDocument6 paginiAn Intelligent Vehicle Monitoring & Contorlling Using ArmmygodspÎncă nu există evaluări

- Anti Breaking SystemDocument3 paginiAnti Breaking SystemmygodspÎncă nu există evaluări

- Grid Connected Battery SystemDocument34 paginiGrid Connected Battery SystemmygodspÎncă nu există evaluări

- Digital Image Processing BasicDocument55 paginiDigital Image Processing BasicmygodspÎncă nu există evaluări

- Hand Motion Based Crane Control Using MEMSDocument4 paginiHand Motion Based Crane Control Using MEMSmygodspÎncă nu există evaluări

- Finger Print Atm SecurityDocument24 paginiFinger Print Atm SecuritymygodspÎncă nu există evaluări

- Finger Print Based Atm Authentication andDocument4 paginiFinger Print Based Atm Authentication andmygodspÎncă nu există evaluări

- Electric ConsumptionDocument1 paginăElectric ConsumptionmygodspÎncă nu există evaluări

- CO2 Storage and LeakageDocument7 paginiCO2 Storage and Leakageaka_1010Încă nu există evaluări

- RFID Based ATM SystemDocument119 paginiRFID Based ATM SystemmygodspÎncă nu există evaluări

- Electric ConsumptionDocument1 paginăElectric ConsumptionmygodspÎncă nu există evaluări

- EmbdDocument42 paginiEmbdmygodspÎncă nu există evaluări

- Palm Print AuthenticationDocument60 paginiPalm Print AuthenticationmygodspÎncă nu există evaluări

- Electric ConsumptionDocument1 paginăElectric ConsumptionmygodspÎncă nu există evaluări

- AbstractDocument1 paginăAbstractmygodspÎncă nu există evaluări

- Chapter03 - How To Retrieve Data From A Single TableDocument35 paginiChapter03 - How To Retrieve Data From A Single TableGML KillÎncă nu există evaluări

- Pediatric Skills For OT Assistants 3rd Ed.Document645 paginiPediatric Skills For OT Assistants 3rd Ed.Patrice Escobar100% (1)

- BS en Iso 11666-2010Document26 paginiBS en Iso 11666-2010Ali Frat SeyranÎncă nu există evaluări

- CEC Proposed Additional Canopy at Guard House (RFA-2021!09!134) (Signed 23sep21)Document3 paginiCEC Proposed Additional Canopy at Guard House (RFA-2021!09!134) (Signed 23sep21)MichaelÎncă nu există evaluări

- Fin 3 - Exam1Document12 paginiFin 3 - Exam1DONNA MAE FUENTESÎncă nu există evaluări

- Land Use Paln in La Trinidad BenguetDocument19 paginiLand Use Paln in La Trinidad BenguetErin FontanillaÎncă nu există evaluări

- Project 1. RockCrawlingDocument2 paginiProject 1. RockCrawlingHằng MinhÎncă nu există evaluări

- Nguyen Dang Bao Tran - s3801633 - Assignment 1 Business Report - BAFI3184 Business FinanceDocument14 paginiNguyen Dang Bao Tran - s3801633 - Assignment 1 Business Report - BAFI3184 Business FinanceNgọc MaiÎncă nu există evaluări

- Ewellery Ndustry: Presentation OnDocument26 paginiEwellery Ndustry: Presentation Onharishgnr0% (1)

- TokyoDocument6 paginiTokyoMarcio BonziniÎncă nu există evaluări

- Comparative Analysis of Mutual Fund SchemesDocument29 paginiComparative Analysis of Mutual Fund SchemesAvinash JamiÎncă nu există evaluări

- Barangay Tanods and The Barangay Peace and OrderDocument25 paginiBarangay Tanods and The Barangay Peace and OrderKarla Mir74% (42)

- Colibri - DEMSU P01 PDFDocument15 paginiColibri - DEMSU P01 PDFRahul Solanki100% (4)

- Planas V Comelec - FinalDocument2 paginiPlanas V Comelec - FinalEdwino Nudo Barbosa Jr.100% (1)

- It14 Belotti PDFDocument37 paginiIt14 Belotti PDFHolis AdeÎncă nu există evaluări

- Ucbackup Faq - Commvault: GeneralDocument8 paginiUcbackup Faq - Commvault: GeneralhherÎncă nu există evaluări

- Catalogue of The Herbert Allen Collection of English PorcelainDocument298 paginiCatalogue of The Herbert Allen Collection of English PorcelainPuiu Vasile ChiojdoiuÎncă nu există evaluări

- TNCT Q2 Module3cDocument15 paginiTNCT Q2 Module3cashurishuri411100% (1)

- SDM Case AssignmentDocument15 paginiSDM Case Assignmentcharith sai t 122013601002Încă nu există evaluări

- Marketing Management - Pgpmi - Class 12Document44 paginiMarketing Management - Pgpmi - Class 12Sivapriya KrishnanÎncă nu există evaluări

- OOPS Notes For 3rd Sem ALL ChaptersDocument62 paginiOOPS Notes For 3rd Sem ALL Chaptersabhishek singh83% (6)

- Computer System Sevicing NC Ii: SectorDocument44 paginiComputer System Sevicing NC Ii: SectorJess QuizzaganÎncă nu există evaluări

- How To Unbrick Tp-Link Wifi Router Wr841Nd Using TFTP and WiresharkDocument13 paginiHow To Unbrick Tp-Link Wifi Router Wr841Nd Using TFTP and WiresharkdanielÎncă nu există evaluări

- Appleyard ResúmenDocument3 paginiAppleyard ResúmenTomás J DCÎncă nu există evaluări

- Gathering Package 2023Document2 paginiGathering Package 2023Sudiantara abasÎncă nu există evaluări

- I5386-Bulk SigmaDocument1 paginăI5386-Bulk SigmaCleaver BrightÎncă nu există evaluări

- IIBA Academic Membership Info-Sheet 2013Document1 paginăIIBA Academic Membership Info-Sheet 2013civanusÎncă nu există evaluări

- Aisc Research On Structural Steel To Resist Blast and Progressive CollapseDocument20 paginiAisc Research On Structural Steel To Resist Blast and Progressive CollapseFourHorsemenÎncă nu există evaluări

- Sena BrochureDocument5 paginiSena BrochureNICOLAS GUERRERO ARANGOÎncă nu există evaluări

- MDC PT ChartDocument2 paginiMDC PT ChartKailas NimbalkarÎncă nu există evaluări