Documente Academic

Documente Profesional

Documente Cultură

Recent Trends in Om

Încărcat de

Sathiyan HRDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Recent Trends in Om

Încărcat de

Sathiyan HRDrepturi de autor:

Formate disponibile

RECENT TRENDS IN OM

Operations management is the process in which resources/inputs are converted into more

useful products. In the light of global competition many recent trends in operations

management have evolved that have impact on manufacturing firms.

Some Of The Recent Trends Are:

1. Flexibility: The ability to adapt quickly to changes in volumes of demand, in the

product mix demanded, and in product design or delivery schedules, has become a

major competitive strategy and a competitive advantage to the firms. This is

sometimes called as agile manufacturing.

2. Total Quality Management: TQM approach has been adopted by many firms to

achieve customer satisfaction by a never ending quest for improving the quality of

goods and services.

3. Time Reduction: Reduction of manufacturing cycle time and speed to marker for

a new product provide a competitive edge to a firm over other firms. When

companies can provide products at the same price and quality, quicker delivery

(short lead time) provide one firm competitive edge over the other.

4. Worker Involvement: The recent trends is to assign responsibility for decision

making and problem solving to the lower levels in the organization. This is known

as employee involvement and empowerment. Examples of employees

empowerment are quality circle and use of work teams or quality improvement

teams.

5. Business Process Re-engineering: BPR involves drastic measures or break-

through improvements to improve the performance of a firm. It involves the

concept of clean-state approach or starting from a scratch in redesigning in

business processes.

6. Global Market Place: Globalization of business has compelled many

manufacturing firms to gave operations in many countries where they have certain

economic advantage. This has resulted in a steep increase in the level of

competition among manufacturing firms throughout the world.

7. Operations Strategy: More and more firms are recognizing the importance of

operations strategy for the overall success of their business and the necessity for

relating it to their overall business strategy.

8. Lean production: Production system have become lean production systems

which have minimal amount of resources to produce a high volume of high

quality goods with some variety. These systems use flexible manufacturing

systems and multi-skilled workforce to have advantages of both mass production

and job production.

9. Just in time production: JIT is a ‘pull’ system of production, so actual orders

provide a signal for when a product should be manufactured. Demand-pull

enables a firm to produce only what is required, in the correct quantity and at the

correct time.This means that stock levels of raw materials, components, work in

progress and finished goods can be kept to a minimum. This requires a carefully

planned scheduling and flow of resources through the production process. For

example, a car manufacturing plant might receive exactly the right number and

type of tyres for one day’s production, and the supplier would be expected to

deliver them to the correct loading bay on the production line within a very

narrow time slot.

10. Computer Aided Manufacturing: Computer-aided manufacturing (CAM) is the

use of computer-based software tools that assist engineers and machinists in

manufacturing or prototyping product components. CAM is a programming tool

that makes it possible to manufacture physical models using computer-aided

design (CAD) programs. CAM creates real life versions of components designed

within a software package. CAM was first used in 1971 for car body design and

tooling.

11. Computer Aided Design: Computer-aided design (CAD) is the use of computer

technology to aid in the design and particularly the drafting (technical drawing

and engineering drawing) of a part or product, including entire buildings. It is

both a visual (or drawing) and symbol-based method of communication whose

conventions are particular to a specific technical field.

12. E-Supply Chain Management: Supply chain management is the management of

supply chain from suppliers to final customers reduces the cost of transporation,

warehousing and distribution through out the supply chain. But SCM was a

traditional concept which is now being replaced by E-SCM. E-Supply chain

management is a series of Internetenabled value-adding activities to guarantee

products created by a manufacturing process can eventually meet customer

requirements and realize returns on investment.Supply chains have advanced in

the last two decades with improved efficiency, agility and accuracy.The recent

advancement of Internet technology has brought more powerful support to

improving supply chain performance.In this context, e-supply chain management

becomes a new term that distinguishes itself by net-centric and real-time features

from traditional supply chain management.

13. Enterprise Resource Planning: Enterprise resource planning (ERP) is an

enterprise-wide information system designed to coordinate all the resources,

information, and activities needed to complete business processes such as order

fulfillment or billing.

14. Environmental Issues: Today’s production managers are concerned more and

more with pollution control and waste disposal which are key issues in protection

of environment and social responsibility. There is increasing emphasis on

reducing waste, recycling waste, using less-toxic chemicals and using

biodegradable materials for packaging.

S-ar putea să vă placă și

- ME-KMBN102-Unit-1 - Complete Typed NotesDocument25 paginiME-KMBN102-Unit-1 - Complete Typed NotesEditz meniaÎncă nu există evaluări

- Nature and Scope of Production Management-1Document5 paginiNature and Scope of Production Management-1Irfan KhanÎncă nu există evaluări

- T.R. Jain & Dr. O.P.KhannaDocument10 paginiT.R. Jain & Dr. O.P.KhannaAnkita KansalÎncă nu există evaluări

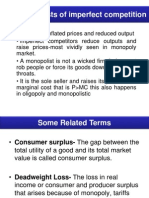

- Economic Costs of Imperfect CompetitionDocument15 paginiEconomic Costs of Imperfect Competitionsszr88Încă nu există evaluări

- New Model of CSR PDFDocument21 paginiNew Model of CSR PDFbayo4toyin100% (1)

- Top Brass RemunerationDocument4 paginiTop Brass RemunerationJaspreetKaurÎncă nu există evaluări

- Mba Project Report On HDFC BankDocument17 paginiMba Project Report On HDFC BankSai YaminiÎncă nu există evaluări

- Job Analysis:: Activities + CasesDocument10 paginiJob Analysis:: Activities + CasesPuja Verma SaxenaÎncă nu există evaluări

- Q - 5 Changing Role of Bank in IndiaDocument3 paginiQ - 5 Changing Role of Bank in IndiaMAHENDRA SHIVAJI DHENAKÎncă nu există evaluări

- Scope of Financial ManagementDocument4 paginiScope of Financial Managementgosaye desalegnÎncă nu există evaluări

- Indian Business Environment IntroductionDocument42 paginiIndian Business Environment Introductionsamrulezzz75% (4)

- Sikkim Manipal University ProjectDocument7 paginiSikkim Manipal University ProjectAnil Kumar SinghÎncă nu există evaluări

- Multiplier Approach To Share ValuationDocument2 paginiMultiplier Approach To Share ValuationI am IndianÎncă nu există evaluări

- aPPLICATION OF Operation ResearchDocument3 paginiaPPLICATION OF Operation ResearchBrylle James BigorniaÎncă nu există evaluări

- Unit II Operations Processes: Process Characteristics in OperationsDocument43 paginiUnit II Operations Processes: Process Characteristics in OperationsSujeet TambeÎncă nu există evaluări

- Report On "Production Management"Document15 paginiReport On "Production Management"Zannatun NayeemÎncă nu există evaluări

- Mba 4th Sem Syllabus....Document5 paginiMba 4th Sem Syllabus....MOHAMMED SHEBEER A50% (2)

- BBM Project FinalDocument13 paginiBBM Project FinalDeepu JoseÎncă nu există evaluări

- IRLL Unit - 1 (MBA - Final)Document14 paginiIRLL Unit - 1 (MBA - Final)Kismat SharmaÎncă nu există evaluări

- OD and CH 2the Nature of Planned ChangeDocument65 paginiOD and CH 2the Nature of Planned ChangePanda BeruÎncă nu există evaluări

- Labor Cost Computation & Control Presentation 4Document82 paginiLabor Cost Computation & Control Presentation 4NayanÎncă nu există evaluări

- HRM NotesDocument63 paginiHRM NotesDhananjay Sharma100% (1)

- Growing Use of Temporary and Contingent WorkersDocument4 paginiGrowing Use of Temporary and Contingent Workerssajid bhattiÎncă nu există evaluări

- Tps Case StudyDocument16 paginiTps Case StudyHomework Ping100% (1)

- Irll NotesDocument26 paginiIrll NotesKopuri Mastan ReddyÎncă nu există evaluări

- Team Work For Conducting TNADocument21 paginiTeam Work For Conducting TNAShubham AgarwalÎncă nu există evaluări

- Role of Family & Society in Developing EntrepreneurshipDocument4 paginiRole of Family & Society in Developing EntrepreneurshipVijay Bala DevakumarÎncă nu există evaluări

- Comparison Between Managerial Economics and Traditional EconomicsDocument2 paginiComparison Between Managerial Economics and Traditional EconomicsAamir KhanÎncă nu există evaluări

- Nature and Objectives of Management AccountingDocument13 paginiNature and Objectives of Management AccountingpfungwaÎncă nu există evaluări

- Unit 5: Emerging Trends in HRMDocument27 paginiUnit 5: Emerging Trends in HRManuradhakampli100% (1)

- Project Management BBA 5th SemDocument13 paginiProject Management BBA 5th Semaishwarya kumar rastogiÎncă nu există evaluări

- MIS2Document6 paginiMIS2Bon Carlo Medina MelocotonÎncă nu există evaluări

- HAL HR StrategiesDocument3 paginiHAL HR StrategiesrohanagarwalÎncă nu există evaluări

- Working Capital Management of EscortDocument74 paginiWorking Capital Management of EscortKavita NadarÎncă nu există evaluări

- Influence of Personality and Self Concept On BuyingDocument19 paginiInfluence of Personality and Self Concept On BuyingArun MishraÎncă nu există evaluări

- Decision Science PPT 1Document26 paginiDecision Science PPT 1Soumik Nag100% (2)

- Unit 12 Sick Industrial UnitDocument17 paginiUnit 12 Sick Industrial UnitGinu George VargheseÎncă nu există evaluări

- AshrulDocument58 paginiAshrulNilabjo Kanti Paul100% (2)

- Types of Manufacturing SystemDocument23 paginiTypes of Manufacturing SystemVishal ChoudharyÎncă nu există evaluări

- Mod 6 Grand StrategiesDocument131 paginiMod 6 Grand Strategieskimsr100% (3)

- Chapter - 12: Risk Analysis in Capital BudgetingDocument28 paginiChapter - 12: Risk Analysis in Capital Budgetingrajat02Încă nu există evaluări

- Unit - V: Conflict Management and Ethics in International Business ManagementDocument28 paginiUnit - V: Conflict Management and Ethics in International Business ManagementKarthikeyan RÎncă nu există evaluări

- System Perspective of Operations ManagementDocument8 paginiSystem Perspective of Operations ManagementwhoreÎncă nu există evaluări

- Working Capital Two Mark QuestionsDocument4 paginiWorking Capital Two Mark QuestionsHimaja SridharÎncă nu există evaluări

- Using Talent Management To Drive A Culture of ExcellenceDocument2 paginiUsing Talent Management To Drive A Culture of ExcellenceHARSHIT KUMARÎncă nu există evaluări

- Hoffers ModelDocument10 paginiHoffers ModelPradnya SurwadeÎncă nu există evaluări

- Unit IV - (Managerial Economics) Market Structures & Pricing StrategiesDocument37 paginiUnit IV - (Managerial Economics) Market Structures & Pricing StrategiesAbhinav SachdevaÎncă nu există evaluări

- Unit IV Budgets & Budgetory ControlDocument19 paginiUnit IV Budgets & Budgetory ControlyogeshÎncă nu există evaluări

- Increased Concern of HRMDocument30 paginiIncreased Concern of HRMAishwarya Chachad33% (3)

- Theories of Corporate GovernanceDocument10 paginiTheories of Corporate GovernanceSuryaa Rajendran100% (1)

- W IPRODocument26 paginiW IPROSamad Bilgi50% (2)

- Consumerism in IndiaDocument26 paginiConsumerism in IndiaMehak Sharma0% (1)

- Walter Model Equity ValuationDocument13 paginiWalter Model Equity ValuationVaidyanathan RavichandranÎncă nu există evaluări

- Visualization BenchmarkingDocument15 paginiVisualization BenchmarkingRanjith S100% (1)

- Nature and Significance of Capital Market ClsDocument20 paginiNature and Significance of Capital Market ClsSneha Bajpai100% (2)

- Value Chain Management Capability A Complete Guide - 2020 EditionDe la EverandValue Chain Management Capability A Complete Guide - 2020 EditionÎncă nu există evaluări

- Production And Operations Management A Complete Guide - 2020 EditionDe la EverandProduction And Operations Management A Complete Guide - 2020 EditionÎncă nu există evaluări

- Order Management A Complete Guide - 2021 EditionDe la EverandOrder Management A Complete Guide - 2021 EditionÎncă nu există evaluări

- The Human in Human ResourceDe la EverandThe Human in Human ResourceÎncă nu există evaluări

- Production and Operations Management A Clear and Concise ReferenceDe la EverandProduction and Operations Management A Clear and Concise ReferenceÎncă nu există evaluări

- Siemens Nxcam 12210609212713114318 PDFDocument48 paginiSiemens Nxcam 12210609212713114318 PDFVj Krish100% (2)

- Report of Ug Siemens NX ModelingDocument22 paginiReport of Ug Siemens NX ModelingBang JayÎncă nu există evaluări

- Safety Measures - Mech - CAD CAM LABDocument1 paginăSafety Measures - Mech - CAD CAM LABmaran2326Încă nu există evaluări

- Airbus Abbreviations and AcronymsDocument103 paginiAirbus Abbreviations and AcronymsLbrito01100% (3)

- Introduction To 3D PrintingDocument27 paginiIntroduction To 3D PrintingRaja kumarÎncă nu există evaluări

- INTERNSHIP PROJECT Catia FinalDocument23 paginiINTERNSHIP PROJECT Catia Finalsynrinxlangthasa1874Încă nu există evaluări

- Introduction To Cad/Cam: Arvind DeshpandeDocument38 paginiIntroduction To Cad/Cam: Arvind Deshpandearvan04Încă nu există evaluări

- Welcome To Imtma: Right Click For Full ScreenDocument18 paginiWelcome To Imtma: Right Click For Full ScreenjanaaidaasÎncă nu există evaluări

- Cad, Cam, Virtual Reality TechnologyDocument1 paginăCad, Cam, Virtual Reality TechnologyIrmawatiÎncă nu există evaluări

- Jawaharlal Nehru Technological University Kakinada: College Name: Sri Sivani College of Engg, Chilakalapalem, Srikakulam:W6Document43 paginiJawaharlal Nehru Technological University Kakinada: College Name: Sri Sivani College of Engg, Chilakalapalem, Srikakulam:W6Devendra PotrakhandaÎncă nu există evaluări

- Name:Sankalp Kashinath Gurav M.E CAD, CAM & Robotics Admission No. 2020PE0699 Subject: CAMDocument19 paginiName:Sankalp Kashinath Gurav M.E CAD, CAM & Robotics Admission No. 2020PE0699 Subject: CAMSankalp GuravÎncă nu există evaluări

- Introduction To CAM - Pdfud Abdul Majeed - 1 - Introduction To CAMDocument12 paginiIntroduction To CAM - Pdfud Abdul Majeed - 1 - Introduction To CAMKiranRao BiradarÎncă nu există evaluări

- Tier I Rule Book - Student Convention 2019-20Document112 paginiTier I Rule Book - Student Convention 2019-20dsathiyaÎncă nu există evaluări

- Top Solid Design 2006 UsDocument221 paginiTop Solid Design 2006 UsLoi Bui MinhÎncă nu există evaluări

- v5r19 Configurations enDocument32 paginiv5r19 Configurations entienphongbkÎncă nu există evaluări

- GTMA News Issue 1 2011Document44 paginiGTMA News Issue 1 2011GTMAAdminÎncă nu există evaluări

- Student's Project InventorDocument10 paginiStudent's Project InventorSatish BollamÎncă nu există evaluări

- Computer Integrated ManufacturingDocument28 paginiComputer Integrated ManufacturingsoorajthevallyÎncă nu există evaluări

- BobCAD V24 TutorialDocument67 paginiBobCAD V24 TutorialgiantepepinÎncă nu există evaluări

- Design and Research of CNC Platform Based On CAN BusDocument5 paginiDesign and Research of CNC Platform Based On CAN BusInternational Journal of Research in Engineering and ScienceÎncă nu există evaluări

- Final PPT Fms and CimoldDocument69 paginiFinal PPT Fms and CimoldNaveen PinnakaÎncă nu există evaluări

- Hurco Machining Centers Brochure PDFDocument52 paginiHurco Machining Centers Brochure PDFGuillermo RamirezÎncă nu există evaluări

- Syllabus Wayne State UniversityDocument5 paginiSyllabus Wayne State Universitytuan viet nguyenÎncă nu există evaluări

- 1 CR5000 PCB-BeginnerDocument205 pagini1 CR5000 PCB-BeginnerNicu Gee75% (4)

- MCQ - Unit 4 Computer Aided ManufacturingDocument3 paginiMCQ - Unit 4 Computer Aided ManufacturingDipak naikÎncă nu există evaluări

- Training NX CAM TR11060 Post Building TechniquesDocument1 paginăTraining NX CAM TR11060 Post Building TechniquesErhan TorunÎncă nu există evaluări

- 1st ModuleDocument26 pagini1st Modulemuniraju mÎncă nu există evaluări

- Technology and The Transformation of WorkDocument22 paginiTechnology and The Transformation of WorkSuryateja MerguÎncă nu există evaluări

- SolidCAM 2014 EngDocument39 paginiSolidCAM 2014 EngĆosić AsimÎncă nu există evaluări