Documente Academic

Documente Profesional

Documente Cultură

Penthouse Winter 1997

Încărcat de

John M. Cavote0 evaluări0% au considerat acest document util (0 voturi)

40 vizualizări2 paginiFly ash should be "cold enoughff" as it enters the superheater and reheater. A change in fuel, especially to one with a lower ash-fusion temperature, can lead to slag and clinker formations. The use of shotguns is a frequent method for destruction of clinkers.

Descriere originală:

Drepturi de autor

© Attribution Non-Commercial (BY-NC)

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentFly ash should be "cold enoughff" as it enters the superheater and reheater. A change in fuel, especially to one with a lower ash-fusion temperature, can lead to slag and clinker formations. The use of shotguns is a frequent method for destruction of clinkers.

Drepturi de autor:

Attribution Non-Commercial (BY-NC)

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

40 vizualizări2 paginiPenthouse Winter 1997

Încărcat de

John M. CavoteFly ash should be "cold enoughff" as it enters the superheater and reheater. A change in fuel, especially to one with a lower ash-fusion temperature, can lead to slag and clinker formations. The use of shotguns is a frequent method for destruction of clinkers.

Drepturi de autor:

Attribution Non-Commercial (BY-NC)

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 2

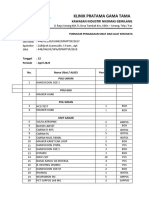

DAVID N. FRENCH, INC.

, METALLURGISTS

ONE LANCASTER ROAD

NORTHBOROUGH, MASSACHUSEllS 01532

TEL: (508) 393-3635

WINTER 1997 VOL* XIII, No* 4

A VIEW FROM THE PENTHOUSE: USEFUL INFORMATION FOR THE WORLD OF BOILERS

DYNAMITE DAMAGE shotguns is a frequent method for

destruction of clinkers. Under most

In a coal-fired boiler, the circumstances, damage to the pressure

combustion characteristics (heat parts by this slag-removal technique

content, % volatiles, etc.) and the is minimal. Occasionally a lead

ash content and composition pellet will lead to a steam leak,

(especially the ash-fusion especially in the thinner tubes of

temperature) determine the size of the reheater. Thicker tubes of

the furnace. The chemical make-up of waterwalls and superheaters are

the ash, often the amount of sodium seldom damaged beyond a slight dent.

and potassium, defines the melting or However, the use of deer slugs for

softening temperature. Usually the the removal of particularly stubborn

higher the sodium and potassium, the slag accumulations can lead to

lower the ash-fusion temperature. To sizeable holes if the slug scores a

prevent fouling, fly ash should be direct hit on a relatively clean

"cold enoughffas it enters the tube. The development of these leaks

superheater and reheater so it does then forces the unit off-line for a

not stick to the steam-cooled tubes. repair. Damage from projectiles is

Thus, the height is adjusted so that often neat, nearly round holes.

the temperature of the gas exiting Traces of lead from the slug can be

the furnace is less than the ash- detected on the rim of the hole by

fusion temperature. Under these careful energy dispersive x-ray (EDX)

temperature conditions, the fly ash analysis.

is delivered to the convection pass The use of dynamite to remove

as fine solid particles. The deposit particularly large or stubborn

build-up remains friable and easily clinker formations is also a common

removed. Periodic use of sootblowers practice. Damage to the superheater

can then maintain the heating surface or reheater is usually limited to

free of ash deposits and keep heat- distortion of the tube bundles. Any

transfer within the design range. gross distortion will compound the

The furnace is uniquely designed for clinker-formation problem by changing

a particular coal. the bundle spacing, however. The

A change in fuel, especially to change in spacing may lead to lanes

one with a lower ash-fusion and fly-ash erosion; as the more

temperature can lead to slag and closely spaced pendants fill with

clinker formations within the ash. Occasionally steam leaks

superheater and/or reheater. When develop at broken alignment clips or

the temperature of the gas exiting other attachments.

the furnace is higher than the Distortion of bundles from

melting point of the ash, the fly ash dynamite damage is usually obvious,

is deposited as molten droplets onto and leaks become obvious during

the tubes in the convection-pass. hydrostatic testing or shortly after

When the droplets freeze on the start-up when the steam leaks are

steam-cooled surfaces, the resultant visible. A more subtle, and

sintered deposit is hard, glassy, and certainly less obvious, form of

cannot be removed by sootblower use. dynamite damage occurs in the

Large clinkers may then develop. microstructure of the ferritic steel.

Control of clinker formation and A typical microstructure for a

removal of these slag masses becomes carbon or low-alloy steel after some

an on-going problem. The use of years of elevated-temperature service

is ferrite and spheroidized carbides, twins do not form by simple plastic

similar to that shown in Figure 1. deformation but require a severe or

harsh impact. The presence of these

deformation twins is proof of impact

damage.

Figure 1

Here the microstructure is a mixture

-- - -

of ferrite and spheroidized carbides Figure 2

with occasional large carbide-free

ferrite grains. In older boiler The shock waves running through

tubes where the sulfur content tends the steel form cracks at and around

to be higher than the modern steel- the manganese-sulfide stringers, see

making practice, microstructures will Figure 3. While this damage may not

contain the long, manganese-sulfide lead to an immediate steam leak; the

stringers, see Figure 1. presence of internal cracks can

The impact from the shock wave of propagate as fatigue or creep-fatigue

a dynamite blast leads to two types damage later on and lead to a steam

of microstructural damage. First, leak.

the formation of deformation twins

within the ferrite; and secondly, the

development of cracks at the

manganese-sulfide stringers. Figure

2 shows the deformation twins, the

nearly straight lines across the

individual ferrite grains. The

presence of these deformation twins

is proof of the impact onto the

ferritic tube. Deformation twins are

fairly common in austenitic stainless

steels and are readily formed by

simple plastic deformation. In

ferritic steels similar to carbon

steel, T-11 or T-22, deformation Figure 3

...............................................................................

OTHERS WHO MIGHT LIKE TO RECEIVE OUR NEWSLETTER:

NAME : COMPANY :

ADDRESS :

...............................................................................

REMEMBER: FOR METALLURGICAL ADVICE, FAILURE ANALYSIS, MATERIAL-CONDITION

ASSESSMENT, AND NEED FOR CHEMICAL CLEANING, CALL DR. FRENCH AT (508) 393-3635

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Piper Lance II - Turbo Lance II-Maintenance - smv1986Document568 paginiPiper Lance II - Turbo Lance II-Maintenance - smv1986willkobiÎncă nu există evaluări

- Suffolk Bus S92 Schedule Effective 5-2712Document2 paginiSuffolk Bus S92 Schedule Effective 5-2712RiverheadLOCAL67% (6)

- Northern Hemisphere Electronic Navigation Resources: Day Skipper and Watch LeaderDocument8 paginiNorthern Hemisphere Electronic Navigation Resources: Day Skipper and Watch LeaderSean DolanÎncă nu există evaluări

- Potentiometric TitrationDocument12 paginiPotentiometric TitrationTien Haminh100% (1)

- Shs Core Subjects MelcsDocument63 paginiShs Core Subjects MelcsRoldan Merjudio100% (1)

- Penthouse January 2007 PDFDocument1 paginăPenthouse January 2007 PDFJohn M. Cavote25% (4)

- Superheater Sample ReportDocument23 paginiSuperheater Sample ReportJohn M. Cavote100% (1)

- Manual On Boiler Tube FailureDocument69 paginiManual On Boiler Tube FailureJohn M. Cavote100% (1)

- Issues Related To T91 - P91 Steels - RKoripelliDocument3 paginiIssues Related To T91 - P91 Steels - RKoripelliJohn M. CavoteÎncă nu există evaluări

- Sample ReportDocument1 paginăSample ReportJohn M. CavoteÎncă nu există evaluări

- Seminar Brochure CDocument2 paginiSeminar Brochure CJohn M. CavoteÎncă nu există evaluări

- Vegas 2008 by United Dynamics Advanced Technologies 502-957-7525Document68 paginiVegas 2008 by United Dynamics Advanced Technologies 502-957-7525John M. CavoteÎncă nu există evaluări

- 2010 Alliance Workshop: Figure 1 Chasm Miao Keng' in Chongqing Province of ChinaDocument8 pagini2010 Alliance Workshop: Figure 1 Chasm Miao Keng' in Chongqing Province of ChinaJohn M. CavoteÎncă nu există evaluări

- Inspection Report: Area: Reheat Bank 2Document10 paginiInspection Report: Area: Reheat Bank 2John M. CavoteÎncă nu există evaluări

- Sample ExecsumDocument19 paginiSample ExecsumJohn M. CavoteÎncă nu există evaluări

- Las Vegas June 2011 UDC Alliance Inter Relationships Combustion APC AgendaDocument2 paginiLas Vegas June 2011 UDC Alliance Inter Relationships Combustion APC AgendaJohn M. CavoteÎncă nu există evaluări

- UDC MACT Workshop Air-In Leakage PresentationDocument7 paginiUDC MACT Workshop Air-In Leakage PresentationJohn M. CavoteÎncă nu există evaluări

- Sample GtrackDocument24 paginiSample GtrackJohn M. CavoteÎncă nu există evaluări

- Penthouse July 2006 Third QuarterDocument2 paginiPenthouse July 2006 Third QuarterJohn M. CavoteÎncă nu există evaluări

- Presentation Draft ME 2010 AtlantaDocument18 paginiPresentation Draft ME 2010 AtlantaJohn M. CavoteÎncă nu există evaluări

- Penthouse Nov 2006 Fourth QuarterDocument2 paginiPenthouse Nov 2006 Fourth QuarterJohn M. CavoteÎncă nu există evaluări

- Epri 2008 FinalDocument13 paginiEpri 2008 FinalJohn M. CavoteÎncă nu există evaluări

- Sample Exec SumDocument29 paginiSample Exec SumJohn M. CavoteÎncă nu există evaluări

- June 2011 Las Vegas Alliance Team Seminar DRAFTDocument3 paginiJune 2011 Las Vegas Alliance Team Seminar DRAFTJohn M. CavoteÎncă nu există evaluări

- Penthouse April 2007 EditDocument2 paginiPenthouse April 2007 EditJohn M. CavoteÎncă nu există evaluări

- FINAL DRAFT Webinar Presentation With NotesDocument68 paginiFINAL DRAFT Webinar Presentation With NotesJohn M. CavoteÎncă nu există evaluări

- Epri 2008 PPDocument29 paginiEpri 2008 PPJohn M. CavoteÎncă nu există evaluări

- Neundorfer 2010 Presentation by United Dynamics Advanced Technologies 502 957 7525Document55 paginiNeundorfer 2010 Presentation by United Dynamics Advanced Technologies 502 957 7525John M. CavoteÎncă nu există evaluări

- Marcus Evans Asset Management 2010Document33 paginiMarcus Evans Asset Management 2010John M. CavoteÎncă nu există evaluări

- GTrack Sample ReportDocument1 paginăGTrack Sample ReportJohn M. CavoteÎncă nu există evaluări

- Insp Check ListDocument2 paginiInsp Check ListJohn M. CavoteÎncă nu există evaluări

- Class OverviewDocument1 paginăClass OverviewJohn M. CavoteÎncă nu există evaluări

- Checklist Brochure CompleteDocument2 paginiChecklist Brochure CompleteJohn M. CavoteÎncă nu există evaluări

- David N. French Metallurgists: 35 Years of Boiler Tube Failure Analysis ExperienceDocument8 paginiDavid N. French Metallurgists: 35 Years of Boiler Tube Failure Analysis ExperienceJohn M. CavoteÎncă nu există evaluări

- Name: Keatlaretse Bridgette Surname: Macucwa Module Name: Social Work Practice Module Code: BSW 2605 Assessment No: 2 Due Date: 14 August 2020Document6 paginiName: Keatlaretse Bridgette Surname: Macucwa Module Name: Social Work Practice Module Code: BSW 2605 Assessment No: 2 Due Date: 14 August 2020keatlaretse macucwaÎncă nu există evaluări

- To Signals and SystemsDocument57 paginiTo Signals and SystemsMUHAMMAD HAFIZUDDINÎncă nu există evaluări

- Latex WikibookDocument313 paginiLatex Wikibookraul_apÎncă nu există evaluări

- Scheme of Examination For Master of Computer APPLICATIONS (M.C.A.) W.E.F. Academic Session 2014-15Document11 paginiScheme of Examination For Master of Computer APPLICATIONS (M.C.A.) W.E.F. Academic Session 2014-15Siddharth JainÎncă nu există evaluări

- 4MA1 1H Que 20210304Document28 pagini4MA1 1H Que 20210304mo gaÎncă nu există evaluări

- Thrust Equation For A Turbofan Double Inlet/Outlet: Joshtheengineer April 8, 2017Document7 paginiThrust Equation For A Turbofan Double Inlet/Outlet: Joshtheengineer April 8, 2017Muhammad RidwanÎncă nu există evaluări

- Summary of C: How To Program Sixth Edition by Deitel: Introduction To Computers, The Internet and The WebDocument15 paginiSummary of C: How To Program Sixth Edition by Deitel: Introduction To Computers, The Internet and The WebFrieda NgaharjoÎncă nu există evaluări

- On Teacher's Philosophy of Education: SPARK Your InterestDocument10 paginiOn Teacher's Philosophy of Education: SPARK Your InterestChuck GarridoÎncă nu există evaluări

- SAP MM Purchase Info Record GuideDocument3 paginiSAP MM Purchase Info Record GuidevikneshÎncă nu există evaluări

- Final AnswersDocument4 paginiFinal AnswersAnshul SinghÎncă nu există evaluări

- X English QPDocument29 paginiX English QPbadasserytechÎncă nu există evaluări

- American Statistical AssociationDocument7 paginiAmerican Statistical Associationmantu6kumar-17Încă nu există evaluări

- ICN Question Bank Unit-1, 2 and 3 (Upto GSM Identifier)Document1 paginăICN Question Bank Unit-1, 2 and 3 (Upto GSM Identifier)Snehal PatelÎncă nu există evaluări

- DLL - Mathematics 5 - Q1 - W4Document9 paginiDLL - Mathematics 5 - Q1 - W4Avelino Coballes IVÎncă nu există evaluări

- Pengadaan Obat Dan Alkes TGL 22 April 2021 Klinik PembantuDocument8 paginiPengadaan Obat Dan Alkes TGL 22 April 2021 Klinik PembantuIsma Prasetya WardaniÎncă nu există evaluări

- 660 Inventions That Changed Our WorldDocument5 pagini660 Inventions That Changed Our WorldKoby RamosÎncă nu există evaluări

- ResearchDocument48 paginiResearchCai De JesusÎncă nu există evaluări

- Filters in GeneralDocument3 paginiFilters in GeneralJoseGarciaRuizÎncă nu există evaluări

- Alenar R.J (Stem 11 - Heliotrope)Document3 paginiAlenar R.J (Stem 11 - Heliotrope)REN ALEÑARÎncă nu există evaluări

- Single Core Bonding Cables Are Not in Scope of Supply.: LLC "RKS-Plast"Document1 paginăSingle Core Bonding Cables Are Not in Scope of Supply.: LLC "RKS-Plast"Sunli Karla Sivincha RomeroÎncă nu există evaluări

- New Economics HAND BOOKDocument29 paginiNew Economics HAND BOOKGrisvia AgustinÎncă nu există evaluări

- Axle, Front Drive - Housing, Swivel PDFDocument2 paginiAxle, Front Drive - Housing, Swivel PDFLeo VegaÎncă nu există evaluări

- Evaluating WebsitesDocument2 paginiEvaluating Websitesapi-322361374Încă nu există evaluări

- LGBT Workplace Equality Policy and Customer Satisfaction: The Roles of Marketing Capability and Demand InstabilityDocument20 paginiLGBT Workplace Equality Policy and Customer Satisfaction: The Roles of Marketing Capability and Demand InstabilityFatima ZafarÎncă nu există evaluări

- Lind 18e Chap005Document35 paginiLind 18e Chap005MELLYANA JIEÎncă nu există evaluări