Documente Academic

Documente Profesional

Documente Cultură

Note Si Somel Utk JD Enjin Nyiur Di Kalangan Masyarakat

Încărcat de

chaeqqDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Note Si Somel Utk JD Enjin Nyiur Di Kalangan Masyarakat

Încărcat de

chaeqqDrepturi de autor:

Formate disponibile

INVENTORY MANAGEMENT Speculative

Definitions Lot Sizing or Cycle

Inventory-physical resource that a firm holds in stock. Mistakes

intent of selling it or transforming it into a more

valuable state How to Measure Inventory

Inventory System- set of policies and controls and Average Aggregate Inventory Value: how much of the

monitors levels of inventory company’s total assets are invested in inventory?

Weeks of Supply Order Timing : Reorder Point (ROP)

Inventory Turnover (Turns) When inventory is depleted to ROP, order

replenishment of quantity EOQ

Reasons Against Inventory ROP = D X LT

Zero Inventory? Non-value added costs D = Demand rate per period

Reducing amounts of raw materials and purchased Opportunity cost LT = lead time in periods

parts and subassemblies by having suppliers deliver Complacency

them directly. Inventory deteriorates, becomes obsolete, lost, stolen,

Reducing the amount of works-in process by using just- etc.

in-time production.

Reducing the amount of finished goods by shipping to Inventory Costs

markets as soon as possible.

Procurement costs Carrying costs Out-of-stock costs

Reasons for Inventories • Order processing • Capital • Lost sales cost

Improve customer service • Shipping (opportunity) costs • Back-order cost

• Handling • Inventory risk costs Quantity Discount

Economies of purchasing & production • Space costs

• Purchasing cost: 1. Write out the total cost equation

Transportation savings c(x)= $100 + $5x • Inventory service

• Mfg. cost: costs 2. Solve EOQ at highest price and no discounts

Hedge against future c(x)=$1,000 + $10x 3. If Qmin falls in a range with a lower price, recalculate EOQ

Unplanned shocks (labor strikes, natural disasters,

assuming holding cost for that range. Call this Q2.

surges in demand, etc.) Independent Demand 4. Evaluate the total cost equation at Q2 at the next highest price

To maintain independence of supply chain items are finished products or parts that are shipped as break point.

end items to customers. OR Use a spreadsheet

Nature of Inventory Forecasting plays a critical role

Quality - inventory can be a “buffer” against poor Due to uncertainty- extra units must be carried in Periodic Review Method

quality; conversely, low inventory levels may force high inventory Q-system - each stock item reordered at different times

quality

- complex, no economies of scope or common

Speed - location of inventory has gigantic effect on Dependent Demand prod./transport runs

speed items are raw materials, component parts, or P-system - inventory levels for multiple stock items

Flexibility - location, level of anticipatory inventory both subassemblies that are used to produce a finished reviewed at same time - can be reordered together

have effects product.

Cost - direct: purchasing, delivery, manufacturing MRP systems Classifying Inventory Items : ABC Classification (Pareto Principle)

indirect: holding, stockout.

A Items: very tight control, complete and accurate

HR systems may promote this-3 year postings Micro Issues

records, frequent review

Functional Roles of Inventory Order Quantity : Economic Order Quantity (EOQ) B Items: less tightly controlled, good records, regular

Transit Q = 2DCo/Ch review

Buffer D = annual demand C Items: simplest controls possible, minimal records,

Seasonal Co = ordering/setup costs large inventories, periodic review and reorder

Decoupling Ch = cost of holding one unit of inventory

• Manufacturing planning and control

Anticipatory Inventory Control

determine requirements by forecasting demand for the Process Design

next production run or purchase • “Focused Factories”

establish current on-hand quantities • Group Technology

add appropriate safety stock based on desired stock • Simplified layouts with little storage space

availability levels and uncertainty demand levels • Jidoka (Stop everything when something goes wrong- a

Tighter coordination along the supply chain

determine how much new production or purchase form of stopping quality problems at their source) and

Goods are pulled along- only make and ship what is needed

needed (total needed - on-hand) Poka-Yoke(failproofing: Examples are gasoline nozzles,

VCR cassettes (they are ejected if inserted incorrectly),

JIT Goals (throughout the supply chain)

Response-Based System inkjet cartridges, etc)

• Eliminate disruptions

replenishment, production, or purchases of stock are • Minimum setups

• Make the system flexible

made only when it has been signaled that there is a

• Reduce setup times and lead times

need for product downstream Personnel and Organizational Elements

• Minimize inventory

requires shorter order cycle time, often more frequent, • Workers as assets

• Eliminate waste

lower volume orders • Cross-trained workers

determine stock requirements to meet only most • Greater responsibility at lower levels

Waste

immediate planning period (usually about 3 weeks) • Leaders as facilitators, not order givers

Waste is ‘anything other than the minimum amount of

• Classic Organizational View

equipment, materials, parts, space, and worker’s time, which are

Service Level Achieved absolutely essential to add value to the product.’

• Item fill rate (IFR): the probability of filling Forms of Waste:

an order for 1 item from current stock • Overproduction

• Waiting time

• Transportation

• Weighted Average Fill Rate (WAFR): multiply • Processing

IFR for each stock item on an order weighted • Inventory

by the ordering frequency for the item • Motion

• Product Defects

JUST-IN-TIME/LEAN PRODUCTION • JIT Organization View

Inventory as a Waste

A repetitive production system in which the processing and • Requires more storage space

movement of materials and goods occur just as they are needed! • Requires tracking and counting

• Increases movement activity

Pre-JIT: Traditional Mass Production • Hides yield, scrap, and rework problems

• Increases risk of loss from theft, damage, obsolescence

Building Blocks of JIT

• Product design

Standard parts

Modular design Planning and Control Systems

Quality • “Small” JIT

• Process design • Stable and level schedules

• Personnel and organizational elements – Mixed Model Scheduling

Post-JIT: “Lean Production”

• “Push” versus “Pull”

– Kanban Systems (Uses simple visual signals to Objective :The degree of compliance of a process or its outcome approve, develop and implement product programs that

control production) with a predetermined set of criteria, which are presumed meet predetermined objectives.

– Examples: essential to the ultimate value it provides

empty slot in hamburger chute • The basic premises for concurrent engineering

empty space on floor • Formulation of a medication – all elements of a product’s life-cycle should be

kanban card taken into careful consideration in the early

Subjective : The level of perceived value reported by the person

o Workcenter B uses parts produced by design phases

who benefits from a process or its outcome.

Workcenter A – The preceding design activities should all be

o When a container is opened by Workcenter occurring at the same time, or concurrently.

• Pain relief provided

B, its kanban card is removed and sent back • It allows for errors and redesigns to be discovered early

to Workcenter A. in the design process when the project is still in a more

Products and services

o Empty box sent back. Signal to pull another abstract stage.

• Product:-tangible items produced.

full box into Workcenter B. – Elements of a product’s life-cycle:

• Service :-refer to work done for clients or stakeholders

o How Many Kanbans? Functionality, Producibility, Assembly,

that does not result in the creation of tangible

Testability, Maintenance , Environmental

deliverables.

impact, Disposal and recycling

y = number of kanban cards

D = demand per unit of time Quality from engineering perspective

C. Value engineering (VE)

T = lead time To ensure quality, both product and process design should be

done efficiently. is a systematic method to improve the "value" of

C = container capacity

goods or products and services by using an

X = fudge factor

Traditional engineering examination of function.

Short time to define the product Value in VE is defined as the ratio of function to cost.

Implementing JIT

Long time to design and redesign the product Value can therefore be increased by either improving

Long overall design time the function or reducing the cost.

Function :- What something does not what something is

Key to shorten the overall design time – Began at General Electric Company during

• define the product better World War II.

• document the design process better – Problem

Shorter overall design time • Shortage of skilled labor, raw

Putting the Squeeze on Resources materials and component parts

A. Traditional Product Development Cycle (PDCA) – Solution

• PLAN :- Design or revise business process components • Suitable replacements for skilled

to improve results. labor, raw material and components

• DO :- Implement the new processes. – Results achieved

• CHECK :- Measure the results of the new processes and • Reduced costs and/or improved

compare the results against the expected results to product quality

Function ( s)

ascertain any differences. Value

• ACT :- Analyze the differences to determine their cause. Cost

INTRODUCTION TO QUALITY

Quality is a dynamic state associated with products, services, Decide where to apply changes.

DEFINITIONS OF QUALITY

people, environment, process that meets or exceeds customer General

expectation B. Concurrent Engineering

– No single definition

is a product development process in which appropriate

ISO 9000

Quality measurement disciplines are committed to work interactively to conceive,

– ISO = the International Organization for 7. Professionalism :- the skill, competence, or character 9. Break down barriers between departments :-the concept of the

Standardization expected of a professional 'internal customer', that each department serves not the

– ISO 9000 = Set of standards for quality 8. Timeliness :- customers waiting time, completed on management, but the other departments that use its outputs.

management time 10. Eliminate slogan :- Eliminate exhortations for the workforce;

– Quality should be defined relative to a set of 9. Completeness :- customer get all they asked for Instead, focus on the system morale.

requirements 10. Pleasantness :- whether the service brings feelings of 11. Eliminate work standards :- Eliminate quotas for production. It

Joseph M. Juran pleasure, enjoyment, or satisfaction encourages delivery of poor-quality goods.

– Fitness for use where fitness is always defined 12. Remove barriers to pride :- Remove barriers that rob people of

by the customer QUALITY THEORIES AND TOOLS pride of workmanship

Frederick Smith 13. Institute education and self-improvement

– Performance to the standard expected by the William Edwards Demming 14. Put everybody to work :- Include every one in the company to

customer accomplish the transformation.

– To the customer this means “ best value for Deming is perhaps the best-known quality pioneer.

money” His approach to quality was statistically based, Deming deadly disease

– Example FEDEX Early in his career, he worked at Western Electric’s, 1. Lack of constancy of purpose

During World War II, he worked with U.S. defense 2. Emphasis on short-term profits

Attributes of Product Quality industries to improve the quality of military items 3. Evaluation of performance, merit rating or annual

(Garvin (1984) from Harvard University) through statistical processes. review

1. Performance - product's primary operating characteristics. After World War II, Deming went to Japan under 4. Mobility of management

2. Features -Extra items added to the performance which government sponsorship to assist with a population 5. Running a company on visible figures alone

supplement their basic functioning census 6. Excessive medical costs for employee health care

3. Reliability -The probability a product functions over time 7. Excessive costs of warrantees

(Measure of reliability: mean time to first failure) W Edwards Deming 14 points for Management:

4. Conformance-Conformance is the degree to which a product's 1. Create constancy of purpose towards improvement. Replace Joseph M Juran

design and operating characteristics meet established standards. short-term reaction with long-term planning. • Based on three processes.

5. Durability -It is a measure of product life. Lifespan before 2. Adopt the new philosophy :-The implication is that • Control versus breakthrough

replacement. management should actually adopt his philosophy, rather than • Project-by-project improvement

6. Serviceability-Serviceability is the speed, competence, and ease merely expect the workforce to do so.

of repair. 3. Cease dependence on inspection to achieve quality. Build

7. Aesthetics-How a product looks, feels, sounds, tastes, or smells, quality into the product in the first place.

etc. (It is a subjective dimension of quality) 4. End awarding business on the basis price tag. Move towards a

8. Perceived Quality -Subjective perceptions based on brand single supplier for any one item. Multiple suppliers mean variation

names, advertising, etc. between feedstocks.

5. Constantly improve the system :-Constantly strive to reduce

Attributes of Service Quality variation.

1. Tangibles - physical elements of the service such as 6. Institute training on the job :-If people are inadequately

facilities and equipment. trained, they will not all work the same way, and this will

2. Service Reliability - dependability, accurate performance introduce variation.

* Pareto Law identified by Juran

3. Responsiveness - the willingness to help customers and 7. Improve leadership :-Deming makes a distinction between

* Pareto Law was named according to

provide prompt service. leadership and mere supervision. The latter is quota- and target-

Italian economist Vilfredo Pareto

4. Assurance - the ability to inspire trust and confidence based.

5. Empathy - the degree to which customers are treated 8.Drive out fear :- Management by fear is counter- productive in

the long term, because it prevents workers from acting in the

• Philosophy: ‘Quality does not happen by accident, it has

as individuals.

6. Availability :- services are easily accessible or obtainable organization's best interests. to be planned.’

• The emphasis of his work is on

– planning – It is first observed by the Italian economist • Assertions

– organizational issues Vilfredo Pareto that 80% of the land in Milan was – “Quality begins with education and ends with education”

– management’s responsibility for quality owned by 20% of the population. – “The first step in quality is to know the requirements of

– the need to set goals and targets for improvement • The Pareto Principle p helps you realize that the the customer”

majority of results come from a minority of inputs – “The ideal state of quality control is when inspections is

• ‘Management controllable defects account for over 80% no longer necessary”

of the total quality problems’. A Pareto chart is a type of chart that contains both bars and – “95% of problems in a company can be solved by the 7

• Juran’s beliefs on quality can be derived from: a line graph, where individual values are represented in tools of quality(data analysis tools):

– management is largely responsible for quality descending order by bars, and the cumulative total is • Histograms, Pareto Charts, Cause and Effect Diagrams,

– quality cannot be consistently improved unless the represented by the line Run Charts, Scatter Diagrams, Flow Charts/Process

improvement is planned. • It is used to identify the vital factors that are causing Maps, Control Charts

– planned improvement must be specific and most of the quality problems

measurable • Concentrating improvement efforts on these few will Armand Feigenbaum

• He defines quality as ‘fitness for use or purpose’ have a greater impact and be more cost effective than Wrote a TQC book and proposed a three step

process for quality improvement:

– It is suggested that this definition is better than undirected efforts.

1 - Quality leadership

conformance to specification’, since a dangerous product

2- Quality technology

could conform to all specifications but still be unfit for use. Koura Ishikawa

3- Organizational commitment

* Basic tool of quality

For quality improvement he outlined 19 steps

1. Quality begins with education and ends with education

1. Quality planning of TQC with emphasis on organizational involvement.

2. The first step in quality is to know the requirements of the

– Identify who the customers are

customer

– Determine the needs of those customers 3. The ideal state of quality control is when inspections is no

• an American quality control expert and businessman

– Translate those needs into our language longer necessary • He originated the approach to quality known as Total

– Develop a product that can respond to those needs 4. Remove the root causes, not the symptoms Quality Control (TQC)

– Optimize the product features so as to meet our needs 5. Quality control is the responsibility of all workers and all • Philosophy

and customer need divisions For quality improvement

6. Do not confuse the means with the objectives – all functions in an organization should be involved in the

2. Quality control 7. Put quality first and set your sights on long-term objectives quality process

8. Marketing is the entrance and exit of quality

– Prove that the process can produce the product under – quality should be built into the product rather than

9. Top management must not show anger when facts are

operating conditions with minimal inspection failure being inspected out.

presented to subordinates

– Transfer the process to Operations. 10. 95% of the problems in a company can be solved by the 7

tools of quality The overall method of Feigenbaum can be reduced to four

3. Quality improvement 11. Data without dispersion information are false data. steps process

– Develop a process which is able to produce the product 1. Set quality standards

– Optimize the process • Commenced his career as a chemist, held a doctorate in 2. Appraise conformance to standards

engineering and was an emeritus professor at Tokyo 3. Act when standards are not met

Pareto Principle University. 4. Plan to make improvements

– is suggested by Juran and he named it after Italian • Believed that, “firms must make everyone responsible for

economist Vilfredo Pareto statistical analysis and interpretation” to be successful Philip Crosby

– It states that, for many events, roughly 80% of the • Described by some as the ‘Father of Quality Circles’ and • Focuses on customer satisfaction as a measure of quality

effects comes from 20% of the causes as a founder of the Japanese quality movement control

• Zero Defect (ZD) = ““Do it right first time Do time”” • Identify the problem

• Also introduced 14 steps to improve quality, among • Brain storm the causes of the problem

these: • Classify the causes by common factors into categories

– Make it clear management is committed to Q • Use the fishbone diagram to illustrate the cause and

– Form Q improvement teams with representatives from effect

each department

– Raise Q awareness among all staff

Q improvement through Crosby’s 14 steps

1. Make it clear that management is committed to Q Two distinct processes with different centers.

2. From Q improvement teams with representatives from Identify between the two processes.

each department

3. Determine how to measure where current and potential

Q problem lie

4. Evaluate the cost of Q and explain it use as a

management Tool Histogram

5. Raise the Q awareness & personal concern of all

employees

6. Take formal actions to correct problems identified

through various steps

7. Establish a committee for zero defect program

8. Trains all employees to actively carry out their part of the

Process is ill defined

Q improvements

9. Hold a zero‐defect day to let all employees realize that

Run Chart

there has been a change

• Run charts display process performance over time

10. Encourage individuals to establish improvement goals

• It is easy to spot upward and downward trends, cycle,

for themselves and their groups

etc. easily using run charts

11. Establish a committee for zero defect program

• Run chats can also be used to track improvements that

12. Trains all employees to actively carry out their part of

have been put into place

the Q improvements

• An average line can be added to a run chart to observe

13. Establish quality councils to communicate on a regular

movement of data away from the average

basis.

14. Do it all over again.

Scatter plot

• Scatter plot is used to investigate a possible relationship

Fishbone Diagram

between two variables that relate to the same event

– It is a graphical technique for grouping ideas about

• A straight line of best fit is often included

the causes of a given quality problem

• Scatter plots can be used to determine the type of

– It helps to identify both the primary and secondary

relationships that occur in a process

causes of a problem

– Positive correlation

– Procedure for developing the fishbone diagram:

– Negative correlation

Flow chart • Six Sigma seeks to improve the quality of process outputs – Disseminate innovation

• Graphical representation of a process by identifying and removing the causes of defects and – Safeguard consumers and users in general, of products

• Steps in a process are shown with symbolic shapes and minimizing variations using quality management tools. and services

the flow of the process is indicated with arrows connecting • Sigma rating is used to measure the defect rate of a – Make life simpler by providing solutions to common

the symbols. manufacturing process problems

• Flowcharts can help • A six‐sigma process is one in which 99.99966% of the

– See whether steps of a process are logical products manufactured are statistically expected to be free In Malaysia, the department of standards Malaysia (DSM) is

– Uncover miscommunication ( process problems) of defects (3.4 defects per million). mandated by the y government of Malaysia to function as

– define boundaries of a process the National Standards Body (NSB) as well as National

– Develop common base knowledge about a process Accreditation Body (NAB)

The Main Objectives of DSM are:

Control Chart – To promulgate, develop and promote national standards

• Control charts are used to identify “common‐cause” and – To manage the national accreditation schemes in

“special‐cause” variations in a process accordance to the international practices

• "common‐cause" is the usual, historical, quantifiable – To maintain credibility, integrity and competency of the

variation in a system national standardization and accreditation system

• "special‐causes" are unusual, not previously observed, – To safeguard the interest of Malaysia at a regional and

non‐quantifiable variation. international levels in the fields of standardization and

• All control chart types have three basic components accreditation.

– A centerline , usually the average of all the samples

ISO Certification

plotted Global Competitiveness

ISO 9000 is a family of standards developed to provide a

– Upper and lower statistical control limits that define the The Global Outlook

framework around which a quality management system

constraints of common cause variations • Better quality products and services will ensure higher

can be effectively implemented.

– Performance data plotted over time recognitions in terms of global competitiveness

• ISO 9001:2000, the requirement standard, includes the

• The basic rule of statistical process control is: • International trade known no boundary but subject to

following main sections:

Variation from common‐cause systems should be left to customers choice and demand plus other factors like

– Quality Management System

chance, but special causes of variation should be identified political matter. All of us are customers

– Management Responsibility

and eliminated. • “Global competition is played out by different rules and

– Resource Management

• Special causes can be identified using tests such as: different stakes at each level” C.K. Prahalad and Gary

– Product Realization

– Data point falling outside the control limit Hamel

– Measurement Analysis and Improvement

– steadily increasing or decreasing data points • Customers groups set their own quality of product that

– Several data points in one side of the center line meet their need

Some Advantages of ISO certification

– Fourteen or more points alternating up and down • Customers in Europe and in Asia request different quality

– Ensure that the development, manufacturing and supply

and different specification

of products and services are becoming more efficient, safer

Six Sigma • According to World Economic Forum (WEF) (2009),

and cleaner.

• Six Sigma is a business management strategy originally competitiveness can be defined as the set of institutions,

– Facilitate trade between countries and make it fairer

developed by Motorola, it is used in many sectors of policies and factors that determine the level of productivity

– Provide governments with a technical base for health

industry. of a country

safety and environmental legislation

• The twelve pillars of competitiveness

– Share technological advances and good management

practice

Inhibitors to Competitiveness – Process planning – Is easy to assimilate

• Business/government related ‐7 deadly diseases by – Production planning – Adds structure to the information

Deming – Service industries – Adapts to changes (a living document)

• Education‐related factor –the higher the education the • When an organization decides to implement QFD, the – Provides framework for sensitivity analysis

faster they become productive employees project manager and team members need to be able to

• Family‐related factor ‐the more motivated and commit a significant amount of time to it, especially in the Organization of Information

knowledgeable they are, the faster they learn and become early stages. • Now, the customer expectations and needs have been

productive employees • There are two types of teams: identified and researched, the QFD team needs to process

– Designing a new product the information.

Design for quality – Improving an existing product • Methods include:

• Requires answer to set of questions : • Time and inter‐team communication are two very – Affinity diagrams

– What are the functions customer wants? important things that each team must use to their fullest – Interrelationship diagrams

– What are the capabilities of current products? potential – Tree diagrams

– Are there better material available? • Team meetings are very important in the QFD process. – Cause‐and‐effect diagrams

– How much the product cost for successful marketplace? – The team leader needs to ensure that the meetings are • An Affinity Diagram should be used when:

– What are critical attribute of performance? run in the most efficient manner and that the members are – Thoughts are too widely dispersed or numerous to

– How much performance does customer want? kept informed. organize.

– Duration of the meeting will rely on where the team’s – New solutions are needed to circumvent the more

Design for Quality Products and Services members are coming from and what needs to be traditional ways of problems solving.

Design process accomplished. – Support for a solution is essential for successful

Design engineer need to brainstorm to generate ideas: implementation.

- e.g. marketing, management, R&D and employee Benefits of QFD • Constructing an affinity diagram requires four simple

and customers •Improves Customer Satisfaction steps:

Projection of customers future needs – Creates focus on customer requirements 1. Phrase the objective.

- Intel producing microprocessors to fit the explosion of – Uses competitive information effectively 2. Record all responses

graphic programs on the net at a faster rate than the – Prioritizes resources 3. Group the responses

competing microprocessor developer – Identifies items that can be acted upon 4. Organize groups in an affinity diagram

– Structures resident experience/information

Quality Functions Deployment •Reduces Implementation Time Conclusion

• Quality function deployment (QFD) is a planning tool used – Decreases midstream design changes • QFD

to fulfill customer expectations. It is a disciplined approach – Limits post introduction problems – Effective management tool

to product design, engineering, and production and – Avoids future application opportunities – Customer expectations are used to drive design process

provides in depth evaluation of a product. – Surfaces missing assumptions or to drive improvement in service industries

• QFD focuses on customer expectations or requirements, •Promotes Teamwork

often referred to as the voice of the customer. – Based on consensus Advantages & Benefits

• It is employed to translate customer expectations, in – Creates communication at interfaces • Orderly way of obtaining information & presenting it

terms of engineering or technical characteristics, that can – Identifies actions at interfaces • Shorter product development cycle

deployed through: – Creates global view out of details • Considerably reduced start‐up costs

– Product planning •Provides Documentation • Fewer engineering changes

– Part development – Documents rationale for design • Reduced chance of oversights during design process

• Environment of teamwork - Mechanism e.g : Hand-over Document, Defects List, Defects Acting to bring expected cost overruns within

• Consensus decisions Liability/ Guarantee Period, Performance Bond, As-built Drawings acceptable limits

• Everything is preserved in writing

3.2 Control During Construction/Production

• Entire organization constantly aware of customer

Control during this stage is most important

requirements

Two types of control

• Marketing—specific sales points have been identified and Time (Schedule) Control and

can be stressed Cost Control

• Results in satisfied customers

Time or Schedule Control is concerned with

PROJECT CONTROL AND TERMINATION Determining the current status of the project schedule

Determining if the project schedule has changed

Control Definition Influencing the factors that create schedule changes

Measuring what is actually achieved in a project with Managing the actual changes as they occur

regard to the OBJECTIVES (t, c, q), comparing it with a

“baseline” (referenced/original) performance and

monitoring and taking corrective measures should there

be unacceptable deviation from the baseline 3.3 Earn Value and S-Curve

Or simply ”tracking, monitoring and steering” a project Earn value analysis compares the cost value of work

so that the objectives will be met done with the value of work that should have been

done (i.e. the base-line)

3.1 Control systems throughout the project Value of work done comprises of:

Control systems / mechanisms must be provided at each Indirect costs

stage of the project Cost of materials delivered on sit

Defining or Initiation Stage Cost of actual physical work on site

- Needed for understanding of the business environment & Earn value can also be presented in the form

making sure all necessary controls are incorporated into the of S-curve –simpler and more widely used

Project Time or Schedule Control: Progress Monitoring Using S-curve examines and compares the value of work done

- Mechanism e.g. : Cos Benefit Analysis; Budget ; Project Comparison Bar Charts with the actual value or progress – in terms of time

Charter (wrt cost, time and quality) Assume the progress of the activity as a direct linear (delays) or amount (over or under-achievement)

Planning and Design Stage function of the elapsed time

- To ensure that the final product will satisfy the client and meet Example: Road construction Important Terms

the specifications of the Project Charter • Time-now is the date when progress is measured

- Mechanism e.g. Benchmarking using models or prototypes or Cost Control • Budget at Completion (BAC) is the original cost estimate

mock structure Influencing the factors that create changes to the cost indicating the funds required to complete work

Execution (Construction / production) stage baseline • Percentage Complete (PC) (planned) is the planned

- To ensure all ‘Plans” are being executed and strictly followed Recording and monitoring cost performance to detect work progress up to time-now

(Schedule Plan, Cost Plan, Quality Plan) and understand changes from the cost baseline • Percentage Complete (PC) (actual) is the actual work

- Mechanism e.g. Time control (Schedule Baseline, Progress Assuring that potential cost overruns do not exceed the progress up to time-now

Comparison Bar Charts, Re-scheduling/ Updates, etc.); Cost authorized funding periodically and in total for the • Earned Value (EV) is the budgeted cost of work actually

control (Earn Value and S-curve); Resource leveling, Quality project. completed on that point of time (based on budgeted

Control Tests Informing appropriate stakeholders of approved rates).

Delivering stage changes EV = PC(actual) x BAC eg 25% x RM 2,500,000 =RM 625,000

- To check the efficiency or quality of the product delivered

• Planned Value (PV) is the portion of cost of work leveled i.e. distributed accordingly at the completed, or some repair work which, if carried out,

planned to have been spent between start date and required time to avoid or minimize will not cause inconvenience to the user or occupier.

time-now fluctuations in day-to-day use. The control mechanism used is “Certificate of Practical

PV = PC (planned) x BAC Resource Leveling (RL) makes use of “floats” or time Completion” issued to the contractor, together with a

• Actual Cost (AC) is the total actual cost incurred tolerances in the schedule to re-schedule resources and list of outstanding works and defects observed in

between the start date and time-now bring back any deviation of actual progress from project to be carried out or made good during a

schedule to within acceptable limits “Defects Liability Period”

RL applies to resources which are hired i.e. labour and DLP is a guarantee period during which the contractor

equipment as the need for these resources fluctuates has to complete any outstanding works or carry out

greatly as some activities start (requiring resources) repairs to any defects in the completed facility, failing

while other finish (releasing resources) which the Performance Bond will be forfeited.

RL improves efficiency and minimize project cost (by Upon completion of the the project, a Handing Over

optimizing labour usage and cost) Document is prepared and signed by the client.This

STEPS: starts the handing over of responsibility to the client for

Determine critical path and floats from network or other the whole project.

techniques

Identify key resource and produce bar chart using network

data

Plot histogram of resource demand

Reschedule timing of activities using float to obtain a more

even demand profile

Redraw the resource profile

S CURVE:

3.5 Control in Project Termination

The Project Manager will continuously monitor, control

and manage the project to ensure the good progress.

But if PM finds the performance is very unsatisfactory

and/or contractor is no longer capable of continuing the

project, then PM may recommend to S.O. Termination

of the project. Performance Bond of the contract will

also be forfeited.

The procedure for issuing notice of termination must

follow conditions of contract e.g. adequate time given

for contractor to improve performance and adequate

notice or warning letters given to terminate the

contract.

3.6 Control in Project Completion and Handing Over

If then project has been successfully completed, then

3.4 Resource Allocation and Leveling

PM must certify this

Resources of a project need to be

In construction projects, completion refers to ”Practical

scheduled i.e. right amount of resources must

Completion” - a stage where the project constructed

be allocated to a given task at the required

has achieved its intended function, or can be occupied

time

or used despite some outstanding work to be

S-ar putea să vă placă și

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Calorific Value of Biomass Fuels PDFDocument3 paginiCalorific Value of Biomass Fuels PDFkechikkrunchÎncă nu există evaluări

- Reactor For PetrochemicalDocument8 paginiReactor For PetrochemicalkechikkrunchÎncă nu există evaluări

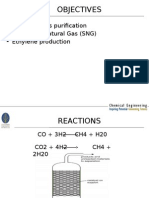

- Objectives: Synthesis Gas Purification Substitute Natural Gas (SNG) Ethylene ProductionDocument5 paginiObjectives: Synthesis Gas Purification Substitute Natural Gas (SNG) Ethylene ProductionkechikkrunchÎncă nu există evaluări

- Lecture 2.0 PolymerisationDocument24 paginiLecture 2.0 PolymerisationkechikkrunchÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)