Documente Academic

Documente Profesional

Documente Cultură

First Page Springer Generation of Gas Discharge Plasma by An Arc Source With A Cold Hollow Cathode, P. M. Schanin, N. N. Koval and Yu. Kh. Akhmadeev

Încărcat de

drcodedTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

First Page Springer Generation of Gas Discharge Plasma by An Arc Source With A Cold Hollow Cathode, P. M. Schanin, N. N. Koval and Yu. Kh. Akhmadeev

Încărcat de

drcodedDrepturi de autor:

Formate disponibile

.0.......".0... ,d f..".,nm'otal [" "'Uj"'" \,,1. 4" , No. 100,1, pp. j11<---) j!. Hu.,'!"" dt",m {'ri"U" , M I.

, M I."" . f.-k' l"'n',,'o'a, No, 3, ZOO.,, pr , 6!---M

0"" ,., N.,,,i,,,, k" <"""i.'"Cl !"",' b,' Sd'''o'... A'm ol, ~."""",,,,

j,

= = = = = = = = = GENERAL EXPERI:\-tENTAL = = = = = = = = =

1F.CHXIQUES

Generation of Gas Discharge Plasma by an Arc Source

with a Cold Hollow Cathode

P. :\f. Scha nln, N. N. Km'al. a nd Yu. Kh . Akluuadeev

In,' l.il.w l' of H igh Currl'lI/. f;!e, 'l.m"ic.'. Siheri<lll Oil,;.•ion, Ru.<.<ian A"<ldl'my of SC;l'n,."".

f'~ AkodOl'kh<'Skiy V.i. 7iml.'k. 634055 Russ ill

e-mllil: .•d,,,,,i,,@op<'e.ha;,I'e.ru

Re"ei"N June 22, 2(114, in Iin_' fo rm, September 2K 2W4

Ahslrlld - The resull, fro,:" a study of a~ arc RIa,rna ,;{mrce wilh a ~"Id h"lIow cathode are presented. The

source generates plasma with a density 01 -10 0 em"- In a volume 01 -0.2 m- 'II discharge currents of up to

ISOA. an are d" eharge "po-rating vollage or J0--40 V. and a low pressure of 0.1- 1 Pa. The m" ti"n or the ,'at h"de

sp"t in rhe cm,>ed ele,tri, and magneric li.ekls inside the h"lI"w c' arhode ami the cath"de', spec'ial design make

u possible to eliminate almost completely the penetration of the Sputlered cathode material into the working

vacuum chamber.

l:-'l RO DUCTION breakdowns bet ween the cathode and anode. In addi-

tion. whe n the ho le ill the arc arre ster co nnecti ng the

At present. low-pressure sources of gas disch arge cathode and anode discha rge reg ions is large, pe ne tra-

plasma wuh a high plasma density are widely used in tion of the droplet fraction into the wor king vacuum

various technological processes: the efficiency of utili z- chamber is obse rved.

ing a source depends on bOlh the pa ramete r, of the pro-

duced pla sma and the characteristics of the disch arge Th is paper pres ents the resu lts from studies of

system. To produce plavmus lnlargc vacuum volumes. plasma sources with ho llow cathodes of different

an arc disc harge is preferred. since tr allows h igh dis- desig ns that con tainno arc arrester,

c harge currents to he attained in a co ntinuous d ischa rge

mode at low vo ltages and low pressures of the working DESIGN OF THE PLASMA SO CRCE

gas. However, in cold-cathode arc disc harges. e rosion

products of the cathode material in the form of atoms Figure I presents a ge neral sc hcmunc of a n arc dis-

and macroscopic drop lets travel from the cathode spo t charge with a ho llow ca thode. During a ll arc d ischarge

to the working reg ion. In certai n tech nolog ical pro- in crossed electric and magneti c fields. the ca thode spot

cesscs. such penetration of the cathode mat erial. es pe- initiated hy a disch arge over the dielectric surface

cially by macroscopic droplets. is impermissibl e; there- moves circularly 0 11 the inner surface of the holl ow

fore. various. so metimes complex methods for filtering cathode , Ion s and atoms o f the spu ttered ca thode mate-

rnacrodroplets ou t of plasma have been develope d I 1--4 J. rial setde un the ca thod e surfac e oppo sit e the cathode

spot. II is known [7J thatthe maximum number of mac-

In an arc discharge with a hollow cathode placed in rodroplc ts eme rge from the ca thode spot al an angle of

an a \ ial magnetic field [5. 6 J. the cathode spot operates -300 to the cathode su rface : there fore. additional mea-

inside the hollow ca thode on its SIde surface , thereby sures 10 prevent their arriva l at the hollow ca thode

considerably reducing the nu mber of mac rod roplets shou ld be taken. This is achieved primaril y due 10 the

cntermg the hollo w anode. the role of which is played directtransit of macrodroplcts from the cathode spot to

by the wall , of the wor king vac uum chamber. However, the anode cavity.

to prevent arc c losure ove r the insu lator surface to the

Based on the above. we propos ed and stud ied a

walls of the holl ow ano de in such 11 discharge system, design fu r a plasma source in whi ch the hollow cathode

an arc arreste r havi ng a floating potential is used 15J. co nsisted of two cyl indrical parts of differen t diame-

The basic features of an arc d ischarge in crossed ters. The main ca thode had a diamet er D '" 110 rnm an d

magneti c and electric fields we re cons ide red in detail In a leng th L '" 200 rnm. while the diame ter d '" SO mm of

[6J. As was show n in tests , when this system ope rates the addi tional ca thode connec ted to the main one was

for a lo ng lime. there is ther mal damage to the organic- equa l 10 the diameter of the arc arrester ho le. Thi s

dielectric surface tha t insula tes the cathode from the allowed us 10compare the penetration o f microdroplets

hollo w anode . due to plasma penetrating into the gap into the anode cavity in different arrangements. The

bel ween the hollow cathode and the arc arrester. When lengt h of the additional hollow cathode was selected

a ceramic dielectric is used, it gets dusty wi th the ero- experimentally on the basis of the conditions for stable

sion products of the ho llow catbodc : this ca n lead 10 disch arge initiation and maintenanc e and the genera-

(1t20-4412!0514S(13 -032S © 2(1)5 Pleiades Pohlishing. tIK.

S-ar putea să vă placă și

- 1997 Goldby AIP 气体凝聚源用于团簇的制造和沉积Document9 pagini1997 Goldby AIP 气体凝聚源用于团簇的制造和沉积1592162022Încă nu există evaluări

- DC PlasmaDocument10 paginiDC PlasmaiyengarnrÎncă nu există evaluări

- RCA Radiotron Manual - R10Document87 paginiRCA Radiotron Manual - R10TheAncientOne100% (1)

- Nanocrystalline Zinc-Oxide-Embedded Zirconium-Doped Hafnium Oxide For Nonvolatile MemoriesDocument4 paginiNanocrystalline Zinc-Oxide-Embedded Zirconium-Doped Hafnium Oxide For Nonvolatile MemoriesAmir HayatÎncă nu există evaluări

- Groovy ICP ETCHER SST G Vinogradov - Apr05Document7 paginiGroovy ICP ETCHER SST G Vinogradov - Apr05Peter-sagami100% (1)

- Plasma-Induced Evolution Behavior of Space-Charge-Limited Current For Multiple-Needle CathodesDocument9 paginiPlasma-Induced Evolution Behavior of Space-Charge-Limited Current For Multiple-Needle CathodesSriÎncă nu există evaluări

- 1981 A High Output Neutron Tube Using An Occluded Gas Ion SourceDocument4 pagini1981 A High Output Neutron Tube Using An Occluded Gas Ion SourceJose SantosÎncă nu există evaluări

- Structured Silicon Anodes For Lithium Battery ApplicationsDocument5 paginiStructured Silicon Anodes For Lithium Battery ApplicationsRafaelÎncă nu există evaluări

- Anode 2Document4 paginiAnode 2Nega AlemayehuÎncă nu există evaluări

- Aug.27, 146 I A 2. F 2,212,845: ... Cross Reference Search RgoDocument5 paginiAug.27, 146 I A 2. F 2,212,845: ... Cross Reference Search RgoJorton Moreira de OliveriaÎncă nu există evaluări

- Zun Nanostencil 2002 ApplPhysLett 81 2202Document3 paginiZun Nanostencil 2002 ApplPhysLett 81 2202Paul SotoÎncă nu există evaluări

- Advances and Future Prospects in Copper ElectrowinningDocument17 paginiAdvances and Future Prospects in Copper ElectrowinningBaraa ShalanÎncă nu există evaluări

- 2005-JES-Etch Characteristics of Al2O3 in ICP and MERIE Plasma EtchersDocument6 pagini2005-JES-Etch Characteristics of Al2O3 in ICP and MERIE Plasma EtchersDr_spIInÎncă nu există evaluări

- X-Ray Diffraction Studies of Catalysts: It Is Now PossibleDocument6 paginiX-Ray Diffraction Studies of Catalysts: It Is Now PossibleIsadora PereiraÎncă nu există evaluări

- Introduction To Plasma ModuleDocument42 paginiIntroduction To Plasma ModuleRanjithPerumalÎncă nu există evaluări

- Potential and Current Requirements For The Cathodic Protection of Steel in SoilsDocument9 paginiPotential and Current Requirements For The Cathodic Protection of Steel in SoilsbountymaniÎncă nu există evaluări

- Microfabrication of DC Microarcjets With UV Lasers - 2007 - Thin Solid FilmsDocument6 paginiMicrofabrication of DC Microarcjets With UV Lasers - 2007 - Thin Solid FilmsShivaNatarajÎncă nu există evaluări

- Lecture 22 Thinfilm Deposition-Sputteringr 9 PDFDocument6 paginiLecture 22 Thinfilm Deposition-Sputteringr 9 PDFu11ee079Încă nu există evaluări

- Fluorination Mechanisms of Al 2 O 3 and Y 2 O 3 Surfaces Irradiated by High-Density C F 4 O 2 and S F 6 O 2 PlasmasDocument6 paginiFluorination Mechanisms of Al 2 O 3 and Y 2 O 3 Surfaces Irradiated by High-Density C F 4 O 2 and S F 6 O 2 PlasmasbitasseomnamÎncă nu există evaluări

- Dewatering Coal Washery Tailing Ponds by ElectroosmosisDocument7 paginiDewatering Coal Washery Tailing Ponds by ElectroosmosisLydia DarmiyantiÎncă nu există evaluări

- 1999 The Behavior of Vacuum Arc DischargesDocument7 pagini1999 The Behavior of Vacuum Arc DischargesJose SantosÎncă nu există evaluări

- Taylor & Francis, LTD., International Institute For Conservation of Historic and Artistic Works Studies in ConservationDocument10 paginiTaylor & Francis, LTD., International Institute For Conservation of Historic and Artistic Works Studies in Conservationdiego ortegaÎncă nu există evaluări

- Effect of ElectrodeDocument7 paginiEffect of ElectrodePho ThingyanÎncă nu există evaluări

- The Haring-Blum Cell: Transactions of The IMFDocument4 paginiThe Haring-Blum Cell: Transactions of The IMFwera RoncaglioloÎncă nu există evaluări

- Atomic Hydrogen Radial Flux Dependence On Plasma Parameters in TextorDocument5 paginiAtomic Hydrogen Radial Flux Dependence On Plasma Parameters in TextorasdfÎncă nu există evaluări

- Corrosion CondenserDocument2 paginiCorrosion CondenserrobinÎncă nu există evaluări

- Numerical Simulation of Ne-Like Ar Plasma DynamicsDocument8 paginiNumerical Simulation of Ne-Like Ar Plasma Dynamicsmaytco84Încă nu există evaluări

- VLSI Ut1Document16 paginiVLSI Ut1Naveen TimmarioÎncă nu există evaluări

- Realistic Guide To OscilloscopesDocument100 paginiRealistic Guide To Oscilloscopesxigajoj513Încă nu există evaluări

- Direct Liquid Injection Metallorganic Chemical Vapor Deposition of Zro Thin Films Using ZR As A Novel PrecursorDocument5 paginiDirect Liquid Injection Metallorganic Chemical Vapor Deposition of Zro Thin Films Using ZR As A Novel PrecursorRe MoÎncă nu există evaluări

- Chapter 9 Thin Film Deposition: 7. Introduction To Sputtering and DC PlasmaDocument41 paginiChapter 9 Thin Film Deposition: 7. Introduction To Sputtering and DC PlasmaRaj TokasÎncă nu există evaluări

- An Oxygen Microsensor With A Guard Cathode, Revsbech, Niels PeterDocument5 paginiAn Oxygen Microsensor With A Guard Cathode, Revsbech, Niels PeterderyhermawanÎncă nu există evaluări

- Electrical Properties of Thinfilm Structures Formed by Pulsed Laser Deposition of Au, Ag, Cu, PD, PT, W, ZR Metals OnDocument7 paginiElectrical Properties of Thinfilm Structures Formed by Pulsed Laser Deposition of Au, Ag, Cu, PD, PT, W, ZR Metals OnwuasamomÎncă nu există evaluări

- 10.1103 PhysRevAccelBeams.20.033502Document7 pagini10.1103 PhysRevAccelBeams.20.033502Bilal AhmedÎncă nu există evaluări

- Plata Cong Rafi ToDocument4 paginiPlata Cong Rafi ToguiburÎncă nu există evaluări

- 1 5051757Document8 pagini1 5051757eze_firmatenseÎncă nu există evaluări

- V A Riaby 2010 J. Phys. Conf. Ser. 223 012007Document6 paginiV A Riaby 2010 J. Phys. Conf. Ser. 223 012007safÎncă nu există evaluări

- Zn-graficas-bonitas-Mahon Et Al-2014-The Canadian Journal of Chemical EngineeringDocument10 paginiZn-graficas-bonitas-Mahon Et Al-2014-The Canadian Journal of Chemical EngineeringEder RysÎncă nu există evaluări

- SSM ECE Engineering Chemistry Assignment 2Document6 paginiSSM ECE Engineering Chemistry Assignment 2knowledge2intelligenceÎncă nu există evaluări

- Multi-Jet Atmospheric Glow Plasma For PCB Desmear ProcessDocument1 paginăMulti-Jet Atmospheric Glow Plasma For PCB Desmear Processvashisht druvaÎncă nu există evaluări

- Principle of Thin Film DepositionDocument41 paginiPrinciple of Thin Film DepositionAyesha SiddikaÎncă nu există evaluări

- Ulcreforr.: AnsmacrDocument4 paginiUlcreforr.: AnsmacrarcÎncă nu există evaluări

- 1 s2.0 S0042207X06001886 MainDocument4 pagini1 s2.0 S0042207X06001886 MainNatanael GomesÎncă nu există evaluări

- Basics of Vaccume and SputtringDocument87 paginiBasics of Vaccume and SputtringlavÎncă nu există evaluări

- D Sonnenberg 16Document5 paginiD Sonnenberg 16Houssem MekniÎncă nu există evaluări

- J Ijhydene 2004 01 009Document9 paginiJ Ijhydene 2004 01 009AKASH PRAVIN JOSE JÎncă nu există evaluări

- A High-Current, High Speed Electron Beam Lithography Column - J Kelly Et Al, J Vac Sci Technol, 19 (4), 1981, 936-940 (Vacuum, Vol. 35, Issue 6) (1985)Document1 paginăA High-Current, High Speed Electron Beam Lithography Column - J Kelly Et Al, J Vac Sci Technol, 19 (4), 1981, 936-940 (Vacuum, Vol. 35, Issue 6) (1985)nevinkoshyÎncă nu există evaluări

- Development of Split Gliding Arc For Surface Treatment of Conductive MaterialDocument6 paginiDevelopment of Split Gliding Arc For Surface Treatment of Conductive MaterialSalah MostafapourÎncă nu există evaluări

- Paper: Hot Electron and Hole Dynamics in Thiol-Capped Cdse Quantum Dots Revealed by 2D Electronic SpectroscopyDocument6 paginiPaper: Hot Electron and Hole Dynamics in Thiol-Capped Cdse Quantum Dots Revealed by 2D Electronic Spectroscopye_mmshÎncă nu există evaluări

- 10 1016@j MSSP 2020 105553Document9 pagini10 1016@j MSSP 2020 105553Lokesh LokuÎncă nu există evaluări

- Slinker 2005 New J. Phys. 7 246Document9 paginiSlinker 2005 New J. Phys. 7 246rajkumarÎncă nu există evaluări

- Nanotecnologia ArticuloDocument4 paginiNanotecnologia ArticuloAndresÎncă nu există evaluări

- Electrochemical Formation and Reduction of Copper Oxide NanostructuresDocument4 paginiElectrochemical Formation and Reduction of Copper Oxide NanostructuresEdgar Fabian Pinzon NietoÎncă nu există evaluări

- Welding QC 10 - TIGDocument9 paginiWelding QC 10 - TIGExsan OthmanÎncă nu există evaluări

- Hodgkin Katz 1949Document41 paginiHodgkin Katz 1949María Celeste Sánchez SugíaÎncă nu există evaluări

- J. Electrochem. Soc.-1952-Booe-197C-200CDocument4 paginiJ. Electrochem. Soc.-1952-Booe-197C-200CGeovanny JaenzÎncă nu există evaluări

- Pumps, Channels and Transporters: Methods of Functional AnalysisDe la EverandPumps, Channels and Transporters: Methods of Functional AnalysisÎncă nu există evaluări

- Induction Coils - How To Make, Use, And Repair Them: Including Ruhmkorff, Tesla, And Medical Coils, Roentgen, Radiography, Wireless Telegraphy, And Practical Information On Primary And Secodary BatteryDe la EverandInduction Coils - How To Make, Use, And Repair Them: Including Ruhmkorff, Tesla, And Medical Coils, Roentgen, Radiography, Wireless Telegraphy, And Practical Information On Primary And Secodary BatteryEvaluare: 5 din 5 stele5/5 (2)

- COUNTERPUNCH Version Sufism in The ServiDocument10 paginiCOUNTERPUNCH Version Sufism in The ServidrcodedÎncă nu există evaluări

- Curing Agents For Epoxy ResinDocument10 paginiCuring Agents For Epoxy ResindrcodedÎncă nu există evaluări

- Testing Tri-State and Pass Transistor Circuit Structures: A Thesis by Shaishav ParikhDocument50 paginiTesting Tri-State and Pass Transistor Circuit Structures: A Thesis by Shaishav ParikhdrcodedÎncă nu există evaluări

- Results of An Informal Survey On The Use of Linear Algebra in Industry and Government, Stephen L Campbell, Carl D Meyer JR, Nicholas J Rose, Linear Algebra and Its Applications v38n (1981) Pp289-94Document6 paginiResults of An Informal Survey On The Use of Linear Algebra in Industry and Government, Stephen L Campbell, Carl D Meyer JR, Nicholas J Rose, Linear Algebra and Its Applications v38n (1981) Pp289-94drcodedÎncă nu există evaluări

- Read Morphisms and Categories: Comparing and Transforming (Jean Piaget) PDF FreeDocument6 paginiRead Morphisms and Categories: Comparing and Transforming (Jean Piaget) PDF FreedrcodedÎncă nu există evaluări

- Privatization and State Action: Do Campus Sexual Assault Hearings Violate Due Process?Document55 paginiPrivatization and State Action: Do Campus Sexual Assault Hearings Violate Due Process?drcodedÎncă nu există evaluări

- Crime Scene ReconstructionDocument27 paginiCrime Scene ReconstructionIta MaghfirahÎncă nu există evaluări

- Trump-Kim Jong Fusion, 18157444 - 10154600998702602 - 8035629931418404296 - NDocument1 paginăTrump-Kim Jong Fusion, 18157444 - 10154600998702602 - 8035629931418404296 - NdrcodedÎncă nu există evaluări

- Performance of Three-Lobe Pressure-Dam BearingsDocument8 paginiPerformance of Three-Lobe Pressure-Dam BearingsdrcodedÎncă nu există evaluări

- Prolog Shoot Sheet: FactsDocument2 paginiProlog Shoot Sheet: FactsdrcodedÎncă nu există evaluări

- Ball Lightning: My ExperienceDocument5 paginiBall Lightning: My ExperiencedrcodedÎncă nu există evaluări

- Corrosion Protection in Steel StructureDocument28 paginiCorrosion Protection in Steel StructurePrantik Adhar Samanta100% (2)

- Compressed Marko Rodin Tesla Tech Article June 14th 2010Document10 paginiCompressed Marko Rodin Tesla Tech Article June 14th 2010Barbharium80% (5)

- A Certain SIAM ReviewDocument7 paginiA Certain SIAM ReviewdrcodedÎncă nu există evaluări

- Glass Ceramic Composition, IPCOM000073080DDocument2 paginiGlass Ceramic Composition, IPCOM000073080DdrcodedÎncă nu există evaluări

- Chapter 10Document28 paginiChapter 10drcodedÎncă nu există evaluări

- Peter Dorato, 1334Document5 paginiPeter Dorato, 1334drcodedÎncă nu există evaluări

- Appendix 02 Multivariate Normal DistributionDocument13 paginiAppendix 02 Multivariate Normal DistributionJorge GonzaÎncă nu există evaluări

- Bio IngDocument29 paginiBio Ingsudipta88Încă nu există evaluări

- Peter Dorato, 1334Document5 paginiPeter Dorato, 1334drcodedÎncă nu există evaluări

- Ohtani Pub WebDocument29 paginiOhtani Pub WebdrcodedÎncă nu există evaluări

- Organometallic Chemistry: Compounds That Contain M-C BondsDocument29 paginiOrganometallic Chemistry: Compounds That Contain M-C BondsdrcodedÎncă nu există evaluări

- The Point of No Return: by Jeffrey Goldberg (The Atlantic Magazine, September 2010)Document18 paginiThe Point of No Return: by Jeffrey Goldberg (The Atlantic Magazine, September 2010)drcodedÎncă nu există evaluări

- Schedule of Loads PDFDocument5 paginiSchedule of Loads PDFmae_morano81% (27)

- 4-LET - General Education - SCIENCE 82-109Document28 pagini4-LET - General Education - SCIENCE 82-109Rogen Hemodo67% (6)

- 20146501.pdf Ga75vsdDocument34 pagini20146501.pdf Ga75vsdCHATEAUVIEUX Patrick100% (1)

- Harris - AN-PRC150 HF-VHF Combat Radio - Instruction ManualDocument49 paginiHarris - AN-PRC150 HF-VHF Combat Radio - Instruction ManualAbhinav Ashok ChandelÎncă nu există evaluări

- 2 Stroke Diesel Engine Components-1Document72 pagini2 Stroke Diesel Engine Components-1EdemÎncă nu există evaluări

- CNG Gas Station GSPCDocument9 paginiCNG Gas Station GSPCMilan KothariÎncă nu există evaluări

- Measuring The Pour Point of Crude Oils: Manual MethodDocument1 paginăMeasuring The Pour Point of Crude Oils: Manual MethodSamuel OlonadeÎncă nu există evaluări

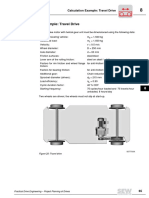

- Travel Drive ExampleDocument10 paginiTravel Drive Examplep-nicoÎncă nu există evaluări

- Chapter 11 - Valves and Actuators With The NAMUR-InterfaceDocument13 paginiChapter 11 - Valves and Actuators With The NAMUR-InterfaceJoseph MagonduÎncă nu există evaluări

- Selector Guide-No Price HysterDocument54 paginiSelector Guide-No Price Hysterrikrdo827296Încă nu există evaluări

- Evolution Spas Manual ENG-19 PDFDocument44 paginiEvolution Spas Manual ENG-19 PDFAnonymous 0aFzcZ100% (1)

- Climbing Film EvaporatorDocument8 paginiClimbing Film Evaporatorsaz140% (1)

- Outline of Air Pollution DispersionDocument32 paginiOutline of Air Pollution DispersionWellfroÎncă nu există evaluări

- Alkylation PDFDocument7 paginiAlkylation PDFVasthadu Vasu Khanan DLÎncă nu există evaluări

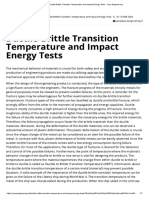

- Ductile-Brittle Transition Temperature and Impact Energy Tests - Yena EngineeringDocument7 paginiDuctile-Brittle Transition Temperature and Impact Energy Tests - Yena EngineeringKASHFI UDDINÎncă nu există evaluări

- Electricity & MagnetismDocument39 paginiElectricity & MagnetismAditya KumarÎncă nu există evaluări

- IEEE 1547 - Explicacion PDFDocument11 paginiIEEE 1547 - Explicacion PDFAlejandro Gil RestrepoÎncă nu există evaluări

- Sustainable Development-Chapter 6Document25 paginiSustainable Development-Chapter 6Lesley GallaÎncă nu există evaluări

- Bazam Company ProfileDocument30 paginiBazam Company ProfileIbrahimrashid Billow HusseinÎncă nu există evaluări

- 825 Series 190CC Motor BriggsDocument27 pagini825 Series 190CC Motor BriggsCTRL ENGENHARIA E MANUTENÇÃO ComprasÎncă nu există evaluări

- Johnson Controls v. Kreuter - ComplaintDocument267 paginiJohnson Controls v. Kreuter - ComplaintSarah BursteinÎncă nu există evaluări

- Lam 101-11Document240 paginiLam 101-11mrcdtsÎncă nu există evaluări

- Ansi C37.32-1996Document42 paginiAnsi C37.32-1996amitdhamijaÎncă nu există evaluări

- 70627-Fault Codes Identification StandardDocument26 pagini70627-Fault Codes Identification StandardNovie Rizky71% (7)

- Cruise Control, CVT and Shift Indicator, Engine ControlDocument27 paginiCruise Control, CVT and Shift Indicator, Engine ControlRicardoÎncă nu există evaluări

- 09 MaschinenfabrikReinhausen On LoadTap ChangerDocument28 pagini09 MaschinenfabrikReinhausen On LoadTap Changerhardian syaputraÎncă nu există evaluări

- EN ASFA AU Koplík UV - VIS - Spectrometry PDFDocument12 paginiEN ASFA AU Koplík UV - VIS - Spectrometry PDFJonathanPolaniaOsorioÎncă nu există evaluări

- Eurocode 8-1-3Document18 paginiEurocode 8-1-3joaoÎncă nu există evaluări

- Vijay Singh CVDocument2 paginiVijay Singh CVVijay ChauhanÎncă nu există evaluări

- Start Practice Exam Test Questions Part 1 of The SeriesDocument155 paginiStart Practice Exam Test Questions Part 1 of The SeriesNida Bagoyboy NatichoÎncă nu există evaluări