Documente Academic

Documente Profesional

Documente Cultură

Three-Phase Motor - Troubleshooting

Încărcat de

Ebi EldhoDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Three-Phase Motor - Troubleshooting

Încărcat de

Ebi EldhoDrepturi de autor:

Formate disponibile

Three-phase motors

Application Note

TROUBLESHOOTING THREE-PHASE MOTORS

MEASURE VOLTAGE 1

ON AT MOTOR TERMINALS

2 TURN OFF AND

LOCK OUT POWER

5 TURN OFF L1

OFF AND LOCK

OUT POWER

L2

L3

ON

IF WITHIN 10%

OF RATED VALUE - VOLTAGE

CORRECT

OFF

4 TURN POWER

IF NOT WITHIN 10%

ON AND TRY

STARTING MOTOR 3 DISCONNECT OF RATED VALUE - VOLTAGE

LOAD INCORRECT

T2

IF ZERO - COIL IS T2

SHORTED

IF INFINITY - COIL IS T8

OPEN

T5 B

A T7 T5 B

T4 A

T8 T9

T4

T9 T3

T7 T6

T1 T6 T3

T1 C

C

DUAL-VOLTAGE, DUAL-VOLTAGE,

DELTA MOTOR 6 CHECK FOR OPEN WYE MOTOR

OR SHORTED WINDING

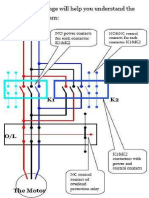

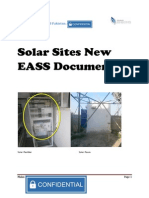

Figure 1. Troubleshoot three-phase motors with an ohmmeter.

Three-phase motors have fewer Troubleshooting See Figure 1. To troubleshoot a

components that may malfunc- three-phase motors three-phase motor, apply the fol-

tion than other motor types. lowing procedure:

Therefore, 3ø motors usually The extent of troubleshooting a 1. Using a voltmeter, measure

operate for many years without 3ø motor is dependent upon the the voltage at the motor ter-

any problems. motor’s application. If the motor minals. If the voltage is pres-

If a 3ø motor is the problem, is used in an application that is ent and at the correct level on

the motor is serviced or replaced. critical to the operation or pro- all three phases, the motor

Servicing usually requires that the duction, testing is usually limited must be checked. If the volt-

motor be sent to a motor repair to checking the voltage at the age is not present on all three

shop for rewinding. If the motor motor. If the voltage is present phases, the incoming power

is less than 1 HP and more than and correct, the motor is supply must be checked.

5 years old, it is replaced. If the assumed to be the problem.

Unless it is very large, the motor 2. If voltage is present but the

motor is more than 1 HP, but less motor is not operating, turn

than 5 HP, it may be serviced or is usually replaced at this time so

production can be resumed. If the handle of the safety

replaced. If the motor is more switch or combination starter

than 5 HP, it is usually serviced. time is not a critical factor, fur-

ther tests can be made in order OFF. Lock out and tag the

to determine the exact problem. starting mechanism per com-

pany policy.

From the Fluke Digital Library @ www.fluke.com/library

3. Disconnect the motor from the opened. Since the coil wind- Troubleshooting guides

load. ing is made of wire only, the

resistance is low. However, Troubleshooting guides for motors

4. After the load is disconnected, state a problem, its possible

turn power ON to try restart- there is resistance on a good

coil winding. The larger the cause(s), and corrective action(s)

ing the motor. If the motor that may be taken. These easy-

starts, check the load. motor, the smaller the resist-

ance reading. to-reference guides, while

5. If the motor does not start, general in nature, may be used

turn it OFF and lock out the After the resistance of one coil to quickly determine potential

power. has been found, the basic elec- problems and possible courses

trical laws of series and parallel of action. See Figure 2.

6. With an ohmmeter, check the circuits are applied. When meas-

motor windings for any opens uring the resistance of two coils

or shorts. Take a resistance in series, the total resistance is

reading of the T1-T4 coil. twice the resistance of one coil.

This coil must have a resist- When measuring the resistance

ance reading. If the reading is of two coils in parallel, the total

zero, the coil is shorted. If the resistance is one half the resist-

reading is infinity, the coil is ance of one coil.

Troubleshooting Guide for Three-Phase Motors

Problem Possible Cause Suggested Test Tool Corrective Action

Motor will not start Wrong motor Most three-phase motors are dual-voltage. Check for proper motor connections.

connections

Blown fuse or Basic electrical tester, Test the OCPD. If voltage is present at the input, but not the output of the OCPD, the fuse is

open CB DMM , clamp meter, blown or the CB is open. Check the rating of the OCPD. It should be at least 125 % of the

or megohmmeter motor’s FLC.

Motor overload on Allow overloads to cool. Reset overloads. If reset overloads do not start the motor,

starter tripped test the starter.

Low or no voltage Basic electrical tester, Check the voltage at the motor terminals. The voltage must be present and within 10 % of the

applied to motor DMM or clamp meter motor nameplate voltage. If voltage is present at the motor but the motor is not operating,

remove the motor from the load the motor is driving. Reapply power to the motor. If the motor

runs, the problem is with the load. If the motor does not run, the problem is with the motor.

Replace or service the motor.

Open control circuit Basic electrical tester, Check for cleanliness, tightness, and breaks. Test the circuit starting with the incoming power

between incoming DMM or clamp meter and moving to the motor terminals. Voltage generally stops at the problem area.

power and motor

Fuse, CB, or overloads Power not applied to Basic electrical tester, Measure voltage at each power line. Correct any power supply problems.

retrip after service all three lines DMM or clamp meter

Blown fuse or open Basic electrical tester, Test the OCPD. If voltage is present at the input, but not the output of the OCPD, the fuse is

CB DMM , clamp meter, blown or the CB is open. Check the rating of the OCPD. It should be at least 125 % of the

or megohmmeter motor’s FLC.

Motor overload on Allow overloads to cool. Reset overloads. If reset overloads do not start the motor,

starter tripped test the starter.

Low or no voltage Basic electrical tester, Check the voltage at the motor terminals. The voltage must be present and within 10 % of the

applied to motor DMM or clamp meter motor nameplate voltage. If voltage is present at the motor but the motor is not operating,

remove the motor from the load the motor is driving. Reapply power to the motor. If the motor

runs, the problem is with the load. If the motor does not run, the problem is with the motor.

Replace or service the motor.

Open control circuit Basic electrical tester, Check for cleanliness, tightness, and breaks. Test the circuit starting with the incoming power

between incoming DMM or clamp meter and moving to the motor terminals. Voltage generally stops at the problem area.

power and motor

Motor shaft does Disconnect the motor from the load. If the motor shaft still does not turn, the bearings are

not turn frozen. Replace or service the motor.

Motor overheats Motor is single Basic electrical tester, Check each of the three-phase power lines for correct voltage.

phasing DMM or clamp meter

Improper ventilation Infrared temperature Clean all ventilation openings. Vacuum or blow dirt out of motor with low-pressure, dry,

compressed air.

Motor is overloaded Basic electrical tester, Check the load for binding. Check shaft straightness. Measure motor current under operating

clamp meter or DMM conditions. If the current is above the listed current rating, remove the motor. Remeasure the

with clamp accessory current under no-load conditions. If the current is excessive under load but not when unloaded,

check the load. If the motor draws excessive current when disconnected, replace or service the

motor.

Excessive harmonics Power quality Check for the presence of harmonics in the feeder supplying the motor, especially 5th harmonic

analyzer which can generate heat rise.

Figure 2. Troubleshooting guides are used to determine problems and possible courses of action.

2 Fluke Corporation Three-phase motors

This article is based on material

excerpted from Electric Motor

Drive Installation and Trou-

bleshooting, Troubleshooting

Electric/Electronic Systems,

2nd Edition, Power Quality Measurement and

Troubleshooting, and Electrical Motor Controls,

2nd Edition published by American Technical

Publishers, Inc. To obtain information on related

training products, visit the American Tech web

site at www.go2atp.com.

Fluke. Keeping your world

up and running.

Fluke Corporation

PO Box 9090, Everett, WA USA 98206

Fluke Europe B.V.

PO Box 1186, 5602 BD

Eindhoven, The Netherlands

For more information call:

In the U.S.A. (800) 443-5853 or

Fax (425) 446-5116

In Europe/M-East/Africa (31 40) 2 675 200 or

Fax (31 40) 2 675 222

In Canada (800) 36-FLUKE or

Fax (905) 890-6866

From other countries +1 (425) 446-5500 or

Fax +1 (425) 446-5116

Web access: http://www.fluke.com

©2003 Fluke Corporation. All rights reserved.

Printed in U.S.A. 8/2003 2105201 A-ENG-N Rev A

3 Fluke Corporation Three-phase motors

S-ar putea să vă placă și

- Troubleshooting Current LoopsDocument14 paginiTroubleshooting Current LoopsrozzillaÎncă nu există evaluări

- Electrician''s Guide to Control and Monitoring Systems: Installation, Troubleshooting, and MaintenanceDe la EverandElectrician''s Guide to Control and Monitoring Systems: Installation, Troubleshooting, and MaintenanceÎncă nu există evaluări

- Motor Controls Troubleshooting of Electric MotorsDocument34 paginiMotor Controls Troubleshooting of Electric MotorsAdil RezoukÎncă nu există evaluări

- Electric Motor Maintenance and Troubleshooting, 2nd EditionDe la EverandElectric Motor Maintenance and Troubleshooting, 2nd EditionEvaluare: 3 din 5 stele3/5 (2)

- Electric Motor Control DiagramsDocument68 paginiElectric Motor Control DiagramsManny100% (6)

- Electric Motor Troubleshooting PolyphaseDocument16 paginiElectric Motor Troubleshooting PolyphaserpshvjuÎncă nu există evaluări

- Maintenance of Electric EquipmentDocument130 paginiMaintenance of Electric EquipmentAnil kadam100% (1)

- Electrical and Electronic Troubleshooting For Industrial EnginesDocument25 paginiElectrical and Electronic Troubleshooting For Industrial EnginespanddyanÎncă nu există evaluări

- Basic Electrical Troubleshooting For Everyone (Gnv64)Document215 paginiBasic Electrical Troubleshooting For Everyone (Gnv64)benjarray86% (7)

- PLC For Motor ControlDocument8 paginiPLC For Motor Controlsunil8080Încă nu există evaluări

- Troubleshooting Motors and Controls 1563825196Document155 paginiTroubleshooting Motors and Controls 1563825196yoseph dejeneÎncă nu există evaluări

- How To Test and Repair Small Engine Ignition System ProblemsDocument5 paginiHow To Test and Repair Small Engine Ignition System ProblemsAlfred E. NewmanÎncă nu există evaluări

- Fuse and Circuit BreakerDocument36 paginiFuse and Circuit BreakerJonathan LeeÎncă nu există evaluări

- Industrial Maintenance Mechanical Systems RedoneDocument91 paginiIndustrial Maintenance Mechanical Systems RedoneLuis Ángel Ávila100% (2)

- Wiring Diagrams For Rotary Phase ConvertorDocument2 paginiWiring Diagrams For Rotary Phase Convertorwhsprz100% (1)

- Electrical SymbolsDocument26 paginiElectrical SymbolsXavier Izquierdo75% (8)

- Motors and Motor StartersDocument32 paginiMotors and Motor StartersbmshivakumarÎncă nu există evaluări

- Installation and Maintenance of Industrial Induction MotorsDocument59 paginiInstallation and Maintenance of Industrial Induction MotorsMichael HailuÎncă nu există evaluări

- Electric BikeDocument203 paginiElectric BikeBeto Jose MendozaÎncă nu există evaluări

- Troubleshooting and Repair of Consumer Electronic EquipmentDocument87 paginiTroubleshooting and Repair of Consumer Electronic EquipmentHenry huddlestonÎncă nu există evaluări

- Relay: Prepared By: Engr. Irish Jasmine C. Morales, RmeDocument17 paginiRelay: Prepared By: Engr. Irish Jasmine C. Morales, Rmegame masterÎncă nu există evaluări

- How To Read A PLC Wiring Diagram (Control Panel Wiring Diagram) - UpmationDocument35 paginiHow To Read A PLC Wiring Diagram (Control Panel Wiring Diagram) - UpmationwebsterchikambaÎncă nu există evaluări

- Fundamentals of PLC FinalDocument117 paginiFundamentals of PLC FinalTetsusaigaÎncă nu există evaluări

- Motor Wiring Digrams and ControlDocument36 paginiMotor Wiring Digrams and ControlEdeuamos true-eÎncă nu există evaluări

- Millwright Industrial Mechanic in Alberta Canada Resume George MadarDocument2 paginiMillwright Industrial Mechanic in Alberta Canada Resume George MadarGeorgeMadarÎncă nu există evaluări

- ElectricalDocument6 paginiElectricalPaulÎncă nu există evaluări

- Construction of TransformerDocument33 paginiConstruction of TransformervurumuuÎncă nu există evaluări

- Relay Logic CircuitDocument9 paginiRelay Logic CircuitAshraf MÎncă nu există evaluări

- How To Use A Multimeter - Using Multimeters For Different Measurement Options (2020 Edition)Document72 paginiHow To Use A Multimeter - Using Multimeters For Different Measurement Options (2020 Edition)Ehab SaberÎncă nu există evaluări

- Electrical Symbols and SchematicsDocument42 paginiElectrical Symbols and Schematicsapi-384232693% (14)

- Industrial Maintenance Mechanics 1Document7 paginiIndustrial Maintenance Mechanics 1Kiran DuggarajuÎncă nu există evaluări

- MotorsDocument18 paginiMotorsAmado CamachoÎncă nu există evaluări

- How To Wire A Proximity Sensor To A PLCDocument11 paginiHow To Wire A Proximity Sensor To A PLCciocioi iancu100% (1)

- Unit 35 Portfolio Answer 2018Document22 paginiUnit 35 Portfolio Answer 2018Hatem HusseinÎncă nu există evaluări

- PLC Technical DefinitionDocument6 paginiPLC Technical DefinitionKyle EmersonÎncă nu există evaluări

- Design of 33/11 KV LT Substation DemoDocument39 paginiDesign of 33/11 KV LT Substation DemoH&B MoviesÎncă nu există evaluări

- MACHINE WORKSHOP AssignmentDocument14 paginiMACHINE WORKSHOP Assignmentsaiq kamranÎncă nu există evaluări

- Practical Troubleshooting of Electrical Equipment and Control CircuitDocument2 paginiPractical Troubleshooting of Electrical Equipment and Control Circuitapi-374299350% (2)

- Hydraulics and Pneumatics SystemsDocument4 paginiHydraulics and Pneumatics SystemsKrista JacksonÎncă nu există evaluări

- Electrician: Syllabus of Semester System For The Trade ofDocument27 paginiElectrician: Syllabus of Semester System For The Trade ofTusharÎncă nu există evaluări

- Common Interview QuestionsDocument5 paginiCommon Interview Questionssopan saÎncă nu există evaluări

- Electrical Troubleshooting ManualDocument12 paginiElectrical Troubleshooting ManualGreg Hanna100% (1)

- Chapter 3 Pneumatic ValvesDocument144 paginiChapter 3 Pneumatic ValvesNguyễn Tự Chung100% (1)

- What Is A Star Delta Starter and How Does It WorkDocument8 paginiWhat Is A Star Delta Starter and How Does It WorkArunkumar GujetiÎncă nu există evaluări

- How To Use A Multimeter PDFDocument18 paginiHow To Use A Multimeter PDFBala Murugan75% (4)

- Successful Electrical MaintenanceDocument126 paginiSuccessful Electrical MaintenanceJohn Khalid100% (7)

- 5 PLC PDFDocument31 pagini5 PLC PDFshihabÎncă nu există evaluări

- Multimeter TesterDocument32 paginiMultimeter TesterMarjenneil0% (1)

- Electrical Troubleshooting Techniques PDFDocument10 paginiElectrical Troubleshooting Techniques PDFbeu catalin100% (1)

- Electricity QuestionsDocument133 paginiElectricity QuestionskartavyajainÎncă nu există evaluări

- 3 Phase Motor Connection Star-Delta (Y-Δ) Reverse -ForwardDocument3 pagini3 Phase Motor Connection Star-Delta (Y-Δ) Reverse -Forwardroy_nhp100% (1)

- Choosing A Laptop For ResolumeDocument3 paginiChoosing A Laptop For ResolumeSez BvÎncă nu există evaluări

- Single Phase MotorsDocument4 paginiSingle Phase MotorsAmit DebnathÎncă nu există evaluări

- Otomasi Sistem Produksi: Hasil PembelajaranDocument10 paginiOtomasi Sistem Produksi: Hasil PembelajaranKancil JuniorÎncă nu există evaluări

- Ee 591 Machine 2 PDFDocument39 paginiEe 591 Machine 2 PDFPrabhat Kumar SahuÎncă nu există evaluări

- Sơ Đ Shunt Strip + Fire AlarmDocument2 paginiSơ Đ Shunt Strip + Fire AlarmBuồnNgủÎncă nu există evaluări

- Motor Wiring Diagram: 9 Lead, Dual Voltage (DELTA Conn.)Document1 paginăMotor Wiring Diagram: 9 Lead, Dual Voltage (DELTA Conn.)Ronald LlerenaÎncă nu există evaluări

- Auto Transformer StarterDocument8 paginiAuto Transformer StarterMuhamad Reduan100% (1)

- Distribution Feeder ProtectionDocument15 paginiDistribution Feeder Protectionteektak1Încă nu există evaluări

- Week 2 - Piping Friction Loss 1t 2022-2023Document113 paginiWeek 2 - Piping Friction Loss 1t 2022-2023Mcoy DomingoÎncă nu există evaluări

- Insulators 101 Panel Final ADocument84 paginiInsulators 101 Panel Final ABlakeÎncă nu există evaluări

- The Hall Effect-1Document4 paginiThe Hall Effect-1lewyn.socialÎncă nu există evaluări

- 123 KV Dry Flexible Termination TFD 123: Cable Accessories and ConnectorsDocument2 pagini123 KV Dry Flexible Termination TFD 123: Cable Accessories and ConnectorsnarinderÎncă nu există evaluări

- Electronic Devices and Circuits Zener and Avalanche BreakdownDocument4 paginiElectronic Devices and Circuits Zener and Avalanche Breakdownanuraganand25Încă nu există evaluări

- Fundamental Concepts in Substation Design PDFDocument26 paginiFundamental Concepts in Substation Design PDFvishalkumarÎncă nu există evaluări

- Unified Power Flow ControllerDocument17 paginiUnified Power Flow ControllerAdeniji Olusegun50% (2)

- Cracking The AP Physics C Exam, 2020 Edition Chapter 5 Drill (Answer Key) PDFDocument9 paginiCracking The AP Physics C Exam, 2020 Edition Chapter 5 Drill (Answer Key) PDFFarhaan Qaisar UsmaniÎncă nu există evaluări

- NNSN SD6x8Document44 paginiNNSN SD6x8Patrice PaulÎncă nu există evaluări

- Fundamentals of Electronics - Awais YasinDocument185 paginiFundamentals of Electronics - Awais YasinAsif HameedÎncă nu există evaluări

- Cow SpreadsheetDocument28 paginiCow SpreadsheetSunilGangwarÎncă nu există evaluări

- Smart Power Generation by Wasted HeatDocument5 paginiSmart Power Generation by Wasted HeatVedant ChoudharyÎncă nu există evaluări

- Design of Electrical MachinesDocument27 paginiDesign of Electrical MachinesAnaZanattaÎncă nu există evaluări

- BTS443P Smart Highside Power SwitchDocument15 paginiBTS443P Smart Highside Power SwitchLuis N. Montiel V.Încă nu există evaluări

- Entropy DefinitionDocument2 paginiEntropy DefinitionFery Reykha OmbingÎncă nu există evaluări

- Epro 61400-2 CD 3070Document120 paginiEpro 61400-2 CD 3070Ayan MajiÎncă nu există evaluări

- Solar Sites New EASS DocumentsDocument11 paginiSolar Sites New EASS Documentsi070120100% (1)

- 320C - Diagrama Eletrico (Ar-Condicionado)Document2 pagini320C - Diagrama Eletrico (Ar-Condicionado)Oficina FernandinhoÎncă nu există evaluări

- 06 Dielectrics Capacitance 2018mkDocument41 pagini06 Dielectrics Capacitance 2018mkTrần ĐứcAnhÎncă nu există evaluări

- Engineering Properties (Al O) : 94% Aluminum Oxide Mechanical Units of Measure SI/Metric (Imperial)Document7 paginiEngineering Properties (Al O) : 94% Aluminum Oxide Mechanical Units of Measure SI/Metric (Imperial)Hendy SetiawanÎncă nu există evaluări

- 2018 16 Calibrating and Operating Coriolis Flow MetersDocument31 pagini2018 16 Calibrating and Operating Coriolis Flow MetersmochdimaskuÎncă nu există evaluări

- Mig Sonic 200 CVCC Service ManualDocument65 paginiMig Sonic 200 CVCC Service Manualbuggy bugger100% (1)

- 500L - MIXING TANK - N4-SMT-03 (MP1), N4-SMT-04 (MP2) - Ellipsoidal DishDocument8 pagini500L - MIXING TANK - N4-SMT-03 (MP1), N4-SMT-04 (MP2) - Ellipsoidal Dishprakash KaleÎncă nu există evaluări

- SVP 917 ManualDocument8 paginiSVP 917 ManualGalvao.endÎncă nu există evaluări

- Ib Physics DefinitionsDocument20 paginiIb Physics DefinitionsJohnny HongÎncă nu există evaluări

- ESD User Handbook Rev2Document12 paginiESD User Handbook Rev2Amit B Kolekar100% (1)

- Mass Volume Density Notes PDFDocument17 paginiMass Volume Density Notes PDFNadya PutriÎncă nu există evaluări

- June 2014 (R) MA - M1 EdexcelDocument9 paginiJune 2014 (R) MA - M1 EdexcelKollol KolllolÎncă nu există evaluări

- Revisi AnggaranDocument11 paginiRevisi Anggaranmas udinÎncă nu există evaluări

- Philippine Distribution Code 2017 EditionDocument159 paginiPhilippine Distribution Code 2017 EditionAllan Soldevilla BitonÎncă nu există evaluări

- The Journeyman Electrician Exam Study Guide: Proven Methods for Successfully Passing the Journeyman Electrician Exam with ConfidenceDe la EverandThe Journeyman Electrician Exam Study Guide: Proven Methods for Successfully Passing the Journeyman Electrician Exam with ConfidenceÎncă nu există evaluări

- Multiplexed Networks for Embedded Systems: CAN, LIN, FlexRay, Safe-by-Wire...De la EverandMultiplexed Networks for Embedded Systems: CAN, LIN, FlexRay, Safe-by-Wire...Încă nu există evaluări

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionDe la EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionEvaluare: 4.5 din 5 stele4.5/5 (543)

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tDe la EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tEvaluare: 4.5 din 5 stele4.5/5 (27)

- A Mind at Play: How Claude Shannon Invented the Information AgeDe la EverandA Mind at Play: How Claude Shannon Invented the Information AgeEvaluare: 4 din 5 stele4/5 (53)

- Conquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeDe la EverandConquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeEvaluare: 4.5 din 5 stele4.5/5 (10)

- Power System Control and ProtectionDe la EverandPower System Control and ProtectionB. Don RussellEvaluare: 4 din 5 stele4/5 (11)

- 2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersDe la Everand2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersEvaluare: 5 din 5 stele5/5 (1)

- Guide to the IET Wiring Regulations: IET Wiring Regulations (BS 7671:2008 incorporating Amendment No 1:2011)De la EverandGuide to the IET Wiring Regulations: IET Wiring Regulations (BS 7671:2008 incorporating Amendment No 1:2011)Evaluare: 4 din 5 stele4/5 (2)

- INCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesDe la EverandINCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesEvaluare: 5 din 5 stele5/5 (1)

- Practical Electrical Wiring: Residential, Farm, Commercial, and IndustrialDe la EverandPractical Electrical Wiring: Residential, Farm, Commercial, and IndustrialEvaluare: 3.5 din 5 stele3.5/5 (3)

- Programming the Raspberry Pi, Third Edition: Getting Started with PythonDe la EverandProgramming the Raspberry Pi, Third Edition: Getting Started with PythonEvaluare: 5 din 5 stele5/5 (2)

- Hacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsDe la EverandHacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsEvaluare: 3.5 din 5 stele3.5/5 (2)

- Digital Transformation: Survive and Thrive in an Era of Mass ExtinctionDe la EverandDigital Transformation: Survive and Thrive in an Era of Mass ExtinctionEvaluare: 4.5 din 5 stele4.5/5 (9)

- Schaum's Outline of Basic Electricity, Second EditionDe la EverandSchaum's Outline of Basic Electricity, Second EditionEvaluare: 5 din 5 stele5/5 (14)

- Retro Gaming with Raspberry Pi: Nearly 200 Pages of Video Game ProjectsDe la EverandRetro Gaming with Raspberry Pi: Nearly 200 Pages of Video Game ProjectsÎncă nu există evaluări

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionDe la EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionEvaluare: 4 din 5 stele4/5 (331)

- Teach Yourself Electricity and Electronics, 6th EditionDe la EverandTeach Yourself Electricity and Electronics, 6th EditionEvaluare: 3.5 din 5 stele3.5/5 (15)

- Build Your Own Electronics WorkshopDe la EverandBuild Your Own Electronics WorkshopEvaluare: 3.5 din 5 stele3.5/5 (3)

- DIY Drones for the Evil Genius: Design, Build, and Customize Your Own DronesDe la EverandDIY Drones for the Evil Genius: Design, Build, and Customize Your Own DronesEvaluare: 3.5 din 5 stele3.5/5 (3)

- Open Radio Access Network (O-RAN) Systems Architecture and DesignDe la EverandOpen Radio Access Network (O-RAN) Systems Architecture and DesignÎncă nu există evaluări

- Empires of Light: Edison, Tesla, Westinghouse, and the Race to Electrify the WorldDe la EverandEmpires of Light: Edison, Tesla, Westinghouse, and the Race to Electrify the WorldEvaluare: 4 din 5 stele4/5 (87)