Documente Academic

Documente Profesional

Documente Cultură

HPAC Article On Specifying VAV Boxes

Încărcat de

joejex123Descriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

HPAC Article On Specifying VAV Boxes

Încărcat de

joejex123Drepturi de autor:

Formate disponibile

S P E C I F I C A T I O N G U I D E 2 0 0 5

Specifying

VAV Boxes lthough differences in quality among

By JEFF STEIN, PE • Taylor Engineering • Alameda, Calif.

minimum-airflow set point is another good way

A the offerings of major variable-air-

volume (VAV) box manufacturers

tend to be small, a number of important zone-level

to deal with densely occupied spaces.)

• Parallel fan-powered. Parallel-fan-powered

boxes make sense in zones with relatively high

decisions regarding VAV boxes must be made to heating requirements, such as north-facing,

achieve a system that is both quiet and energy-effi- perimeter zones. Energy codes, such as ANSI/

cient and that provides thermal comfort. Assuming ASHRAE/IESNA Standard 90.1, Energy Standard

the most common building-level choice (overheard for Buildings Except Low-Rise Residential Buildings,

single duct with hot-water reheat), this article and Title 24, Part 6, of the California Code of

will focus on the important zone-level and controls Regulations, generally prohibit reheating more

decisions a specifying engineer must make. than 30 percent of maximum airflow.

BOX TYPE BOX SIZE

The first decision concerns which type of box For a given design airflow, at least two or three

to use. The options are: sizes of VAV box could be chosen. Box sizing is a

• Cooling only. Generally, cooling-only boxes tradeoff between first cost, pressure drop, reheat

should be used only where minimum ventilation energy, space requirements, and noise. Larger boxes

is not a concern and, therefore, can be set at zero. cost slightly more, require more space, and have

A telecommunication room is just such a place. higher minimum controllable airflow rates (which

Another is a large open office with multiple boxes, could result in more wasted reheat energy) than

some serving heating and ventilation needs and smaller ones, which have higher pressure drops and

others cooling only. are noisier.

• Reheat. Because they are less expensive, quieter, Research has shown that the best way to optimize

and more efficient and require less maintenance these tradeoffs is to develop a sizing chart based on a

than fan-powered boxes, reheat boxes should be total-pressure drop of about 0.5 in. wg.1 Following

used for most heating applications. are the basic steps of box sizing:

• Series fan-powered. Series-fan-powered boxes 1) Select a product line to design around.

make sense where very high minimum-airflow 2) Decide on an acoustical criteria (e.g., radiated

rates are required. For example, a series box could NC 30). Note that VAV-box manufacturers report

be used in an interior conference room in which Noise Criteria (NC) using the standard attenuation

the minimum ventilation is more than 50 percent factors in ARI Standard 885-98, Procedure for

of the design cooling airflow. (Using reheat Estimating Occupied Space Sound Levels in the

boxes with carbon-dioxide controls to reset the Application of Air Terminals and Air Outlets, which

Jeff Stein, PE, is a senior engineer with Taylor Engineering and a member of ASHRAE Standard Project

Committee 130, Methods of Testing for Rating Ducted Air Terminal Units.

40 November 2005 • HPAC Engineering

S P E C I F I C A T I O N G U I D E 2 0 0 5

assumes a mineral-fiber ceiling and a

plenum that is 3-ft deep and at least

30-ft wide or is lined with insulation. Calculating Total-Pressure Drop

If your application is not close to these

AV boxes should be selected based where:

assumptions, develop new attenuation

factors, or use revised NC criteria. V on total pressure, not static pressure,

because it is total pressure that a central

∆TP = total-pressure drop

∆SP = static-pressure drop

3) Compare the manufacturer’s data

to your load calculations for a few fan must overcome. The ratio of static ∆VP = velocity-pressure drop

relatively high heating-load zones to pressure to velocity pressure can vary by vin = inlet velocity

determine if you can get away with box type, box manufacturer, and even box vout = outlet velocity

using only one-row coils. If you need size. Total-pressure drop can be cfm = airflow rate

any two-row coils, develop your sizing calculated as follows: D = box inlet diameter (feet)

chart based on two rows. TP = SP+ VP W = inside (clear) width of box outlet

2 (outside dimensions [feet] less insulation

v v

2

4) Use the manufacturer’s software or

= SP+ in – out thickness)

catalog and a spreadsheet to determine 4005 4005

the maximum airflow each box size can H = inside (clear) height of box outlet

2

4cfm cfm

2

(outside dimensions [feet] less insulation

achieve without violating the acoustical = SP+ 2

–

criteria and the total-pressure-drop 4005πD 4005 WH thickness)

criteria. Most manufacturers, unfortu-

nately, publish only static-pressure drop, AMPLIFICATION mines the amount of amplification it can

so you probably will need to calculate One of the few distinguishing features provide, as well as the amount of noise

velocity-pressure drop based on box of VAV boxes is airflow-sensor design. and pressure drop it creates. The greater

dimensions and iterate to find the Most manufacturers use a velocity-pres- the amplification, the lower the mini-

maximum airflow. sure sensor that provides an amplified mum controllable airflow. The first two

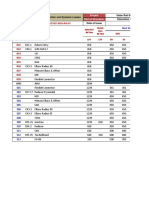

Table 1 is a sample VAV-box sizing pneumatic signal to the VAV-box con- references listed at the end of this article

chart. troller. The shape of the sensor deter- discuss how to calculate amplification

from manufacturers’ data and how to

Inlet size (in.) 6 8 10 12 14 16 calculate minimum controllable airflow.

Maximum flow (cfm) 343 568 940 1,210 1,667 2,162 While all manufacturers claim that

Inlet area (sq ft) 0.20 0.35 0.55 0.79 1.07 1.40 their patented airflow sensors provide

Velocity in (fpm) 1,747 1,627 1,723 1,541 1,560 1,548 better amplification, less noise, and lower

Inlet velocity pressure (in. wg) 0.190 0.165 0.185 0.148 0.152 0.149 pressure drop than those of their com-

Outlet width (in.) 12 12 14 16 20 24 petitors, there is a clear tradeoff: Some

Outlet height (in.) 8 10 12.5 15 17.5 18 airflow sensors provide higher amplifica-

Outlet area (sq ft) 0.53 0.69 1.04 1.46 2.18 2.72 tion, but at the expense of higher pressure

Outlet velocity (fpm) 641 826 905 830 766 796

drop. Thus, comparing manufacturers

based only on pressure drop (or the

Outlet-velocity pressure (in. wg) 0.026 0.043 0.051 0.043 0.037 0.040

maximum airflow rate for a given total

Velocity-pressure drop (in. wg) 0.16 0.12 0.13 0.11 0.12 0.11

pressure drop) may not be fair because a

Static-pressure drop (in. wg) 0.24 0.28 0.27 0.30 0.29 0.29

VAV box with a low pressure drop could

Total-pressure drop (in. wg) 0.40 0.40 0.40 0.40 0.40 0.40

have poor amplification. A better metric

Radiated Noise Criteria 28 25 27 27 27 24 for comparing VAV boxes is turndown

Minimum controllable (i.e., the ratio of minimum controllable

velocity-pressure signal (in. wg) 0.004 0.004 0.004 0.004 0.004 0.004

airflow to maximum airflow). Although

Amplification factor 2.80 2.24 1.96 2.03 1.97 1.94

amplification typically is not included

Minimum velocity (fpm) 151 169 181 178 180 182

in VAV-box schedules, requirements for

Minimum controllable flow (cfm) 30 59 99 140 193 254

amplification and/or turndown are good

Best turndown (percent) 9 10 10 12 12 12 to include in specifications.

Worst turndown (percent) 30 17 17 15 16 15

Average turndown (percent) 15 SUBMITTAL REVIEW

TABLE 1. Sample VAV-box sizing chart. A two-row hot-water coil, 1.5-in. dP across the If a contractor submits a product line

box, and ARI Standard 885-98 noise-attenuation factors assumed. other than the one you designed around,

42 November 2005 • HPAC Engineering

S P E C I F I C A T I O N G U I D E 2 0 0 5

create a new sizing chart, compare it to grounds for rejecting the substitution. and up because:

your box schedule, and issue a revised • The odd sizes (and the 4-in. size)

schedule if any of the boxes are too big EVEN VS. ODD SIZES usually are nothing more than the next-

or too small. Also, see if the new sizes Most VAV-box manufacturers make larger even-sized box with an adapter

and/or the amplification of the new boxes of the following sizes: 4 in., 5 in., at the inlet to accommodate smaller

airflow sensors affect the minimum- 6 in., 7 in., 8 in., 9 in., 10 in., 12 in., inlet duct. This extra fitting can affect

airflow set point for any of your zones. If 14 in., 16 in., and 24 in. by 16 in. While pressure drop, leakage, and airflow-

they significantly increase any of your one might assume that life-cycle cost sensor performance, particularly if it

minimum-airflow set points, consider (first cost, energy cost, etc.) would be is not installed properly (which can be

using the minimum-airflow set points optimized by including all of these sizes difficult to verify in the field).

on your schedule and the amplification in a sizing chart, you should consider • Most contractors do not provide

requirements in your specification as specifying only the even sizes from 6 in. odd-size ducts, making reducers and

VAV-Box Control Points and Control Sequences

ne of the most important (and,

O unfortunately, often overlooked)

decisions an engineer must make

Maximum-airflow

set point

Reheat-valve position

concerns what VAV-box control points

and control sequences to include in

control specifications. Many engineers Airflow

still are using the single-maximum-control set point

Minimum-

sequence, a relic from the days of airflow

set point

pneumatic controls. With modern direct-

digital-control systems, there is a much

more energy-efficient way to control

VAV boxes: the dual-maximum-control Reheat

scheme.

The single-maximum-control and dual-

maximum-control sequences are

Heating-PI signal Deadband Cooling-PI signal

illustrated in figures 1 and 2, respectively.

The single-maximum-control sequence FIGURE 1. Single-maximum-control sequence.

requires that the minimum-airflow set

point be high enough to provide design

heating airflow at a reasonable supply-air Maximum Maximum

supply-air cooling-airflow

temperature (e.g., 90 F). Thus, the temperature set point

minimum typically is set at 30 to 50 percent Supply-air-temperature

set point (requires

of the maximum, which means that at low discharge-temperature sensor)

load, the space is overcooled in deadband Maximum

and driven into reheat. heating-

airflow

In the dual-maximum-control sequence, set point

Airflow set point

as the load goes from full cooling to full

heating, the cfm set point is reset from

maximum to minimum before the supply- Minimum-

airflow

air-temperature set point is reset from set point

Reheat

minimum (e.g., 55 F) to maximum (e.g.,

90 F). If more heat is needed, the cfm set

point is reset from minimum to heating

Heating-PI signal Deadband Cooling-PI signal

maximum. Because it is decoupled from

Continued on Page 44 FIGURE 2. Dual-maximum-control sequence.

HPAC Engineering • November 2005 43

S P E C I F I C A T I O N G U I D E 2 0 0 5

expanders necessary.

• Many local dealers do not stock odd-

Continued from Page 43 controls specifications should require

size VAV boxes in their warehouses and, the heating needs, the minimum-airflow that VAV-box controllers be fully

thus, may substitute even sizes anyway. set point can be as low as the controllable programmable. The dual-maximum-

Using only even sizes 6 in. and larger minimum of the VAV box (as long as control sequence still is a new concept to

does not significantly affect average ventilation requirements are met). When most controls vendors; even if they tell

turndown. a dual-maximum-control scheme is used, you that their configurable, pre-

the minimum-airflow set point typically is programmed controllers can implement

REFERENCES

10 to 20 percent of design airflow. the dual-maximum sequence, chances

1) Taylor, S.T., & Stein, J. (2004). Simulation models of typical office that they will not be able to do it correctly

Sizing VAV boxes. ASHRAE Journal, 46, buildings have shown that switching from are good. Therefore, the best way to

30-35. a single-maximum-control approach with ensure that the dual-maximum-control

2) Hydeman, M., Taylor, S., Stein, J., a 40-percent minimum-airflow set point to sequence can be implemented properly is

Kolderup, E., & Hong, T. (2003, Octo- a dual-maximum-control approach with a to require fully programmable controllers.

ber). Advanced variable air volume 20-percent minimum-airflow set point can Another VAV-box control point one

system design guide. California Energy save 30 cents per square foot per year.2 should consider requiring is VAV-box

Commission Publication 500-03-082- For the dual-maximum-control damper position—either modulating

A-11. Available at http://www.energy.ca sequence to be implemented, controls (analog output) or floating (two digital

.gov/reports/2003-11-17_500-03-082_ specifications must require an analog outputs). Knowing VAV-box damper

A-11.PDF input for VAV-box supply-air temperature. position is extremely helpful in implement-

3) Hydeman, M., & Stein, J. (2003, (This is not required for the single- ing static-pressure reset, which can save

May). A fresh look at fans. HPAC Engi- maximum-control scheme.) Additionally, as much as 50 percent of fan energy.3

neering, pp. 28-30, 32, 35-37, 39-41.

44 November 2005 • HPAC Engineering

S-ar putea să vă placă și

- Structure Maintainer, Group H (Air Conditioning & Heating): Passbooks Study GuideDe la EverandStructure Maintainer, Group H (Air Conditioning & Heating): Passbooks Study GuideÎncă nu există evaluări

- PRICE - Air Distribution GuideDocument5 paginiPRICE - Air Distribution Guidenvenkat.narayan100% (1)

- Design of Cond TrapDocument7 paginiDesign of Cond TrapgtdprasadÎncă nu există evaluări

- Es Hvacdesigntips1001Document1 paginăEs Hvacdesigntips1001sajuhereÎncă nu există evaluări

- Ngineering ATA: Temperature & Altitude Effects On FansDocument3 paginiNgineering ATA: Temperature & Altitude Effects On FansMohamed TahounÎncă nu există evaluări

- Contoh DuctDocument10 paginiContoh DuctBudiman Raharjo'bjo'Încă nu există evaluări

- % Outdoor Air CalculationDocument6 pagini% Outdoor Air Calculationamirin_kingÎncă nu există evaluări

- ASHRAE Journal - Select & Control Economizer Dampers in VAV Systems - TaylorDocument7 paginiASHRAE Journal - Select & Control Economizer Dampers in VAV Systems - Taylorsajuhere100% (1)

- 2012 VAV Boxes Energy Efficiency, Air Leakage and ASHRAE 90.1Document29 pagini2012 VAV Boxes Energy Efficiency, Air Leakage and ASHRAE 90.1din_thorpe3248Încă nu există evaluări

- Need For Balancing ValvesDocument12 paginiNeed For Balancing ValvesBubai111Încă nu există evaluări

- Shop Drawing: Welcome Air-Tech (M) SDN BHDDocument1 paginăShop Drawing: Welcome Air-Tech (M) SDN BHDKarthi KeyanÎncă nu există evaluări

- Project Name: Doc No: Air System Name: Rev: Equipment Type: Date: Space Used For: Sheet No: Floor: Reference: ClientDocument10 paginiProject Name: Doc No: Air System Name: Rev: Equipment Type: Date: Space Used For: Sheet No: Floor: Reference: ClientMukti WibowoÎncă nu există evaluări

- Zoning Reference GuideDocument20 paginiZoning Reference GuideqwincyÎncă nu există evaluări

- Es Hvacdesigntips1100Document1 paginăEs Hvacdesigntips1100sajuhereÎncă nu există evaluări

- VAV Terminal UnitsDocument15 paginiVAV Terminal Unitsckyee88Încă nu există evaluări

- HVAC ReportDocument5 paginiHVAC ReportrazahÎncă nu există evaluări

- Es Hvacdesigntips0700Document1 paginăEs Hvacdesigntips0700sajuhereÎncă nu există evaluări

- Ventilation Design Sample For Locker Rooms and HACCPDocument10 paginiVentilation Design Sample For Locker Rooms and HACCPerickquinto100% (1)

- Part 10. All-Air Systems - Chapter 4. Dual-Duct System: Table 1 Summarizes The Cooling Load Requirements of 2)Document1 paginăPart 10. All-Air Systems - Chapter 4. Dual-Duct System: Table 1 Summarizes The Cooling Load Requirements of 2)Karthikeyan SankarrajanÎncă nu există evaluări

- FA128-12 AnalysisLabExhaustDocument4 paginiFA128-12 AnalysisLabExhaustTomy WongÎncă nu există evaluări

- Access Floor GRILLESDocument24 paginiAccess Floor GRILLESGangruka LordÎncă nu există evaluări

- Engineering Guide For Vav TerminalsDocument36 paginiEngineering Guide For Vav TerminalsAmar Singh CÎncă nu există evaluări

- Pre Startup DTDocument1 paginăPre Startup DTsajuhereÎncă nu există evaluări

- Combining DOAS and VRF, Part 1 of 2Document8 paginiCombining DOAS and VRF, Part 1 of 2miniongskyÎncă nu există evaluări

- HVAC - Overview of Space Heating Systems PDFDocument68 paginiHVAC - Overview of Space Heating Systems PDFFredie UnabiaÎncă nu există evaluări

- World Highest Building (Burj Kalifa) Air DisruptionDocument40 paginiWorld Highest Building (Burj Kalifa) Air DisruptionPrabu RajaÎncă nu există evaluări

- Cooling Coil Design (SI Units)Document3 paginiCooling Coil Design (SI Units)Christopher PersaudÎncă nu există evaluări

- High-Rise Fan - Coil - EngineerDocument15 paginiHigh-Rise Fan - Coil - EngineerMIN GUIÎncă nu există evaluări

- HVAC Design I - Class 8Document7 paginiHVAC Design I - Class 8Wyatt C. Lewis100% (1)

- AHU Friction Loss CalculationsDocument4 paginiAHU Friction Loss CalculationsAdnan AttishÎncă nu există evaluări

- Fabric Ducting Technical Data Eng North AmericaDocument32 paginiFabric Ducting Technical Data Eng North AmericaVictor MendozaÎncă nu există evaluări

- Im j1 Personnel Cooling Load Estimation 2014Document40 paginiIm j1 Personnel Cooling Load Estimation 2014Melvin SanchezÎncă nu există evaluări

- PVC Duct DesignDocument10 paginiPVC Duct DesigncitramuaraÎncă nu există evaluări

- 02 Cooling Load Calculation - HAPDocument2 pagini02 Cooling Load Calculation - HAPU DEEPAKÎncă nu există evaluări

- AHU InstallationDocument2 paginiAHU InstallationYazan AkÎncă nu există evaluări

- Relief Valve SizingDocument3 paginiRelief Valve SizingcutefrenzyÎncă nu există evaluări

- Ides-Edu: Lecture 7: Sizing Natural Ventilation SystemsDocument17 paginiIdes-Edu: Lecture 7: Sizing Natural Ventilation Systemsabhijeet7362Încă nu există evaluări

- Saving Energy in Lab Exhaust SystemsDocument11 paginiSaving Energy in Lab Exhaust Systemspal_stephenÎncă nu există evaluări

- Building HVAC Requirements: 4.1 OverviewDocument55 paginiBuilding HVAC Requirements: 4.1 OverviewHaroon GhaniÎncă nu există evaluări

- Psychrometric DiagramDocument6 paginiPsychrometric DiagramDavid LambertÎncă nu există evaluări

- Ishrae Variable Volume Pumping SystemDocument14 paginiIshrae Variable Volume Pumping SystemAidrus AliÎncă nu există evaluări

- Air Device Cross Reference GuideDocument2 paginiAir Device Cross Reference Guidesolowe988Încă nu există evaluări

- Ductwork DesignDocument26 paginiDuctwork DesignHafiz Hassan100% (1)

- Negative Room PressureDocument1 paginăNegative Room Pressureamg007Încă nu există evaluări

- BSE 3712 Intergrated System Design Report: Heating, Ventilation and Air ConditioningDocument19 paginiBSE 3712 Intergrated System Design Report: Heating, Ventilation and Air ConditioningChan Tsz HimÎncă nu există evaluări

- Geothermal HVAC: Shifting Performance Risk From Buyer To SellerDocument5 paginiGeothermal HVAC: Shifting Performance Risk From Buyer To SellerKagitha TirumalaÎncă nu există evaluări

- AHU Vs FCU Comparison PDFDocument5 paginiAHU Vs FCU Comparison PDFamirin_kingÎncă nu există evaluări

- Percent Outdoor Air (%OA) Calculation and Its Use: Application NoteDocument7 paginiPercent Outdoor Air (%OA) Calculation and Its Use: Application NoteAce Glen GarciaÎncă nu există evaluări

- Ashrae 15-34-Rev 3 MitsubishiDocument7 paginiAshrae 15-34-Rev 3 MitsubishiJosho SandovalÎncă nu există evaluări

- Supply Air DiffuserDocument6 paginiSupply Air Diffuserntt_121987Încă nu există evaluări

- Dehumidification Calcs AshraeDocument7 paginiDehumidification Calcs AshraeSujit RajanÎncă nu există evaluări

- ASHRAE Rousseau Et AlDocument5 paginiASHRAE Rousseau Et AlSantanu DasÎncă nu există evaluări

- HVAC Report FINALDocument65 paginiHVAC Report FINALIanÎncă nu există evaluări

- Design and Installation HVAC SystemsDocument36 paginiDesign and Installation HVAC SystemsSales and Promotions In KSAÎncă nu există evaluări

- Hap Ehelp 022Document5 paginiHap Ehelp 022Abed NaemÎncă nu există evaluări

- Hospital HVAC Design A Challenge For IAQ, Energy Recovery and System Reliability - Issue Jul-Sep 2002Document11 paginiHospital HVAC Design A Challenge For IAQ, Energy Recovery and System Reliability - Issue Jul-Sep 2002Go Tze FongÎncă nu există evaluări

- Fan Fundamentals PDFDocument57 paginiFan Fundamentals PDFPablo Guzman RetamalÎncă nu există evaluări

- Jsir 65 (4) 344-348Document5 paginiJsir 65 (4) 344-348shubhamdereÎncă nu există evaluări

- Dimensioning CabinetDocument3 paginiDimensioning CabinetGerman FavelaÎncă nu există evaluări

- Air Distribution For Comfort and Iaq: KruegerDocument10 paginiAir Distribution For Comfort and Iaq: KruegerhuynhtheanÎncă nu există evaluări

- Belt Drive Numerical 1Document6 paginiBelt Drive Numerical 1Prateek ridersÎncă nu există evaluări

- Fabrication Erection and Installation Procedure For PipingDocument36 paginiFabrication Erection and Installation Procedure For Pipinggst ajah100% (2)

- Types of PendulumsDocument10 paginiTypes of PendulumsAdrian Arasu100% (1)

- Operation and Maintenance of Power PlantDocument31 paginiOperation and Maintenance of Power PlantAnkur Pathak100% (1)

- Calculation Report On Bearing-Aashto-2012Document12 paginiCalculation Report On Bearing-Aashto-2012Tawfiqul IslamÎncă nu există evaluări

- Module 2Document43 paginiModule 2Manchimsetty Sri NidhiÎncă nu există evaluări

- ZYMT CNC Press Brake ConfigurationDocument8 paginiZYMT CNC Press Brake ConfigurationIonuţ RădescuÎncă nu există evaluări

- High-Density Polyethylene (PE) Line Pipe: Standard Specification ForDocument13 paginiHigh-Density Polyethylene (PE) Line Pipe: Standard Specification ForAhmad Zubair RasulyÎncă nu există evaluări

- Project Name: Xflow Local Protection Water Mist System Area Reference: Main EngineDocument5 paginiProject Name: Xflow Local Protection Water Mist System Area Reference: Main EngineAlexDorÎncă nu există evaluări

- AISI 1008 Steel: UNS G10080Document2 paginiAISI 1008 Steel: UNS G10080omneyaaÎncă nu există evaluări

- Ignition SystemDocument51 paginiIgnition SystemEyob TeklemariamÎncă nu există evaluări

- Gujarat Technological UniversityDocument2 paginiGujarat Technological UniversityMaulik PatelÎncă nu există evaluări

- Week 4 (Science)Document12 paginiWeek 4 (Science)Jeandro AgnesÎncă nu există evaluări

- TSSA-DLB-2020-Feb-09-2021-Biogas ProjectDocument9 paginiTSSA-DLB-2020-Feb-09-2021-Biogas ProjectNazrul IslamÎncă nu există evaluări

- Assignment On Wave Function and Born's Interpretation On Wave FunctionDocument6 paginiAssignment On Wave Function and Born's Interpretation On Wave FunctionMehak MughalÎncă nu există evaluări

- Signum-Technical-Guide LO SAMPLING GUIDEDocument30 paginiSignum-Technical-Guide LO SAMPLING GUIDEshirishkv100% (1)

- 603Document7 pagini603jessa marie sayconÎncă nu există evaluări

- Is.2951.2.1965 Head Loss in Flow Through PipesDocument19 paginiIs.2951.2.1965 Head Loss in Flow Through PipeskdpgrahiÎncă nu există evaluări

- IGCSE 13 Forces&MovementDocument26 paginiIGCSE 13 Forces&MovementHakim Abbas Ali PhalasiyaÎncă nu există evaluări

- Volume DampersDocument8 paginiVolume DampersglennpanÎncă nu există evaluări

- Refractory Equipment GAODETECDocument9 paginiRefractory Equipment GAODETECorangel anayaÎncă nu există evaluări

- Paper Id (Me302) : Nav'.O (Document2 paginiPaper Id (Me302) : Nav'.O (RaJan GargÎncă nu există evaluări

- WEG Alternadores Sincronos Linha Ag10 12638144 Manual Portugues BRDocument139 paginiWEG Alternadores Sincronos Linha Ag10 12638144 Manual Portugues BRAntonio Monteiro100% (1)

- D-Erection Manual Vol.1 of 2 Maaden TCM A00226 Rev.0. 2011Document255 paginiD-Erection Manual Vol.1 of 2 Maaden TCM A00226 Rev.0. 2011ganesan 00110% (1)

- Anillo Líquido 3Document4 paginiAnillo Líquido 3carlosÎncă nu există evaluări

- Fundamentals of Fluid Mechanics Chapter 12 TurbinesDocument44 paginiFundamentals of Fluid Mechanics Chapter 12 Turbinesalisnowkiss6570Încă nu există evaluări

- Filter PartnumberDocument1.019 paginiFilter PartnumberjaijeyenderÎncă nu există evaluări

- F120 - F160 Peco ManualDocument44 paginiF120 - F160 Peco ManualBernie WireÎncă nu există evaluări

- Viscometer Test PDFDocument2 paginiViscometer Test PDFAshishJamadarÎncă nu există evaluări

- Finite Element Analysis of Cylinder Piston Impact Based On ANSYS/LS-DYNADocument4 paginiFinite Element Analysis of Cylinder Piston Impact Based On ANSYS/LS-DYNAvenalum90Încă nu există evaluări