Documente Academic

Documente Profesional

Documente Cultură

530 Manual

Încărcat de

philpfisterDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

530 Manual

Încărcat de

philpfisterDrepturi de autor:

Formate disponibile

Deep Sea Electronics Plc

MODEL 530

AUTOMATIC TRANSFER SWITCH

CONTROL MODULE

Author:- Miles Revell

Deep Sea Electronics Plc

Highfield House

Hunmanby

North Yorkshire

YO14 OPH

England

Tel: +44 (0) 1723 890099

Fax: +44 (0) 1723 893303

E-Mail: Sales@Deepseaplc.com

DSE 530 ISSUE 1 10/03/2004 MR 1

2 DSE 530 ISSUE 1 10/03/2004 MR

TABLE OF CONTENTS

Section Page

INTRODUCTION ................................................................................................................................4

CLARIFICATION OF NOTATION USED WITHIN THIS PUBLICATION........................................4

1. OPERATION ...................................................................................................................................5

1.1 CONTROL .................................................................................................................................5

FIG 1 - FRONT PANEL LAYOUT.........................................................................................5

1.2 AUTOMATIC MODE OF OPERATION .....................................................................................5

1.3 MANUAL RESTORE MODE OF OPERATION.........................................................................6

1.4 MANUAL OPERATION .............................................................................................................7

1.5 MANUAL OPERATION WITH EXTERNAL PUSHBUTTONS ..................................................8

2. FUNCTIONS & INDICATIONS .......................................................................................................9

FIG 2 - LED DESCRIPTIONS ..............................................................................................9

2.1 INPUT FUNCTIONS..................................................................................................................9

2.2 OUTPUT FUNCTIONS............................................................................................................11

2.3 AC ONLY OPERATION FUNCTION.......................................................................................12

3. INSTALLATION INSTRUCTIONS ................................................................................................14

3.1 PANEL CUT-OUT ...................................................................................................................14

FIG 3 - CUT-OUT DIMENSIONS .......................................................................................14

3.2 COOLING ................................................................................................................................14

3.3 UNIT DIMENSIONS ................................................................................................................14

FIG 4 - DIMENSIONS.........................................................................................................14

3.4 FRONT PANEL LAYOUT........................................................................................................15

FIG 5 - FRONT PANEL ......................................................................................................15

3.5 REAR PANEL LAYOUT ..........................................................................................................15

FIG 6 - REAR PANEL.........................................................................................................15

4. ELECTRICAL CONNECTIONS ....................................................................................................16

4.1 CONNECTION DETAILS ........................................................................................................16

PLUG “A” 20WAY ......................................................................................................................16

PLUG “B” 12 WAY .....................................................................................................................17

4.2 CONNECTOR FUNCTION DETAILS .....................................................................................17

PLUG “A” 20 WAY .....................................................................................................................17

PLUG “B” 12 WAY .....................................................................................................................18

CALIBRATION SOCKET ...........................................................................................................18

5. SPECIFICATION...........................................................................................................................19

6. COMMISSIONING ........................................................................................................................20

PRE-COMMISSIONING ............................................................................................................20

7. FAULT FINDING ...........................................................................................................................21

8. TYPICAL WIRING DIAGRAM.......................................................................................................22

9. CALIBRATION ..............................................................................................................................23

9.1 PC INTERFACE MODULE 808 ..............................................................................................23

10. ICON DESCRIPTIONS ...............................................................................................................23

10.1 ICONS ...................................................................................................................................23

11. APPENDIX .................................................................................................................................23

11.1 LED IDENTIFICATION DIAGRAM........................................................................................24

FIG 7 - AUXILIARY LED’S ............................................................................................................24

11.2 FACTORY DEFAULT CONFIGURATION ............................................................................24

DSE 530 ISSUE 1 10/03/2004 MR 3

INTRODUCTION

The 530 is a fully configurable automatic transfer switch control module. It is designed to monitor

the incoming AC mains supply (1 or 3 phases) for under/over voltage and under/over frequency.

Should these fall out of limits the module will issue a start command to the generating set

controller. Once the set is available and producing an output within limits the ATS module will

control the transfer devices and switch the load from the mains to the generating set. Should the

mains supply return to within limits the module will command a return to the mains supply and shut

down the generator after a suitable cooling run. Various timing sequences are used to prevent

nuisance starting and supply breaks.

Configuration is by PC based software and the proven 808 interface using an FCC68 socket on the

rear of the module. This allows rapid and secure configuration of the module and also allows the

157 relay expansion module to be utilised. The FCC68 socket also provides full real-time

diagnostics on the status of the 530 module, its inputs and outputs.

Configuration and connection options allow for a wide range of higher functions such as ‘Auto start

inhibit’, ’Manual restore to mains’, ‘Load inhibit’ (both mains and gen-set), ‘Lamp test’, Push-button

transfer control, External mains or Gen-set failure inputs, etc.

A clear mimic diagram with ‘International’ symbols and LED indications provide at a glance

information as to supply availability and load switching status. Further LED indication is provided

for ‘Start delay in progress’ and ‘Mains return timer active’. Two user configurable LED’s are

provided to allow the user to display specific states.

Five user configurable relays are provided to allow control of contactors, different breaker types

and engine control modules and alarm systems.

The module features a self seeking power supply which will utilise power from the Mains AC

supply or the Generator AC supply. A DC supply to the module is not essential for basic operation,

though some higher functions require it.

The module is mounted in a robust plastic case, connection to the module is via plug and socket

connectors.

CLARIFICATION OF NOTATION USED WITHIN THIS PUBLICATION.

Highlights an essential element of a procedure to ensure

NOTE: correctness.

Indicates a procedure or practice which, if not strictly observed,

CAUTION!: could result in damage or destruction of equipment.

Indicates a procedure or practice which could result in injury to

WARNING!: personnel or loss of life if not followed correctly.

DEEP SEA ELECTRONICS PLC own the copyright to this manual,

which cannot be copied, reproduced or disclosed to a third party

without prior written permission.

4 DSE 530 ISSUE 1 10/03/2004 MR

1. OPERATION

On connection of the AC power or the optional DC power supply to the module, the module

becomes active.

NOTE:-The following description of operation assumes that the optional DC supply is

used.

1.1 CONTROL

Control of the 530 module is by a four position rotary key-switch, mounted on the front of the

module with AUTO, AUTO WITH MANUAL RESTORE and MANUAL RUN ON LOAD and OFF-

LOAD positions.

FIG 1 - FRONT PANEL LAYOUT

1.2 AUTOMATIC MODE OF OPERATION

If the module is placed in ‘AUTO’ mode, it will monitor the incoming mains supply.

Should the incoming mains supply fail (or fall outside of pre-set limits), the

following sequence will occur.

The module will start its ‘Start Delay’ timer, this is used to ensure that the start event is really

required and the failure is not just a momentary dip in the supply. Once this timer has expired the

module will continue with its normal sequence.

NOTE:- If the Mains supply returns to within limits during the Start Delay timer the

unit will return to a stand-by state.

The start and run generator output relay is de-energised and the relay contacts close, giving a

‘Remote Start’ signal to the engine starting controller. The generator failure timer is also

initiated at this time.

DSE 530 ISSUE 1 10/03/2004 MR 5

The engine starting controller will now start the generator, the 530 module will monitor the

generator voltage and frequency (and an optional generator ready input) and once the monitored

values are above a pre-set ‘Loading’ level the generator will become available. This is indicated by

the illumination of the appropriate LED on the mimic diagram.

As soon as the generator is available the warm-up timer is initiated. Once the warm-up timer

has expired the Mains close signal will be removed. The transfer timer will then be initiated.

Once the transfer timer has expired the generator close signal will be supplied.

On return of the mains supply to within limits, the Mains Return delay timer is initiated, once the

timer expires the Generator Close signal is removed, removing the load. The transfer timer is

then initiated, once this has expired the Mains Close signal is supplied. The Cooling timer is

then initiated, allowing the engine a cooling down period off load before shutting down. Once the

Cooling timer expires the Start and run generator signal is removed, bringing the generator to a

stop.

Should the Mains fall out of limits during the cooling down period, the set will return on load after

the Start Delay Timer has expired.

1.3 MANUAL RESTORE MODE OF OPERATION

If the module is placed in ‘MANUAL RESTORE’ mode, it will monitor the incoming

mains supply . Should the incoming mains supply fail (or fall outside of pre-set

limits), the following sequence will occur.

The module will start its ‘Start Delay’ timer, this is used to ensure that the start event is really

required and the failure is not just a momentary dip in the supply. Once this timer has expired the

module will continue with its normal sequence.

NOTE:- If the Mains supply returns to within limits during the Start Delay timer the

unit will return to a stand-by state.

The start and run generator output relay is de-energised and the relay contacts close, giving a

‘Remote Start’ signal to the engine starting controller. The generator failure timer is also

initiated at this time.

The engine starting controller should now start the generator, the 530 module will monitor the

generator voltage and frequency (and an optional generator ready input) and once the monitored

values are above a pre-set ‘Loading’ level the generator will become available. This is indicated by

the illumination of the appropriate LED on the mimic diagram.

As soon as the generator is available the warm-up timer is initiated. Once the warm-up timer

has expired the Mains close signal will be removed. The transfer timer will then be initiated.

Once the transfer timer has expired the generator close signal will be supplied.

On return of the mains supply to within limits, the Mains Return delay timer is initiated, once the

timer expires the 530 module will wait for a manual restore to mains. This is achieved by placing

the key-switch control into the ‘Auto’ position, the sequence will then continue as described in

section 1.2 above. Once the transfer back to the mains supply has taken place the key-switch

control may be returned to the ‘Manual Restore’ position.

Should the Mains fall out of limits during the cooling down period, the set will return on load after

the Start Delay Timer has expired.

6 DSE 530 ISSUE 1 10/03/2004 MR

1.4 MANUAL OPERATION

NOTE:- The following sequence is only applicable to controllers not using external

push-button control.

To initiate a start sequence in MANUAL, turn the selector switch to START AND

RUN GENERATOR OFF LOAD.

NOTE:- There is no Start Delay in this mode of operation unless the function has been

enabled via the PC software.

The start and run generator output relay is de-energised and the relay contacts close, giving a

‘Remote Start’ signal to the engine starting controller. The generator failure timer is also

initiated at this time.

The engine starting controller should now start the generator, the 530 module will monitor the

generator voltage and frequency (and an optional generator ready input) and once the monitored

values are above a pre-set ‘Loading’ level the generator will become available. This is indicated by

the illumination of the appropriate LED on the mimic diagram.

To transfer the load from the mains supply to the generator, turn the selector

switch to START AND RUN GENERATOR ON LOAD.

If the generator is not running the start sequence will be followed as above. As soon as the

generator is available the warm-up timer is initiated. Once the warm-up timer has expired the

Mains close signal will be removed. The transfer timer will then be initiated.

Once the transfer timer has expired the generator close signal will be supplied.

This will transfer the load to the generating set. To re-transfer back to the mains

supply return the selector switch to the START AND RUN GENERATOR OFF

LOAD position.

If it is required to re-load the generator, return the selector switch to the START

AND RUN GENERATOR ON LOAD position. This sequence may be repeated as

required.

To stop the generator return the selector switch to the AUTO position. The

generator Close signal is removed, removing the load from the generator. The

transfer timer is then initiated, once this has expired the Mains Close signal is

supplied. The Cooling timer is then initiated, allowing the engine a cooling down period off load

before shutting down. Once the Cooling timer expires the Start and run generator signal is

removed, bringing the generator to a stop.

Should the Mains fall out of limits during the cooling down period, the set will return on load after

the Start Delay Timer has expired.

DSE 530 ISSUE 1 10/03/2004 MR 7

1.5 MANUAL OPERATION WITH EXTERNAL PUSHBUTTONS

If the module has been configured to use external ‘To Mains’ and ‘To Generator’ pushbuttons the

normal ‘Manual’ mode of operation is over-ridden and the following sequence is observed;

Turn the selector switch to START AND RUN GENERATOR OFF LOAD.

The start and run generator output relay is de-energised and the relay contacts close, giving a

‘Remote Start’ signal to the engine starting controller. The generator failure timer is also

initiated at this time.

The engine starting controller should now start the generator, the 530 module will monitor the

generator voltage and frequency (and an optional generator ready input) and once the monitored

values are above a safe ‘Loading’ level the generator will become available. This is indicated by

the illumination of the appropriate LED on the mimic diagram.

To load the set operate the external ‘To Generator’ Pushbutton; the Mains close signal will be

removed. The transfer timer will then be initiated. Once the transfer timer has expired the

generator close signal will be supplied.

To unload the set and transfer back to the mains supply operate the external ‘To Mains’

Pushbutton; the generator close signal will be removed. The transfer timer will then be initiated.

Once the transfer timer has expired the mains close signal will be supplied.

If the selector switch is placed in the START AND RUN GENERATOR ON LOAD

position, the load will be transferred to the generator

If the selector switch is then returned to the START AND RUN GENERATOR OFF

LOAD position the load will not re-transfer to the mains supply unless the external

‘To Mains’ pushbutton is operated

To stop the generator return the selector switch to the AUTO position. The

generator Close signal is removed, removing the load from the generator. The

transfer timer is then initiated, once this has expired the Mains Close signal is

supplied. The Cooling timer is then initiated, allowing the engine a cooling down period off load

before shutting down. Once the Cooling timer expires the Start and run generator signal is

removed, bringing the generator to a stop.

Should the Mains fall out of limits during the cooling down period, the set will return on load after

the Start Delay Timer has expired.

8 DSE 530 ISSUE 1 10/03/2004 MR

2. FUNCTIONS & INDICATIONS

The module status is indicated by front panel LED’s. This allows for easy monitoring of system

operation.

MAINS AVAILABLE LED

Indicates that the incoming AUXILIARY LED’s

AC Mains supply is within limits Normally not configured. Use

and available to supply the load. PC 808 software to configure

function.

GENERATOR AVAILABLE LED

Indicates that the generator

Output voltage and frequency START DELAY ACTIVE

are within acceptable limits LED

and available to supply the load. Indicates that the 530 internal

start delay timer is running.

Once expired the start signal

GENERATOR ON LOAD LED will be given to the generator

Indicates that the generator close controller.

Signal has been supplied.

Alternatively it can be configured MAINS RETURN TIMER

To give ‘True’ indication of load ACTIVE LED

Indicates that the 530’s internal

Switching device status.

mains return timer is running.

Once expired the load will be

MAINS ON LOAD LED transferred back to the mains

As above but with respect to the supply.

Mains.

FIG 2 - LED DESCRIPTIONS

NOTE 1:-The MAINS AVAILABLE and GENERATOR AVAILABLE LED’s can be re-

configured to indicate a number of different functions. The default functions are

GENERATOR AVAILABLE indicates generator within limits.

MAINS AVAILABLE indicate NOT mains failure (mains out of limits or aux. mains fail.).

For full details refer to the 808 Software Manual.

NOTE 2:-The GENERATOR ON LOAD and MAINS ON LOAD LED’s can be re-

configured to use feedback from the contactor or breaker auxiliaries to give true

indication of load switching status. The default functions are:-

GENERATOR ON LOAD indicates generator close signal active.

MAINS ON LOAD indicates mains close signal active.

For full details refer to the 808 Software Manual.

NOTE 3:- The auxiliary LED’s can be used to indicate different functions which may

be required. These include WARMING TIMER ACTIVE, COOLING TIMER ACTIVE, START

AND RUN GENERATOR ACTIVE, MAINS FAILURE, etc. A window is provided for the user

to alter the LED’s description. For full details refer to the 808 Software Manual.

2.1 INPUT FUNCTIONS

The 530 has inputs dedicated to the functions as listed below.

AUXILIARY GENERATOR READY, this is a normally open (default) +ve signal. It is used to

provide a confirmation signal that the generator is ready to load. The 530 will monitor the

generator voltage and frequency to ensure that they are within limits, this input then provides

confirmation from the generator start controller(On a 520 module the ‘Load Transfer’ output can

be connected to this input). If this signal is not present the generator will not take load even

though the output voltage and frequency are acceptable. This may be useful if other sequences

occur on the generator before it is ready to load, such as smoke limiting, etc.

DSE 530 ISSUE 1 10/03/2004 MR 9

AUXILIARY MAINS FAILURE, this is a normally open (default) -ve signal. The 530 module will

monitor the incoming single or three phase supply for Over voltage, Under Voltage, Over

Frequency or Under frequency. It may be required to monitor a different mains supply or some

aspect of the incoming mains not monitored by the 530 (such as phase rotation). If the devices

providing this additional monitoring are connected to operate this input, the 530 will operate as if

the incoming mains supply has fallen outside of limits, the generator will be instructed to start and

take the load. Removal of the input signal will cause the module to act if the mains has returned to

within limits.

AUTO RETURN TO MAINS INHIBIT, this is a normally open (default) -ve signal. If this input is

active the 530 with operate in a similar manner to the MANUAL RESTORE selector switch mode.

To use this function the 530 selector switch should be placed in the AUTO mode. In the event of a

mains failure the generator will be instructed to start and take load. On main return the module will

continue to run the generator on load until this AUTO RETURN TO MAINS INHIBIT input is

removed. Once the input is removed the module will transfer the load back to the mains supply

and follow a normal generator stop sequence. This input allows the 530 to be fitted as part of a

system where the manual restoration to mains is controlled remotely or by an automated system.

AUTO START INHIBIT, this is a normally open (default) -ve signal. It is used to provide an over-

ride function to prevent the 530 from calling for the generator in the event of a mains out of limits

condition occuring. If this input is active and a mains failure occurs the 530 will continue to operate

with the mains on load, it will not give a start command to the generator. If this input signal is then

removed the 530 will operate as if a mains failure has occurred, starting and loading the generator.

This function can be used to give an ‘AND’ function so that a generator will only be called to start if

the mains fails and another condition exists which requires the generator to run.

MAINS CLOSED AUXILIARY INPUT, this is a normally open (default) -ve signal. It is used to

provide feedback to allow the 530 to give true indication of the contactor or circuit breaker

switching status. It should be connected to the mains load switching device auxiliary contact. To

use true indication via the MAINS ON LOAD LED the 530 will need to be reconfigured to use the

MAINS CLOSED AUXILIARY INPUT ACTIVE state to drive this LED.

GENERATOR CLOSED AUXILIARY INPUT, this is a normally open (default) -ve signal. It is used

to provide feedback to allow the 530 to give true indication of the contactor or circuit breaker

switching status. It should be connected to the mains load switching device auxiliary contact. To

use true indication via the GENERATOR ON LOAD LED the 530 will need to be reconfigured to

use the GENERATOR CLOSED AUXILIARY INPUT ACTIVE state to drive this LED.

MAINS LOAD INHIBIT, this is a normally open (default) -ve signal. It is used to prevent the 530

from loading the mains supply. If the mains supply is already on load activating this input will

cause the 530 to unload the mains supply. Removing the input will allow the mains to be loaded

again.

NOTE:-This input only operates to control the mains switching device if the 530 load

switching logic is attempting to load the mains. It will not control the mains switching

device when the generator is on load.

GENERATOR LOAD INHIBIT, this is a normally open (default) -ve signal. It is used to prevent the

530 from loading the generator. If the generator is already on load activating this input will cause

the 530 to unload the generator. Removing the input will allow the generator to be loaded again.

NOTE:-This input only operates to control the generator switching device if the 530

load switching logic is attempting to load the generator. It will not control the generator

switching device when the mains is on load.

10 DSE 530 ISSUE 1 10/03/2004 MR

EXTERNAL RESET/LAMP TEST, this is a normally open (default) -ve signal. It is used to provide

a test facility for the front panel indicators fitted to the 530 module. When the input is activated all

LED’s should illuminate. The input also serves a second function, in that it also provides a reset

signal to clear any latched alarms. The 530 has facility to provide a latched alarm on Generator

Failure or Mains Failure, these latched alarms must be manually cleared if set. This is achieved

by activating the reset input.

NOTE:-The default configuration does not use the latched alarms and if required they

need to be set using the 808 PC software.

TRANSFER TO MAINS BUTTON, this is a normally open (default) -ve signal. It is used to transfer

the load to the mains supply when running in START AND RUN GENERATOR OFF LOAD

MODE.

NOTE:-The default configuration has transfer by pushbutton disabled. If this function

is required the 530 module must be reconfigured using the 808 PC software.

TRANSFER TO GENERATOR BUTTON, this is a normally open (default) -ve signal. It is used to

transfer the load to the generator when running in START AND RUN GENERATOR OFF LOAD

MODE.

NOTE:-The default configuration has transfer by pushbutton disabled. If this function

is required the 530 module must be reconfigured using the 808 PC software.

2.2 OUTPUT FUNCTIONS

The 530 module is fitted with a number of relay output. The default functions are as detailed

below, if other functions are required the module can be reconfigured using the 808 PC software.

START AND RUN GENERATOR, normally closed volt free contact. This output supplies the start

and run signal to the generator automatic start controller. The volt free configuration allows it to

be used with different starting controllers or custom built panels. The relay will activate whenever

the 530 calls for the generator to start. If the 530 stops the generator, this output will become

inactive.

NOTE:- The Start and Run Relay is normally closed to enable the 530 to operate

without a DC supply present. Loss of both AC and DC supply will result in the relay being

closed.

CLOSE MAINS RELAY, normally closed volt free contact. This output supplies the close signal to

the mains contactor or breaker. The volt free configuration allows it to be used with different types

of switching device. The relay will activate whenever the 530 calls for the mains supply to be

loaded. When the 530 unloads the mains supply this output will become inactive.

NOTE:- The Close Mains Relay is normally closed to enable the 530 to operate

without a DC supply present. Loss of both AC and DC supply will result in the relay being

closed.

CLOSE GENERATOR RELAY, normally open volt free contact. This output supplies the close

signal to the generator contactor or breaker. The volt free configuration allows it to be used with

different types of switching device. The relay will activate whenever the 530 calls for the generator

to be loaded. When the 530 unloads the generator this output will become inactive.

DSE 530 ISSUE 1 10/03/2004 MR 11

AUXILIARY 1 RELAY, normally open volt free contact. This output can be configured for a

number of different functions or used to control tripping of circuit breakers, etc. The default

configuration for the 530 module has this output set as GENERATOR FAILURE ALARM. If for

any reason the generator fails to become available within a pre-set time (fail to start for example)

or falls out of limits when loaded, this output will be activate. Should the generator the become

available the output will become in-active.

AUXILIARY 2 RELAY, change-over volt free contact. This output can be configured for a number

of different functions or used to control tripping of circuit breakers, etc. The change over

configuration allows for suitable fail safe operation. The default configuration for the 530 module

has this output set as MAINS FAILURE ALARM. If for any reason the mains fails or falls out of

limits this output will be activate. Should the mains return the output will become in-active.

NOTE:- If it is required to change the function of the auxiliary relays it is possible to

reconfigure the 530 module using the 808 PC software.

2.3 AC ONLY OPERATION FUNCTION

The 530 has a self seeking power supply which will power the module from the Mains AC supply,

the Generator AC supply or from the optional DC supply.

If the module is operated with AC supplies only then operation will follow that described above with

the exception of ‘Auto’ or ‘Manual Restore’ mode operation in the event of a main failure.

If the module is placed in ‘Auto’ or ‘Manual Restore’ mode, it will monitor the incoming mains

supply. Should the incoming mains supply fail (or fall outside of pre-set limits), the following

sequence will occur.

The module will enter it’s ‘dead’ state and the start and run generator output relay is de-

energised and the relay contacts close, giving a ‘Remote Start’ signal to the engine starting

controller.

NOTE:- The Start Delay timer in this instance is not used. If a start delay is required

this must be provided by the generator start controller.

The engine starting controller should now start the generator, the 530 module will seek generator

AC supply to power itself and then monitor the generator voltage and frequency (and an optional

generator ready input) and once the monitored values are above a safe ‘Loading’ level the

generator will become available. This is indicated by the illumination of the appropriate LED on the

mimic diagram. Operation of the 530 will now follow as described previously.

As soon as the generator is available the warm-up timer is initiated. Once the warm-up timer

has expired the Mains close signal will be removed. The transfer timer will then be initiated.

Once the transfer timer has expired the generator close signal will be supplied.

NOTE:- If the Mains supply returns the 530 module will then have two AC supplies

available. Therefore operation on mains return will follow that described previously.

12 DSE 530 ISSUE 1 10/03/2004 MR

On return of the mains supply to within limits, the Mains Return delay timer is initiated, once the

timer expires the Generator Close signal is removed, removing the load. The transfer timer is

then initiated, once this has expired the Mains Close signal is supplied The Cooling timer is then

initiated, allowing the engine a cooling down period off load before shutting down. Once the

Cooling timer expires the Start and run generator signal is removed, bringing the generator to a

stop.

Should the Mains fall out of limits during the cooling down period, the set will return on load after

the Start Delay Timer has expired.

DSE 530 ISSUE 1 10/03/2004 MR 13

3. INSTALLATION INSTRUCTIONS

The model 530 ATS control Module has been designed for front panel mounting. Fixing is by 2

spring loaded clips for easy assembly.

3.1 PANEL CUT-OUT

91.00mm

138.50mm

FIG 3 - CUT-OUT DIMENSIONS

In conditions of excessive vibration the module should be mounted on suitable anti-vibration

mountings.

3.2 COOLING

The module has been designed to operate over a wide temperature range -15 to +55º C. However

allowances should be made for the temperature rise within the control panel enclosure. Care

should be taken NOT to mount possible heat sources near the module unless adequate ventilation

is provided. The relative humidity inside the control panel enclosure should not exceed 85%.

3.3 UNIT DIMENSIONS

All dimensions in mm.

96.0mm

91.0mm

155.0mm 144.0mm

530 ATS Unit Arrangement

Panel Cut-out: 91mmx138.5mm

7.5mm

FIG 4 - DIMENSIONS

14 DSE 530 ISSUE 1 10/03/2004 MR

3.4 FRONT PANEL LAYOUT

FIG 5 - FRONT PANEL

3.5 REAR PANEL LAYOUT

Prog

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

Automatic Transfer Switch

21 22 23 24 25 26 27 28 29 30 31 32

FIG 6 - REAR PANEL

DSE 530 ISSUE 1 10/03/2004 MR 15

4. ELECTRICAL CONNECTIONS

Connections to the 530 Module are via plug and sockets.

4.1 CONNECTION DETAILS

The following describes the connections and recommended cable sizes to the 2 plugs and sockets

on the rear of the 530 Module. See rear panel layout FIG 5.

PLUG “A” 20WAY

PIN DESCRIPTION CABLE NOTES

No SIZE

1 DC Plant Supply Input 2.5mm (Recommended Fuse 6A)

(+ve)

2 DC Plant Supply Input 2.5mm

(-ve)

3 Auxiliary Relay 1 2.5mm Voltage Free contact, normally open.

NOT RATED FOR MAINS VOLTAGE.

4 Auxiliary Relay 1 2.5mm Voltage Free contact, normally open.

NOT RATED FOR MAINS VOLTAGE.

5 Start/Run Generator 2.5mm Voltage Free contact, normally closed.

NOT RATED FOR MAINS VOLTAGE.

6 Start/Run Generator 2.5mm Voltage Free contact, normally closed.

NOT RATED FOR MAINS VOLTAGE.

7 Auxiliary Relay 2 2.5mm Voltage Free contact, normally closed.

NOT RATED FOR MAINS VOLTAGE.

8 Auxiliary Relay 2 2.5mm Voltage Free contact, common.

NOT RATED FOR MAINS VOLTAGE.

9 Auxiliary Relay 2 2.5mm Voltage Free contact, normally closed.

NOT RATED FOR MAINS VOLTAGE.

10 Auxiliary generator ready 0.5mm Switch to +ve. Signal from gen-start module

input that generator is available.

11 Auxiliary mains failure 0.5mm Switch to -ve. Signal from additional mains

input monitoring devices.

12 Auto Return to mains 0.5mm Switch to -ve. Signal to prevent return to

inhibit input mains supply on mains restoration until

required.

13 Auto start inhibit input 0.5mm Switch to -ve. Signal to prevent calling for

generator in the event of mains out of limits

condition.

14 Mains closed auxiliary 0.5mm Switch to -ve. Provides contactor/circuit -

input breaker auxiliary feedback.

15 Generator closed auxiliary 0.5mm Switch to -ve. Provides contactor/circuit

input breaker auxiliary feedback.

16 Mains load inhibit input 0.5mm Switch to -ve. Prevents the mains being

loaded until required.

17 Generator load inhibit 0.5mm Switch to -ve. Prevents the generator being

input loaded until required.

18 External reset/Lamp test 0.5mm Switch to -ve. Clears latched alarms and

input performs lamp test function.

19 Transfer to mains push- 0.5mm Switch to -ve. Allows push-button

button input contactor or breaker control.

20 Transfer to generator 0.5mm Switch to -ve. Allows push-button

push-button input contactor or breaker control.

16 DSE 530 ISSUE 1 10/03/2004 MR

PLUG “B” 12 WAY

PIN DESCRIPTION CABLE NOTES

No SIZE

21 Mains contactor close 1.0mm Voltage free contact. Normally closed.

relay

22 Mains contactor close 1.0mm Voltage free contact. Normally closed.

relay

23 DO NOT USE Ensure no connection is made to this pin.

24 Mains Input Live L3 1.0mm Incoming AC mains supply. Recommended

fuse 2A.

25 Mains Input Live L2 0.5mm Incoming AC mains supply. Recommended

fuse 2A.

26 Mains Input Live L1 0.5mm Incoming AC mains supply. Recommended

fuse 2A

27 Mains Input Neutral 0.5mm Incoming AC mains supply.

28 Generator Input Neutral 0.5mm Incoming Generator supply.

29 Generator Input L1 0.5mm Optional, specified on ordering.

Tachometer must be completely isolated.

30 DO NOT USE Ensure no connection is made to this pin

31 Generator contactor close 1.0mm Voltage free contact, normally open.

relay

32 Generator contactor close 1.0mm Voltage free contact, normally open.

relay

4.2 CONNECTOR FUNCTION DETAILS

The following describes the functions of the 2 connectors on the rear of the module. See rear panel

layout FIG 6.

PLUG “A” 20 WAY

PIN DESCRIPTION

No

1 DC Supply +ve. System DC positive input. (Battery Positive). (Optional)

2 DC Supply -ve. System DC negative input. (Battery negative). (Optional)

3 Auxiliary relay 1. A low voltage rated contact used for system status output of

alternative to supply tripping signals to a circuit breaker scheme.

4 Auxiliary relay 1. A low voltage rated contact used for system status output of

alternative to supply tripping signals to a circuit breaker scheme.

5 Start/Run generator contact. Signals the generator start controller to run the

generator. A normally closed contact which is held open when a start is not

required, ensure fail safe operation.

6 Start/Run generator contact. Signals the generator start controller to run the

generator. A normally closed contact which is held open when a start is not

required, ensure fail safe operation.

7 Auxiliary Relay output 2. As for Auxiliary output 1 but a change-over contact.

8 Auxiliary Relay output 2. As for Auxiliary output 1 but a change-over contact.

9 Auxiliary Relay output 2. As for Auxiliary output 1 but a change-over contact.

10 Auxiliary generator ready input. Used for the engine control module to confirm that

the generator is ready to be loaded. (Optional)

11 Auxiliary Mains failure input. Used to signal an externally detect mains failure or to

provide additional mains sensing capabilities. Forces a mains fail condition to

occur when monitored parameter as healthy.

12 Auto return to mains inhibit input. Prevents the load being transferred back to the

mains supply following a failure. Generator will remain running on load until signal

is removed.

DSE 530 ISSUE 1 10/03/2004 MR 17

PIN DESCRIPTION

No

13 Auto-start inhibit input. Prevents the start signal from being issued if in mains falls

outside of limits. Optional DC supply must be present if this function is to be used.

14 Mains closed auxiliary input. Used to connect to the contactor auxiliary contacts to

give optional feedback to indicate contactor operation.

15 Generator closed auxiliary input. Used to connect to the contactor auxiliary

contacts to give optional feedback to indicate contactor operation.

16 Mains Load Inhibit input. Used to prevent the mains supply from being loaded, or if

on-load will cause contactor to open.

17 Generator Load Inhibit input. Used to prevent the generator from being loaded, or if

on-load will cause contactor to open.

18 External reset/Lamp test input. Used to provide a lamp test facility for the LED

indicators and to clear the latch alarms, (Mains Failure and Generator Failure) if

used.

19 Transfer to Mains Pushbutton input. Connects to external ‘To Mains’ pushbutton

to allow transfer of load to mains in ‘Start and Run Generator off-load’ mode.

20 Transfer to Generator Pushbutton input. Connects to external ‘To Generator’

pushbutton to allow transfer of load to generator in ‘Start and Run Generator off-

load’ mode.

PLUG “B” 12 WAY

PIN DESCRIPTION

No

21 Mains Contactor Close relay output (Voltage Free). A mains rated contact used to

close the mains contactor or breaker.

22 Mains Contactor Close relay output (Voltage Free). A mains rated contact used to

close the mains contactor or breaker.

23 DO NOT USE

24 Mains Live input L3. Connect to the incoming mains L3 supply (if present)

25 Mains Live input L2. Connect to the incoming mains L2 supply (if present)

26 Mains Live input L1. Connect to the incoming mains L1 supply. Used for both

sensing and to power the 530 module.

27 Mains Neutral input. Connect to the incoming mains supply neutral supply. Used

for both sensing and to power the 530 module.

28 Generator Neutral input. Connect to the generator neutral supply. Used for both

sensing and to power the 530 module.

29 Generator Live input L1. Connect to the generator L1 supply. Used for both

sensing and to power the 530 module.

30 DO NOT USE

31 Generator Contactor Close relay output (Voltage free). A mains rated contact used

to close the generator contactor or breaker.

32 Generator Contactor Close relay output (Voltage free). A mains rated contact used

to close the generator contactor or breaker.

CALIBRATION SOCKET

PIN DESCRIPTION CAUTION!:- THIS SOCKET IS

No FOR THE CONNECTION OF

1 Ground APPROPRIATE PRODUCTS

2 Transmit Data MANUFACTURED BY DEEP SEA

ELECTRONICS PLC ONLY,

3 Receive Data

CONNECTION OF ANY OTHER

4 +5 Supply

DEVICE MAY CAUSE DAMAGE

AND WILL INVALIDATE THE

WARRANTY.

5. SPECIFICATION

18 DSE 530 ISSUE 1 10/03/2004 MR

DC Supply (Optional) 8.0 to 35 V Continuous.

Cranking Dropouts Able to survive 0 V for 50 mS, providing supply was at least

10 V before dropout and supply recovers to 5V

Max. Operating Current 150 mA at 12 V. 95 mA at 24 V.

Max. Standby Current (Powered by AC supply) 34.7 mA at 115V. 16.1mA at 230V.

AC Voltage Input Range (For AC 115V Version:- 88 - 160 V ac RMS

only powered operation) 230V Version:- 176 - 305 V ac RMS

AC Frequency Input Range 10 - 75 Hz

AC Voltage Adjustment Range 115V Version:- 55 - 152 V ac RMS

(and AC Input sensing range) 230V Version:- 110 - 304 V ac RMS

AC Freq. Adjustment Range 10 - 75Hz

Mains Rated Relay Outputs 8 Amp RMS rated 1 off each NO/NC.

DC Low voltage Relay Outputs 8 Amp DC at supply voltage 1 off each NO/NC/CO

Dimensions 96 X 144 X 155 DIN (Excluding Key-switch)

Operating Temperature Range -15 to +55°C

DSE 530 ISSUE 1 10/03/2004 MR 19

6. COMMISSIONING

PRE-COMMISSIONING

Before the system is started, it is recommended that the following checks are made:-

6.1. The unit is adequately cooled and all the wiring to the module is of a standard and rating

compatible with the system.

6.2. The unit DC supply (if used) is fused and connected direct to the battery and of correct

polarity.

6.3. The AC supplies are fused and correctly connected to the appropriate feeds.

NOTE:- If single phase sensing is required it is possible to configure the module to

monitor L1 only. Alternatively if it is not feasible to configure the module the single phase

can be fed into all three phase inputs.

6.1. To check the 530 take appropriate measures to prevent the engine from

starting (disable the operation of the fuel solenoid). After a visual

inspection to ensure it is safe to proceed, connect the battery supply. Turn the selector

switch to “START AND RUN GENERATOR OFF LOAD”.

6.2. The Start/run signal will be given to the generator start control which should then attempt to

start the generator. Returning the 530 selector switch to either ‘AUTO’ position will remove

the start /run signal.

6.1. Restore the engine to operational status (reconnect the fuel solenoid),

again select “START AND RUN GENERATOR OFF LOAD” and this time

the engine should start and once it is up to operating parameters the

‘GENERATOR AVAILABLE LED’ should illuminate.

6.1. Select ‘START AND RUN GENERATOR ON LOAD’ on the selector

switch, the mains contactor or breaker should open and after a short delay

the generator contactor or breaker should close. The generator is now on load.

6.2. Select ‘AUTO’ on the 530. After the ‘MAINS RETURN TIMER’ has expired the generator

contactor or breaker should open, and after a short delay the mains contactor or breaker

should close. The start/run signal will be maintained for a period of time to run the generator

off-load to allow it to cool. At the end of the ‘COOLING TIMER’ the start/run signal will be

removed and the generator instructed to stop.

6.3. If a mains failure is simulated with the 530 in ‘AUTO’ mode this will have the same effect as

seen in steps 6.3 and 6.4 above. Restoring the mains supply to the module will follow the

same sequence as seen in 6.5 above.

6.4. All internal timers and selections should now be adjusted to the customers specifications or

to the engine and alternator manufacturers recommendations.

6.5. If despite repeated checking of the connections between the 530 and the customers system,

satisfactory operation cannot be achieved, then the customer is requested to contact the

factory for further advice on:-

INTERNATIONAL TEL: 44 (0) 1723 377566

INTERNATIONAL FAX: 44 (0) 1723 354453

E-mail: Support@Deepseaplc.com

20 DSE 530 ISSUE 1 10/03/2004 MR

7. FAULT FINDING

SYMPTOM POSSIBLE REMEDY

Unit is inoperative Select AUTO on the front panel. Check the AC mains

supply to the unit. Check the AC fuses. If used check the

battery and wiring to the unit. Check the DC supply. Check

the DC fuse.

Unit shuts down Check the AC supplies are within the module specification.

Check that 530 module is the correct version (115V or

230V Nominal)

Check DC supply voltage is not above 35 Volts or below 8

Volts. Check the operating temperature is not above

55 °C. Check the DC fuse.

Unit attempts to start the generator Check AC supply to unit is in limits.

when mains is present. Check setting on 530 module are correct.

Check Auxiliary mains failure input is not active.

Check configured polarity is correct.

Generator does not become Check AC output is within limits.

available. Check settings on 530 module.

Check Auxiliary Generator Ready input is correctly

configured and connected.

Check configured polarity is correct.

No start delay timer (if used) Check DC supply is present.

Check setting on 530 module

Engine runs but generator will not Check Warm up timer has timed out.

take load Check 530 operating mode is correct.

NOTE:- Fault finding can be assisted greatly by utilising the Diagnostic feature

available from the PC Interface. This will display the module state, any alarm conditions

present and the state of all inputs and outputs. It is recommended that diagnostics are

used to aid fault finding where-ever possible.

DSE 530 ISSUE 1 10/03/2004 MR 21

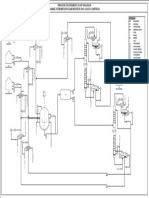

8. TYPICAL WIRING DIAGRAM

NOTE:- The above diagram shows a typical contactor based system. It is also

possible to reconfigure the 530 module to enable connection to various breaker

schemes. If unsure as to how to achieve this please refer to the 808 software manual or

alternatively contact Deep Sea personnel.

INTERNATIONAL TEL: 44 (0) 1723 377566

INTERNATIONAL FAX: 44 (0) 1723 354453

E-mail: Support@Deepseaplc.com

22 DSE 530 ISSUE 1 10/03/2004 MR

9. CALIBRATION

The 530 module can be calibrated by using either a PC with Interface Module 808.

9.1 PC INTERFACE MODULE 808

The PC interface 808 kit comprises the following:-

• 808 Interface Module

• 25 to 9 way adapter

• FCC 68 (4 Pin) Connecting Lead

• Floppy disc with configuration software

10. ICON DESCRIPTIONS

The DSE P530 module is supplied with graphical icons instead of text. This enables the module to

be used where text in the English language may cause problems and also allows for a standard

module for all world markets to be used.

10.1 ICONS

Symbol Meaning Description

Start and run generator Gives a start and run signal to the generator

off-load controller.

Start and run generator As above, but will also transfer the load to the

on-load generator once it is available.

Automatic mode of Fully automatic operation. Giving start signal to

operation generator on mains failure and then loading the

generator. On mains return transferring back to the

mains supply and stopping the generator.

Automatic mode with As above but on mains return no action will be taken

manual restore to mains to restore to the mans supply until selector switch is

returned to the ‘Auto’ position.

Mains return timer active This indicates that the mains supply has returned to

within limits, but has not yet been in limits long

enough for the load to transfer back to it.

Start delay timer active This indicates (if DC supply present) that the

incoming AC mains supply has failed, but has not

been out of limits long enough for a generator start

to be called for.

Mains Indicates the incoming mans supply

Generator Indicates the generator which is being controlled

Load Indicate the load to which the Mains of the generator

are being fed.

Available Indicates that either the mans or the generator

supplies are present and within limits.

On load Indicates that either the mains or the generator has

been selected to supply the load.

DSE 530 ISSUE 1 10/03/2004 MR 23

11. APPENDIX

11.1 LED IDENTIFICATION DIAGRAM

FIG 7 - AUXILIARY LED’S

Note:- The Software disk supplied with the Calibration Interface (808) contains a

Microsoft Word document for the automatic creation of suitable label inserts for the

Auxiliary LED’s.

11.2 FACTORY DEFAULT CONFIGURATION

The 530 module when shipped contains the following configuration, allowing it to be used as a

standard module if no configuration interface is available. (The 230V version is used for this

example. The 115V version is similar with the exception of analogue levels.)

P53x 230V Configuration

Title: P530a 230V Config

Created by: Miles Revell

Date: 20 March 1998

Filename: P530A

MISCELLANEOUS ITEMS

Item Value

Immediate Mains Dropout No

Start delay in manual No

Transfer by buttons enable No

Number of mains phases monitored 3

24 DSE 530 ISSUE 1 10/03/2004 MR

CONFIGURABLE INPUTS

Input channel Polarity

Auxiliary generator ready Close to activate

Auxiliary mains failure Close to activate

Auto return to mains inhibit Close to activate

Mains closed auxiliary Close to activate

Generator closed auxiliary Close to activate

External rest / lamp test Close to activate

Transfer to mains button Close to activate

Transfer to generator button Close to activate

RELAY OUTPUTS

Output channel Polarity Control source

Start/run generator (NC) De-energize 2 Start and run generator

Auxiliary relay 1 (NO) Energize 7 Generator failure (unlatched)

Auxiliary relay 2 (CO) De-energize 13 Mains failure (unlatched)

Close Generator (NO) Energise 18 Close generator

Close Mains (NC) De-energise 17 Close mains

Expansion output 1 Energise 0 Unused

Expansion output 2 Energise 0 Unused

Expansion output 3 Energise 0 Unused

Expansion output 4 Energise 0 Unused

Expansion output 5 Energise 0 Unused

Expansion output 6 Energise 0 Unused

Expansion output 7 Energise 0 Unused

Expansion output 8 Energise 0 Unused

FRONT PANEL LED’s

LED Polarity Control source

Generator available Lit 53 Gen. Available (immediate)

Generator on load Lit 18 Close generator

Mains available Not Lit 13 Mains failure (unlatched)

Mains on load Lit 17 Close mains

LED 1 Lit 0 Unused

LED 2 Lit 0 Unused

LED 3 Lit 1 Start delay

LED 4 Lit 5 Mains returning

SYSTEM TIMERS

Timer Mins:secs

Start delay time 0:05

Mains return time 0:10

Transfer delay time 0:01

Generator fail delay time 0:45

Warm up time 0:00

Cooling time 0:00

Mains transient ignore time 0:02

Generator transient ignore time 0:02

Breaker close pulse time 0:00.5

Breaker trip pulse time 0:00.5

ANALOGUE LEVELS

Level Value

Mains over frequency trip 55.0 Hz

Mains over frequency hysteresis 3.0 Hz

Mains under frequency trip 45.0 Hz

Mains under frequency hysteresis 3.0 Hz

Mains over voltage trip 276.0 V

Mains over voltage hysteresis 23.0V

Mains under voltage trip 184.0V

Mains under voltage hysteresis 23.0 V

Generator under frequency trip 40.0Hz

Generator loading frequency 45.0Hz

Generator under voltage trip 184.0V

Generator loading voltage 207.0V

DSE 530 ISSUE 1 10/03/2004 MR 25

Deep Sea Electronics Plc

CUSTOMER BULLETIN

Recommended Configuration for 530 Modules

DETAILS

This document is intended to clarify the function of the 530 module in specific switching

applications.

Output Control Source Selection

Continuous Close and Trip Signals Required Pulsed Close and Trip Signals required

Close Mains Close Mains

Set Mains relay to de-energise using ‘CLOSE Set Mains relay to de-energise using ‘CLOSE MAINS

MAINS’ PULSE’

Trip Mains (if required) Trip Mains

Set an Auxiliary relay to de-energise using ‘CLOSE Set an Auxiliary relay to energise using ‘TRIP MAINS

MAINS’ PULSE’

Close Generator Close Generator

Set Alternator relay to energise on ‘CLOSE Set Alternator relay to energise on ‘CLOSE

GENERATOR’ GENERATOR PULSE’

Trip Generator (if required) Trip Generator

Set an Auxiliary relay to de-energise on ‘CLOSE Set an Auxiliary relay to de-energise on ‘TRIP

GENERATOR’ GENERATOR PULSE’

NOTE:-There are no special Timer WARNING!:-The above scheme requires some

requirements with the above scheme. consideration of the timer settings to function

correctly. The ‘breaker trip pulse timer’ cannot

(For details on setting the outputs please refer to be longer than the ‘Transfer delay timer’.

either the P808 Software Manual or the P808 For Therefore it is important to ensure that the

Windows Software Manual and the P530 Operators ‘Transfer delay timer’ setting is equal to or

Manual) greater than the ‘breaker trip pulse timer’.

26 DSE 530 ISSUE 1 10/03/2004 MR

S-ar putea să vă placă și

- Dse 530 Manual PDFDocument25 paginiDse 530 Manual PDFjonatan samuel huamanÎncă nu există evaluări

- Deep Sea 500 Ats ManDocument18 paginiDeep Sea 500 Ats ManLeo Burns50% (2)

- DSE530 Operator ManualDocument26 paginiDSE530 Operator ManualRonald Victor Galarza Hermitaño0% (1)

- Dse 521 ManualDocument19 paginiDse 521 ManualAhmed ChanaouiÎncă nu există evaluări

- Manual Modulo DSE520Document20 paginiManual Modulo DSE520jordaz30Încă nu există evaluări

- Deep Sea Electronics PLC: Complex Solutions Made SimpleDocument25 paginiDeep Sea Electronics PLC: Complex Solutions Made SimpleRamaÎncă nu există evaluări

- DSE710Document26 paginiDSE710Muhammad Umer Adnan33% (3)

- Dse4130 ManualDocument28 paginiDse4130 ManualJoseMiguelBlancoAlvarezÎncă nu există evaluări

- 7000 Series Deep Sea PLC Operators ManualDocument122 pagini7000 Series Deep Sea PLC Operators ManualMaya MayoshkaÎncă nu există evaluări

- Dse 8610Document119 paginiDse 8610Akhmad FatoniÎncă nu există evaluări

- DSE8660 Operators ManualDocument85 paginiDSE8660 Operators ManualRahmat Nur Ilham100% (1)

- MANUAL OPERAÇÃO - 057-074 - 7200 - 7300 - OpsDocument122 paginiMANUAL OPERAÇÃO - 057-074 - 7200 - 7300 - OpsAlexandreÎncă nu există evaluări

- Dse4120 Manual PDFDocument30 paginiDse4120 Manual PDFnhocti007Încă nu există evaluări

- Ultra: DSE3000 Series Control ModuleDocument45 paginiUltra: DSE3000 Series Control ModuleGabriel RochaÎncă nu există evaluări

- EM-SGS-6340-24T 48T 24P4S 20S4C4X Configuration Guide v1.0Document555 paginiEM-SGS-6340-24T 48T 24P4S 20S4C4X Configuration Guide v1.0Jonathan Fabian Sanchez AlvarezÎncă nu există evaluări

- Manual Deep Sea 520Document19 paginiManual Deep Sea 520MH..202380% (5)

- Motores EletronicosDocument90 paginiMotores EletronicosValdemir da silvaÎncă nu există evaluări

- Deep Sea Electronics PLC: MODEL 521 Remote Start Engine Management SystemDocument19 paginiDeep Sea Electronics PLC: MODEL 521 Remote Start Engine Management SystemAhmed ChanaouiÎncă nu există evaluări

- Deep Sea 7110 ManualDocument62 paginiDeep Sea 7110 ManualMaribel Mendez75% (4)

- Mrcool 13seer r410 Cond Install ManualDocument40 paginiMrcool 13seer r410 Cond Install ManualRay RavelÎncă nu există evaluări

- Multilin™ 9450/9650: Instruction ManualDocument152 paginiMultilin™ 9450/9650: Instruction ManualAnonymous sLRlLluÎncă nu există evaluări

- Trans AmfDocument75 paginiTrans AmfBilel OukilÎncă nu există evaluări

- Trans-Auto Eng Man v16Document77 paginiTrans-Auto Eng Man v16asif MehmoodÎncă nu există evaluări

- Automatic Mains Failure Unit TRANS-AMF - ENG - MAN - V57Document84 paginiAutomatic Mains Failure Unit TRANS-AMF - ENG - MAN - V57tazzamal abbasÎncă nu există evaluări

- Trans-Amf Eng Man v28Document80 paginiTrans-Amf Eng Man v2825nanangkr1Încă nu există evaluări

- Dse720 ManualDocument25 paginiDse720 ManualJesus Manuel Aguirre AguirreÎncă nu există evaluări

- Deep Sea 8610 ManualDocument119 paginiDeep Sea 8610 ManualSBLOK GERADORESÎncă nu există evaluări

- Automatic Mains Failure Unit For Gas/Diesel/Gasoline Generators With J1939 Ecus User ManualDocument84 paginiAutomatic Mains Failure Unit For Gas/Diesel/Gasoline Generators With J1939 Ecus User Manualelgourch saidÎncă nu există evaluări

- DeepSea 8620 User GuideDocument40 paginiDeepSea 8620 User GuideMTU650100% (1)

- EMKO Trans AMF - syncRO Genset Controller Instruction Manual ENGDocument129 paginiEMKO Trans AMF - syncRO Genset Controller Instruction Manual ENGHayk AvetisyanÎncă nu există evaluări

- PDSP T 10 300kvaDocument74 paginiPDSP T 10 300kvaZirek MohamedÎncă nu există evaluări

- Deep Sea Electronics PLC: DSE331 ATS Controller Operators ManualDocument38 paginiDeep Sea Electronics PLC: DSE331 ATS Controller Operators ManualJesus R. Argollo EspejoÎncă nu există evaluări

- IK-525-DM3 IK-525-DM4 Dual Media Air Heater CleanersDocument135 paginiIK-525-DM3 IK-525-DM4 Dual Media Air Heater CleanersPhạm Hưng100% (1)

- Canbus Wiring For DSE ControllersDocument90 paginiCanbus Wiring For DSE ControllersBejoy ThomasÎncă nu există evaluări

- Trans-Amf Eng Man v44Document84 paginiTrans-Amf Eng Man v44AyeminThetÎncă nu există evaluări

- Manual Relé GE 750Document454 paginiManual Relé GE 750Bolivar MartinezÎncă nu există evaluări

- Emko Trans AMFDocument69 paginiEmko Trans AMFRahmat Nur IlhamÎncă nu există evaluări

- Trans-Mini - AMF Eng Man v11Document69 paginiTrans-Mini - AMF Eng Man v11alperdaÎncă nu există evaluări

- More User Manuals OnDocument66 paginiMore User Manuals OnIsaac Joshua Rivas BarrientosÎncă nu există evaluări

- Deep Sea 335Document88 paginiDeep Sea 335nestor arias castÎncă nu există evaluări

- DSE335 Operators Manual PDFDocument88 paginiDSE335 Operators Manual PDFArc HieÎncă nu există evaluări

- WWSPMDocument49 paginiWWSPMAndrea CupelloÎncă nu există evaluări

- Automatic Start Unit For Gas/Diesel/Gasoline Generators With J1939 Ecus User ManualDocument61 paginiAutomatic Start Unit For Gas/Diesel/Gasoline Generators With J1939 Ecus User Manualroberto sanchezÎncă nu există evaluări

- Dse500 ManualDocument18 paginiDse500 ManualHuannt Huan0% (1)

- 369 Motor Management Relay - MULTILIN PDFDocument280 pagini369 Motor Management Relay - MULTILIN PDFMario Guzman100% (1)

- Deep Sea 4420 ManualDocument55 paginiDeep Sea 4420 ManualBara100% (1)

- OFF Grid Solar PCU Manual: India's First 5 Mode Solar InverterDocument34 paginiOFF Grid Solar PCU Manual: India's First 5 Mode Solar InverterV'nay KuMarÎncă nu există evaluări

- Automatic Transfer Switch Trans-ATS - D - Manual - EN V03Document54 paginiAutomatic Transfer Switch Trans-ATS - D - Manual - EN V03POTÊNCIA ATIVA GERADORESÎncă nu există evaluări

- 750-760 7.4xDocument452 pagini750-760 7.4xMuhammad YusriÎncă nu există evaluări

- Lead Acid Battery Solar Storage System ManualpsgDocument37 paginiLead Acid Battery Solar Storage System ManualpsgHub Goertz100% (1)

- MFR 3 Multi Function Relay: ManualDocument165 paginiMFR 3 Multi Function Relay: ManualTariqMaqsoodÎncă nu există evaluări

- Digital Weighing Indicator User ManualDocument75 paginiDigital Weighing Indicator User ManualsaadÎncă nu există evaluări

- Frontier 570 Service Manual PDFDocument1.011 paginiFrontier 570 Service Manual PDFTruong Son100% (3)

- Chainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesDe la EverandChainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesEvaluare: 5 din 5 stele5/5 (1)

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsDe la EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsÎncă nu există evaluări

- Abc of Power Modules: Functionality, Structure and Handling of a Power ModuleDe la EverandAbc of Power Modules: Functionality, Structure and Handling of a Power ModuleÎncă nu există evaluări

- EQUITONE Installation Guide AU 15Document44 paginiEQUITONE Installation Guide AU 15anon_250483148Încă nu există evaluări

- Bolts ConnectionDocument3 paginiBolts ConnectionMukhlish AkhatarÎncă nu există evaluări

- 5 Common Motor Load Types: Load Profile (Speed Range, Torque and Power)Document2 pagini5 Common Motor Load Types: Load Profile (Speed Range, Torque and Power)arieldimacaliÎncă nu există evaluări

- Lsis Air Circuit BreakersDocument3 paginiLsis Air Circuit BreakersECATOnlineÎncă nu există evaluări

- Electronics World 1965 01Document104 paginiElectronics World 1965 01Supr RayÎncă nu există evaluări

- Staircase & Ramps Duration (DAYS) Appendix StaircaseDocument7 paginiStaircase & Ramps Duration (DAYS) Appendix StaircaseLai ChungyiÎncă nu există evaluări

- KROSS 2014 Bicycle CatalogueDocument108 paginiKROSS 2014 Bicycle CatalogueAndrzej GawlikÎncă nu există evaluări

- Ecomax Use Installation and Servicing Manual 261444 PDFDocument60 paginiEcomax Use Installation and Servicing Manual 261444 PDFEnisÎncă nu există evaluări

- TM 5-3805-254-14P-2 Part 6 Ihc F-5070Document116 paginiTM 5-3805-254-14P-2 Part 6 Ihc F-5070AdvocateÎncă nu există evaluări

- A-1 Quality IMDRDocument32 paginiA-1 Quality IMDRAyushÎncă nu există evaluări

- Set Point and Alarm List (Threshold) Fgs SystemDocument1 paginăSet Point and Alarm List (Threshold) Fgs SystemjajakaÎncă nu există evaluări

- ASTM C 226 - 02 Standard Speci Cation For Air-Entraining Additions For Use in The Manufacture of Air-Entraining Hydraulic CementDocument4 paginiASTM C 226 - 02 Standard Speci Cation For Air-Entraining Additions For Use in The Manufacture of Air-Entraining Hydraulic CementfilipeÎncă nu există evaluări

- Dga 1000 PartsDocument20 paginiDga 1000 Partswaltech2005Încă nu există evaluări

- Tugas 7 - Pik - Pefd Pabrik Nitrobenzena - Yohanes Nico Prabowo - Kelas A - 8Document1 paginăTugas 7 - Pik - Pefd Pabrik Nitrobenzena - Yohanes Nico Prabowo - Kelas A - 8Nico MarpaungÎncă nu există evaluări

- Eng MaterialsDocument2 paginiEng MaterialsKeith Tanaka MagakaÎncă nu există evaluări

- Ta-30 Manual MaintenanceDocument29 paginiTa-30 Manual MaintenanceAntonio Carrion100% (1)

- DHA World Heat TreatDocument4 paginiDHA World Heat TreatMichael KrummÎncă nu există evaluări

- AC DC Install Guide 2.0Document6 paginiAC DC Install Guide 2.0Hybrid RacingÎncă nu există evaluări

- Daewoo Piping Design PracticeDocument120 paginiDaewoo Piping Design Practicesmithwork100% (1)

- Agilent Tech., 6060B DMM Serive Manual PDFDocument95 paginiAgilent Tech., 6060B DMM Serive Manual PDFLulu Sweet ThingÎncă nu există evaluări

- Anotec 90-09 Solid Stick AnodesDocument2 paginiAnotec 90-09 Solid Stick AnodesMohsin AliÎncă nu există evaluări

- Ashutosh Jaiswal Resume (NEW)Document2 paginiAshutosh Jaiswal Resume (NEW)api-3707632Încă nu există evaluări

- Customers ProductsDocument15 paginiCustomers ProductsabidnfcÎncă nu există evaluări

- Pure VDocument2 paginiPure VMorris MorrisonÎncă nu există evaluări

- FM EXGas HazardPosterDocument1 paginăFM EXGas HazardPosterMike ClancyÎncă nu există evaluări

- Test Report: Customer Project Order RefDocument4 paginiTest Report: Customer Project Order RefSang Penggila HujanÎncă nu există evaluări

- Sanitary EngineeringDocument4 paginiSanitary Engineeringelcivileng0% (1)

- Pulse1 U6 Tests and Exams-1Document65 paginiPulse1 U6 Tests and Exams-1carmen91% (11)

- CWG - Katalog Drum PumpDocument54 paginiCWG - Katalog Drum PumpimtiyazÎncă nu există evaluări

- Coins and Coin MakingDocument2 paginiCoins and Coin MakingDwitney BethelÎncă nu există evaluări