Documente Academic

Documente Profesional

Documente Cultură

Electric Motor Vibration

Încărcat de

Pawan ChaturvediDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Electric Motor Vibration

Încărcat de

Pawan ChaturvediDrepturi de autor:

Formate disponibile

Technical Bulletin 02/99

ELECTRIC MOTOR

VIBRATION

by Alex Settimi Sohler BALANCING TYPE OF MACHINE

Technical Manager NORMAL General application machines such as pumps, fans,

I

for WEG Australia (N) compressors, crushers, etc

REDUCED Precision machines such as drilling and precision milling

n recent years vibration monitoring has become part of the (R) machines, lathes, etc

maintenance procedure of many firms. On one hand vibration

SPECIAL High precision machines such as grinding and balancing

analysis is a powerful tool for assessing machinery condition (S) machines.

and preventing unexpected failures, on the other hand, TABLE 2: Application of grades of balancing

determining if a motor vibration is within the limits set by

5

standards is not as simple as it may seem. If compliance with

standards or benchmarking is the objective of a vibration 2 6

analysis test, it should be carried out in accordance with the

4

international standards. IEC 34-14 (AS 1359-50 and

3

AS2625) deals with vibration tests and limits for rotating 1

electrical machinery. According to IEC a motor vibration must

be measured at rated voltage, rated frequency, with a virtually

sinusoidal wave form, uncoupled from the prime mover and FIGURE 1: Measuring points

driven load. The keyway must be filled with a half key - either a

full length rectangular key of half height or a half length key of YOU WEG MOTORS ARE

DID OW

full height centred axially in the keyway is acceptable. Vibration KN DYNAMICALLY BALANCED

must be measured in 6 points, which covers the three

FOR LOW VIBRATION

dimensions the machine may vibrate in (see figure 1). The

machine must also be tested in a state of free suspension so Motors can be either statically or dynamically balanced. Moreover

that all external excitations are eliminated. This condition is balancing can be done in 1, 2 or more planes. Since the rotor is a

achieved by suspending the machine on a spring or by dynamic component static balancing is not the best method. On the

mounting in on an elastic base. The three grades of balancing other hand, dynamic balancing machines require substantial

investment. Some companies dynamically balance their motors, but

and respective maximum vibration level are listed in table 1

only a few carry this out at motor rated speed. WEG motors are all

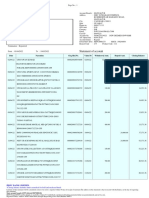

Grade Rated Speed Maximum r.m.s. Values of Vibration Velocity (mm/s)

(rpm) Machines Measured in a State of Free Suspension dynamically balanced by computerised machines in two planes at

56 ≤ Η < 132 132 〈 H ≤ 225 225 〈 H ≤ 400 400 〈 H ≤ 630

or close to motor rated speed, even the large 16 ton rotors. Although

WEG guarantees compliance with grade N, due to the strict quality

N 600 ≤ n ≤ 1800 1.8 1.8 2.8 2.8 control and consistent manufacturing process, most WEG motors

(normal) 1800 〈 n ≤ 3600 1.8 2.8 4.5 4.5 comply with grade R or better. This ensures

600 ≤ n ≤ 1800

R

(reduced) 1800 〈 n ≤ 3600

0.71

1.12

1.12

1.8

1.8

2.8 • reliability in operation

S 600 ≤ n ≤ 1800 0.48 0.71 1.12 • enhanced bearing and equipment life

(special) 1800 〈 n ≤ 3600 0.71 1.12 1.8

• minimum mechanical stress

TABLE 1: Maximum vibration levels as per IEC 34-14. Machines with

shaft height greater than 630mm the limit values should be subject to prior WEG is ahead of the standards to ensure your company also keeps

agreement between manufacturer and purchaser.

ahead of the competition.

To ensure compliance with these vibration levels, motors must

be properly balanced. In fact, vibration is created by forces

arising from uneven mass distribution of a rotating body. The

balancing process aims at improving the mass distribution,

hence minimising unbalanced forces, which can be detrimental

to the equipment. Nevertheless, in the real world, no matter

how good the balancing process is there will always be a

residual unbalance, hence the limits in table 1.

Motor manufacturers usually balance their motors to grade N.

Grade R and S are available on request. Table 2 gives some

guidance on the application of the different balancing grades. FIGURE 2: One of WEG’s computerised balancing machines

www.weg.com.br

S-ar putea să vă placă și

- Vibration Shaft Vs MotorDocument1 paginăVibration Shaft Vs Motoralexmontell100% (1)

- Motor Vibration AnalysisDocument61 paginiMotor Vibration Analysiskiki kamuiÎncă nu există evaluări

- Vibration Acceptance Test ReportDocument20 paginiVibration Acceptance Test ReportfazzlieÎncă nu există evaluări

- Motor Current SignatureDocument5 paginiMotor Current Signaturel1f3b00kÎncă nu există evaluări

- Vibration - Electrical or Mechanical - EASADocument3 paginiVibration - Electrical or Mechanical - EASAGilbÎncă nu există evaluări

- Dynamic Vibration AbsorberDocument67 paginiDynamic Vibration AbsorberNajeeb ShakirÎncă nu există evaluări

- Motor Current Signal AnalysisDocument13 paginiMotor Current Signal Analysissureshnfcl100% (1)

- Understanding End Play and Its Impact On Axial Alignment: Sleeve BearingsDocument3 paginiUnderstanding End Play and Its Impact On Axial Alignment: Sleeve Bearingsemiljanlaze100% (1)

- A Presentation On Turbogenerator and ExcitorDocument15 paginiA Presentation On Turbogenerator and ExcitorPrakhar MehrotraÎncă nu există evaluări

- Advanced Vibration Analysis On Gear Box TrainDocument25 paginiAdvanced Vibration Analysis On Gear Box Trainoded98100% (1)

- Short Course: Motor Current Signature Analysis FOR Diagnosis of Faults in Induction Motor DrivesDocument20 paginiShort Course: Motor Current Signature Analysis FOR Diagnosis of Faults in Induction Motor Drivessubha_yavanaÎncă nu există evaluări

- Datasheet de Motor Sincrono de Media TensionDocument40 paginiDatasheet de Motor Sincrono de Media TensionKamal ArreazaÎncă nu există evaluări

- SM101 Life Expectancy Analysis Program (LEAP) Rev ADocument2 paginiSM101 Life Expectancy Analysis Program (LEAP) Rev Aashish0011Încă nu există evaluări

- Diagnosis of Common Vibration Problems: Prof. Dr. Fawkia RamadanDocument13 paginiDiagnosis of Common Vibration Problems: Prof. Dr. Fawkia Ramadanفرح تامر100% (1)

- Generator Stator End Winding Vibration Problems PDF FreeDocument5 paginiGenerator Stator End Winding Vibration Problems PDF FreeandikaubhÎncă nu există evaluări

- Extracto ISO 10816Document10 paginiExtracto ISO 10816clroyo9475Încă nu există evaluări

- Vibration LimitsDocument37 paginiVibration LimitssanketÎncă nu există evaluări

- ACOEM (OneProd) Vs CSI 2140 ComparisonDocument2 paginiACOEM (OneProd) Vs CSI 2140 ComparisonSyed Huzaifa Ahmed (Larf Nalavale)100% (1)

- Existing Motor Repair Practices and Energy EfficiencyDocument59 paginiExisting Motor Repair Practices and Energy EfficiencynikcsitÎncă nu există evaluări

- EASA Motor Repair and Motor Efficiency PDFDocument16 paginiEASA Motor Repair and Motor Efficiency PDFflash_24014910Încă nu există evaluări

- IEC Vibration Severity ChartDocument1 paginăIEC Vibration Severity Chartcraig pretorius100% (1)

- VIBRATION ANALYSIS FUNDAMENTALSDocument76 paginiVIBRATION ANALYSIS FUNDAMENTALSAbderrahim Abaray100% (4)

- 1 GE Format Motor Protection - Single SessionDocument53 pagini1 GE Format Motor Protection - Single SessionDileep GantaÎncă nu există evaluări

- Temperature Winding CorrectionDocument4 paginiTemperature Winding CorrectionedgardÎncă nu există evaluări

- Unbalanced Magnetic Pull and Air-Gap Monitoring For Large HydrogeneratorsDocument2 paginiUnbalanced Magnetic Pull and Air-Gap Monitoring For Large HydrogeneratorsbasilecoqÎncă nu există evaluări

- VPI Vs Resin Rich PDFDocument5 paginiVPI Vs Resin Rich PDFKUNALJAYÎncă nu există evaluări

- Coupled Vibration Analysis For PumpDocument0 paginiCoupled Vibration Analysis For Pumpilmu2Încă nu există evaluări

- Condition Monitoring of Centrifugal Blower Using Vibration Analysis PDFDocument10 paginiCondition Monitoring of Centrifugal Blower Using Vibration Analysis PDFJose PradoÎncă nu există evaluări

- Vibration Guide FundamentalsDocument2 paginiVibration Guide FundamentalsErez Matana100% (1)

- Basics Vibration MeasurementDocument5 paginiBasics Vibration MeasurementMohan Arumugavallal100% (1)

- Orbit Plot BasicsDocument50 paginiOrbit Plot BasicsAshish SinghÎncă nu există evaluări

- Bump TestDocument123 paginiBump Testtylerdurdane100% (1)

- Vertical Motor Case History Shurafa IIR Rotate 2012Document4 paginiVertical Motor Case History Shurafa IIR Rotate 2012aal_shurafa100% (1)

- Electric Motor Diagnostics Defect Frequencies and Data ColleDocument51 paginiElectric Motor Diagnostics Defect Frequencies and Data ColleSubrata Dubey50% (2)

- Motor Bearing Failure Analysis by Vibration MonitoringDocument180 paginiMotor Bearing Failure Analysis by Vibration MonitoringGeert Henk Wijnants100% (1)

- Lecture Note on Fault Analysis and Predictive MaintenanceDocument57 paginiLecture Note on Fault Analysis and Predictive Maintenancepeach5Încă nu există evaluări

- Vibration AnalysisDocument22 paginiVibration Analysisvenkat chakÎncă nu există evaluări

- Motor Current Signature Analysis and InterpretationDocument6 paginiMotor Current Signature Analysis and InterpretationJayant KumarÎncă nu există evaluări

- Mcsa PDFDocument12 paginiMcsa PDFdurgaprasad reganiÎncă nu există evaluări

- Vibration Diagnostics ChartDocument49 paginiVibration Diagnostics ChartHaitham MohammadÎncă nu există evaluări

- AA ARM2017 Vibration AnalysisDocument39 paginiAA ARM2017 Vibration Analysismahmoud fawzyÎncă nu există evaluări

- Diagnostic Techniques For Vibration Analysis of BearingsDocument9 paginiDiagnostic Techniques For Vibration Analysis of BearingsMohd Asiren Mohd Sharif100% (1)

- Timebase Plots ExplainedDocument18 paginiTimebase Plots ExplainedManuel L LombarderoÎncă nu există evaluări

- NEMA MG-1 (Part 12-18)Document119 paginiNEMA MG-1 (Part 12-18)Majho Canilang0% (1)

- Current Signature AnalysisDocument7 paginiCurrent Signature Analysisliepan_bara75% (4)

- Vibration SensorsDocument93 paginiVibration Sensorsthai huynh leÎncă nu există evaluări

- Condition Monitoring of Rotary Equipments by Vibration AnalysisDocument34 paginiCondition Monitoring of Rotary Equipments by Vibration Analysispradeep.selvarajanÎncă nu există evaluări

- Identification of Torsional Vibration Features in Electrical Powered Rotating EquipmentDocument9 paginiIdentification of Torsional Vibration Features in Electrical Powered Rotating EquipmentHasan PashaÎncă nu există evaluări

- Vibration Analysis of Rotating Machines With Case Studies PDFDocument7 paginiVibration Analysis of Rotating Machines With Case Studies PDFShailesh Barbate100% (1)

- Repair Replance Decisions PDFDocument16 paginiRepair Replance Decisions PDFAngel Gutierrez100% (1)

- SPM HD Case StoryDocument34 paginiSPM HD Case StorycatraioÎncă nu există evaluări

- Techniques of Vibration MeasurementDocument36 paginiTechniques of Vibration MeasurementDeep SY100% (1)

- PM734B - Technical Data Sheet Winding 07Document6 paginiPM734B - Technical Data Sheet Winding 07LeenaÎncă nu există evaluări

- UCI274GDocument9 paginiUCI274GChristian Rivera FloverÎncă nu există evaluări

- CG AlternatorsDocument23 paginiCG AlternatorsHitesh Shinde100% (2)

- Data Sheet Stamford UCI274E1-Wending 311-3 PhaseDocument9 paginiData Sheet Stamford UCI274E1-Wending 311-3 PhaseCimmangÎncă nu există evaluări

- PM734C - Technical Data Sheet Winding 07Document6 paginiPM734C - Technical Data Sheet Winding 07LeenaÎncă nu există evaluări

- HCM434C - Winding 311: Technical Data SheetDocument9 paginiHCM434C - Winding 311: Technical Data SheetalcoholahmedÎncă nu există evaluări

- Digital Vibration Meter: 5.2 An Introduction To Vibration MeasurementDocument2 paginiDigital Vibration Meter: 5.2 An Introduction To Vibration MeasurementAsep SaoriÎncă nu există evaluări

- Stamford-Uci 27 4FDocument9 paginiStamford-Uci 27 4FKevin GuoÎncă nu există evaluări

- ThesisDocument128 paginiThesisPawan ChaturvediÎncă nu există evaluări

- Plasma and OxifuelDocument20 paginiPlasma and OxifuelPawan ChaturvediÎncă nu există evaluări

- DPSB Cir Not 2023 24 001Document2 paginiDPSB Cir Not 2023 24 001Pawan ChaturvediÎncă nu există evaluări

- AssignmentDocument1 paginăAssignmentPawan ChaturvediÎncă nu există evaluări

- Claim Form PDFDocument5 paginiClaim Form PDFmeghaÎncă nu există evaluări

- DPSB Cir Not 2023 24 001Document2 paginiDPSB Cir Not 2023 24 001Pawan ChaturvediÎncă nu există evaluări

- Unit 1 - A - Improper IntegralDocument8 paginiUnit 1 - A - Improper IntegralPawan ChaturvediÎncă nu există evaluări

- DPSB Cir Not 2022 23 019Document2 paginiDPSB Cir Not 2022 23 019Pawan ChaturvediÎncă nu există evaluări

- AIGA 046 - 08 Periodic Inspection of Static Cryogenic Vessels - Reformated Jan 12Document13 paginiAIGA 046 - 08 Periodic Inspection of Static Cryogenic Vessels - Reformated Jan 12aliÎncă nu există evaluări

- Class 5BDocument1 paginăClass 5BPawan ChaturvediÎncă nu există evaluări

- Statement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceDocument3 paginiStatement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalancePawan ChaturvediÎncă nu există evaluări

- OIL Cleanliness FundamentalsDocument43 paginiOIL Cleanliness FundamentalsPawan ChaturvediÎncă nu există evaluări

- API 571 Training CourseDocument140 paginiAPI 571 Training Courseapply1984237197% (29)

- Is 1200 15Document12 paginiIs 1200 15ramachandra_20012040Încă nu există evaluări

- Astm B88 2009 PDFDocument7 paginiAstm B88 2009 PDFAntonio JÎncă nu există evaluări

- Using BOM's To Gain Planning & Scheduling Efficiencies: Jeff SmithDocument27 paginiUsing BOM's To Gain Planning & Scheduling Efficiencies: Jeff SmithPawan ChaturvediÎncă nu există evaluări

- Mutual Fund Tracker IndiaDocument979 paginiMutual Fund Tracker IndiaMahesh NaikÎncă nu există evaluări

- Foster BUTYLAR NXT PDS R1019Document2 paginiFoster BUTYLAR NXT PDS R1019Pawan ChaturvediÎncă nu există evaluări

- Statement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceDocument5 paginiStatement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalancePawan ChaturvediÎncă nu există evaluări

- A648Document4 paginiA648Hanibale Nuril HakimÎncă nu există evaluări

- Astm A420a420m 16Document6 paginiAstm A420a420m 16Chistian AcostaÎncă nu există evaluări

- Ecan 19112QZ00NDocument2 paginiEcan 19112QZ00NPawan ChaturvediÎncă nu există evaluări

- SC119 - Umoja Plant Maintenance Overview - CBT PPT - V5Document67 paginiSC119 - Umoja Plant Maintenance Overview - CBT PPT - V5graemesquires85Încă nu există evaluări

- General Partner Information and Project Scope Definition Natural Gas TransmissionDocument6 paginiGeneral Partner Information and Project Scope Definition Natural Gas TransmissionPawan Chaturvedi100% (1)

- Mechanical Maintennace PlansDocument168 paginiMechanical Maintennace PlansPawan ChaturvediÎncă nu există evaluări

- Fine Filter BrochureDocument6 paginiFine Filter BrochurePawan ChaturvediÎncă nu există evaluări

- ARPM Handbook Rev April 2015 PDFDocument194 paginiARPM Handbook Rev April 2015 PDFKavir RamdassÎncă nu există evaluări

- 90 Tips & Tricks Every SAP Super User Should KnowDocument90 pagini90 Tips & Tricks Every SAP Super User Should Knowkumar N100% (2)

- Hydraulic Hoses V2Document96 paginiHydraulic Hoses V2Taufiq WibawaÎncă nu există evaluări

- Transformation - 2DDocument93 paginiTransformation - 2DKashika MehtaÎncă nu există evaluări

- Statistical EnsemblesDocument11 paginiStatistical EnsemblesArnab Barman RayÎncă nu există evaluări

- FP - A.1 - ABB - A Novel Monitoring System For Generator Circuit-Breakers To Increase Availability of Power PlantsDocument8 paginiFP - A.1 - ABB - A Novel Monitoring System For Generator Circuit-Breakers To Increase Availability of Power PlantsmhdsolehÎncă nu există evaluări

- Measures of Central Tendency: No. Biostat - 5 Date: 18.01.2009Document40 paginiMeasures of Central Tendency: No. Biostat - 5 Date: 18.01.2009pradeepÎncă nu există evaluări

- Modal Testing and Analysis: Experimental Methods for Structural DynamicsDocument15 paginiModal Testing and Analysis: Experimental Methods for Structural DynamicsAbbas MohajerÎncă nu există evaluări

- Chapter 03 - Chaotic Synchronization, Conditional Lyapunov Exponents and Lyapunov's Direct MethodDocument30 paginiChapter 03 - Chaotic Synchronization, Conditional Lyapunov Exponents and Lyapunov's Direct Method王和盛Încă nu există evaluări

- Ultrasonic Flaw Detection DGS/AVG TechniqueDocument2 paginiUltrasonic Flaw Detection DGS/AVG TechniquePradip Tapan BanerjeeÎncă nu există evaluări

- Regression Analysis and Calibration Recommendations For The Characterization of Balance Temperature EffectsDocument23 paginiRegression Analysis and Calibration Recommendations For The Characterization of Balance Temperature EffectsTarık YılmazÎncă nu există evaluări

- A Study of Impurities in Intermediates and 3,4-Methylenedioxymethamphetamine (MDMA) Samples Produced Via Reductive Amination RoutesDocument17 paginiA Study of Impurities in Intermediates and 3,4-Methylenedioxymethamphetamine (MDMA) Samples Produced Via Reductive Amination RoutesandonovkaÎncă nu există evaluări

- Torque SteerDocument7 paginiTorque SteerAyushÎncă nu există evaluări

- Cbse 2009 Physics Board Paper Class XIIDocument17 paginiCbse 2009 Physics Board Paper Class XIINeil Mahaseth86% (7)

- A17. Six-Phase Fractional-Slot-per-Pole-per-Phase Permanent-Magnet Machines With Low Space Harmonics For Electric Vehicle ApplicationDocument10 paginiA17. Six-Phase Fractional-Slot-per-Pole-per-Phase Permanent-Magnet Machines With Low Space Harmonics For Electric Vehicle Applicationwalidghoneim1970Încă nu există evaluări

- Sabp A 049 PDFDocument10 paginiSabp A 049 PDFWalid Megahed100% (1)

- Optical Fiber Communication (EEE 4175) : Ray Theory - 2Document18 paginiOptical Fiber Communication (EEE 4175) : Ray Theory - 2Saikat MahmudÎncă nu există evaluări

- The Farce of GravityDocument2 paginiThe Farce of GravityPaul RainesÎncă nu există evaluări

- Handbook of Supersonic Aerodynamics Volume - 3 - Sec - 7Document79 paginiHandbook of Supersonic Aerodynamics Volume - 3 - Sec - 7maurizio.desio4992Încă nu există evaluări

- Hoschke 2011Document26 paginiHoschke 2011Angelica Ma Zapata67% (3)

- Eastman 50D 5245Document6 paginiEastman 50D 5245Felipe Gaglianone OlabarrietaÎncă nu există evaluări

- Hadean EonDocument13 paginiHadean Eonjimin parkÎncă nu există evaluări

- Phy Paper With Answer SolutionDocument11 paginiPhy Paper With Answer SolutionArifÎncă nu există evaluări

- A I0131e PDFDocument219 paginiA I0131e PDFTëk AñdotÎncă nu există evaluări

- L As Level Physics A 2821 01 January 2008 Question Paper Old g481Document16 paginiL As Level Physics A 2821 01 January 2008 Question Paper Old g481dasha962Încă nu există evaluări

- Detection of Adulteration of Ghee (Clarified Milk Fat) With Palmolein and Sheep Body Fat Using Reichert-Meissl (RM) Value Coupled With Solvent Fractionation TechniqueDocument7 paginiDetection of Adulteration of Ghee (Clarified Milk Fat) With Palmolein and Sheep Body Fat Using Reichert-Meissl (RM) Value Coupled With Solvent Fractionation Techniquekamal gandhiÎncă nu există evaluări

- 4582 SEPIMAX Zen Slides GB July 2013 PDFDocument42 pagini4582 SEPIMAX Zen Slides GB July 2013 PDFLinda HamidÎncă nu există evaluări

- Republic of The Philippines Department of Education Deped Complex, Pasig City Science Iii K To 12 Curriculum Guide Planner / Budget of WorkDocument3 paginiRepublic of The Philippines Department of Education Deped Complex, Pasig City Science Iii K To 12 Curriculum Guide Planner / Budget of WorkLedie Lou Cetoy SuperalesÎncă nu există evaluări

- DTC P0771 Shift Solenoid "E" Performance (Shift Solenoid Valve SR)Document5 paginiDTC P0771 Shift Solenoid "E" Performance (Shift Solenoid Valve SR)Marco Antonio RamirezÎncă nu există evaluări

- Intro Well FoundationDocument23 paginiIntro Well FoundationgoutammandÎncă nu există evaluări

- C. T. F. Ross BSC, PHD (Auth.) ) Finite Element PR PDFDocument227 paginiC. T. F. Ross BSC, PHD (Auth.) ) Finite Element PR PDFகுட்டி பையன்Încă nu există evaluări

- Steel Designer's Manual, 6th Edition, 2003 R20070821FDocument5 paginiSteel Designer's Manual, 6th Edition, 2003 R20070821Fsaad7159Încă nu există evaluări