Documente Academic

Documente Profesional

Documente Cultură

FMEA Format

Încărcat de

crazy_hornetDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

FMEA Format

Încărcat de

crazy_hornetDrepturi de autor:

Formate disponibile

Historial de Revisiones para Formatos

Numero Descripción:

FMEA (Falure Mode and Effects Analysis)

Rev. Originador Descripcion de la Revision Fecha

FORM FR 013 Rev. 00

Failure Mode and Effect Analysis Product Part Number: Rev. Date: FMEA Number:

FMEA

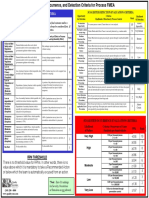

S= Severity number It is a estimated impact of the failure "RPN" Values

O= Occurrence number It is a estimate that the failure will occur 1 <= <= 48 Low risk of product

D= Detection number It is a estimate of the effectiveness of the detection system 49 <= <= 284 Moderated risk

285 <= <= 1000 High risk

RPN= Risk priority number RPN= S x O x D

Process Function Potential Failure Potential Effect (s) Potential cause (s) / Current process Recommended Actions Results

Severity

Responsible and

Detect

Occur

RPN

Class

(Requirements) Mode of failure Mechanism of failure Control Actions target completion date Action taken S O D RPN

2 of 3 Form: FR 032 Rev. 00

Severity

Effect Severity criteria Ranking

Hazardous without May endanger machine or assembly operator. Very high severity ranking when a potential failure mode effects

10

warning safe operation and / or involves noncompliance with regulation. Failure will occur without warning.

Hazardous with May endanger machine or assembly operator. Very high severity ranking when a potential failure mode effects

9

warning safe operation and / or involves noncompliance with regulation. Failure will occur with warning.

Major disruption to production line. 100% of product may have to be scrapped. Item inoperable, loss of primary

Very high 8

function. Customer very dissatisfied

Minor disruption to production line. A portion of product may have to be sorted and scraped, item operable, but

high 7

at reduced level. Customer dissatisfied

Minor disruption to production line. A portion of product may have to be scraped (no sorting), item operable, but

Moderate 6

some comfort items inoperable. Customer experience discomfort

Minor disruption to production line, 100% of product may have to be reworked. Item operable, bur some comfort

Low 5

items operable at reduce level of performance. Customer experiences some dissatisfaction

Minor disruption to production line. Product may have to be sorted and a portion reworked. Minor adjustments

Very low 4

do not conform. Defect noticed by customer

Minor disruption to production line. Product may have to be reworked online, but out of station. Minor

Minor 3

adjustments do not conform. Detect noticed by average customer

Minor disruption to production line. Product may have to be reworked online, but out of station. Minor

Very minor 2

adjustments do not conform. Detect noticed by discriminating customer

None No effect 1

Occurrence Detection

Probability of failure Possible failure rates Ranking Ranking Suggested range of detection methods Insp. Types

Very High: Failure almost >1 in 2 10 10 Cannot detect or is not checked c

inevitable 1 in 3 9 9 Control is achieved with indirect or random check only c

High: Generally associated with 1 in 8 8 8 Control is achieved with visual inspection only c

processes similar to previous 1 in 20 7 7 Control is achieved with double visual inspection only c

processes that have often failed 6 Control is achieved with charting methods, such as SPC c, b

Moderate: Generally associated 1 in 80 6 Control is based on variable gauging after parts have left

with processes similar to previous 1 in 400 5 5 the station, or Go/No Go gauging performed on 100% of b

processes that have experienced 1 in 2000 4 the parts after parts have left the station

occasional failures Error detection in subsequence operations, OR gauging

Low: Isolated failures associated 4 performed on setup and first-piece check (for set-up b, a

1 in 15000 3

with similar processes causes only)

Very low: Only isolated failures Error detection in-station, or error detection in subsequent

associated with almost identical 1 in 150000 2 3 operations by multiple layers of acceptance: supply select b, a

processes install, verify. Cannot accept discrepant part.

Remote: Failure is unlikely. Error detection in-station (automatic gauging with automatic

2 b, a

No failures associated with almost 1 in 1500000 1 stop feature). Cannot pass discrepant part.

identical processes Discrepant parts cannot be made because item has been

1 a

error-proofed by process/product design

a= Error proof; b= Gauging; c= Manual

FR 032 Back Rev. 00

S-ar putea să vă placă și

- Process Hazard Analysis: (Failure Mode Effect Analysis)Document41 paginiProcess Hazard Analysis: (Failure Mode Effect Analysis)Nate JamesÎncă nu există evaluări

- Failure Modes and Effect Analysis of Electro-Pneumatics SystemDocument9 paginiFailure Modes and Effect Analysis of Electro-Pneumatics SystemmutluÎncă nu există evaluări

- FmeaDocument31 paginiFmeainder_sandhuÎncă nu există evaluări

- 2015 - Almeida Et Al. - Multicriteria and Multiobjective Models For Risk, Reliability and Maintenance Decision AnalysisDocument417 pagini2015 - Almeida Et Al. - Multicriteria and Multiobjective Models For Risk, Reliability and Maintenance Decision AnalysisRamon SwellÎncă nu există evaluări

- HazanDocument16 paginiHazanshweta.vrÎncă nu există evaluări

- Pfmea TemplateDocument2 paginiPfmea TemplateAdetunji Babatunde TaiwoÎncă nu există evaluări

- FMEA - PZCI TemplateDocument8 paginiFMEA - PZCI TemplateMgr ProdÎncă nu există evaluări

- 203 LSS Gbo - FmeaDocument47 pagini203 LSS Gbo - FmeaRocker byÎncă nu există evaluări

- Failure Mode and Effects Analysis of PCB For Quality Control ProcessDocument10 paginiFailure Mode and Effects Analysis of PCB For Quality Control Processapurav_27Încă nu există evaluări

- Template AMEFDocument10 paginiTemplate AMEFElvis DiazÎncă nu există evaluări

- QRM For Water System 18-01-2024Document29 paginiQRM For Water System 18-01-2024anji reddyÎncă nu există evaluări

- Copis & FmeaDocument16 paginiCopis & FmeaEXDE601E100% (2)

- Fmea GuideDocument11 paginiFmea GuideSASIKUMARÎncă nu există evaluări

- 13 Fmea 1Document36 pagini13 Fmea 1hello2er.ajayÎncă nu există evaluări

- FMEA TemplateDocument6 paginiFMEA TemplateHiếu Trần100% (1)

- "Fmea & Case Study": Kelompok: Rohmat Setiawan Titin NuryawatiDocument41 pagini"Fmea & Case Study": Kelompok: Rohmat Setiawan Titin Nuryawatirohmat_setiawan77Încă nu există evaluări

- FMEADocument24 paginiFMEARaajha MunibathiranÎncă nu există evaluări

- Failure Mode Effect Analysis: Dr. Ir. Muhammad SabriDocument42 paginiFailure Mode Effect Analysis: Dr. Ir. Muhammad Sabricalvin100% (1)

- Dfmea TemplateDocument5 paginiDfmea TemplateHerbert WeigeltÎncă nu există evaluări

- FMEA Failure Mode Effect AnalysisDocument61 paginiFMEA Failure Mode Effect AnalysisAbhijeet RandhirÎncă nu există evaluări

- Failure Mode Design ProjectDocument12 paginiFailure Mode Design ProjectSaddam AbdullahÎncă nu există evaluări

- Failure Mode Effect Analysis With Pareto Chart For Various Critical Equipment Used in Ceramic IndustryDocument6 paginiFailure Mode Effect Analysis With Pareto Chart For Various Critical Equipment Used in Ceramic IndustrynsrinÎncă nu există evaluări

- FMEADocument3 paginiFMEAyadiÎncă nu există evaluări

- Fmea Guide q1Document161 paginiFmea Guide q1Mahesh VaneÎncă nu există evaluări

- WangChinPoonYang ESWA PDFDocument13 paginiWangChinPoonYang ESWA PDFSmart BoyÎncă nu există evaluări

- FMEA Minus The Pain FiguresDocument3 paginiFMEA Minus The Pain FiguresMUNISÎncă nu există evaluări

- FMEA Guide-Q1Document161 paginiFMEA Guide-Q1R.BalasubramaniÎncă nu există evaluări

- Failure Mode and Effects AnalysisDocument5 paginiFailure Mode and Effects AnalysisSamantha IsabelÎncă nu există evaluări

- Fmea PDFDocument161 paginiFmea PDFManoj KumarÎncă nu există evaluări

- Teaching An Old FMEA New TricksDocument21 paginiTeaching An Old FMEA New TricksJossie FuentesÎncă nu există evaluări

- Risk Reduction Strategy QSB-PlusDocument19 paginiRisk Reduction Strategy QSB-PlusAhmed HassanÎncă nu există evaluări

- Process Failure Mode and Effects Analysis: Occurrence RatingDocument6 paginiProcess Failure Mode and Effects Analysis: Occurrence RatingKaran Singh RaiÎncă nu există evaluări

- Substation Earth Testing Job Safety AnalysisDocument5 paginiSubstation Earth Testing Job Safety AnalysishkaruvathilÎncă nu există evaluări

- Substation Earth Testing Job Safety AnalysisDocument5 paginiSubstation Earth Testing Job Safety Analysispartho banerjeeÎncă nu există evaluări

- FMEADocument9 paginiFMEADhivakar S K100% (1)

- Fmea Template Qms Adm B F 1002Document8 paginiFmea Template Qms Adm B F 1002Allen de GuzmanÎncă nu există evaluări

- CD6 Prototype PFMEADocument4 paginiCD6 Prototype PFMEAmpedraza-1Încă nu există evaluări

- PFMEA RankingDocument1 paginăPFMEA RankingSachin KumbharÎncă nu există evaluări

- QSP 14 Fmea Procedure - 01Document7 paginiQSP 14 Fmea Procedure - 01kmvimal36Încă nu există evaluări

- Etech Automation Mr. Varun Dev FMEA / 26221839 05.10.2012 Mr. Sethupathi Terminal BendingDocument4 paginiEtech Automation Mr. Varun Dev FMEA / 26221839 05.10.2012 Mr. Sethupathi Terminal BendingMadan PrakashÎncă nu există evaluări

- Failure Analysis: Basic ConceptsDocument72 paginiFailure Analysis: Basic Conceptsbrucemartin3100% (1)

- Failure Mode and Effects Analysis of Hotwell System Motor Operated Butterfly ValveDocument19 paginiFailure Mode and Effects Analysis of Hotwell System Motor Operated Butterfly ValveBalan SelvanÎncă nu există evaluări

- FMEA GuideDocument161 paginiFMEA GuideGyanesh_DBÎncă nu există evaluări

- FMEA1Document25 paginiFMEA1azadsingh1Încă nu există evaluări

- Risk Assessment Aluminum CladdingDocument6 paginiRisk Assessment Aluminum CladdingkannanjaduzzÎncă nu există evaluări

- PFMEA Reference Card PDFDocument2 paginiPFMEA Reference Card PDFRajesh Yadav100% (6)

- 20bba0194 TQM Da 1 FmeaDocument9 pagini20bba0194 TQM Da 1 Fmeavani sureshÎncă nu există evaluări

- Risk Assessment Concrete WorkDocument10 paginiRisk Assessment Concrete WorkkannanjaduzzÎncă nu există evaluări

- FMEADocument9 paginiFMEARashmita SahooÎncă nu există evaluări

- A Dempster-Shafer Theory-Based Approach To The Failure Mode, Effects andDocument11 paginiA Dempster-Shafer Theory-Based Approach To The Failure Mode, Effects and弘瑞 蒋Încă nu există evaluări

- PFMEA EncodeDocument4 paginiPFMEA EncodeBooniz-bonice EliasÎncă nu există evaluări

- Watchdog Sepam 05Document9 paginiWatchdog Sepam 05gede_trinataÎncă nu există evaluări

- Risk Assessment (Volume Fraction)Document2 paginiRisk Assessment (Volume Fraction)Owais MalikÎncă nu există evaluări

- Process Potentail Failure Mode and Effects AnalysisDocument1 paginăProcess Potentail Failure Mode and Effects Analysiscong daÎncă nu există evaluări

- PFMEA Ranking Table Rating Criteria Action GuidelineDocument10 paginiPFMEA Ranking Table Rating Criteria Action GuidelineEnrico Miguel AquinoÎncă nu există evaluări

- Engineering Failure Analysis: Jianping Yang, Hong-Zhong Huang, Li-Ping He, Shun-Peng Zhu, Dunwei WenDocument9 paginiEngineering Failure Analysis: Jianping Yang, Hong-Zhong Huang, Li-Ping He, Shun-Peng Zhu, Dunwei WenChristian SilalahiÎncă nu există evaluări

- P740en PRC11 PDFDocument14 paginiP740en PRC11 PDFMochamad EffendiÎncă nu există evaluări

- Problem Analysis: Problem Analysis P740/En Pr/C11 Micom P740 Page 1/14Document14 paginiProblem Analysis: Problem Analysis P740/En Pr/C11 Micom P740 Page 1/14ZokiÎncă nu există evaluări

- Dell 3400 LCD FmeaDocument13 paginiDell 3400 LCD Fmeaarif.fahmiÎncă nu există evaluări

- FMEADocument74 paginiFMEAzulfiqarali721Încă nu există evaluări

- RPN RankingsDocument5 paginiRPN RankingsThế PhongÎncă nu există evaluări

- OE Training - UpdatedDocument24 paginiOE Training - Updatedvipin paul0% (2)

- Apqp & PpapDocument63 paginiApqp & Ppapjd4u100% (1)

- Department of Defense Handbook Companion Document TO MIL-STD-1916Document127 paginiDepartment of Defense Handbook Companion Document TO MIL-STD-1916summerssatomsÎncă nu există evaluări

- Fmea Failure Mode and Effects Analysis: Adapted From Presentation by Dr. StamperDocument23 paginiFmea Failure Mode and Effects Analysis: Adapted From Presentation by Dr. Stamperhasan_taşkınÎncă nu există evaluări

- Evaluation and Improvement of Distribution System Reliability Indices Using ETAP SoftwareDocument18 paginiEvaluation and Improvement of Distribution System Reliability Indices Using ETAP SoftwareJesifAhmedÎncă nu există evaluări

- R05 Certified Reliability EngineerDocument3 paginiR05 Certified Reliability EngineerAnonymous OFKjccHO100% (1)

- FMEA RCM Course - Foundations of Effective FMEA - RS 470 CourseNotes - Rev9.1Document358 paginiFMEA RCM Course - Foundations of Effective FMEA - RS 470 CourseNotes - Rev9.1gminayas100% (1)

- CSSYB Insert B1698 PDFDocument8 paginiCSSYB Insert B1698 PDFVinit ShahÎncă nu există evaluări

- Apqp Stages AIAG-1Document49 paginiApqp Stages AIAG-1Jose Antonio Santoyo RayaÎncă nu există evaluări

- Failure Mode Effect Analysis APR132K7Document4 paginiFailure Mode Effect Analysis APR132K7Elvis DiazÎncă nu există evaluări

- 2010 HP&D Asia - Dam Safety During Design, Construction and Operation - BARKER PDFDocument11 pagini2010 HP&D Asia - Dam Safety During Design, Construction and Operation - BARKER PDFMihai MihailescuÎncă nu există evaluări

- Guideline On Mahindra Part Approval Process: (For Bought-Out Parts)Document21 paginiGuideline On Mahindra Part Approval Process: (For Bought-Out Parts)Sam AnuÎncă nu există evaluări

- MaintenanceProgusingReliabilityMethods MSG-3 Issue2Document5 paginiMaintenanceProgusingReliabilityMethods MSG-3 Issue2Luis Enrique La Font Franco0% (1)

- Process Verification VsDocument6 paginiProcess Verification Vschemist_tmaÎncă nu există evaluări

- Failure Mode and Effect AnalysisDocument34 paginiFailure Mode and Effect AnalysisAshok100% (3)

- Design For Reliability June 2007Document42 paginiDesign For Reliability June 2007Teshome DengisoÎncă nu există evaluări

- Ansi - Ieee STD 352 - 1987Document118 paginiAnsi - Ieee STD 352 - 1987ERICK MARTINEZ AGUIRREÎncă nu există evaluări

- Variations in Risk Management Models: A Comparative Study of The Space Shuttle Challenger DisastersDocument13 paginiVariations in Risk Management Models: A Comparative Study of The Space Shuttle Challenger DisastersSriÎncă nu există evaluări

- Potential Failure Mode and Effects Analysis (Fmea) Reference Manual Fourth Edition (Pdfdrive)Document150 paginiPotential Failure Mode and Effects Analysis (Fmea) Reference Manual Fourth Edition (Pdfdrive)Filip MoravčíkÎncă nu există evaluări

- Se - FmeaDocument21 paginiSe - FmeaAshokÎncă nu există evaluări

- FMEA2002Document22 paginiFMEA2002deleep6132Încă nu există evaluări

- Risk Management and Human ErrorDocument91 paginiRisk Management and Human Errorpei3721Încă nu există evaluări

- Advanced Product Quality Planning: Campodarsego, 4-8 April 2005Document17 paginiAdvanced Product Quality Planning: Campodarsego, 4-8 April 2005fabrizio100% (1)

- Part F - Additional Class NotationsDocument368 paginiPart F - Additional Class NotationsNicolas Matias CÎncă nu există evaluări

- MCQ Collection Ap 2020Document7 paginiMCQ Collection Ap 2020Venkadeshwaran KuthalingamÎncă nu există evaluări

- Volkswagen: Product Safety Representative (PSB)Document4 paginiVolkswagen: Product Safety Representative (PSB)Helton MotaÎncă nu există evaluări

- QMP-10 New Product DevelopmentDocument15 paginiQMP-10 New Product Developmentom cnc100% (1)

- AIAG AssessmentDocument40 paginiAIAG Assessmentthucdang.enimacÎncă nu există evaluări