Documente Academic

Documente Profesional

Documente Cultură

Exhaust and Jacket Water Heat Recovery From Generator

Încărcat de

Muhammad Abdul SamadDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Exhaust and Jacket Water Heat Recovery From Generator

Încărcat de

Muhammad Abdul SamadDrepturi de autor:

Formate disponibile

Annexure - III (B)

Project :

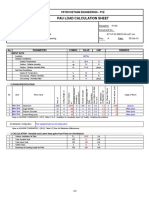

POWER GENERATION GAS CONSUMPTION

A GENRATOR'S GAS CONSUMPTION.

Equipment Rating QTY Gas Req. in Gas Req. in Gas Req. in Gas Req. in Gas Req. in

KW Nos. KW/H BTU/HR FT3/HR MCF/HR MMBtu/HR

GAS GENERATORS 900 KW 2 5584 19,053,399 22682.6177127048 22.6826177127048 19.05

Waukesha,

Genrators, Model no VHP5904LTD (900KW)

Equipment Rating QTY Gas Req. in Gas Req. in Gas Req. in Gas Req. in Gas Req. in

KW Nos. KW/H BTU/HR FT3/HR MCF/HR MMBtu/HR

GAS GENERATORS 625 KW 1 1794 6,121,382 7287.35963047857 7.28735963047857 6.92

Waukesha,

Genrators, Model no VGF48GL/GLD (625 KW)

Power Genration Gas Requirment (Includes safe side if increse in future 15 % safty.) 34 MCF/HR

file:///conversion/tmp/scratch/56250532.xls S. MEHBOOB & COMPANY

56250532.xls Consulting Engineers

Annexure - I (A)

Project :

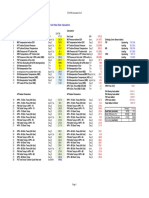

EXHAUST ENERGY RECOVERY FROM GENERATOR # 01

Generator Model #

RECOVERABLE ENERGY FOR COOLING (UTILIZING WHRB)

Generator Exhaust Temperature (T1) = 470 ºC 878 ºF

Mass flow rate of waste gas= 1.5611111 Kg/ Sec 5620 Kg/ hr

Final Boiler Stack Temperature (T2) = 150 ºC 302 ºF

RECOVERABLE HEAT = m x c X ΔT

RECOVERABLE HEAT = lbs/ hr x Constant X ( T1 - T2 )

2 1.17 X ( 470 - 150 )

RECOVERABLE HEAT = 1.8265 X ( 320 ) = 584 Kw/HR

1994329 Btu/ hr

Standard Boiler Efficency 80% and 2 % system loses = 456 Kw/HR

Steam Prodution Analysis-- 2

Heat energy available Q= 456 KWt

Required Steam Pressure 8 bar Hg = 2769 KJ/Kg

Temperature of feed water 85 Deg C Hf = 355.91 KJ/Kg

Enthalpy Difference Hfg 2413.09

STEAM GENERATED M 0.19 Kg/s

STEAM GENERATED M 680.13 Kg/h

Cooling Available (i.e 4.4 Kg/ hr Steam required to produce 1 TR refer Chiller Catlaugue) = 154.58 TR

Ruppees Saving per Hour

Heat Energy avilable 455.89 KWt

Heat Energy available in Btu 1.56 MMBtu

Gas GCV 950 Btu/ft3

Gas fuel flow rate 1,637.38 ft3/hr

Gas Fuel rate from SSGC 308 Rs./MMBtu

Fuel cost to produce 680 Kg/h steam at 479.10 Rs./hr

file:///conversion/tmp/scratch/56250532.xls S. MEHBOOB & COMPANY

56250532.xls Consulting Engineers

Annexure - I (B)

Project :

EXHAUST ENERGY RECOVERY FROM GENERATOR # 02

Generator Model #

RECOVERABLE ENERGY FOR COOLING (UTILIZING WHRB)

Generator Exhaust Temperature (T1) = 431 ºC 807.8 ºF

Mass flow rate of waste gas= 0.9941667 Kg/ Sec 3579 Kg/ hr

Final Boiler Stack Temperature (T2) = 150 ºC 302 ºF

RECOVERABLE HEAT = m x c X ΔT

RECOVERABLE HEAT = Kg/sec x KJ/Kg X ( ºC - ºC )

1 1.17 X ( 431 - 150 )

RECOVERABLE HEAT = 1.163175 X ( 281 ) = 327 KW

1115266 Btu/ hr

Standard Boiler Efficency 80% and 2 % system loses = 255 KW

Steam Prodution Analysis-- 2

Heat energy available Q= 254.94 kW

Required Steam Pressure 8 bar Hg = 2769 KJ/Kg

Temperature of feed water 85 Deg C Hf = 355.91 KJ/Kg

Enthalpy Difference Hfg 2413.09

STEAM GENERATED M 0.11 Kg/s

STEAM GENERATED M 380.34 Kg/h

Cooling Available (i.e 4.4 Kg/ hr Steam required to produce 1 TR refer Chiller Catlaugue) = 86.44 TR

Ruppees Saving per Hour

Heat Energy avilable 254.94 KWt

Heat Energy available in Btu 0.87 MMBtu

Gas GCV 950 Btu/ft3

Gas fuel flow rate 915.65 ft3/hr

Gas Fuel rate from SSGC 308 Rs./MMBtu

Fuel cost to produce 380 Kg/h steam at 267.92 Rs./hr

file:///conversion/tmp/scratch/56250532.xls S. MEHBOOB & COMPANY

56250532.xls Consulting Engineers

Annexure - II (A)

Project :

JACKET WATER ENERGY RECOVERY FROM GENERATOR # 01

Calculation for Volume flow rate

Engine Load % JGS 420 100 %

Input data

Heat dissipation from J/W 673 KWt

Heat dissipation from lube oil [ LT Circuit ] * 424 KWt

High temp intercooler. 475 KWt

Total heat 1572.00 KWt

Recoverable heat 673.00 KWt

Energy Available 538.40 KWt

D = Density of water 0.98 Kg/Lit.

Cp = Specific heat of water 0.071 Kw min/Kg K

Outlet Temp from heat HX, T 1 95 Deg. C

Inlet temp to HX, T 2 80 Deg. C

Delta T = 15 Deg. C

Output data

Where V = Water flow rate in Lit./min

V= 515.857047 Lit./min 136.27501486 gpm

or

Total water flow required 30.95 m3/hr.

RECOVERABLE ENERGY FOR COOLING (UTILIZING WHRB)

Heat to be reject = 538.40 Kw

Generator Exhaust Temperature = T1 = 95 ºc

Mass flow rate of waste gas = ? Kg/hr

Final Boiler Stack Temperature = T2 = 80 ºc

RECOVERABLE HEAT = m x c X ΔT

RECOVERABLE HEAT = lbs/hr x Constant X ( T1 - T2 )

538.4 = ? 4.2 X ( 95 - 80 )

538.4 538.4

Mass Flow Rate = = = = 8.546 Kg/Sec

4.2 x 15 63

30765.7142857143

Mass Flow Rate = =

1000

= 31 Ton/hr

Which corresponds to (Refer Annexure X i.e LG HW Chiller Catalugue for tonage available) 109.87755 Tons

Fuel cost to produce steam

Heat Energy avilable 538.40 KWt

Heat Energy available in Btu 1.84 MMBtu

Gas GCV 950 Btu/ft3

Gas Fuel flow rate 1,933.71 ft3/hr

Gas Fuel rate from SSGC 308 Rs./MMBtu

Fuel cost to produce 30.95 m3/h water at 565.80 Rs./hr

* Non-recoverable from L T Circuit

file:///conversion/tmp/scratch/56250532.xls S. MEHBOOB & COMPANY

56250532.xls Consulting Engineers

Annexure - II (B)

Project :

JACKET WATER ENERGY RECOVERY FROM GENERATOR # 02

Calculation for Volume flow rate

Engine Load % 100 %

Input data

Heat dissipation from J/W 497 KWt

Heat dissipation from lube oil [ LT Circuit ] * 87 KWt

High temp intercooler. 55 KWt

Total heat 639.00 KWt

Recoverable heat 497.00 KWt

Energy Available 397.60 KWt

D = Density of water 0.98 Kg/Lit.

Cp = Specific heat of water 0.071 Kw min/Kg K

Outlet Temp from heat HX, T 1 95 Deg. C

Inlet temp to HX, T 2 80 Deg. C

Delta T = 15 Deg. C

Output data

Where V = Water flow rate in Lit./min

V= 380.952381 Lit./min 100.63697234 gpm

or

Total water flow required 22.86 m3/hr.

RECOVERABLE ENERGY FOR COOLING (UTILIZING WHRB)

Heat to be reject = 397.60 Kw

Generator Exhaust Temperature = T1 = 95 ºc

Mass flow rate of waste gas = ? Kg/hr

Final Boiler Stack Temperature = T2 = 80 ºc

RECOVERABLE HEAT = m x c X ΔT

RECOVERABLE HEAT = lbs/hr x Constant X ( T1 - T2 )

397.6 = ? 4.2 X ( 95 - 80 )

397.6 397.6

Mass Flow Rate = = = = 6.3111 Kg/Sec

4.2 x 15 63

22720

Mass Flow Rate = =

1000

= 23 Ton/hr

Which corresponds to (Refer Annexure X i.e LG HW Chiller Catalugue for tonage available) 81.142857 Tons

Fuel cost to produce steam

Heat Energy avilable 397.60 KWt

238

Heat Energy available in Btu 1.36 MMBtu 190

174.8

Gas GCV 950 Btu/ft3 412.8

Gas Fuel flow rate 1,428.01 ft3/hr

Gas Fuel rate from SSGC 308 Rs./MMBtu

Fuel cost to produce 22.86 m3/h water at 417.84 Rs./hr

* Non-recoverable from L T Circuit

file:///conversion/tmp/scratch/56250532.xls S. MEHBOOB & COMPANY

56250532.xls Consulting Engineers

Annexure - IV (A)

Project :

ENERGY RECOVERY FROM GENERATOR # 01

Electrical Output = Rating @ P.F. .8 = 900 Kw

Thermal Output = From Exhaust Recoverable + From Jacket Water Recoverable

Thermal Output = 455.89 + 538.40

Electrial Output + Thermal Output

Overall Efficiency (ή) =

Energy Input

900 + 994.29 1894.29

Overall Efficiency (ή) = = = 67.847 %

2792 2792

Overall Efficiency (ή) = 67.847221 %

Power to Heat Ratio

POWER : HEAT

900 : 994.29

1 : 1.10477155555556

Heat to Power Ratio

HEAT : RATIO

994.29 : 900

1 : 1.6

file:///conversion/tmp/scratch/56250532.xls S. MEHBOOB & COMPANY

56250532.xls Consulting Engineers

Annexure - IV (B)

Project :

ENERGY RECOVERY FROM GENERATOR # 02

Electrical Output = Rating @ P.F. .8 = 625 Kw

Thermal Output = From Exhaust Recoverable + From Jacket Water Recoverable

Thermal Output = 254.94 + 397.60

Electrial Output + Thermal Output

Overall Efficiency (ή) =

Energy Input

625 + 652.54 1277.54

Overall Efficiency (ή) = = = 71.212 %

1794 1794

Overall Efficiency (ή) = 71.212079 %

Power to Heat Ratio

POWER : HEAT

625 : 652.54

1 : 1.0440715144

Heat to Power Ratio

HEAT : RATIO

652.54 : 625

1 : 1.6

file:///conversion/tmp/scratch/56250532.xls S. MEHBOOB & COMPANY

56250532.xls Consulting Engineers

Annexure - IV

Project :

TOTAL ENERGY RECOVERY FROM GENERATORS

Electrical Output = Rating @ P.F. .8 = 1525 Kw

Thermal Output = From Exhaust Recovery + From Jacket Water Recovery

Thermal Output = 710.84 + 935.00

Thermal Output = 15.50% + 20.39%

Electrial Output + Thermal Output

Overall Efficiency (ή) =

Energy Input

1525.00 + 1645.84 3170.84

Overall Efficiency (ή) = = = 69.142 %

4586 4586

Overall Efficiency (ή) = 69.141716 %

Power to Heat Ratio

POWER : HEAT

1525 : 1645.84

1 : 1.07923875180328

Heat to Power Ratio

HEAT : RATIO

1645.84 : 1525

1 : 1.6

file:///conversion/tmp/scratch/56250532.xls S. MEHBOOB & COMPANY

56250532.xls Consulting Engineers

S-ar putea să vă placă și

- 1.5 NPS RecuperatorDocument7 pagini1.5 NPS RecuperatorAnonymous pVoSWn8yh0Încă nu există evaluări

- Instructions Natural Gas Boiler Calculations: AcknowledgementsDocument17 paginiInstructions Natural Gas Boiler Calculations: AcknowledgementsDavid Muñoz CastroÎncă nu există evaluări

- Waste Heat Recovery: AHEF.120.MD. Energy Efficiency Audit Guide For CHP and HobDocument30 paginiWaste Heat Recovery: AHEF.120.MD. Energy Efficiency Audit Guide For CHP and HobMoriyasuNguyen100% (1)

- 0 Boiler Design SoftwearDocument54 pagini0 Boiler Design SoftwearNITINÎncă nu există evaluări

- Double Pipe Heat Ex ChangerDocument2 paginiDouble Pipe Heat Ex ChangerSaqib RaoufÎncă nu există evaluări

- Header & Piping SizingDocument9 paginiHeader & Piping Sizingmedicbest0% (1)

- Boiler CalculationDocument4 paginiBoiler Calculationmohsin husen BargirÎncă nu există evaluări

- Hybrid Cooling TowerDocument12 paginiHybrid Cooling TowerANIMESH JAINÎncă nu există evaluări

- Rigours Preheater: Feed - 1694.44 2.85 21.14 792.89 0.05 0.00Document14 paginiRigours Preheater: Feed - 1694.44 2.85 21.14 792.89 0.05 0.00semarasik_651536604100% (1)

- Heat Load Cold StoreDocument17 paginiHeat Load Cold StorevishyachuÎncă nu există evaluări

- D.A.Steam Load CalculatorDocument2 paginiD.A.Steam Load CalculatorHarwi PatiÎncă nu există evaluări

- Helical Coil - With AgitationDocument3 paginiHelical Coil - With AgitationUmair FareedÎncă nu există evaluări

- Steam Coil CalculationDocument10 paginiSteam Coil CalculationRajaramÎncă nu există evaluări

- Fgas Refrigerant CalculatorDocument12 paginiFgas Refrigerant CalculatorKhadija MirajÎncă nu există evaluări

- Shell Side Fluid SteamDocument6 paginiShell Side Fluid SteamrajachemÎncă nu există evaluări

- Upl HBDSDocument32 paginiUpl HBDSSuparna BhoseÎncă nu există evaluări

- A. Process Inputs Fluid Flow Rate (Kg/hr) Density (gm/cc) Sp.Heat (Kcal/kg.°C) λ (Kcal/kg) Inlet Temperature °CDocument12 paginiA. Process Inputs Fluid Flow Rate (Kg/hr) Density (gm/cc) Sp.Heat (Kcal/kg.°C) λ (Kcal/kg) Inlet Temperature °CPrad1979100% (1)

- CH 14Document23 paginiCH 14esojsuil_tgÎncă nu există evaluări

- P&F HX - Counter Flow: Plate & Frame Heat Exchanger Sizing Waterside Economizer (Wse) FormulasDocument4 paginiP&F HX - Counter Flow: Plate & Frame Heat Exchanger Sizing Waterside Economizer (Wse) Formulasjnmanivannan100% (1)

- Calculation of Scrubber DiameterDocument44 paginiCalculation of Scrubber DiameterRamakrishna SomuÎncă nu există evaluări

- HVAC Cooling Load Estimate SheetDocument1 paginăHVAC Cooling Load Estimate SheetideepujÎncă nu există evaluări

- Shell&Tube TEMAsheet 1Document1 paginăShell&Tube TEMAsheet 1Rikiya FebriyanÎncă nu există evaluări

- Energy BalanceDocument11 paginiEnergy BalanceBharat VaajÎncă nu există evaluări

- C3CYCLVDocument13 paginiC3CYCLVUok RitchieÎncă nu există evaluări

- Gas Properties, Flowrate and Conditions: Reciprocating Compressor Calculation SheetDocument5 paginiGas Properties, Flowrate and Conditions: Reciprocating Compressor Calculation SheetNaqqash Sajid0% (2)

- Sizing of Steam Coil of Insulated Tank Rev 3 PDFDocument2 paginiSizing of Steam Coil of Insulated Tank Rev 3 PDFdhavalesh1Încă nu există evaluări

- Load CalculationDocument10 paginiLoad CalculationalbertooooooÎncă nu există evaluări

- Hot Air Generator Cost SheetDocument4 paginiHot Air Generator Cost Sheetrat12345Încă nu există evaluări

- Dehumidification 1Document24 paginiDehumidification 1Praveenkumar KashyabÎncă nu există evaluări

- Shellmax Boiler Design CalculationDocument2 paginiShellmax Boiler Design Calculationrahult19Încă nu există evaluări

- Double FdexchangerDocument8 paginiDouble FdexchangerBoško IvanovićÎncă nu există evaluări

- Perhitungan Dan Disain HeaterDocument19 paginiPerhitungan Dan Disain HeatersehonoÎncă nu există evaluări

- Dearator Calculations Book1 Rev1Document8 paginiDearator Calculations Book1 Rev1MechanicalVee18Încă nu există evaluări

- Final Ventury Working For Wet Alkaline ScrubberDocument11 paginiFinal Ventury Working For Wet Alkaline ScrubberNanasaheb JagtapÎncă nu există evaluări

- PAU Calculation Sheet Vr.0Document1 paginăPAU Calculation Sheet Vr.0Arshavin Watashi Wa100% (1)

- Coal CombustionDocument3 paginiCoal CombustionRahul ChandrawarÎncă nu există evaluări

- Sizing For Vaporiser/Flash Vessel: InputsDocument3 paginiSizing For Vaporiser/Flash Vessel: InputsSaravana ChandranÎncă nu există evaluări

- Batch Time Calculation For Isothermal Cooling in Internal Coil Vessel With AgitationDocument2 paginiBatch Time Calculation For Isothermal Cooling in Internal Coil Vessel With Agitationdhavalesh1100% (1)

- Determination and Correlation of Heat Transfer Coefficients in A Falling Film Evaporator PDFDocument7 paginiDetermination and Correlation of Heat Transfer Coefficients in A Falling Film Evaporator PDFGonzaloÎncă nu există evaluări

- Economizer Design CalculationsDocument4 paginiEconomizer Design CalculationsDaniyal HashmiÎncă nu există evaluări

- Calculation of Heat and Mass BalanceDocument18 paginiCalculation of Heat and Mass BalanceJitendra Bhatia100% (3)

- Evaporator DesignDocument1 paginăEvaporator DesignNaqqash SajidÎncă nu există evaluări

- Heat Exchanger AnalysisDocument1 paginăHeat Exchanger AnalysishuangjlÎncă nu există evaluări

- 302 ProjectDocument35 pagini302 Projectredpanda193Încă nu există evaluări

- BoilerDocument29 paginiBoilerhonchoabhiÎncă nu există evaluări

- FUELSDocument15 paginiFUELSJohn Archie MendozaÎncă nu există evaluări

- Calciner Op Ex CalculationDocument9 paginiCalciner Op Ex CalculationNair YadukrishnanÎncă nu există evaluări

- Savings From Surface Condenser Usage Instead of Venting The SteamDocument9 paginiSavings From Surface Condenser Usage Instead of Venting The SteamManoj BÎncă nu există evaluări

- Steam Calculation On Basis of Flow-Temperature (1) 2222Document5 paginiSteam Calculation On Basis of Flow-Temperature (1) 2222hmaza shakeelÎncă nu există evaluări

- Ael-2597-Mec-Cl-0305-R0 - Design Calculation of Heating CoilDocument2 paginiAel-2597-Mec-Cl-0305-R0 - Design Calculation of Heating CoilbecpavanÎncă nu există evaluări

- 10.dowtherm A Util He 1xDocument47 pagini10.dowtherm A Util He 1xRafi Theda PrabawaÎncă nu există evaluări

- Steam Turbine CalculationDocument1 paginăSteam Turbine CalculationYYON KYNN KOHÎncă nu există evaluări

- Gps Waukesha 7042 BrochureDocument2 paginiGps Waukesha 7042 BrochureAlan SantosÎncă nu există evaluări

- Thermal Design - 2 Effect Forward-Feed Evaporator Nama Aristya Kurniawan NIM 114 152 5005 Design BasisDocument4 paginiThermal Design - 2 Effect Forward-Feed Evaporator Nama Aristya Kurniawan NIM 114 152 5005 Design BasisAristya KurniawanÎncă nu există evaluări

- GTCGR & Boiler Efficiciency During Trial Opn Tanda U#5Document1 paginăGTCGR & Boiler Efficiciency During Trial Opn Tanda U#5om prakash pathakÎncă nu există evaluări

- Lampiran 2 Perhitungan Tugas Khusus 2Document7 paginiLampiran 2 Perhitungan Tugas Khusus 2Ainan AziziÎncă nu există evaluări

- Circulation Heaters Engineering InformationDocument3 paginiCirculation Heaters Engineering InformationWaqasÎncă nu există evaluări

- Formulas Card Back PDFDocument1 paginăFormulas Card Back PDFHaryÎncă nu există evaluări

- Effect of Primary Reformer Steam To Carbon Ratio On Ammonia Plant EfficiencyDocument2 paginiEffect of Primary Reformer Steam To Carbon Ratio On Ammonia Plant EfficiencyManish GautamÎncă nu există evaluări

- 08Document11 pagini08Muhammad Abdul SamadÎncă nu există evaluări

- Net Positive Suction Head or NPSHDocument4 paginiNet Positive Suction Head or NPSHsateesh chandÎncă nu există evaluări

- Design Crieteria of HVAC System and Water CalcsDocument6 paginiDesign Crieteria of HVAC System and Water CalcsMuhammad Abdul SamadÎncă nu există evaluări

- Exp Tank SizingDocument2 paginiExp Tank SizingJoshi DhvanitÎncă nu există evaluări

- Section A (MECHANICS) - A4 (Kinematics) - Multiple Choice QuestionsDocument6 paginiSection A (MECHANICS) - A4 (Kinematics) - Multiple Choice QuestionsA.BensonÎncă nu există evaluări

- WilsonDocument51 paginiWilsonbedip20200Încă nu există evaluări

- Destilación Solar JOULEDocument16 paginiDestilación Solar JOULEClemen AlarconÎncă nu există evaluări

- Lesson 5 - Infomation SheetDocument11 paginiLesson 5 - Infomation SheetAlfie LariosaÎncă nu există evaluări

- Concept R3 AnswerDocument44 paginiConcept R3 Answershsh.shetty4456Încă nu există evaluări

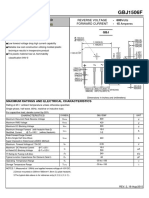

- GBJ1Document2 paginiGBJ1Ariel VicuñaÎncă nu există evaluări

- Contact ForceDocument2 paginiContact ForcejuliaÎncă nu există evaluări

- Chapter 1 Transformer 2016Document88 paginiChapter 1 Transformer 2016Duydo BuiÎncă nu există evaluări

- Answer Key For WK3-4Document9 paginiAnswer Key For WK3-4April Joy LascuñaÎncă nu există evaluări

- 7th STD Science Book in English 1st TermDocument111 pagini7th STD Science Book in English 1st TermNandagopalÎncă nu există evaluări

- W5 - Liberty Union HSD - R.SpecificHeatExtraPractice - ANSWERKEYDocument5 paginiW5 - Liberty Union HSD - R.SpecificHeatExtraPractice - ANSWERKEYMirjeta ZymeriÎncă nu există evaluări

- CH 23 FDocument24 paginiCH 23 FSaBarney StinsonÎncă nu există evaluări

- 9A23303 Fluid Flow in BioprocessesDocument4 pagini9A23303 Fluid Flow in BioprocessessivabharathamurthyÎncă nu există evaluări

- Sams8 5388 LG 32LC7DCDocument12 paginiSams8 5388 LG 32LC7DCsvctechÎncă nu există evaluări

- Science 8 Module 6Document8 paginiScience 8 Module 6Kristel TelmoÎncă nu există evaluări

- Flexible AC Transmission SystemDocument5 paginiFlexible AC Transmission SystemAliq FazliÎncă nu există evaluări

- MCQ 2Document52 paginiMCQ 2eka123Încă nu există evaluări

- 993 1295 1 PBDocument9 pagini993 1295 1 PBLaksita Widi Kusuma WardaniÎncă nu există evaluări

- DC Drive ABBDocument80 paginiDC Drive ABBAlfiansyah Dharma Setia DjaketraÎncă nu există evaluări

- Problemas de Transformadores (Ejemplos)Document13 paginiProblemas de Transformadores (Ejemplos)Brayan Alexis Perez Del RazoÎncă nu există evaluări

- 9A02305 Electrical CircuitsDocument2 pagini9A02305 Electrical CircuitssivabharathamurthyÎncă nu există evaluări

- Text v2Document102 paginiText v2David WalshÎncă nu există evaluări

- Bumper CarsDocument3 paginiBumper CarsZainul AbedinÎncă nu există evaluări

- 653f859a9063ce0018aebb0f ## M-TPDocument28 pagini653f859a9063ce0018aebb0f ## M-TPnishantkumar.im22Încă nu există evaluări

- Science 8 Q1 Week 6 7Document13 paginiScience 8 Q1 Week 6 7Rachelle Mitch R. TamparongÎncă nu există evaluări

- 4 - Engineering Mechanics 2 - SolutionsDocument10 pagini4 - Engineering Mechanics 2 - SolutionsLATIGAR, JEFFERSON 0.Încă nu există evaluări

- Trade Electrician: Syllabus Breakup DailyDocument53 paginiTrade Electrician: Syllabus Breakup Dailygaurav kumar67% (3)

- Electrical Machines II Atif Iqbal PDFDocument52 paginiElectrical Machines II Atif Iqbal PDFSantosh VarshneyÎncă nu există evaluări

- High Voltage Centre Break Disconnectors 72 5 KV Up To 245 KVDocument8 paginiHigh Voltage Centre Break Disconnectors 72 5 KV Up To 245 KVsajjad ramezanzadehÎncă nu există evaluări

- Assignment # 4 MomentsDocument9 paginiAssignment # 4 MomentsKalidÎncă nu există evaluări