Documente Academic

Documente Profesional

Documente Cultură

Ann Taylor Manual 6-13-08

Încărcat de

Prasant MaharanaDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Ann Taylor Manual 6-13-08

Încărcat de

Prasant MaharanaDrepturi de autor:

Formate disponibile

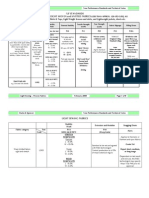

ANN TAYLOR PROCEDURES MANUAL

SECTION 10

PART I

RAW MATERIAL AND FINISHED PRODUCT

PERFORMANCE AND TESTING PROCEDURES

STANDARDS & PROCEDURES

ANN TAYLOR PROCEDURES MANUAL

TABLE OF CONTENTS

PROCEDURES FOR DEVELOPMENT .............................................................................................................................. 3

CORPORATE PRODUCT TESTING PROGRAM ............................................................................................................... 3

Spinner’s Certificate .......................................................................................................................................................4

Fur and Faux Fur ...........................................................................................................................................................5

Shearling ........................................................................................................................................................................5

RESTRICTED SUBSTANCES COMPLIANCE ...............................................................................................................6

RETESTING RESTRICTED SUBSTANCE.....................................................................................................................6

ANN TAYLOR RESTRICTED SUBSTANCES LIST .......................................................................................................7

DEVELOPMENT TESTING ............................................................................................................................................. 13

Trim Component Testing - Development ......................................................................................................................13

Yarn Testing – Development (Basic Yarn Test Package) ...............................................................................................14

Yarn in Yarn Form .......................................................................................................................................................14

Yarn in Knit Form ........................................................................................................................................................15

Fabric Testing - Development .......................................................................................................................................16

PRODUCTION TESTING ................................................................................................................................................ 17

Trim Component Testing (including test protocols) ......................................................................................................17

Yarn Testing - Production ............................................................................................................................................26

Yarn in Yarn Form .......................................................................................................................................................27

Yarn in Knitted Form ...................................................................................................................................................28

Fabric Production Testing ............................................................................................................................................29

Garment Production Testing .........................................................................................................................................31

TEST REQUEST PROCEDURES..................................................................................................................................... 33

APPROVED LABORATORIES FOR ANN TAYLOR SOFTLINES PRODUCTS ................................................................ 36

ANN TAYLOR TEST PACKAGE PRICES – SOFTLINES .................................................................................................. 40

ANN TAYLOR INDIVIDUAL TEST PRICES ..................................................................................................................... 42

Ann Taylor Adult Test Request Form—TRIM................................................................................................................ 44

Ann Taylor Adult Test Request Form—FABRIC/ YARN ................................................................................................ 45

Ann Taylor Adult Test Request Form—GARMENT ....................................................................................................... 46

PRODUCT PERFORMANCE .......................................................................................................................................... 47

TESTING PROTOCOLS .................................................................................................................................................. 50

BOTTOMS (#001) ........................................................................................................................................................51

TOPS, DRESSES, JACKETS (#002) (CAREER/CASUAL) .............................................................................................54

SUITS/COORDINATES (#003) (CAREER/CASUAL) .....................................................................................................57

OUTERWEAR (#004) ...................................................................................................................................................60

DENIM APPAREL (#005) .............................................................................................................................................63

INTIMATES (#006) .......................................................................................................................................................66

SLEEPWEAR (#007) ....................................................................................................................................................69

TESTING ACTIVE/SWIMWEAR (#008) ........................................................................................................................72

SWEATERS (#009).......................................................................................................................................................76

LEATHER (#010) ..........................................................................................................................................................79

ADDITIONAL TESTING (#011) .....................................................................................................................................81

Basic Care Labels ........................................................................................................................................................... 83

Branded & Co-Branded Product ..................................................................................................................................... 84

BOTTOMS (#001A) ......................................................................................................................................................85

TOPS, DRESSES, JACKETS (#002A) ...........................................................................................................................87

SUITS/COORDINATES (#003A) ...................................................................................................................................89

OUTERWEAR (#004A) .................................................................................................................................................91

DENIM APPAREL (#005A) ...........................................................................................................................................93

INTIMATES (#006A).....................................................................................................................................................96

SWEATERS (#009A) ....................................................................................................................................................98

Section 10 Raw Material & Finished Product 2

Performance & Testing Procedures June 2008

ANN TAYLOR PROCEDURES MANUAL

PROCEDURES FOR DEVELOPMENT

• Each fabric/yarn that is considered for development is required to be accompanied by a

“Fabric/Yarn Information Sheet (FIS/YIS)”. This form is to be completed by the Mill and a copy

• is to be sent to the appropriate Ann Taylor Product Developer. According to the information that

the Mills supply, New York Sourcing will decide to either pursue or drop/substitute the quality,

depending on the end use.

• If deemed suitable for the product, new fabrics will be evaluated, prior to making bulk commits,

to make sure all standards can be met (See “Development Testing” for details).

CORPORATE PRODUCT TESTING PROGRAM

• Ann Taylor has established a basic testing program to monitor and ensure compliance with applicable

legislation and corporate quality standards. Basic test packages have been developed for products

and components, including trim components, yarns, textiles, and garments.

• All products, including trim components, yarns, textiles, and garments must be tested at Production

stage prior to shipment. Each supplier is solely responsible for ensuring that prior to shipment each

product has been tested in accordance with the applicable basic testing package. All finished

products care and content must be appropriately labeled in accordance with United States Federal

Trade Commission Regulations.

• Each supplier is responsible for the submission of the required number of samples, in all styles and

all colors purchased, for evaluation. The supplier is required to submit the required number of

samples to the laboratory accompanied by the completed Ann Taylor Test Request Form (see pages

44-46).

• Ann Taylor will be monitoring to ensure that all products are tested.

• Ann Taylor will pay for all development testing when it is specifically requested by the appropriate

Ann Taylor buying agent, Merchandise Manager, or Product Manager.

Note: If the item developed is purchased for production, the supplier will be required to pay

the development testing charges.

• All suppliers who provide textiles and finished products to Ann Taylor, or to other Ann Taylor suppliers

for confirmed Ann Taylor orders, are required to incur the cost of all production testing, including the

cost of merchandise destroyed during the process. This independent testing is required to verify that

all products are in compliance with all applicable legislation and established performance standards.

Suppliers will be invoiced directly for the testing charges by the Ann Taylor approved testing laboratory.

Section 10 Raw Material & Finished Product 3

Performance & Testing Procedures June 2008

ANN TAYLOR PROCEDURES MANUAL

Spinner’s Certificate

1. Spinner’s certificate is a document used by spinner to confirm a certain type of fiber, including

trademarks, used in spinning.

2. Types of fibers that require spinner’s certificate include the followings:

- Merino wool

- Lambs’ wool

- Shetland wool

- Angora rabbit hair

- Premium cotton fibers such as Pima, Egyptian, Sea Island etc.

- Fiber trademarks such as Lycra®, Elite®, Tencel® etc.

3. Apart from the spinner’s certificate, additional supporting tests will be performed by BV or ITS Shanghai

on claimed fiber type or fiber trademarks (e.g. Antron), where applicable.

4. Information on date of issue, client's address, authorized signature, yarn description, RMID (Raw

Material Identification) number, etc. must be included on the document.

5. Spinner’s certificate is valid ONLY for 12 months from date of issue.

Section 10 Raw Material & Finished Product 4

Performance & Testing Procedures June 2008

ANN TAYLOR PROCEDURES MANUAL

Fur and Faux Fur

Genuine Fur

Ann Taylor Stores Corporation has a “no-fur” policy for all brands. This excludes shearling.

Garment Containing Faux Fur

In order to ensure compliance with the corporate policy on real fur, items that contain faux fur must be

accompanied by a test report confirming this prior to shipping.

Shearling

Garment Containing Shearling (not fur)

All shearling furs require fiber content test performed on bulk raw material. This test must be performed

by a CCMI approved laboratory and submitted to Ann Taylor prior to shipping.

Section 10 Raw Material & Finished Product 5

Performance & Testing Procedures June 2008

ANN TAYLOR PROCEDURES MANUAL

RESTRICTED SUBSTANCES COMPLIANCE

It is critically important for Ann Taylor to know that our products are safe for customer’s end use.

To accomplish this, we have created a restricted substances list with implementation dates. It is

mandatory that all raw materials shipped by September 1, 2008, and finished products by

November 1, 2008 are in full compliance.

RETESTING RESTRICTED SUBSTANCE

Any raw material that fails initial testing for restricted substances must indicate on subsequent

test request form what corrective action has been taken to ensure compliance with Ann Taylor’s

standards.

Section 10 Raw Material & Finished Product 6

Performance & Testing Procedures June 2008

ANN TAYLOR PROCEDURES MANUAL

ANN TAYLOR RESTRICTED SUBSTANCES LIST

June 2008 Version

Standard Reason for

CAS Number Chemical Name/Color Index Name Ann Taylor Limits Test Method Compliance Date

Origin Restriction

DYES

AZO Dyes which, by reductive cleavage of one or more AZO groups, may release one or more of the following aromatic amines.

60-09-3 4-Amino azobenzene1 Not Detected European Legislated Textiles (EU): Immediate

97-56-3 o-Aminoazotoluene Union & EN 14362-1

(below China

92-67-1 4-Aminodiphenyl detection Polyester(EU):

99-55-8 2-Amino-4-nitrotoluene limits - see test EN 14362-2

90-04-0 o-Anisidine method)

92-87-5 Benzidine Leather(EU):

CEN ISO/TS 17234

106-47-8 p-Chloroaniline

95-69-2 4-Chloro-o-toluidine Textiles(China)

120-71-8 p-Cresidine GB/T 17592-2006

615-05-4 2,4-Diaminoanisole Test

101-77-9 4,4'-Diamino-diphenylmethane Method for 4-

91-94-1 3,3'-Dichlorobenzidine Aminoazobenzene

(pAAB)

119-90-4 3,3'-Dimethoxybenzidine

119-93-7 3,3'-Dimethylbenzidine confirmation § 64

838-88-0 3,3'-Dimethyl-4,4'-diamino-diphenylmethane LFGB 8 82.02-9

101-14-4 4,4'-Methylene-bis-(2-chloroaniline)

91-59-8 2-Naphthylamine

101-80-4 4,4'-Oxydianiline

139-65-1 4,4'-Thiodianiline

95-80-7 2,4-Toluenediamine

95-53-4 o-Toluidine

137-17-7 2,4,5-Trimethylaniline

95-68-1 2,4-Xylidine2

87-62-7 2,6-Xylidine2

Footnotes:

1. Applicable in the European Union Regulation Only

2. Applicable in the Chinese Regulation only

Disperse Dyes

2475-45-8 Disperse Blue 1 Not Detected Germany Legislated DIN 54231 Immediate

56524-77-7 or Disperse Blue 35 Disperse Dyes

56524-76-6 (below

detection levels -

12223-01-7 Disperse Blue 106

see

61951-51-7 Disperse Blue 124 regulation)

730-40-5 Disperse Orange 3

13301-61-6 Disperse Orange 37/76

2872-52-8 Disperse Red 1

2832-40-8 Disperse Yellow 3

Other Dyes

118685-33-9 Navy Blue 0.1% by mass European Legislated Solvent extraction Immediate

Union and GC-MS or LC

MS

Section 10 Raw Material & Finished Product 7

Performance & Testing Procedures June 2008

ANN TAYLOR PROCEDURES MANUAL

SOLVENTS (Aliphatic Chlorohydrocarbons)

76-01-7 Pentachloroethane 0.1%(mass) - Germany Legislated Headspace All raw materials shipped by

56-23-5 Carbon Tetrachloride total and Japan GC-MS 9/1/08 and finished product by

11/1/08

630-20-6 1,1,1,2-Tetrachloroethane

79-34-5 1,1,2,2-Tetrachloroethane

67-66-3 Chloroform

79-00-5 1,1,2-Trichloroethane

75-35-4 1,1-Dichloroethylene

71-55-6 1,1,1-Trichloroethane

127-18-4 Tetrachloroethylene3

Footnotes:

3. Applicable in the Japan Regulation Only

PESTICIDES

93-72-1 2-(2,4,5-trichlorophenoxy) propionic acid, its Not Switzerland Legislated U.S. EPA Method All raw materials shipped by

salts and compounds Detected & Finland 8081A/8151A 9/1/08 and finished product by

(those 11/1/08

pesticides

without

93-76-5 2,4,5-trichlorophenoxyacetic acid, its salts and indication

compounds are regulated

309-00-2 Aldrin (both Switzerland and Finland) under

57-74-9 Chlordane (both Switzerland and Finland) Switzerland)

72-54-8 Dichloro-diphenyl-dichloro ethane (DDD)

72-55-9 Dichloro-diphenyl-dichloro ethylene (DDE)

50-29-3 Dichloro-diphenyl-tichloro ethane (DDT) (both

Switzerland and Finland)

60-57-1 Dieldrin (5) Also Japan (both Switzerland and

Finland

72-20-8 Endrine (both Switzerland and Finland)

76-44-8 Heptachlorine (both Switzerland and Finland)

1024-57-3 Epoxy-heptachlorine

118-74-1 Hexachlorobenzene (both Switzerland and

Finland)

608-73-1 Hexachlorocyclohexane (HCH, all isomers)

except gamma-hexachlorocyclohexane (except

linande [58-89-9] in medical products)

465-73-6 Isodrin

4234-79-1 Kelevane

143-50-0 Kepone (Chlordecone)

58-89-8 Lindane

72-43-5 Methoxychlor

2385-85-5 Mirex (Finland only)

72-56-0 Perthane

82-68-8 Quintozene

8001-50-1 Strobane

297-78-9 Telodrin

8001-35-2 Toxaphene (both Switzerland and Finland)

1336-36-3 Halogenated biphenyls, including

53469-21-9 Polycholorinated biphenyl (PCB) (both

and various Switzerland and Finland)

Various Halogenated terphenols, including

Polychlorinated terphenyl (PCT)

Various Halogentaed naphthalenes

Various Halogentaed diarylalkanes

Halogenated diphenyl methanes, including

99688-47-8 Monomethyl-dibromo-diphenyl methane

81161-70-8 Monomethyl-dichloro-diphenyl methane

76253-60-6 Monomethyl-tetrachloro-diphenyl methane

87-86-5 Pentachlorophenol (PCP), its salts and

compounds

25167-83-3 Tetrachlorophenol (TeCP), its salts and

compounds

Section 10 Raw Material & Finished Product 8

Performance & Testing Procedures June 2008

ANN TAYLOR PROCEDURES MANUAL

DIOXINS And FURANS

Group 1 Sum of Germany Legislated US EPA 8290 All raw materials shipped by

1746-01-6 2,3,7,8-Tetrachlorodibenzo-p-dioxin Group 1: 9/1/08 and finished product

40321-76-4 1,2,3,7,8-Pentachlorodibenzo-p-dioxin 1 µg/kg by 11/1/08

51207-31-9 2,3,7,8-Tetrachlorodibenzofuran

57117-31-4 2,3,4,7,8-Pentachlorodibenzofuran

39227-28-6 Group 2 Sum of

19408-74-3 1,2,3,4,7,8-Hexachlorodibenzo-p-dioxin Group 1 &

57653-85-7 1,2,3,7,8,9-Hexachlorodibenzo-p-dioxin 2:

57117-41-6 1,2,3,6,7,8-Hexachlorodibenzo-p-dioxin 5 µg/kg

70648-26-9 1,2,3,7,8-pentachlorodibenzofuran

72918-21-9 1,2,3,4,7,8-Hexachlorodibenzofuran

57117-44-9 1,2,3,7,8,9-Hexachlorodibenzofuran

60851-34-5 1,2,3,6,7,8-Hexachlorodibenzofuran

2,3,4,6,7,8-Hexachlorodibenzofuran

Group 3 Sum of

35822-46-9 1,2,3,4,6,7,8-Heptachlorodibenzo-p-dioxin Group 1, 2

3268-87-9 1,2,3,4,6,7,8,9-Octachlorodibenzo-p-dioxin & 3:

67562-39-4 1,2,3,4,6,7,8-Heptachlorodibenzofuran 100 µg/kg

55673-89-7 1,2,3,4,7,8,9-Heptachlorodibenzofuran

39001-02-0 1,2,3,4,6,7,8,9-Octachlorodibenzofuran

Group 4 Sum of

50585-41-6 2,3,7,8-Tetabromodibenzo-p-dioxin Group

109333-34-8 1,2,3,7,8-Pentabromodibenzo-p-dlox n 4:

67933-57-7 2,3,7,8-Tetrabromodibenzofuran 1 µg/kg

131166-92-2 2,3,4,7,8-Pentabromodibenzofuran

Group 5 Sum of

107555-93-1 1,2,3,4,7,8-Hexabromodibenzo-p-dioxin Group

no CAS #'s 1,2,3,7,8,9-Hexabromodibenzo-p-dioxin 4 & 5:

available 1,2,3,6,7,8-Hexabromodibenzo-p-dioxin

1,2,3,7,8-Pentabromodibenzofuran 5 µg/kg

ASBESTOS

77536-66-4 Actinolite Not European Legislated Microscopic All raw materials shipped by

12172-73-5 Amosite etected Union examination; 9/1/08 and finished product

77536-67-5 Anthrophyllite minimum by 11/1/08

12001-29-5 Chrysotile magnification 1

12001-28-4 Crocidolite 250, polarized

77536-68-6 Tremolite light filter

attached; ratio of

fiber length to

diameter is at

least 3:1

FLUORINATED GREENHOUSE GASES

2551-62-4 Sulphur hexafluoride - S F 6 Not European Legislated Headspace for All raw materials shipped by

detected Union GC/MS 9/1/08 and finished product

Hydrofluorocarbons (HFCs): by 11/1/08

75-46-7 HFC-23 - CHF 3 Thermal

Adsorption GC/MS

75-10-5 HFC-32 - CH2F2

593-53-3 HFC-41 - CH3F

138495-42-8 HFC-43-10mee - C5H2F 1 0

354-33-6 HFC-125 - C2HF5

359-35-3 HFC-134 - C2H2F4

811-97-2 HFC-134a - C H 2F C F 3

75-37-6 HFC-152a - C2H4F2

420-46-2 European

Union

470-46-6 HFC-143a - C2H3F3

431-89-0 HFC-227ea - C3HF7

HFC-236cb - CH2F C F 2CF3

431-63-0 HFC-236ea - CHF 2CHFCF 3

690-39-1 HFC-236fa - C3H2F6

679-86-7 HFC-245ca - C3H3F5

460-73-1 HFC-245fa - CHF 2C H 2CF3

Section 10 Raw Material & Finished Product 9

Performance & Testing Procedures June 2008

ANN TAYLOR PROCEDURES MANUAL

406-58-6 HFC-365mfc - CF3CH2CF2CH3

Per-fluorocarbons (PFCs):

75-73-0 Perfluoromethane - CF4

76-16-4 Pertluoroethane - C2F6

76-19-7 Perfluoropropane - C3F8

355-25-9 Perfluorobutane - C4F10

67-8-26-2 Perfluoropentane - C5F12

355-42-0 Pertluorohaxane - C6F14

115-25-3 Perfluorocyclobutane - c-C4F8

FLAME RETARDANTS

85535-84-8 Chlorinated paraffins (C10-C13) May not be European Legislated Solvent extraction Immediate

used Union and GC-MS or

LC-MS

Methanol

59536-65-1 Polybrominated biphenyls (PBBs) May not be European Legislated extraction:

used Union analysis by GC-

MS or LC-MS

Solvent extraction

and analysis by

GC-MS or LC-MS

32534-81-9 Penta-bromodiphenyl ether (pentaBDE) May not be European Legislated

used Union

32536-52-0 Octa-bromodiphenyl ether (octaBDE)

126-72-7 Tris (2,3-dibromopropyl) phosphate (TRIS) Not Detected European Legislated

Union

5412-25-9 Bis (2,3-dibromopropyl) phosphate Not Detected Japan Legislated

545-55-1 Tris (1-aziridinyl)-phosphine oxide (TEPA) Not Detected European Legislated

Union

1163-19-5 Decabromodiphenyl ether (DecaBDE) 0.1% by weight Sweden Legislated

Section 10 Raw Material & Finished Product 10

Performance & Testing Procedures June 2008

ANN TAYLOR PROCEDURES MANUAL

METALS

Restrictions for Textiles

7440-43-9 Cadmium (Cd) 100 ppm Netherlands Legislated Total Digestion

Immediate

18540-29-9 Chromium (Cr+6) – hexavalent Not detected Germany Legislated DIN 53314; C18

(below filtration and

detection reanalysis of all

limits - see test positive results

method)

7439-92-1 Lead (Pb) PVC 30 ppm United Legislated Total

PU 100 ppm States San Francisco digestion

Superior Court,

317256, CGC-02-

403328, and CGC-05-

440721

Restrictions for Leather

7440-43-9 Cadmium (Cd) 100 ppm Netherlands Legislated Total digestion Immediate

7439-92-1 Lead (Pb) 100 ppm Denmark Legislated Total digestion

18540-29-9 Chromium (Cr+6) - hexavalent Not detected Germany Legislated DIN 53314; C18

(below filtration and

detection reanalysis of all

limits - see test positive results.

method)

Restrictions for Metal Parts

7439-92-1 Lead (Pb) 100 ppm Denmark Legislated Total digestion Immediate

7440-02-0 Nickel (Ni) (in metal items) 0.5 European Legislated Nickel release by Immediate

µg/cm2/week Union EN 1811 Abrasion

of coated items by

EN 12472

Restrictions for Heavy Metals

7440-43-9 Antimony 60 ppm European Legislated EN 71, Part III Immediate

Arsenic 25 ppm Union ASTM F963

Barium 1000 ppm

7440-43-9 Cadmium 75 ppm

18540-29-9 Chromium 60 ppm

7439-92-1 Lead 90 ppm

Mercury 60 ppm

Selenium 500 ppm

Restrictions for Plastics, Plastic Film, Surface Coatings and Printing

7440-43-9 Cadmium (Cd) 100 ppm European Legislated EN 1122 Immediate

Union

7439-92-1 Lead (Pb) in Paint/Surface Coating 600 ppm CPSC Legislated 16 CFR 1303; Lead in PU

ASTM E613/1645

(mod.) All raw materials shipped by

9/1/08.,and finished product

7439-92-1 Lead (Pb) in PVC Ca Prop 65 Legislated EPA 3051B/3051 by 11/1/08

San Francisco

Handbag, small leather goods, picture frame, 200 ppm Superior Court,

mirror compact, jewelry, trinket box, season 317256, CGC-02-

ornaments 403328, and CGC-05-

440721

Gloves, scarves, hats, socks, footwear, hair 30 ppm

accessories, belts, sunglasses, reading

glasses

7439-92-1 Lead (Pb) in PU 100 ppm Germany Legislated EPA 3051B/3051

Section 10 Raw Material & Finished Product 11

Performance & Testing Procedures June 2008

ANN TAYLOR PROCEDURES MANUAL

Restrictions for Adult Jewelry

7439-92-1 Lead (Pb)

Class 1 No requirement Ca Prop 65 Legislated EPA 3051B/3051 Immediate

Class 2

Other Metal 100,000 ppm

(Electroplated) 60,000 ppm After 12/31//08

Other Metal (Unplated) 15,000 ppm

Plastic/rubber(including PVC) 600 ppm

200 ppm After 12/31//08

Dyes & Surface Coating 600 ppm

Class 3

Not Class 1 or 2 600 ppm

ORGANOTIN COMPOUNDS

56573-85-4 Tributyltin (TBT) Not Detected Japan Legislated Performance All raw materials shipped by

(0.5 ppm based method of 9/1/08.,and finished product

each) ethanol extraction by 11/1/08

derivitization and

analysis by GC

668-34-8 Triphenyltin (TPhT) MS or LC-MS

ISO 17353-2004

MISCELLANEOUS CHEMICALS

50-00-0 Formaldehyde Not detected Japan Legislated ISO 14184-1 or Immediate

0-36 months (below JIS L1041 (Law

detection 112) or

limits - see DIN 53315

test

method)

>36 months (with direct skin contact 75 ppm Japan Legislated ISO 14184-1 or

JIS L1041 (Law

112) or

DIN 53315

Phthalates <1,000 ppm European Legislated Determination of Immediate

84-74-2 Dibutyl phthalate (DBP) (0.1% by Union defined Ortho

85-68-7 Butyl benzyl phthalate (BBP) Phthalic Esters in

117-81-7 Di-2-ethylhexyl phthalate (DEHP)

weight). Synthetic Fibers

117-84-0 Di-n-ocyl phthalate (DNOP) and

26761-40- Di-iso-decyl-phthalate (DIDP) Thermoplastics by

428553-12-0 Di-iso-nonyl phthalate (DINP) LC-DAD-MS or

GC-MS

Confirmation of

failure by

fragmentation

HPLC-MS

Section 10 Raw Material & Finished Product 12

Performance & Testing Procedures June 2008

ANN TAYLOR PROCEDURES MANUAL

DEVELOPMENT TESTING

The Development Testing Program has been established to test products and evaluate specific

performance characteristics of “questionable” or “new” trims, components, yarns, or textiles prior to

confirming the bulk production order. Conducting a test during the development stages of production

does not exempt the supplier from testing bulk production in accordance with the full basic testing

packages.

For On-going/carryover qualities

• No testing required.

For New qualities

• At minimum, test those select qualities which are considered most critical

• NY Product Development, in conjunction with the appropriate buying office, will decide which new

qualities are to be tested. Fabric information sheets (FIS), past history, as well as any additional

information from the supplier should be used as resources.

• Product Development always has the option of testing all new qualities.

Trim Component Testing - Development

• Specialized trim and embellishment components, both functional and decorative, may be tested in

the development stage (see above for details) in accordance with the full Basic Trim Component

Testing Package prior to placing the order with the trim supplier. This would assure that the trim

component meets the requirements prior to selection for production.

• Trim Testing Exemptions

Zippers: Ann Taylor does not require testing to be performed on Coats, Ideal Fasteners & YKK

zipper components for audits

Certain trim components: Ann Taylor does not require testing to be performed on Scovill shanks,

rivets, and snaps components for adults.

Remark: Testing is still required on infant and toddler items.

• For suggested testing, please see “Trim Component Testing--Production”.

• Ann Taylor is responsible for charges incurred at development stage.

Section 10 Raw Material & Finished Product 13

Performance & Testing Procedures June 2008

ANN TAYLOR PROCEDURES MANUAL

Yarn Testing – Development (Basic Yarn Test Package)

(If requested)

st

Number of Samples Required for Testing: 2.5 yards 1 color minimum width 36”

1 yard each additional color minimum width 36”

1 cone, 10 yards minimum

Yarn in Yarn Form

To be performed by country sourcing the yarn (i.e. unfinished).

• Development yarn should be submitted as fully processed product.

Required test Test Method Required standard Notes

PHYSICAL

CHARACTERISTICS

AATCC 20/20A Single fiber: no tolerance Test one solid and all top-

FIBER CONTENT

ASTMD276/629 Blends: +/- 3% dyed mélanges.

YARN SIZE ASTM D1059 +/- 10% One color only

Against claimed

TWIST PER INCH ASTM D1423 As specified One color only

by yarn supplier

YARN STRENGTH ASTM D2256 As specified One color only

by yarn supplier

Note 1:

Colorfastness testing is not part of the development protocol. However, Ann Taylor Production/Product

Development, yarn mill, and dyer should identify potential issues with respect to colorfastness at the earliest possible

stage.

Note 2:

Additional testing may be required upon request.

Note 3:

For 100% Cashmere only, add the following tests on the fiber itself:

1. Diameter of Fiber (ASTM D2130)

2. Fiber Length (ASTM D1575)

Section 10 Raw Material & Finished Product 14

Performance & Testing Procedures June 2008

ANN TAYLOR PROCEDURES MANUAL

Yarn in Knit Form

• To be performed by country manufacturing the garment (If requested)

• Can be garment or knit down – discussed with NY PD.

• Should be performed in every stitch and gauge.

Required test Test Method Required standard Notes

PERFORMANCE

FLAMMABILITY 16 CFR 1610 Class 1 One color only

See “Performance

Specifications -

Flammability” for

details

BURSTING STRENGTH ASTM D3786 Minimum(psi) One color only

Fabric Weight:

<4.0 oz/sq yard: 40

4.1-6.0 oz/sq yard: 50

>6.1 oz/sq yard: 55

Lace: 35

Sweaters: 40

PILLING ASTM D3512 All others: 3.5 One color only

Random Tumble Polyester/nylon: 3

(30 minutes)

BS EN ISO Sweaters and Animal Fibers:

12945 Part 1

Specialty animal 3.5

fibers: 2 hours

Other animal 3.5

fibers: 4 hours

STRETCH AND ASTM D2594 In stretch direction only : Stretch only

RECOVERY use “Growth” For samples with elastic content > One color only

for pass/fail 10% (60 sec.)

determination; Recovery: 85%

“Recovery” for Growth: 5%

informational For samples with elastic content <

purposes only 10% (1hr.)

Recovery: 70%; Growth: 7%

DIMENSIONAL AATCC 135, Length x width (max. %) One color only

STABILITY TO 3 cycles Cotton/blends: -5/+3 x -5/+3

WASHING (as per care Rayon/blends -5/+5 Washable fabrics;

instructions) Pique/Rib/Jacquard/Pointelle: -7/+3 x - Dryclean only (hand

7/+3 wash)

For “dryclean Thermal/Waffle:-10/+3 x-10/+3

only” fabrics: Poly/Nylon/silk/others:-3/+3 x -3/+3

Hand wash, line Ribs with elastic yarn: -8/+3 x -8/+3

dry or flat dry Sweaters: -5/+3 x -5/+3

DIMENSIONAL AATCC 158, Length x Width (max.%) One color only

STABILITY TO 1 cycle -3/+2 x -3/+2 Dryclean fabrics

DRYCLEANING Sweaters: -5/+2 x -5/+2

APPEARANCE AFTER AATCC 135/158, Color change: 4 One color only

WASHING/ as per care Self-staining: 4.5

DRYCLEANING (3 cycles/1cycle) No visual change in appearance

DIMENSIONAL Coteco Length x Width (max.%) One color only

STABILITY AFTER -3/+2 x -3/+2 (not required for

STEAM PRESS sweaters)

Section 10 Raw Material & Finished Product 15

Performance & Testing Procedures June 2008

ANN TAYLOR PROCEDURES MANUAL

Fabric Testing - Development

(If requested)

st

Number of Samples Required for Testing: 2.5 yards 1 color, minimum width 36”

1 yard each additional color, minimum width 36”

Any fabric submitted for testing must be representative of all finishing processes it will be subject to

during manufacturing (i.e.: durable water repellents, sanding/brushing, flocking, printing, etc).

For washed programs (such as indigo-dyed denim and heavy garment washed fabrics):

• The fabric supplier/manufacturer is responsible for the charges incurred in testing the fabric

“before-wash/finish”.

• Ann Taylor is responsible for the charges incurred in testing the fabric “after-wash/finish”.

• The garment manufacturer is responsible for the charges incurred in testing the garments after the

wash/finish.

Basic Development Test Package

• *Dimensional stability and Appearance after 3 launderings or 1 dryclean

• *Dimensional stability after steam press

• Fabric count

• Fabric weight

• Fiber content

• Flammability (see “Performance Specifications—Flammability” for details)

• *pH–denim, leather, washed garments

• Bursting strength (knits)

• Pile retention (corduroy, velvet, velour only)

• Pilling resistance (knits / wovens)

• Abrasion—denims only

• Seam slippage (wovens)

• Spirality (knits) / Torqueing (wovens)

• Stretch and Recovery (fabrics containing stretch fibers, such as Spandex, Lastol, Elasterell-p )

• Tearing strength (wovens / leather)

• Tensile strength (wovens / leather)

• Yarn size (only if requested)

• Spray Test—only if claiming “water repellent”

• Rain Test—only if classifying as “Rainwear”

* For washed programs—these tests are not needed in the “before-wash” state.

See “Performance Specification Sheets/Test Protocols” for standards and test methods.

Section 10 Raw Material & Finished Product 16

Performance & Testing Procedures June 2008

ANN TAYLOR PROCEDURES MANUAL

PRODUCTION TESTING

The Production Testing Program has been established to test products and evaluate specific performance

characteristics of trim, yarn, textile, or garment prior to shipment. Note: if the final fabric has mechanical

(wash)/chemical finish, the basic test package must be performed on finished fabric.

Trim Component Testing (including test protocols)

All trim components, both functional and decorative (with the exception of adult Coats, Ideal & YKK zipper

components), are required to be tested in accordance with the following protocols.

Non-metallic Trim (page 1 of 2) Specification #812

Examples: buttons, ball stoppers, etc.

(Excluding: metal, rubber, soft plastic, fabric, leather)

Minimum sample requirement: 1 Gross (144 pieces)

Required test Test Method Required standard Notes

Flammability 16 CFR 1610 Class 1 One color only

(fabric trims) (see “Performance

Specifications - Flammability

for details)

Appearance After AATCC 150 No breaking, cracking, Test any one color,

Laundering/ 5X Home chipping or dulling of the three representative

Drycleaning Laundering surface sizes/shapes

(machine wash (i.e. large, medium, small,

warm, tumble dry circle, square, heart, etc.)

medium)

If failures, may need to test

AATCC158 additional sizes/shapes.

3X Commercial

Drycleaning Does not have to be

performed if the colorfastness

tests under “dyed to match”

are performed.

Steam press Coteco Staining min. 4.5 Test any one color, at least

No visual change in three representative

appearance sizes/shapes

(i.e. large, medium, small)

If dyed to match (instead of internal dyed)

add the following tests (test all colors):

Color fastness to AATCC 61 Color change: min. 4 Test all colors, at least three

washing IIA Staining: min. 4 representative sizes/shapes

(i.e. large, medium, small)

Color fastness to AATCC 132 Color change: min. 4 Test all colors, at least three

drycleaning Staining: min. 4 representative sizes

(i.e. large, medium, small)

Colorfastness to AATCC 116 Dry: min. 4.5 Test all colors,

crocking Wet: min. 4 any one size

Section 10 Raw Material & Finished Product 17

Performance & Testing Procedures June 2008

ANN TAYLOR PROCEDURES MANUAL

Non-metallic Trim (page 2 of 2) Specification #812

Excluding metal, rubber, soft plastic, fabric, leather

If coated or painted

add the following tests

Required test Test Method Required standard Notes

Lead content 16 CFR 1303 No more than 0.06% (600 All colors

ASTM ppm) lead content based on

E1613/E1645 the weight of the dried

(Mod.) paint or coating film

Heavy Metals EN 71, Part III Antimony: 60 Must not exceed these limits

ASTM F963 Arsenic: 25 (ppm) for soluble migrated

Barium: 1000 element

Cadmium: 75

Chromium: 60

Lead: 90

Mercury: 60

Selenium: 500

Nickel Test EN 1811 Transfer to skin less than Only if supplier indicated that the

EN12472 0.5. micrograms per square item is “nickel-free”.

(report results centimeter per week

with and without (Nickel is possible in coatings or

coating) special colors)

If material contains PVC or PU (including PVC or neoprene rain suits and coats, and decals and attachments on clothing)

Required Test Test Method Required Standard Notes

Lead Content EPA 3051 (Modified) PVC 30 ppm All colors

(San Francisco Superior Court, 317256, PU 100 ppm

CGC-02-403328, and CGC-05-440721)

If Button

add the following tests

Center Strength

a. Shank/2 & 4 holes BS 4162 Section Up to 16 ligne: 16 lbf Test all shapes/sizes.

plastic & wooden 4.0 (modified) Up to 25 ligne: 20 lbf One color only.

buttons Larger than 25 ligne: 30 lbf

b. Shell buttons 15 lbf

c. Horn button 18 lbf

If Snap

add the following test

Snap Action ASTM D4846 Min: 2 lbs Test all sizes/shapes. One

BV-S 1045 Max: 5 lbs color only.

Section 10 Raw Material & Finished Product 18

Performance & Testing Procedures June 2008

ANN TAYLOR PROCEDURES MANUAL

Trim made of metal Specification #813

Minimum sample requirement: 1 Gross (144 pieces)

Required test Test Method Required standard Notes

Corrosion ASTM B117 G85 (Mod) No visual change in appearance Test any one size

Resistance 24 hours in 1% Salt Spray No signs of staining, corrosion, All colors and finishes

(Fog) oxidation or discoloration.

Nickel test EN 1811 Transfer to skin less than 0.5 Only if supplier

EN 12472 micrograms per square centimeter per indicated that the item

Report results with and week is “nickel-free”.

without coating

Heavy Metals EN 71, Part III Antimony: 60 Must not exceed

ASTM F963 Arsenic: 25 these limits (ppm) for

Barium: 1000 soluble migrated

Cadmium: 75 element

Chromium: 60

Lead: 90

Mercury: 60

Selenium: 500

If coated or painted

add the following tests

Lead content 16 CFR 1303 No more than 0.06% All colors

ASTM E1613/E1645 (600 ppm) lead content based

(Mod.) on the weight of the dried

paint or coating film

Appearance After AATCC 150 No cracking, chipping or dulling Test any one color,

Laundering/ 5X Home Laundering of the surface three representative sizes

Drycleaning (machine wash warm, (i.e. large, medium, small)

tumble dry medium)

Note: Trim to be applied on

AATCC158 fabric or mock-up garment after

3X Commercial testing.

Drycleaning

If material contains PVC or PU (including PVC or neoprene rain suits and coats, and decals and attachments on clothing)

Required Test Test Method Required Standard Notes

Lead Content EPA 3051 (Modified) PVC 30 ppm All Colors

(San Francisco Superior Court, 317256, PU 100 ppm

CGC-02-403328, and CGC-05-440721)

If Snap

Add the following test

Snap Action BV S1045 Min: 2 lbs Test all sizes. One color only.

Max: 5 lbs

Section 10 Raw Material & Finished Product 19

Performance & Testing Procedures June 2008

ANN TAYLOR PROCEDURES MANUAL

Zippers (page 1 of 2) Specification #814

Use: A = jeans, B= bottoms, C= dresses/tops, D= outerwear (for pockets “C” can be used)

Minimum sample requirement: 120 (at least 6” in length)

Required Standard (lbf)

Required test Test Method Use Use Use Use Notes

A B C D

Crosswise chain ASTM 2061 80 60 50 75

strength (14.1)

Top stop holding ASTM 2061 20 16 16 20

(22.2)

Bottom stop holding ASTM 2061 16 12 12 20 Non separating zipper only.

(stringer separation) (22.5) Lower standards are acceptable

if zipper bottom is secured by

appropriate sewing in garment.

Fixed retainer ASTM 2061 NA NA 16 20 Separating zippers only.

pull off (30.2)

Separable pin ASTM 2061 NA NA 16 20 Separating zippers only.

pull off (30.1)

Holding strength of ASTM 2061 12 6 4 7 Only if locking slider.

slider lock (82-91) Report any failure

Examine all components after

testing and report any damage

(i.e. elements, etc.).

Color fastness to AATCC 61 Color change: min. 4 Slider and stringer

washing IIA Staining: min. 4 Test each color

Color fastness to AATCC 132 Color change: min. 4 Slider and stringer

drycleaning Staining: min. 4 Test each color.

Colorfastness to ASTM 2054 Dry: min. 4.5 Test each color.

Crocking AATCC 116 Wet: min. 4 Tape only.

Colorfastness to Coteco Staining min. 4.5 Complete zipper

Steam Press Color change: 4 and Test each color

no visual change in

appearance.

Operability ASTM D2062 No sticking Test 3 different zippers

Section 10 Raw Material & Finished Product 20

Performance & Testing Procedures June 2008

ANN TAYLOR PROCEDURES MANUAL

Zippers (page 2 of 2) Specification #814

Required test Test Method Required Standard (lbf) Notes

Nickel test EN 1811 Transfer to skin less than Nickel is possible in coatings or

EN 12472 0.5. micrograms per special colors

Report results square centimeter per

with and week

without

coating

If used for swimwear

Colorfastness and AATCC 106 Color change: min. 4 Stringer and slider

appearance after (modify if Staining: min. 4 Test each color.

exposure to necessary) Appearance: No visual

sea water change.

Colorfastness and AATCC 162 Color change: min. 4 Stringer and slider

appearance after Appearance: No visual Test each color.

exposure to change

chlorinated pool

water

If painted or coated

Add the following tests

Lead content 16 CFR 1303 No more than 0.06% All colors

ASTM (600 ppm) lead content

E1613/E1645 based on the weight of

(mod.) the dried paint or coating

film

Heavy Metals ASTM F963 Maximums If metal--all with or without

EN 71, Part III See “Accessories made surface coating. If coated, test

of metal” coating in each color.

If material contains PVC or PU (including PVC or neoprene rain suits and coats, and decals and attachments on clothing)

Required Test Test Method Required Standard Notes

Lead Content EPA 3051 (Modified) PVC 30 ppm All Colors

(San Francisco Superior Court, 317256, PU 100 ppm

CGC-02-403328, and CGC-05-440721)

If made of metal

Heavy Metals ASTM F963 See above See above

EN 71 Part III

Corrosion Resistance ASTM B117 No visual change in Test any one size

G85 (mod) appearance All colors and finishes

24 hrs in 1% No signs of staining,

salt spray corrosion, oxidation or

(fog) discoloration.

Note: Exempt from the above tests are Coats, Ideal Fasteners & YKK zipper components for adults.

Section 10 Raw Material & Finished Product 21

Performance & Testing Procedures June 2008

ANN TAYLOR PROCEDURES MANUAL

Patches, appliqués, twill tapes etc. (Page 1 of 2) Specification #815

Made of fibers, including velcro, dyed elastic, leather patches, etc.

Minimum sample requirement: 1 yard (if in fabric form of at least 40” in width) OR 4 yards (taping)

Required test Test method Required Standard Notes

Colorfastness and AATCC 61, IIA Color change: min. 4 Test all colors

appearance after Staining: min. 4

washing Self staining: min. 4.5

No visual change in

appearance

Colorfastness and AATCC 132 Color change: min. 4 Test all colors

appearance after Staining: min. 4

drycleaning Self staining: min. 4.5

No visual change in

appearance

Colorfastness to AATCC 8 Dry: min. 4 Test all colors

crocking or Wet: min. 3 Report which test procedure

AATCC 116 was used

If item is too

small

If item is a tape, ribbon, elastic, etc. add the following tests:

Dimensional stability AATCC 135 Report actual shrinkage. Test one color only

to laundering Acceptance depends on Three launderings

compatibility with fabric in

specific garment

Dimensional stability AATCC 158 Report actual shrinkage. Test one color only

to drycleaning Acceptance depends on One drycleaning only

compatibility with fabric in

specific garment

If used on inside of garment add the following test:

Color fastness to AATCC 15 Color change: min. 3.5 Example: neck tape, etc.

perspiration Staining: min. 4 Test all colors.

Section 10 Raw Material & Finished Product 22

Performance & Testing Procedures June 2008

ANN TAYLOR PROCEDURES MANUAL

Patches, appliqués, twill tapes etc. (page 2 of 2) Specification #815

Made of fibers, including velcro, dyed elastic, etc.

If used in swimwear add the following tests:

Required test Test method Required Std. Notes

Colorfastness and AATCC 106 Color change: min. 4 Test all colors

appearance after Staining: min. 4

exposure to sea water Self staining: min. 4.5

No visible change in appearance

Colorfastness and AATCC 162 Color change: min. 4 Test all colors

appearance after No visible change in appearance

exposure to

chlorinated pool water

If material contains PVC or PU (including PVC or neoprene rain suits and coats, and decals and attachments on clothing)

Required Test Test Method Required Notes

Standard

Lead Content EPA 3051 (Modified) PVC 30 ppm All Colors

(San Francisco Superior Court, 317256, CGC- PU 100 ppm

02-403328, and CGC-05-440721)

Down and Feather Testing Specification #816

Minimum sample requirement: 300 grams of down and one garment or mock-up.

Required Test Test Method Required standard Notes

PENETRATION IDFB, Method 5530 Minimum 4 Fabric against actual filling

RESISTANCE FTM 191, Method One color only

5530 (mod.)

FEATHER/DOWN IDFB Method 3 No more than: For labeling, “USA Standards -

COMPOSITION Fed Standard 148a 10% down fiber Down and Feather Products

10% feather fibers Labeling Guidelines”

2% landfowl feathers

2% damaged feathers

2% residue

FILL POWER IDFB 10, IDFB 32 Minimum

(tumble dry method) 550 cubic inches/oz

OXYGEN IDFB 21 Less than 10

NUMBER

TURBIDITY IDFB 22 Minimum

550 mm

Section 10 Raw Material & Finished Product 23

Performance & Testing Procedures June 2008

ANN TAYLOR PROCEDURES MANUAL

Rubber and soft plastic patches Specification #817

Minimum sample requirement: 40 pieces

Required test Test number Required Standard Notes

Colorfastness and AATCC 61 IIA Color change: min. 4 All colors

appearance after Staining: min. 4 Add appearance to evaluation

washing No brittleness, cracking or

chipping

Colorfastness and AATCC 132 Color change: min. 4 Not for rubber (known to fail,

appearance after Staining: min. 4 use “do not dryclean” label)

drycleaning No brittleness, cracking or All colors

chipping Add appearance to evaluation

Ageing under 48 hrs under No discoloration, staining, Any one color

hot/humid conditions 50C (120F) and brittleness, cracking or

95% rh chipping

Ageing under cold 48 hrs under 0 No brittleness, cracking or Any one color

conditions C (32 F) chipping Note: test sample must be

evaluated immediately, while

still cold.

Phthalates (in PVC) Solvent <1000 ppm of listed PVC

extraction with substances - see Test all colors

LC-MS or GC- “Standards”

MS Analysis

Cadmium Content EN 1122 <0.01% by weight PVC, Pigment Coated/Painted

plastic

BHT content ASTM 4275 Less than 25 ppm Phenol compounds (foam,

plastic, etc.)

If used for swimwear add the following tests:

Colorfastness and AATCC 106 Color change: min. 4 Test all colors

appearance after Staining: min. 4

exposure to sea water No visible change in

appearance

Colorfastness and AATCC 162 Color change: min. 4 Test all colors

appearance after No visible change in

exposure to chlorinated appearance.

pool water

If material contains PVC or PU (including PVC or neoprene rain suits and coats, and decals and attachments on clothing)

Required Test Test Method Required Standard Notes

Lead Content EPA 3051 (Modified) PVC 30 ppm All Colors

(San Francisco Superior Court, 317256, PU 100 ppm

CGC-02-403328, and CGC-05-440721)

Section 10 Raw Material & Finished Product 24

Performance & Testing Procedures June 2008

ANN TAYLOR PROCEDURES MANUAL

LABELS

Number of labels required for testing: 25 labels minimum SPECIFICATION #560

# OF

TEST DESCRIPTION REQUIREMENTS TEST METHOD SAMPLINGS/

READINGS

1. Durability to 50 launderings and No adverse effects AATCC 135/158 3

5 drycleaning (washing conditions as

per care instructions)

2. Colorfastness to Laundering AATCC 61

- color change 4.0 minimum 1

- staining 3.5 minimum

3. Colorfastness to Drycleaning AATCC 132

- color change 4.0 minimum 1

- staining 3.5 minimum

4. Colorfastness to Chlorine Bleach 4.0 minimum AATCC TS001 1

5. Colorfastness to Non-Chlorine Bleach 4.0 minimum AATCC TS001 2

6. Colorfastness to Crocking (dry/wet) 4.0 minimum/3.0 minimum AATCC 116 1

7. Colorfastness to Perspiration 4.0 minimum AATCC 15 1

- color change 3.0 minimum

- staining

8. Colorfastness to Water: Sea (swimwear) AATCC 106 1

- color change 4.0 minimum

- staining 3.0 minimum

9. Colorfastness to Water: Chlorinated Pool AATCC 162 1

(swimwear)

- color change 4.0 minimum

If material contains PVC or PU (including PVC or neoprene rain suits and coats, and decals and attachments on clothing)

Required Test Test Method Required Standard Notes

Lead Content EPA 3051 (Modified) PVC 30 ppm All Colors

(San Francisco Superior Court, 317256, PU 100 ppm

CGC-02-403328, and CGC-05-440721)

Size Stickers SPECIFICATION #561

Sample Required: 20 sticker labels and one (1) yard fabric of each color in garment order. Lab. may request

additional labels if necessary.

Note: Sticker label MUST NOT be pre-applied on fabric.

Required Test Test Method Required Standard Notes

Ageing Test (under BV S1052 No noticeable change on sticker All color fabrics in garment

hot/humid conditions) and residual adhesive left on order

test fabric.

BHT Content ASTM D4275 Less than 25 ppm Each sticker type

Section 10 Raw Material & Finished Product 25

Performance & Testing Procedures June 2008

ANN TAYLOR PROCEDURES MANUAL

Yarn Testing - Production

st

Number of Samples Required for Testing: 2.5 yards 1 color minimum width 36”

1 yard each additional color minimum width 36”

1 cone, 10 yards minimum

Yarn in Yarn Form

Production Stage (including yarn testing protocol)

• All yarns purchased by Ann Taylor must be tested in accordance with the full Basic Yarn Testing

Package and include the (Basic Yarn Test Package) prior to shipment from the suppliers.

• Samples in all colors from the first bulk production must be submitted to an Ann Taylor approved

testing laboratory for evaluation.

• “Unfinished” yarn

o To be performed by country sourcing the yarn and only required if sourcing country is different

than country manufacturing the garment

o Physical testing—cone of yarn should be submitted to the laboratory.

o Colorfastness testing--basic jersey knitdown should be submitted to the laboratory

• “Finished” Yarn:

o To be performed by country manufacturing the garment.

o Production yarn must be submitted as a knitdown in the correct color, stitch/gauge and finish

{washing, brushing, printing, etc} to the laboratory for evaluation.

• For 100% Cashmere only, add the following tests on the fiber itself:

Diameter of Fiber (ASTM D2130)

Fiber Length (ASTM D1575)

Section 10 Raw Material & Finished Product 26

Performance & Testing Procedures June 2008

ANN TAYLOR PROCEDURES MANUAL

Yarn in Yarn Form - Production Specification #719

Required test Test Method Required Notes

Standard

PHYSICAL

CHARACTERISTICS

FIBER CONTENT AATCC 20/20A Single fiber: No Test one solid and all top-dyed

ASTMD276/629 tolerance mélanges.

Blends: +/- 3%

YARN SIZE ASTM D1059 +/- 10% One color only

against claimed

TWIST PER INCH ASTM D1423 As specified One color only

by yarn supplier

YARN STRENGTH ASTM D2256 As specified One color only

by yarn supplier

COLORFASTNESS/

PERFORMANCE

pH AATCC 81 White (bleached), All colors

Wool/wool blends:

4.5-7

Others: 6-8

COLORFASTNESS TO AATCC 61 Minimum All colors

LAUNDERING/DRYCLEANING 1A - hand wash Color change: 4

2A - machine wash Color staining: 3.5

40 C - cold Self-staining: 4.5

49 C - warm

AATCC 132

COLORFASTNESS TO NON- AATCC TS-001 Minimum All colors

CHLORINE BLEACH Color change: 4 Washable fabrics

COLORFASTNESS TO AATCC TS-001 Minimum All colors

CHLORINE BLEACH Color change: 4 Washable fabrics

COLORFASTNESS TO AATCC 15 Minimum All colors

PERSPIRATION Color change: 4

Color staining: 3.5

Self-staining: 4.5

COLORFASTNESS TO AATCC 8, 116 Minimum (wet/dry) All colors (except white)

CROCKING Light: 3/4 Lab discretion on light colors and

Medium/dark: certain neutrals

2.5/3.5

Pigment/ sulfur 2/3

sueded (brushed,

peached, sanded)

COLORFASTNESS TO LIGHT AATCC 16 Minimum All colors

Option 3 Light/neutral colors: (except lining/pocketing fabrics)

20 hours 3.5

All others: 4

Section 10 Raw Material & Finished Product 27

Performance & Testing Procedures June 2008

ANN TAYLOR PROCEDURES MANUAL

Yarn in Knitted Form

Testing at Production Stage. Full Garment to be performed by country manufacturing the garment.

- Must be performed on a finished garment at manufacturing stage.

- One color per style

- Every stitch and gauge Specification #720

Required test Test Method Required standard Notes

PHYSICAL

FIBER CONTENT AATCC 20/20A Single Fiber: No tolerance One color only

ASTM D276/629 Blends: +/- 3% When applicable, due to

construction, embellishments,

trims, etc,

PERFORMANCE

FLAMMABILITY 16 CFR 1610 Class 1 One color only

(See“Performance Specifications-

Flammability for details)

BURSTING STRENGTH ASTM D3786 Minimum (psi) One color only

Fabric Weight:

<4.0 oz/sq yard: 40

4.1-6.0 oz/sq yard: 50

>6.1 oz/sq yard: 55

Lace: 35

Sweaters: 50

PILLING ASTM D3512 All others: 3.5 Woven/knit: One color only

Random Tumble Polyester/nylon: 3 Knit/sweater only: If failure, test 2

(30 minutes) additional colors

Sweaters and

Animal Fibers:

BS EN ISO 12945

Part 1 (4 hours) Class 3.5

Specialty animal

fibers: 2 hours Class 3.5

STRETCH AND ASTM D2594 In stretch direction only : Stretch only

RECOVERY use “Growth” for For samples with elastic content One color only

pass/fail > 10% (60 sec.)

determination; Recovery: 85%

“Recovery” for Growth: 5%

informational For samples with elastic content

purposes only < 10% (1hr.)

Recovery: 70%

Growth: 7%

DIMENSIONAL STABILITY AATCC 135, 3 Length x Width (max. %) One color only

TO WASHING cycles Cotton/blends: -5/+3 x -5/+3

(as per care Rayon -5/+5 Washable fabrics;

instructions) Pique/Rib/Jacquard/Pointelle: -7/+3 Dryclean only (hand wash)

x -7/+3

For “dryclean only” Thermal/Waffle:-10/+3 x -10/+3

fabrics: Poly/Nylon/silk/others:-3/+3 x -3/+3

Hand wash, line dry Ribs with elastic yarn: -8/+3

or flat dry Sweaters: -5/+3 x -5/+3

DIMENSIONAL STABILITY AATCC 158, Length x Width (max. %) One color only

TO DRYCLEANING 1 cycle -3/+2 x -3/+2 Dryclean fabrics

Sweaters: -5/+2 x -5/+2

APPEARANCE AFTER AATCC 135/158, as Color change: 4 One color only

WASHING/ per care Self-staining: 4.5

DRYCLEANING (3 cycles/ 1 cycle) No visual change in appearance

DIMENSIONAL STABILITY Coteco No visual change in appearance Dryclean/dryclean only garments

/APPEARANCE AFTER Length x Width (max %) One color only

STEAM PRESS -3/+2 x -3/+2 Not required for sweaters

Section 10 Raw Material & Finished Product 28

Performance & Testing Procedures June 2008

ANN TAYLOR PROCEDURES MANUAL

Fabric Production Testing

Number of Samples Required for Testing: 2.5 yards 1st color, minimum width 36”.1 yard each additional

color, Minimum width 36”

Responsibility of Fabric Suppliers

• The fabric supplier is responsible for testing all fabrics according to the Ann Taylor requirements prior

to shipment from the mill and for the costs of such tests.

• The full basic textile package must be done on the first production dye lot of each fabric. Test report

will be valid for two seasons. (Ann Taylor will specify if any additional tests must be done depending

on the fabric).

For each quality textile, only one color is required to be fully tested in accordance with the full basic

textile testing package. Each additional color of the same quality is only required to be tested for all

applicable colorfastness tests (see “Performance Specification Sheets/Testing Protocols” for details).

• The tests must be done by an Ann Taylor designated commercial laboratory. All required fabric

information must be given to the laboratory (see “Ann Taylor Test Request Form—Fabric”).

• In addition, the fabric supplier must test each dye lot internally to assure that all fabrics meet the

requirements. These test reports do not have to be submitted to Ann Taylor, but the supplier must

keep them for review by Ann Taylor personnel if problems arise.

• For garments produced at vertically integrated manufacturing plants, the factory is required to submit

both the textiles and garments independently for evaluation in accordance with both the full basic

textile and garment testing packages.

Note: All colors must be tested prior to ordering care labels. Labels may vary per color and must

be ordered per lab test report recommendations. Final care label depends on how the garment as

whole performs (and confirmed by the garment test).

General Fabric Testing Requirements

• All fabric testing must be done according to the Performance Specification Sheets/Test Protocols

(including “Additional Testing”, when applicable).

• The fabric supplier must submit all fabrics from the first production dye lot each season.

• Any care label referenced must be selected from the list of Ann Taylor standard care labels. Any

deviation must be approved by the NY Director of Fabric and Testing.

• Fabric used for trim, lining, etc. must undergo the same testing procedures as regular fabrics.

• All tests must be performed according to the test procedures listed (i.e. AATCC, ASTM, etc.).

• All fabrics submitted must be representative of all finishing processes it will be subject to during

manufacturing (i.e., stone/antique washing, garment washing, flocking, printing, etc).

• For washed programs (such as indigo-dyed denim and heavy garment washed fabrics), before- and

after- wash testing are required (see below for details).

Before-Wash Testing

• Bursting strength (knits)

• Fabric weight

• Fabric count

• Fiber content

Section 10 Raw Material & Finished Product 29

Performance & Testing Procedures June 2008

ANN TAYLOR PROCEDURES MANUAL

• Flammability (see “Performance Specifications—Flammability” for details)

• Pile retention (corduroy, velvet, velour only)

• Pilling resistance (knits / wovens)

• Abrasion—denim only

• Seam slippage (wovens)

• Stretch and Recovery (fabrics containing stretch fibers, such as Spandex,

Lastol, Elasterell-p)

• Tearing strength (wovens)

• Tensile strength (wovens)

• Yarn size (only if requested)

• Spray Test—only

if claiming “water

repellent”

• Rain Test—only if classified rainwear”

SEE “PERFORMANCE SPECIFICATION SHEETS/TEST PROTOCOLS” FOR STANDARDS AND TEST METHODS.

After-Wash/Finish Testing

See “Performance Specification Sheets/Test Protocols” for full testing, standards, and test

methods.

Note 1: The fabric supplier/manufacturer is responsible for the charges incurred in testing the

fabric “before-wash/finish” (see below).

Note 2: The garment manufacturer is responsible for the charges incurred in testing the fabric

“after-wash/finish” (see Performance Specification Sheets/Test Protocols).

Note 3: The garment manufacturer is responsible for the charges incurred in testing the

garments after the wash/finish.

• All colorfastness tests are done against AATCC multifiber #10 (except crocking) unless otherwise

stated in the testing protocols. Multifiber #1 should be used if rayon or silk is present in the fabric.

Multifiber # 10 & #1 will be used if acrylic and silk and/or rayon are present in the fabric.

(Note: If the results are marginal and the fabric is used in a critical combination, then the tests should

be repeated against the actual component fabrics used in a garment).

• For color-blocked items, it is recommended that mock-ups be made in all colorways and submitted for

colorfastness testing before fabric shipment.

• Fabrics must be washed/dried three times, or drycleaned one time for all shrinkage and appearance

tests.

• Please review carefully the requirements for flammability testing in this section.

• Colorfastness to laundering:

Hand washables: AATCC 61-1A

Hand wash cold: test performed at 40 C

Hand wash warm: test performed at 49 C

Machine washables: AATCC 61-2A

Machine wash cold: test performed at 40 C

Machine wash warm: test performed at 49 C

• All Fabrics containing metal/metallic, in addition to all applicable basic tests must also be subject to

further construction analysis: 1) number of yarns used to weave/knit fabric & number of plies/yarn and

2) fiber content by weight of each yarn.

Section 10 Raw Material & Finished Product 30

Performance & Testing Procedures June 2008

ANN TAYLOR PROCEDURES MANUAL

Garment Production Testing

Number of Samples Required for Testing: 3 Garments

Responsibility of Garment Suppliers

The garment supplier is responsible for all garments to be tested according to the Ann Taylor

requirements (full Basic Garment Testing Package) and for the costs of such tests.

The factory must send a representative garment from the beginning of their bulk production to an

Ann Taylor designated commercial laboratory.

• All the required garment information must be given to the laboratory (see “Ann Taylor

Test Request Form—Garment”)

• Additional garments must be sent to the laboratory if needed (consult with lab).

*NOTE: Production garments must have all production trim/embellishments attached. If a total

of 3 garments are not sent, the testing lab will contact the requestor for the additional garment.

The testing lab will not proceed with the garment test until both garments have been received.

Garment Test

The purpose of garment testing is to evaluate all the different components of a garment together

while being cleaned three times (one time for drycleaning) according to the care label. We are

looking for appearance, bleeding, puckering, shrinkage, or anything that would make the garment

look or feel undesirable. Special attention should be paid to trims, accessories, and garment

prints.

Care labels submitted must be taken from the Ann Taylor standard care labels. Any deviation

must be approved by the NY Director of Fabric and Testing.

The garment test will also evaluate the strength of all seams, stress points, and trim

attachments, as well as verify the care instructions and fiber content labeling. For fiber content

label, fiber content must be tested in fabric stage and verified at garment stage on all styles prior

to order labels.

For zipper(s) that is/are attached to the garment, the operability, chain crosswise, top stop

holding, bottom stop holding and holding strength of slider lock tests are required.

The garment test must be performed by an Ann Taylor designated commercial laboratory. See

“Approved Laboratories for AT Softline Product”.

Production textiles in all colors must be tested prior to submitting samples for garment testing.

The garment testing does not replace the required fabric tests but is in addition to these. The

fabric tests are important because problems with such items as tensile strength, light fastness,

colorfastness to perspiration, chlorine, seawater, etc. are not revealed by our garment test.

Garments must be tested in the production stage and test report will be valid for two seasons.

The testing must be done after the garment is completely finished, including “garment wash”,

“enzyme wash”, “stone wash”, etc, if applicable.

See “Performance Specification Sheets/Testing Protocols” for a list of the required tests.

If garment dye/garment finished – need to add colorfastness tests.

Section 10 Raw Material & Finished Product 31

Performance & Testing Procedures June 2008

ANN TAYLOR PROCEDURES MANUAL

Colorfastness to crocking test is required to be performed on all denim production garments. If

dry crocking does not meet dry crocking Class 3, or wet crocking class 2, wash garment 1X

according to the care label of garment and repeat crocking test. If the crocking improves to a

satisfactory rating, the fabric can be accepted provided that the care instruction is modified to

include “wash before wearing” (before all other instructions).

The cost of the testing is the responsibility of the garment supplier.

This procedure does not relieve the garment supplier of his responsibility to assure the

performance of the garments by total internal quality control throughout the production cycle.

Each type/style of garment must be tested (in the correct textile quality), especially if different

kinds of trim and different fabrics are used together in the same garment.

• It is not necessary to test every color combination, but all critical color combinations

must be tested

o Combinations of bright/deep colors with white/cream.

o Pay special attention to contrasting trim

o All combinations of “red” with other light colors must always be tested because

this is the color most like to bleed.

o All color contrast combinations with fabrics that are known to be marginal in

colorfastness (from fabric tests) must be tested.

• For color-blocked items, it is recommended that mock-ups be made in all colorways

and submitted for colorfastness testing before fabric shipment.

If the same garment style is made by more than one supplier, it must be tested individually from

each supplier.

Section 10 Raw Material & Finished Product 32

Performance & Testing Procedures June 2008

ANN TAYLOR PROCEDURES MANUAL

TEST REQUEST PROCEDURES

PROCEDURE FOR REQUESTING TESTING SERVICES

The following is the standard operating procedure for processing test requests.

Ann Taylor Request Form

In order to process your requests as quickly as possible, it is imperative that all testing be

submitted on an Ann Taylor Test Request Form (see page 35-37) to an approved testing

laboratory (see “Approved Laboratories for Ann Taylor Softlines Product”). Request forms

must be filled out completely and accurately at the time of submission, including:

• Fiber Content – Do not abbreviate. Must use proper FTC generic names for fiber(s).

If the product contains a trade name fiber, it must be listed in conjunction with the

appropriate FTC generic name.

• Quality/Style Number – For trim, yarn, and textiles, use the raw material supplier’s

quality identification number. For garments/finished products, use the assigned Ann

Taylor style number.

• Color – Identify using Ann Taylor approved name(s) and number(s).

• AT Division – Must indicate as appropriate--either Stores, Loft, or Factory Stores.

• AT Department number - Must indicate appropriate 2 digit AT department number.

• All trim, fabric, and garment details as listed on the test request forms.

• Requestor name/telephone/fax/e-mail – Must indicate the full name of person

requesting testing including telephone number, fax number, and e-mail address.

• Proposed Care Instructions – Must be included, and should reference AT standard

care instructions. If proposed care instructions indicate laundering, must include wash

temperature and cycle, bleaching instructions, dry temperature and cycle, and ironing

instructions. If care instructions are unknown, please indicate “lab to provide”. .

• Service requested –Check appropriate box.

• Requested testing

1) Must advise if sample is Development or Production.

2) Must select type of testing.

a) Basic Test Package - no additional information is required.

b) Additional Color Test Only – must also advise previous full basic test report

number.

c) Retest - must also advise previous report number and the failed property

(properties) that are to be re-tested.

d) Other - must specify requested test(s).

e) Garment Test -must also advise corresponding fabric and trim test report

numbers.

• Product Category - Check all appropriate boxes.

• Billing Information - Must be fully completed including: company name, address,

contact name, telephone number and fax number.

• AT Contact Name - Must be included

Note: Request forms must be fully completed before the laboratories are able to process

your request. It is important to note that the information provided on the request form is

required by Ann Taylor for product tracking purposes and will determine which performance

standard to apply to your product.

Section 10 Raw Material & Finished Product 33

Performance & Testing Procedures June 2008

ANN TAYLOR PROCEDURES MANUAL

Requests received without all the required information cannot be processed and will be

handled as follows:

• Testing Services Coordinator will contact the supplier via telephone, fax and/or e-mail and

request the required information.

• The requestor will be notified and a “Hold” status will be placed on the request.

• The sample and all paperwork will be held for two working days.

• Should the supplier fail to reply within the two-day time period, the request will be

“Canceled” and the requestor will be notified for disposition of samples.

• Upon receipt of required information/samples, the request will be reprocessed and

the “revised date” will appear on the Request form as well as on the Test report.

Processing Routine Requests for Testing:

The following summarizes the standard procedure for processing routine test requests. The

Testing Service will test only what is requested in accordance with Ann Taylor standards and

policy. When a submission is received that does not fall within the guidelines below, the

requestor will be notified prior to the start of testing.

I. Initial Submissions:

Testing service will test only what is requested by the supplier, as stated in the request

form!

• Requests for all “Basic Package” testing will override all other requests for testing.

• In cases where fabric and/or garment package testing does not include all special testing

requested, the additional tests will be included along with the standard test package.

• In cases where fabric and/or garment package testing has not been requested, only the

tests specified will be performed.

• Please state weight in fabric oz/sq. yd, g/m2 or sweater garment lbs/dz. Do not

abbreviate care instructions or fiber content.

• Garment testing and additional colorway testing must have the original report numbers

referenced, otherwise the requests will be placed on “Hold”.

II. Retest Submissions:

For retest submissions include previous report number and specify which test needs to be

performed. Retest submissions received without a previous report number listed and without

specific instructions included, will be handled using the “Hold” criteria listed above.

Note: Any variations to standard BV testing procedures will be outlined in the “executive

summary” section of the corresponding test report.

III. Ann Taylor Testing Service Options:

The network of testing laboratories makes every effort to evaluate products in the shortest

possible time.

• Regular Service: 3 working days, beginning the day after the laboratory receives the

samples. (Normal fee applied)

• Priority Service: 2 working days, beginning the day after the laboratory receives the

samples. (Normal fee + 40% surcharge applied)

• Express Service: 1 working day, beginning the day after the laboratory receives the

samples. This only applies to tests that can be processed and submitted within 1 working

day (normal fee + 50% surcharge applied).

Section 10 Raw Material & Finished Product 34

Performance & Testing Procedures June 2008

ANN TAYLOR PROCEDURES MANUAL

Testing for “Priority” and “Express” services are limited only to those tests that can be

completed within the specified service time. Requests received, with either of these services

selected, requiring a test(s) that falls outside of the service parameters, will follow on a separate

report and the vendor and appropriate requestor personnel will be notified. Use the express

service option only when necessary to minimize reporting delays created by a significant increase

in "special" service requests. Full package testing cannot be completed with Express Service.

*Notes:

• If due to tests required, more than the requested service is needed to complete

testing, the lab must communicate to the requestor within 24 hours of receipt of the