Documente Academic

Documente Profesional

Documente Cultură

2.1 Range of Feasibility: Project Management and Operational Research

Încărcat de

Prince EshwarDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

2.1 Range of Feasibility: Project Management and Operational Research

Încărcat de

Prince EshwarDrepturi de autor:

Formate disponibile

TABLE OF CONTENTS

CHAPTER TOPIC PAGE

01 Background theory – Linear programming 2

1.1 Methodology Explanation 3

1.2 Limitations of linear programming 4

02 Analysis of case

2.1 Range of Feasibility 8

2.2 Range of optimality 9

2.3 Reduced cost 10

2.4 Shadow price 10

2.5 Slack or Surplus 11

03 Discussion of three options 12

04 Recommendations 16

05 Reference 17

Project Management and Operational Research Page 1

1. Introduction to Linear programming

Introduction:

Linear programming or mathematical programming is the branch of management science that deals

with solving optimization problem, in which we want to maximize a function such as profit or

expected return or minimize a function such as cost, time, distance. In a decision-making

embroilment, model formulation is important because it represents the essence of business decision

problem. The term formulation is used to mean the process of converting the verbal description and

numerical data into mathematical expressions, which represents the relevant relationship among

decision factors, objectives and restrictions on the use of resources. Linear Programming (LP) is a

particular type of technique used for economic allocation of 'scarce' or 'limited' resources, such as

labor, material, machine, time, warehouse space, capital, energy, etc. to several competing activities,

such as products, services, jobs, new equipment, projects, etc. on the basis of a given criterion of

optimally. The phrase scarce resources mean resources that are not in unlimited in availability during

the planning period. The criterion of optimality generally is either performance, return on investment,

profit, cost, utility, time, distance, etc.

George B Dentzing develops this technique when he was working with US air force during world war

2, Which is primarily used for solving military logistic problem. But in today’s world, the technique is

being used in all functional areas of management, hospitals, airlines, agriculture, military operations,

oil refining, education, energy planning, pollution control, transportation planning and scheduling,

research and development.

The most important of application of linear programming has been the allocation problem, allocation

of scare resource for optimal results. Usually there are many jobs which share the common resources and

the variable resources are not adequate enough to allow each job to be carried out to the fullest extent.

Therefore, the objective in such a situation is to allot available resources to the job in such way as to

either maximize the total revenue or to minimize the total cost subject to resource constraints.

Linear programming can be applied to various fields of study. Most extensively it is used in

business and economic situations, but can also be utilized for some engineering problems. Some

industries that use linear programming models include transportation, energy, telecommunications,

and manufacturing. It has proved useful in modeling diverse types of problems in planning, routing,

scheduling, assignment, and design.

Project Management and Operational Research Page 2

Methodology

It is a model that does seek to maximize or minimize a linear objectives function subject to a set of

linear constraints. But all the means is that the objective function and constraints contain only

mathematical term involving variables (X1, X2, X2) that are raised to the first power (e.g 5X1).

Mathematical model:

The general mathematical model of the linear-programming problem

Maximize (or Minimize) the Objective Function:

C X + C X + … + CX + … + C X

1 1 2 2 j j n n

Subject to the conditions (constraints)

A X + A X + … + A X + … + A X {<=, =, >=} B

11 1 12 2 1j j 1n n 1

A X + A X + … + A X + … + A X {<=, =, >=} B

21 2 22 2 2j j 2n n 2

………………………………………………………………………….

A X + A X + … + A X + … + A X {<=, =, >=} B

i1 2 i2 2 ij j in n i

………………………………………………………………………….

A X + A X + … + A X + … + A X {<=, =, >=} B

m1 2 m2 2 mj j mn n m

And

X1, X2,.. Xj, … , Xn ≥ 0 (non-negativity)

Where:

Cj for j= 1,2,…,n; Bi for i= 1,2,…,n and Aij are all constants

A is a matrix of known coefficients

Cj for j= 1,2,…,n are called cost coefficients

Xj for j= 1,2,…,n are variables to be solved for. Finding out X j we will know the optimal

solution.

(Source: Gauss 2003, p.6)

Project Management and Operational Research Page 3

Applications of Linear Programming

Applications Objective Constraints

Manufacturing Determine production quantities that Labor availability

maximize profit Resource availability

Finance Allocate funds to maximize Diversification

expected return Acceptable risk levels

Advertising Select a media mix that maximizes Budget

exposure to a target population Length of advertising campaign

Worker Assign workers to production and Production quotas

Training training activities to maximize profit Number of qualified instructors

while building a workforce and trainees available

Construction Plan tasks and assign labor to met a Ordering of tasks

production schedule Project deadline

Oil Refining Blend raw crude oils into different Supply of raw crude oil and

grades of gasoline demand for different grades of

gasoline

Required characteristics of the

different grades of gasoline

Transportation Assign delivery of resources to Supply/ demand of product

minimize transportation costs Shipping capacities

Agriculture Determine a plant rotation plan to Anticipated demand for crops

maximize long term profit Rotation restrictions

Military Assign troops and material to Troop availability/ training

Operations accomplish a military mission Transportation of resources

(Source: Lawrence & Pasternack 2002, p.50)

LIMITATION OF LINEAR PROGRAMMING IN REAL – LIFE SITUATIONS

1. Forecasting is based on the past data – hence it may not always accurate and it can give wrong

results.

2. Defining the specific objective function is not easy for all linear programs.

3. The data available may be conflicting in nature. This may cause confusion during analysis.

4. LP is based upon relative relations between input and output. This means that input and output

Project Management and Operational Research Page 4

are multiplicative, divisible and additive, but the relation between input and output are not

always linear.

BAY CITY MOVERS

Bay City Movers is a local company that specializes in intercity moves. In the business plan

submitted to its backers, Bay City has committed itself to a total trucking capacity of at least 36 tons.

The company is in the process of replacing its entire fleet of trucks with 1 ton picks up trucks and 2.5-

ton moving van type trucks. The 1 ton pick up trucks will be manned by one worker, whereas the

large vans will utilize a total of four personnel for larger moves.

Bay City Movers currently employs 48 workers and has facilities for 40 trucks. Pick up trucks cost

the company $24,000 and the moving vans cost $60,000. The company wishes to make a minimum

investment in trucks that will provide a trucking capacity of at least 36 tons while not requiring any

new hires or trucking facilities.

Although the continuity assumption is violated (since the number of each truck purchased must be

integer), use a linear programming model to determine the optimal purchase of pick up trucks and

vans for Bay City Movers. You will find that alternative optimal solutions are possible.

Prepare a report detailing several of these options and discuss the pros and cons of each. Among the

alternatives, you should present in your report are the following:

5. Purchasing only one type of truck.

1. Purchasing the same number of pick up trucks as moving vans.

Purchasing the minimum total number of trucks.

Project Management and Operational Research Page 5

Mathematical model for Bay City movers:

The company is in the process of replacing their entire fleets of trucks with one ton

pick up trucks and 2.5-ton moving van type trucks.

There are two variables in the case. They are:

Let X1 be 1-ton pick up trucks.

X2 be 2.5-ton moving van trucks.

The three constraints in the case are:

Let C1 which represents the capacity of the trucks

C2 that represents the number of workers currently employed for the job

C3 represents the facilities provided to the trucks.

The objective of the case is to reduce the investment-involved n the replacement of the fleet of trucks.

The objective function:

DECISION VARIABLES

Minimize 2400X1+60000X2

Subject to:

X1+4X2<= 48 (Worker)

X1+X2<= 40 (Facility)

X1+2.5X2>= 36 (trucking capacity)

X1, X2 >= 0 (Non negativity)

Project Management and Operational Research Page 6

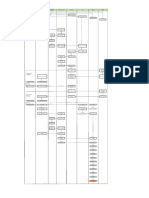

WinQSB Printout:

INPUT-

OUTPUT-

Project Management and Operational Research Page 7

Range of Feasibility

The range of feasibility of Bay City movers:

In case of Capacity:

The range of feasibility for the company is 30 to 44 where the minimum ranges being the 30

and the maximum range being 44. The actual capacity utilized are 36units, 8 more units can be

increased, by paying a certain price if the company feels that they can improve the output by

increasing the capacity.

In case of workers:

The actual workers utilized by the company are 48 and the range, which is inside the range,

which is from 36 to 57.6. So the company can increase by their workers by hiring 10 more workers.

In case of Facility:

The range of feasibility varies from 24 to M (Infinity) so there is no maximum given to

which the company can definitely figure on when they come to the increasing their facility. The

current facility constraint utilized by the company is 24 we know that there is a scope to increase but

due to lack of the maximum range the company does not get a clear idea of which extent they

increase.

Project Management and Operational Research Page 8

RANGE OF OPTIMALITY

In case of Pick up truck:

The actual cost of one unit of pick up truck is 24,000. The range from which the range of

optimality varies is from 24,000 to M (infinity) this shows that the cost can be increased to infinity but

the cost cannot be reduced than the minimum range which is 24,000 by doing so the optimum solution

will tend to change.

In case of Moving van:

The cost involved in one moving van is 60,000. The range of optimality, which has the

minimum range of –M (Infinity) and the maximum range being the 60,000 the company cannot

exceed its cost or the maximum range but try and reduce its cost if it wants to.

Project Management and Operational Research Page 9

REDUCED COST

The reduced cost for both the pick up truck and the moving van are zero. So there is no requirement

for the company to reduce in their costs. Thus 24,000 being the reduced cost of Pick up truck and

60,000 being the reduced cost of Moving van remain constant.

SHADOW PRICE

Project Management and Operational Research Page 10

Capacity-

Every unit of capacity over 36 units will cost the company 24,00 per unit.

Workers and Facility-

Since the shadow price of both workers and facility are zero the company need not increase

on the number of units, which they already have.

SLACK OR SURPLUS

Capacity and Workers:

The slack or surplus for both the capacity and workers being zero, it means that the

company is utilizing their resources related to the workers and capacity to its optimum thus there is no

surplus.

Facility-

Project Management and Operational Research Page 11

The surplus for facility are 16 units, thus the company is not utilizing its resources efficiently

when it comes to facility.

Discussion of three options

Option 1

Purchasing only one type of truck

Purchasing only Pick up truck:

Input:

Project Management and Operational Research Page 12

Output:

This is the purchase of only pick up truck. The optimum solution over here is feasible. The maximum

capacity of the pick up truck is 40. The minimum purchase of the pick up trucks is 36. The number of

workers utilized totally is 36. The maximum allowable trucks that can be purchased are 8. Thus the

values are feasible enough for the company to work on and achieve their objectives.

Purchase only Moving vans:

Input

Project Management and Operational Research Page 13

Output

Since the minimum and maximum range of capacity is negative and the company, which has a huge

difference of range when it comes to the number of workers, and high shadow price for every extra

unit of worker, thus the solution is infeasible.

OPTIONS 2

Purchasing equal number of pick up trucks as moving vans:

Project Management and Operational Research Page 14

Input:

Output:

The capacity is being negative and a huge shadow price for purchase of a new unit of worker being

high the optimum solution is infeasible.

OPTION 3

Project Management and Operational Research Page 15

PURCHASING THE MINIMUM TOTAL NUMBER OF TRUCKS

INPUT

OUTPUT

The solution arrived for purchasing minimum total number of trucks is, for Pickup trucks it is 16 and

for van it is 8. The unit cost for each truck is one. The unit cost being 1 for both the cases indicate that

the company can reduce its cost. Through this the objective function 24 is achieved. The total

investment the company has to use is 864,000. Thus the solution is also feasible.

RECOMMENDATIONS AND CONCLUSION

Project Management and Operational Research Page 16

In the above problem of Bay City Movers, the main objective function is to minimize the cost of

purchase of moving vans and pickup trucks (i.e., 24000 X1 + 60000 X2)

When we analyze the option 1, purchasing only one truck, it was feasible because, the solution given

in the WinQsb is very effective for the company to achieve its objective function.

When we analyze the option 3, purchasing minimum total number of trucks, the solution is feasible, as

it is given that the company can purchase 16 pickup trucks and 8 moving vans, which ultimately come

up to 24, which is the objective function of the company and hence it is feasible.

The most recommended option for the company to achieve the objective function; minimum

purchasing of trucks is option 3. As it says the cost for each truck is only 1 and the minimum trucks

and vans they can purchase is 16 and 8, the minimum total trucks are 24. It is recommendable that if

the company chooses option three, it can attain the objective of getting more profits, by reducing the

cost of purchase.

Reference

Project Management and Operational Research Page 17

Dantzig, G. (1999).Linear Programming-Theory and Extensions. Berlin:Springer

Karloff, H.(1991) Linear Programming, Boston: Ashton Press

Gass.S. (1985), Linear Programming – Method and Application

Loomba, N (1964). Paul. Linear Programming: An Introductory Analysis. New York: McGraw-Hill.

Project Management and Operational Research Page 18

S-ar putea să vă placă și

- Anticipating Correlations: A New Paradigm for Risk ManagementDe la EverandAnticipating Correlations: A New Paradigm for Risk ManagementÎncă nu există evaluări

- Linear Programming Note PDFDocument308 paginiLinear Programming Note PDFthomas erikeÎncă nu există evaluări

- Linear Programming IntroductionDocument7 paginiLinear Programming Introductionemmanuel alimaÎncă nu există evaluări

- Linear Programming Graphical MethodDocument7 paginiLinear Programming Graphical MethodDevkaran LodhiÎncă nu există evaluări

- LP (Model Formulation) - AssignmentDocument4 paginiLP (Model Formulation) - AssignmentUTTAM KOIRALAÎncă nu există evaluări

- Advantages of Linear ProgrammingDocument11 paginiAdvantages of Linear ProgrammingSiddharthh Nutan GokaniÎncă nu există evaluări

- Linear Programming ProblemDocument39 paginiLinear Programming ProblemJaya PrakashÎncă nu există evaluări

- Concept and DefinitionDocument42 paginiConcept and DefinitionSuman Naveen JaiswalÎncă nu există evaluări

- Chapter 4Document56 paginiChapter 4Amanu WorkuÎncă nu există evaluări

- CH 2 LPPMDocument88 paginiCH 2 LPPMsemetegna she zemen 8ተኛው ሺ zemen ዘመን100% (1)

- Advanced Apparel Manufacturing ManagementDocument27 paginiAdvanced Apparel Manufacturing ManagementPrachi YashÎncă nu există evaluări

- Science A Modeling and Case Studies Approach With Spreadsheets 4th Edition Hillier 007809660x 9780078096600Document36 paginiScience A Modeling and Case Studies Approach With Spreadsheets 4th Edition Hillier 007809660x 9780078096600dannygibbsyeqszxgdor100% (19)

- CH-2 Linear ProgrammingDocument69 paginiCH-2 Linear Programmingbelay mihreteÎncă nu există evaluări

- Module - 1 Lecture Notes - 2 Optimization Problem and Model FormulationDocument5 paginiModule - 1 Lecture Notes - 2 Optimization Problem and Model Formulationraj ranjanÎncă nu există evaluări

- Structural Seismic Design Optimization Frameworks: An OverviewDocument14 paginiStructural Seismic Design Optimization Frameworks: An OverviewAjayvidyanand SharmaÎncă nu există evaluări

- Mini Projet en AnglaisDocument17 paginiMini Projet en AnglaisHammoutene MohamedÎncă nu există evaluări

- Chapter Two Linear ProgrammingDocument44 paginiChapter Two Linear ProgrammingEndalk AsfawÎncă nu există evaluări

- SLM Unit 02 MB0048Document27 paginiSLM Unit 02 MB0048Pankaj KumarÎncă nu există evaluări

- Full Download Solutions Manual To Accompany Introduction To Management Science 4th Edition PDF Full ChapterDocument36 paginiFull Download Solutions Manual To Accompany Introduction To Management Science 4th Edition PDF Full Chapterdisbenchcrang9xds100% (16)

- Meaning of Linear ProgrammingDocument4 paginiMeaning of Linear ProgrammingYaimaran MaibamÎncă nu există evaluări

- Chapter 2 Linear Programming 2021Document115 paginiChapter 2 Linear Programming 2021dagmawiÎncă nu există evaluări

- CHAPTER 6 System Techniques in Water Resuorce PPT YadesaDocument32 paginiCHAPTER 6 System Techniques in Water Resuorce PPT YadesaGod is good tubeÎncă nu există evaluări

- OPRE 6366. SCM: 3. Aggregate PlanningDocument21 paginiOPRE 6366. SCM: 3. Aggregate PlanningNikhil PrasannaÎncă nu există evaluări

- Linear Programming 2Document60 paginiLinear Programming 2mengistuÎncă nu există evaluări

- Chapter Two - Operations ResearchDocument93 paginiChapter Two - Operations ResearchAYNETU TEREFEÎncă nu există evaluări

- Chapter 5 - Linear ProgrammingDocument4 paginiChapter 5 - Linear ProgrammingSandraÎncă nu există evaluări

- Resource ManagementDocument42 paginiResource ManagementZamruth FathimaÎncă nu există evaluări

- J080 OM ResearchPaper 2Document9 paginiJ080 OM ResearchPaper 2Hemil ShahÎncă nu există evaluări

- Performance CH 4Document76 paginiPerformance CH 4Yasichalew sefineh100% (2)

- Linear Programming 1Document67 paginiLinear Programming 1Clauie BarsÎncă nu există evaluări

- Partial Evaluation Strategies For Expensive Evolutionary Constrained Optimization PDFDocument15 paginiPartial Evaluation Strategies For Expensive Evolutionary Constrained Optimization PDFAMISHI VIJAY VIJAYÎncă nu există evaluări

- Linear ProgrammingDocument8 paginiLinear Programmingemmanuel alimaÎncă nu există evaluări

- Master of Business Administration: Quantitative Analysis For Management DecisionsDocument75 paginiMaster of Business Administration: Quantitative Analysis For Management DecisionsDawit TesfayeÎncă nu există evaluări

- Linear Programming Linear ProgrammingDocument67 paginiLinear Programming Linear ProgrammingDrRitu MalikÎncă nu există evaluări

- OR ProblemsDocument104 paginiOR Problemsjayaramulu123Încă nu există evaluări

- Module 1Document12 paginiModule 1Kristine BalanayÎncă nu există evaluări

- Application of Goal Programming in Project Selection DecisionDocument13 paginiApplication of Goal Programming in Project Selection DecisionKartik SoniÎncă nu există evaluări

- CH 12Document12 paginiCH 12Siwon YoonÎncă nu există evaluări

- Introduction To Optimization and LP PDFDocument28 paginiIntroduction To Optimization and LP PDFUsman GhaniÎncă nu există evaluări

- Cs6704 - Resources Management TechniquesDocument54 paginiCs6704 - Resources Management TechniquesShereen FathimaÎncă nu există evaluări

- 96-IspDocument6 pagini96-IspRizwan KhanÎncă nu există evaluări

- Lesson - 04Document24 paginiLesson - 04vineeth.vininandanam.kÎncă nu există evaluări

- Formulating and Solving A Linear Programming Model For Product-Mix Linear Problems With N ProductsDocument5 paginiFormulating and Solving A Linear Programming Model For Product-Mix Linear Problems With N ProductsMoshi SaidÎncă nu există evaluări

- Transportation Problem: A Special Case For Linear Programming ProblemsDocument36 paginiTransportation Problem: A Special Case For Linear Programming ProblemsAlem Abebe AryoÎncă nu există evaluări

- Operations ResearchDocument7 paginiOperations Researchanas aliÎncă nu există evaluări

- Minimize Time and Cost For Successful Completion of A Large Scale Project Applying Project Crashing Method PDFDocument9 paginiMinimize Time and Cost For Successful Completion of A Large Scale Project Applying Project Crashing Method PDFMugabe GomosÎncă nu există evaluări

- Mb0048 Unit 02-SlmDocument18 paginiMb0048 Unit 02-SlmNeetu AhmedÎncă nu există evaluări

- Fuzzy Optimal Inventory and Shipment Policy On Non - Coordinated Supply Chain Under Quadratic Price Dependent DemandDocument10 paginiFuzzy Optimal Inventory and Shipment Policy On Non - Coordinated Supply Chain Under Quadratic Price Dependent DemandIJRASETPublicationsÎncă nu există evaluări

- Operations ResearchDocument35 paginiOperations ResearchIGO SAUCEÎncă nu există evaluări

- 25-07-2022-1658751170-6-.-2. Engg - Marginal Analysis For Group TOPSIS With An Application ToDocument8 pagini25-07-2022-1658751170-6-.-2. Engg - Marginal Analysis For Group TOPSIS With An Application ToImpact JournalsÎncă nu există evaluări

- Ch06 Linear ProgrammingDocument35 paginiCh06 Linear ProgrammingRehan FarhatÎncă nu există evaluări

- Chapter-2 Linear Programing MLT Lecture NoteDocument33 paginiChapter-2 Linear Programing MLT Lecture NoteMIHRET ADDISSUÎncă nu există evaluări

- Scieman Chapter 2Document5 paginiScieman Chapter 2Kate Monic Cual GordoncilloÎncă nu există evaluări

- 2009 05 PDFDocument9 pagini2009 05 PDFgurunathan14Încă nu există evaluări

- Ee5551 Newproj ReportDocument18 paginiEe5551 Newproj ReportPoornima BehlÎncă nu există evaluări

- Chapter 1 or NotesDocument17 paginiChapter 1 or NotesKhan AshfaqueÎncă nu există evaluări

- Accelerating Complex Problem-Solving Skills: Problem-Centered Training Design MethodsDe la EverandAccelerating Complex Problem-Solving Skills: Problem-Centered Training Design MethodsÎncă nu există evaluări

- Laws of Production FunctionDocument32 paginiLaws of Production Functionchandanpalai91Încă nu există evaluări

- PROJECT - Joining The MarketDocument5 paginiPROJECT - Joining The Marketrobr5604Încă nu există evaluări

- China Railway Construction Corporation Attaining Globalization Via HighDocument18 paginiChina Railway Construction Corporation Attaining Globalization Via HighCyril Ang-numbaalaÎncă nu există evaluări

- Engineering, Construction and Architectural Management: Article InformationDocument16 paginiEngineering, Construction and Architectural Management: Article InformationGishan Nadeera GunadasaÎncă nu există evaluări

- Test Bank For Financial Markets and Institutions 12th Edition by MaduraDocument25 paginiTest Bank For Financial Markets and Institutions 12th Edition by Madurabelayrubiblex9oujx100% (31)

- Handball Love ? ?Document1 paginăHandball Love ? ?Ramona Ioana UngurÎncă nu există evaluări

- Invitation For Membership: Institute For Lean Construction Excellence (Ilce)Document6 paginiInvitation For Membership: Institute For Lean Construction Excellence (Ilce)JitendraHatwarÎncă nu există evaluări

- iSEEit 2021 MEDDICC ChecklistDocument18 paginiiSEEit 2021 MEDDICC ChecklistDavid Collet100% (1)

- Employees As Strategic Communicators in Public RelationDocument20 paginiEmployees As Strategic Communicators in Public RelationPuspasari SeptamaÎncă nu există evaluări

- Owner'S Manual For Chain Hoist: English Original InstructionsDocument114 paginiOwner'S Manual For Chain Hoist: English Original InstructionsPePe RodasÎncă nu există evaluări

- Million Dollar HabitsDocument12 paginiMillion Dollar HabitsEnriqueÎncă nu există evaluări

- A Framework For OFAC Compliance CommitmentsDocument12 paginiA Framework For OFAC Compliance CommitmentsNeeladri CÎncă nu există evaluări

- Shareholder Primacy, ControllingDocument23 paginiShareholder Primacy, ControllinganonymouseÎncă nu există evaluări

- DMLF Newsletter Issue 1Document6 paginiDMLF Newsletter Issue 1Dagnachew Tesfaye AbetewÎncă nu există evaluări

- Vol - CXXV-No .122 2Document76 paginiVol - CXXV-No .122 2Dummy AccountÎncă nu există evaluări

- SwotDocument13 paginiSwotGabrielle May LacsamanaÎncă nu există evaluări

- Bài tập nhóm chương 3 - nhóm 4-k24kt02Document18 paginiBài tập nhóm chương 3 - nhóm 4-k24kt02Lúa PhạmÎncă nu există evaluări

- Fa Aug 2020Document4 paginiFa Aug 2020Ieymarh Fatimah100% (1)

- TLE10.business EnvironmentDocument2 paginiTLE10.business EnvironmentAubrey Lynn JoyohoyÎncă nu există evaluări

- A Rare Guide To SAP SDDocument152 paginiA Rare Guide To SAP SDpower100183% (6)

- Company Profile: Plot 13, Buganda Road, Mukwano Courts P.O. Box 102380, Kampala, UgandaDocument24 paginiCompany Profile: Plot 13, Buganda Road, Mukwano Courts P.O. Box 102380, Kampala, UgandaronaldÎncă nu există evaluări

- E-Procurement in B2BDocument12 paginiE-Procurement in B2BjaideepÎncă nu există evaluări

- F B Manager Job SpecificationDocument2 paginiF B Manager Job SpecificationSureskumarMariskrishanan100% (1)

- CMMDocument41 paginiCMMakmalÎncă nu există evaluări

- OPPL Water Based Inks - April 2023Document199 paginiOPPL Water Based Inks - April 2023PuthirayaeniÎncă nu există evaluări

- Swim Lane ChartDocument1 paginăSwim Lane ChartDÃljït SīñghÎncă nu există evaluări

- CWTS Midterm Exam 1Document3 paginiCWTS Midterm Exam 1Jenelyn RusianaÎncă nu există evaluări

- Musab Khan CV PKDocument2 paginiMusab Khan CV PKMusab Khalid KhanÎncă nu există evaluări

- Hudson's Bay - EDI 810 Invoice PDFDocument19 paginiHudson's Bay - EDI 810 Invoice PDFkiran itharajuÎncă nu există evaluări

- Prof Sales ReviewerDocument6 paginiProf Sales ReviewerAlthea MoveÎncă nu există evaluări