Documente Academic

Documente Profesional

Documente Cultură

Hollow Sections 2nd Edt

Încărcat de

ksuscribdacctDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Hollow Sections 2nd Edt

Încărcat de

ksuscribdacctDrepturi de autor:

Formate disponibile

HOLLOW SECTIONS IN

STRUCTURAL APPLICATIONS

J. Wardenier, J.A. Packer, X.-L. Zhao and G.J. van der Vegte

ISBN 978-90-72830-86-9

CIDECT, Geneva, Switzerland, 2010

The publisher and authors have made careful efforts to ensure the reliability of the data contained in this

publication, but they assume no liability with respect to the use for any application of the material and

information contained in this publication.

Printed by Bouwen met Staal

Boerhaavelaan 40

2713 HX Zoetermeer, The Netherlands

P.O. Box 190

2700 AD Zoetermeer, The Netherlands

Tel. +31(0)79 353 1277

Fax +31(0)79 353 1278

E-mail info@bouwenmetstaal.nl

ii

PREFACE

The global construction market requires a world-wide coordination of product-, testing-, design- and execution-

standards, so that contracts for delivery of products and for engineering- and construction services can be

agreed on a common basis without barriers.

The mission of CIDECT is to combine the research resources of major hollow section manufacturers in order to

create a major force in the research and application of hollow steel sections world wide. This forms the basis of

establishing coordinated and consistent international standards.

For the ease of use of such standards, it is however necessary to reduce their content to generic rules and to

leave more object-oriented detailed rules to accompanying non-conflicting complementary information, that

have the advantage to be more flexible for the adaptation to recent research results and to be useable together

with any international code.

The book by J. Wardenier, J.A. Packer, X.-L. Zhao and G.J. van der Vegte "Hollow sections in structural

applications" is such a source, developed in an international consensus of knowledge on the topic. It

incorporates the recently revised design recommendations for hollow sections joints of the International

Institute of Welding, IIW (2009) and CIDECT (2008 and 2009). Both are consistent with each other and are the

basis for the Draft ISO standard for Hollow Section Joints (ISO 14346) and may form the basis for future

maintenance, further harmonisation and further development of Eurocode 3 (EN 1993-1-8), AISC (ANSI/AISC

360) and the CISC recommendations.

For the use together with EN 1993-1-8 and ANSI/AISC 360, both being based on the previous IIW (1989)

recommendations, the main differences to these rules are highlighted.

The authors are all internationally recognized experts in the field of tubular steel structures, three of them

having been chairmen of the IIW-Subcommission XV-E on "Tubular Structures" since 1981. This committee is

the pre-eminent international authority producing design recommendations and standards for onshore tubular

structures.

This book should therefore be an invaluable resource for lecturers, graduate students in structural, architectural

and civil engineering, explaining the important principles in the behaviour of tubular steel structures. It is also

addressed to designers of steel structures who can find in it the special items related to the use of hollow

sections, in particular joints, their failure modes and analytical models as supplements to more general design

codes.

Aachen, Germany, August 2010

Prof. Dr.-Ing. Dr.h.c. Gerhard Sedlacek

iii

iv

ACKNOWLEDGEMENTS

This book gives the background to design with structural hollow sections in general and in particular for joints to

hollow sections. For the latter, the recently updated recommendations of the International Institute of Welding

(IIW, 2009) and CIDECT (2008 and 2009) are adopted.

The background to design recommendations with the relevant analytical models is especially important for

students in Structural and Civil Engineering, whereas the design recommendations themselves serve more as

an example. Since the available hours for teaching Steel Structures, and particularly Tubular Structures, vary

from country to country, this book has been written in a modular form. The presentation generally follows

European codes, but the material is readily adapted to other (national) codes.

Since the first edition of this book was used not only by students but also by many designers, this second

edition was needed due to the recent update of the recommendations by IIW and the subsequent revision of

the CIDECT Design Guides Nos. 1 and 3 in 2008 and 2009.

The new IIW (2009) recommendations and the revised CIDECT Design Guides Nos. 1 and 3 (2008 and 2009)

are consistent with each other and are the basis for the Draft ISO standard for Hollow Section Joints (ISO

14346). Although the current Eurocode 3 (EN 1993-1-8, 2005) and AISC (2010) recommendations are still

based on the previous IIW (1989) and CIDECT (1991 and 1992) recommendations, it is expected that in the

next revision these will follow the new IIW and CIDECT recommendations presented in this book.

Besides the static design recommendations and background for hollow section joints, information is given for

member design in Chapter 2, composite structures in Chapter 4, and fire resistance in Chapter 5. These

chapters fully comply with the latest versions of the Eurocodes (EN 1993 and EN 1994). Further, fatigue design

of hollow section joints is covered in Chapter 14.

We wish to thank our colleagues from the IIW Sub-commission XV-E "Tubular Structures" and from the

CIDECT Project Working Group and the CIDECT Technical Commission for their constructive comments during

the preparation of this book.

We are very grateful that Prof. J. Stark and Mr. L. Twilt were willing to check Chapters 4 and 5 respectively on

composite members and fire resistance.

Appreciation is further extended to the authors of CIDECT Design Guides Nos. 1 to 9 and to CIDECT for

making parts of these Design Guides or background information available for this book.

Finally, we wish to thank CIDECT for the initiative to update this book.

Delft, The Netherlands, September 2010

Jaap Wardenier

Jeffrey A. Packer

Xiao-Ling Zhao

Addie van der Vegte

CONTENTS

1. Introduction 1

1.1 History and developments 1

1.2 Designation 2

1.3 Manufacturing of hollow sections 2

2. Properties of hollow sections 9

2.1 Mechanical properties 9

2.2 Structural hollow section dimensions and dimensional tolerances 10

2.3 Geometric properties 11

2.4 Drag coefficients 14

2.5 Corrosion protection 14

2.6 Use of internal void 15

2.7 Aesthetics 15

3. Applications 29

3.1 Buildings and halls 29

3.2 Bridges 29

3.3 Barriers 29

3.4 Offshore structures 30

3.5 Towers and masts 30

3.6 Special applications 30

4. Composite structures 37

4.1 Introduction 37

4.2 Design methods 37

4.3 Axially loaded columns 37

4.4 Resistance of a section to bending 39

4.5 Resistance of a section to bending and compression 39

4.6 Influence of shear forces 39

4.7 Resistance of a member to bending and compression 39

4.8 Load introduction 41

4.9 Special composite members with hollow sections 41

5. Fire resistance of hollow section columns 49

5.1 Introduction 49

5.2 Fire resistance 50

5.3 Unfilled hollow section columns 52

5.4 Concrete filled hollow section columns 53

5.5 Water filled hollow section columns 55

5.6 Joints 56

6. Design of hollow section trusses 65

6.1 Truss configurations 65

6.2 Joint configurations 65

6.3 Limit states and limitations on materials 66

6.4 General design considerations 67

6.5 Truss analysis 68

7. Behaviour of joints 75

7.1 General introduction 75

7.2 General failure criteria 77

7.3 General failure modes 77

v

7.4 Joint parameters 77

8. Welded joints between circular hollow sections 81

8.1 Introduction 81

8.2 Modes of failure 81

8.3 Analytical models 81

8.4 Experimental and numerical verification 83

8.5 Basic joint strength formulae 83

8.6 Evaluation to design rules 84

8.7 Other types of joints 85

8.8 Design charts 86

8.9 Relation to the previous recommendations of IIW (1989) and CIDECT (1991) 87

8.10 Concluding remarks 87

9. Welded joints between rectangular hollow sections 103

9.1 Introduction 103

9.2 Modes of failure 103

9.3 Analytical models 104

9.4 Experimental and numerical verification 106

9.5 Basic joint strength formulae 106

9.6 Evaluation to design rules 107

9.7 Other types of joints or other load conditions 107

9.8 Design charts 109

9.9 Concluding remarks 109

10. Welded joints between hollow sections and open sections 129

10.1 Introduction 129

10.2 Modes of failure 129

10.3 Analytical models 129

10.4 Experimental verification 131

10.5 Evaluation to design rules 131

10.6 Joints predominantly loaded by bending moments 131

11. Welded overlap joints 141

11.1 Introduction 141

11.2 Modes of failure 141

11.3 Analytical models for RHS overlap joints 141

11.4 Analytical models for CHS overlap joints 143

11.5 Analytical models for overlap joints with an open section chord 143

11.6 Experimental and numerical verification 143

11.7 Joint strength formulae 144

12. Welded I beam-to-CHS or RHS column moment joints 151

12.1 Introduction 151

12.2 Modes of failure 151

12.3 Analytical models 151

12.4 Experimental and numerical verification 153

12.5 Basic joint strength formulae 153

12.6 Concluding remarks 154

13. Bolted joints 161

13.1 Flange plate joints 161

13.2 End joints 161

13.3 Gusset plate joints 162

13.4 Splice joints 162

vi

vii

13.5 Beam-to-column joints 162

13.6 Bracket joints 163

13.7 Bolted subassemblies 163

13.8 Purlin joints 163

13.9 Blind bolting systems 163

13.10 Nailed joints 163

14. Fatigue behaviour of hollow section joints 175

14.1 Definitions 175

14.2 Influencing factors 175

14.3 Loading effects 176

14.4 Fatigue strength 177

14.5 Partial factors 177

14.6 Fatigue capacity of welded joints 177

14.7 Fatigue capacity of bolted joints 179

14.8 Fatigue design 180

15. Design examples 193

15.1 Uniplanar truss of circular hollow sections 193

15.2 Uniplanar truss of square hollow sections 197

15.3 Multiplanar truss (triangular girder) 197

15.4 Multiplanar truss of square hollow sections 199

15.5 Joint check using the joint resistance formulae 199

15.6 Concrete filled column with reinforcement 200

16. References 209

Symbols 221

CIDECT 229

viii

1. INTRODUCTION

Design is an interactive process between the

functional and architectural requirements and the

strength and fabrication aspects. In a good design, all

these aspects have to be considered in a balanced

way. Due to the special features of hollow sections

and their joints, it is here even of more importance

than for steel structures of open sections. The

designer should therefore be aware of the various

aspects of hollow sections.

Many examples in nature show the excellent

properties of the tubular shape with regard to loading

in compression, torsion and bending in all directions,

see Figs. 1.1 and 1.2. These excellent properties are

combined with an attractive shape for architectural

applications (Figs. 1.3 and 1.4). Furthermore, the

closed shape without sharp corners reduces the area

to be protected and extends the corrosion protection

life (Fig. 1.5).

Another aspect which is especially favourable for

circular hollow sections is the lower drag coefficients if

exposed to wind or water forces. The internal void can

be used in various ways, e.g. to increase the bearing

resistance by filling with concrete or to provide fire

protection. In addition, heating or ventilation systems

sometimes make use of the hollow section columns.

Although the manufacturing costs of hollow sections

are higher than those for other sections, leading to

higher unit material cost, economical applications are

achieved in many fields. The application field covers

all areas, e.g. architectural, civil, offshore, mechanical,

chemical, aeronautical, transport, agriculture and

other special fields. Although this book will be mainly

focused on the background to design and application,

in a good design not only does the strength have to be

considered, but also many other aspects, such as

material selection, fabrication including welding and

inspection, protection, erection, in service inspection

and maintenance.

One of the constraints initially hampering the

application of hollow sections was the design of the

joints. However, nowadays design recommendations

exist for all basic types of joints, and further research

evidence is available for many special types of joints.

Based on the research programmes carried out,

CIDECT (Comit International pour le Dveloppement

et l'Etude de la Construction Tubulaire) has published

Design Guides Nos. 1 to 9 for use by designers in

practice. Since these nine Design Guides are all

together too voluminous for educational purposes and

do not give the theoretical background, it was decided

to write this book especially to provide background

information for students and practitioners in Structural

and Civil Engineering.

This book is written in a limit states design format

(also known as LRFD or Load and Resistance Factor

Design in the USA). This means that the effect of the

factored loads (the specified or unfactored loads

multiplied by the appropriate load factors) should not

exceed the factored resistance of the joint or member.

The factored resistance expressions, in general,

already include appropriate material and joint partial

safety factors (

M

) or joint resistance (or capacity)

factors (). This has been done to avoid interpretation

errors, since some international structural steelwork

specifications use

M

values 1,0 as dividers (e.g.

Eurocodes), whereas others use values 1,0 as

multipliers (e.g. in North America and Australia). In

general, the value of 1/

M

is almost equal to .

1.1 HISTORY AND DEVELOPMENTS

The excellent properties of the tubular shape have

been recognised for a long time; i.e. from ancient time,

nice examples are known. An outstanding example of

bridge design is the Firth of Forth Bridge in Scotland

(1890) with a free span of 521 m, shown in Fig. 1.6.

This bridge has been built up from tubular members

made of rolled plates which have been riveted

together, because at that time, other fabrication

methods were not available for these sizes.

In the same century, the first production methods for

seamless and welded circular hollow sections were

developed. In 1886, the Mannesmann brothers

developed the skew roll piercing process

(Schrgwalzverfahren), shown in Fig. 1.7, which made

it possible to roll short thick walled tubulars. This

process, in combination with the pilger process

(Pilgerschrittverfahren, Fig. 1.8), developed some

years later, made it possible to manufacture longer

thinner walled seamless hollow sections.

In the first part of the previous century, an Englishman,

Whitehouse, developed the fire welding of circular

hollow sections. However, the production of welded

circular hollow sections became more important after

the development of the continuous welding process in

1930 by the American, Fretz Moon (Fig. 1.9).

Especially after the Second World War, welding

processes have been perfected, which made it

possible for hollow sections to be easily welded

1

together.

The end cutting required for fitting two circular hollow

sections together was considerably simplified by the

development of a special end preparation machine by

Mller (Fig. 1.10).

For manufacturers who did not have such end cutting

machines, the end preparation of circular hollow

sections remained a handicap.

A way of avoiding the connection problems was the

use of prefabricated connectors, e.g. in 1937

Mengeringhausen developed the Mero system. This

system enabled the fabrication of large space

structures in an industrialized way (Fig. 1.11).

In 1952, the rectangular hollow section was developed

by Stewarts and Lloyds (now Corus Tubes). This

section, with nearly the same properties as the

circular hollow section, enables the connections to be

made by straight end cuttings.

In the fifties, the problems of manufacturing, end

preparation and welding were all solved and from that

point of view the way to a successful story was open.

The remaining problem was the determination of the

strength of unstiffened joints.

The first preliminary design recommendations for

truss connections between circular hollow sections

were given by Jamm in 1951. This study was followed

by several investigations in the USA (Bouwkamp,

1964; Natarajan & Toprac, 1969; Marshall & Toprac,

1974), Japan (Togo, 1967; Natarajan & Toprac,

1968), and Europe (Wanke, 1966; Brodka, 1968;

Wardenier, 1982; Mang & Bucak, 1983; Puthli, 1998;

Dutta, 2002).

Research on joints between rectangular hollow

sections started in Europe in the sixties, followed by

many other experimental and theoretical

investigations. Many of these were sponsored by

CIDECT.

Besides these investigations on the static behaviour,

in the last 25 years much research was carried out on

the fatigue behaviour and other aspects, such as

concrete filling of hollow sections, fire resistance,

corrosion resistance and behaviour under wind

loading.

1.2 DESIGNATION

The preferred designations for structural applications

are:

- Circular hollow sections (CHS)

- Rectangular hollow sections (RHS)

- Square hollow sections (SHS)

In Canada and the USA, it is common to speak about

Hollow Structural Sections (HSS), whereas in Europe

also the term Structural Hollow Sections (SHS) is

used.

1.3 MANUFACTURING OF HOLLOW

SECTIONS

As mentioned, hollow sections can be produced

seamless or welded. Seamless hollow sections are

made in two phases, i.e. the first phase consists of

piercing an ingot and the second step considers the

elongation of this hollow bloom into a finished circular

hollow section. After this process, the tube can go

through a sizing mill to give it the required diameter.

More information about other processes, most of them

based on the same principle, is given by Dutta (2002).

Nowadays, welded hollow sections with a longitudinal

weld are mainly made employing either electrical

resistance welding processes or induction welding

processes, shown in Fig. 1.12. A strip or plate is

formed by rollers into a cylindrical shape and welded

longitudinally. The edges are heated, e.g. by electrical

resistance, then the rollers push the edges together,

resulting in a pressure weld. The weld protrusion on

the outside of the tube is trimmed immediately after

welding.

Rectangular hollow sections are made by deforming

circular hollow sections through forming rollers, as

shown in Fig. 1.13. This forming process can be done

hot or cold, using either seamless or longitudinally

welded circular hollow sections. Although it is

common practice to use longitudinally welded hollow

sections, for the very thick sections, seamless

sections may be used.

Square or rectangular hollow sections are sometimes

made by forming a single strip to the required shape

and closing it by a single weld, preferably in the

middle of a face.

Large circular hollow sections are also made by rolling

plates through a so-called U-O press process shown

in Fig. 1.14. After forming the plates to the required

2

shape, the longitudinal weld is made by a submerged

arc welding process.

Another process for large tubulars is to use a

continuous wide strip, which is fed into a forming

machine at an angle to form a spirally formed circular

cylinder, see Fig. 1.15. The edges of the strip are

welded together by a submerged arc welding process

resulting in a so-called spirally welded tube.

More detailed information about the manufacturing

processes and the limitations in sizes can be obtained

from Dutta (2002).

3

Fig. 1.1 Reeds in the wind

Fig. 1.3 Airport Bangkok, Thailand

Fig. 1.2 Bamboo

Fig. 1.4 Ripshorster Bridge, Germany

4

Fig. 1.5 Paint surface for hollow sections vs open

sections

Fig. 1.7 Skew roll piercing process

(Schrgwalzverfahren)

Fig. 1.6 Firth of Forth Bridge, Scotland

Fig. 1.8 Pilger process (Pilgerschrittverfahren)

5

forming rollers

heating

welding rollers

welded CHS

heating

coil

forming rollers

heating

welding rollers

welded CHS

heating

coil

Fig. 1.9 Fretz Moon process

Fig. 1.11 Mero connector

Fig. 1.10 End cutting machine

Pressure rollers

inductor

Welded CHS

Pressure rollers

inductor

Welded CHS

Pressure rollers

inductor

Welded CHS

Fig. 1.12 Induction welding process

6

Fig. 1.13 Manufacturing of rectangular hollow sections

Fig. 1.14 Forming of large CHS

Fig. 1.15 Spirally welded CHS

7

8

2. PROPERTIES OF HOLLOW

SECTIONS

2.1 MECHANICAL PROPERTIES

Hollow sections are made of similar steel as used for

other steel sections, thus in principle there is no

difference in mechanical properties.

Tables 2.1a and 2.2a show, as an example, the

mechanical properties according to the European

standard EN 10210-1 (2006) for hot finished structural

hollow sections of non-alloy and fine grain structural

steels. The cold formed sections are given in EN

10219-1 (2006): Cold formed welded structural hollow

sections of non-alloy and fine grain structural steels

(see Tables 2.1b and 2.2b). As shown, the

requirements of EN 10210-1 and EN 10219-1 are

almost identical.

Hollow sections can also be produced in special

steels, e.g. high strength steel with yield strengths up

to 690 N/mm

2

or higher, weathering steels and steel

with improved or special chemical compositions, etc.

Generally, the design of members is based on the

yield strength. In this chapter the recommended

M0

and

M1

factors of 1,0 are adopted for the design yield

strength f

yd

.

In statically indeterminate structures, sufficient

deformation capacity or rotation capacity is required

for redistribution of loads. In this case, yielding of

members or yielding in the joints may provide the

required rotation capacity. A tensile member made of

ductile steel can be brittle if a particular cross section

is weakened, e.g. by holes, in such a way that this

cross section fails before the whole member yields. It

is therefore required that yielding occurs first. This

shows that the yield-to-ultimate tensile strength ratio is

also important, especially for structures with very

non-uniform stress distributions, which is a situation

that occurs in tubular joints. Some codes, such as

Eurocode 3 (EN 1993-1-1, 2005), specify the following

requirement for the minimum ratios:

1 , 1

f

f

yd

u

> (2.1a)

The IIW (2009) recommendations and many offshore

codes require a higher ratio between f

u

and f

yd

:

8 , 0

f

f

or 25 , 1

f

f

u

yd

yd

u

s > (2.1b)

This is only one aspect for ductility. In the case of

impact loading, the steel and members should also

behave in a ductile manner. Hence, Tables 2.1a and

2.2a also give requirements based on the standard

Charpy test to ensure adequate notch toughness.

Nowadays, more refined characterisation methods

exist to describe the ductility of cracked bodies, e.g.

the CTOD (Crack Tip Opening Displacement) method.

These characterisation methods are generally used

for pressure vessels, transport line pipes and offshore

applications, which are beyond the scope of this book.

Another characterisation is sometimes required for

thick walled sections which are loaded in the

thickness direction. In this case, the strength and

ductility in the thickness direction should be sufficient

to avoid cracking, called lamellar tearing, see Fig. 2.1.

This type of cracking is caused by non metallic

manganese-sulphide inclusions. Thus, if the sulphur

content is very low or the sulphur is joined with other

elements such as calcium (Ca), such a failure can be

avoided. Indirectly this is obtained by requiring a

certain reduction of area R

AZ

in the tensile test. For

example, R

AZ

= 35 means that in the tensile test the

cross sectional area at failure has been reduced by

35% compared to the original cross sectional area.

In most structural steel specifications the minimum

required yield strength, ultimate tensile strength,

elongation and the Charpy V-notch values are

specified. Design standards or specifications give

further limitations for the f

u

/f

y

ratio, whereas depending

on the application, more restrictive requirements may

be given related to CTOD values or the properties in

the thickness direction (Z quality).

Another aspect is the effect of cold forming on the

mechanical properties of the parent steel. In the case

of cold forming of hollow sections, the yield strength

and to a lesser extent the ultimate tensile strength are

increased, especially in the corners, as shown in Fig.

2.2. Further, the yield-to-ultimate tensile ratio is

increased and the elongation slightly decreased.

If the standards, e.g. EN 10210-1 and EN 10219-1,

specify the properties at a particular cross section

location based on the finished product, these

properties have been already partly taken into

account. Thus, this generally applies in Europe.

9

However, some standards outside Europe specify the

material properties of the parent material. In this case,

the increased yield strength can be taken into account

for design. A small corner radius produces a small

cold formed area with a large cold forming effect and

consequently a large increase in yield strength, while

a large corner radius does just the opposite.

According to research work of Lind & Shroff (1971),

the product of area and increase in yield strength can

approximately be taken as constant. Lind & Shroff

assumed that in every corner of 90 the yield strength

of the parent material f

yb

is increased over a length of

7t to the ultimate tensile strength of the parent

material f

u

. The total increase over the section 4(7t)t(f

u

-

f

yb

) can be averaged over the section, resulting in a

design yield strength f

ya

, as shown in Fig. 2.2.

It is noted that the cold formed sections should satisfy

the requirements for minimum inside corner radius to

guarantee sufficient ductility, see Table 2.3 for fully

aluminum killed steel (steel with limited Si content).

Part 10 of Eurocode 3 (EN 1993-1-10, 2005) specifies

the material selection. Here, a permissible thickness

can be determined based on a reference temperature,

the steel grade and quality and the stress level. The

reference temperature covers, besides the air

temperature, also cold forming effects, strain rate, etc.

However, the current rules cannot be adopted to cold

formed hollow sections because the determination of

the effect of cold forming for cold formed hollow

sections is not yet clearly specified. Based on the data

obtained by Soininen (1996), Kosteski et al. (2003),

Bjrk (2005), Khn (2005), Puthli & Herion (2005) and

Sedlacek et al. (2008), presently a proposal is being

worked out for an amendment of EN 1993-1-10. In

this proposal of CEN/TC 250/SC 3-N 1729 (2010), it is

recommended that for cold formed hollow sections

according to EN 10219, the procedure for hot formed

material can be used provided that for the cold

forming effects the reference temperature is reduced

by AT

cf

. For CHS, AT

cf

varies from 0 C to 20 C

depending on the thickness and the d/t ratio. For RHS

with steel qualities according to EN 10219, AT

cf

varies

from 35 C to 45 C depending on the thickness and

the ratio between the inside corner radius and the

thickness. For cold formed hollow sections with

Charpy impact strengths significantly exceeding the

requirements of EN 10219, a lower value of AT

cf

is

allowed.

2.2 STRUCTURAL HOLLOW SECTION

DIMENSIONS AND DIMENSIONAL

TOLERANCES

The dimensions and sectional properties of structural

hollow sections have been standardised in EN (EN

10210-2, 2006; EN 10219-2, 2006) and ISO standards

(ISO 657-14, 2000; ISO 4019, 2001) for hot finished

and cold formed structural hollow sections

respectively.

The two applicable standards in Europe are EN

10210-2 (2006) "Hot finished structural hollow

sections of non-alloy and fine grain steels Part 2:

Tolerances, dimensions and sectional properties" and

EN 10219-2 (2006) "Cold formed welded structural

hollow sections of non-alloy and fine grain steels

Part 2: Tolerances, dimensions and sectional

properties". However, the majority of manufacturers of

structural hollow sections do not produce all the sizes

shown in these standards. It should be further noted

that other sizes, not included in these standards, may

be produced by some manufacturers.

The majority of the tolerances given in EN 10219-2

are the same as those in EN 10210-2, see Tables

2.4a and 2.4b.

Internationally, the delivery standards in various

countries deviate considerably with respect to the

thickness and mass tolerances (Packer, 1993). In

most countries besides the thickness tolerance, a

mass tolerance is given, which limits extreme

deviations. However, in some production standards,

e.g. in the USA, the thickness tolerance is not always

compensated by a mass tolerance. This has resulted

in associated design specifications which account for

this, by designating a lower "design wall thickness" of

0,9 or 0,93 times the nominal thickness t. In Eurocode

3, where design is based on nominal thicknesses, the

thickness tolerances in EN 10210-2 and EN 10219-2

are (partly) compensated by the mass tolerance. It is

foreseen that in the next revision these tolerances will

be tightened.

Although the circular, square and rectangular hollow

sections are the generally-used shapes; other shapes

are sometimes available. For example, some tube

manufacturers deliver the shapes given in Table 2.5.

Of these, the elliptical hollow sections have become

more popular for architectural designs. These shapes

are not dealt with further in this book. However, more

information about elliptical hollow sections can be

found in Bortolotti et al. (2003), Chan & Gardner

(2008), Choo et al. (2003), Martinez-Saucedo et al.

10

(2008), Packer et al. (2009b), Pietrapertosa & Jaspart

(2003), Theofanous et al. (2009), Willibald et al.

(2006) and Zhao & Packer (2009).

2.3 GEOMETRIC PROPERTIES

2.3.1 Tension

The design capacity N

t,Rd

of a member under tensile

loading depends on the cross sectional area and the

design yield strength, and is independent of the

sectional shape. In principle, there is no advantage or

disadvantage in using hollow sections from the point

of view of the amount of material required. The design

capacity is given by:

yd Rd , t

Af N = (2.2)

If the cross section is weakened by bolt holes or slots,

the net cross section should also be checked, in a

similar way as for other sections, e.g. according to

Eurocode 3 (EN 1993-1-8, 2005):

9 , 0

f A

N

2 M

u net

Rd , t

= (2.3)

where the partial safety factor

M2

= 1,25.

The factor 0,9 may vary from country to country

depending on the partial factor

M

used. Where ductile

behaviour is required (e.g. under seismic loading), the

yield resistance shall be less than the ultimate

resistance at the net section of fastener holes.

2.3.2 Compression

For centrally loaded members in compression, the

critical buckling load depends on the slenderness

and the section shape.

The slenderness is given by the ratio of the buckling

length

b

and the radius of gyration i.

i

b

= (2.4)

The radius of gyration of a hollow section (in relation

to the member mass) is generally much higher than

that for the weak axis of an open section. For a given

length, this difference results in a lower slenderness

for hollow sections and thus a lower mass when

compared with open sections.

The buckling behaviour is influenced by initial

eccentricities, straightness and geometrical tolerances

as well as residual stresses, non-homogeneity of the

steel and the stress-strain relationship.

Based on extensive investigations by the European

Convention for Constructional Steelwork (ECCS) and

CIDECT, "European buckling curves" (Fig. 2.3 and

Table 2.7) have been established for various steel

sections including hollow sections. They are

incorporated in Eurocode 3 (EN 1993-1-1, 2005).

The reduction factor ; shown in Fig. 2.3 is the ratio of

the design buckling capacity N

b,Rd

to the axial plastic

capacity.

yd

Rd , b

Rd , pl

Rd , b

f

f

N

N

= = ; (2.5)

where:

f

b,Rd

=

A

N

Rd , b

(2.6)

The non-dimensional slenderness is determined

by:

E

= (2.7)

where:

y

E

f

E

t = (Euler slenderness) (2.8)

The buckling curves for the hollow sections are

classified according to Table 2.6. Most open sections

fall under curves "b" and "c". Consequently, for the

case of buckling, the use of hot formed hollow

sections generally provides a considerable saving in

material.

Fig. 2.4 illustrates, for a buckling length of 3 m, a

comparison between the required mass of open and

hollow sections for a given load. It shows that in those

cases in which loads are small, leading to relatively

slender sections, hollow sections provide a great

advantage (considerably lower use of material).

However, if loads are higher, resulting in low

slenderness, the advantage (in %) will be less.

The overall buckling behaviour of hollow sections

improves with increasing diameter- or width-to-wall

11

thickness ratio. However, this improvement is limited

by local buckling. To prevent local buckling, d/t or b/t

limits are given e.g. in Eurocode 3 (EN 1993-1-1,

2005), see Table 2.7. In the case of thin walled

sections, interaction between global and local buckling

should be considered.

In addition to the improved buckling behaviour due to

the high radius of gyration and the enhanced design

buckling curve, hollow sections can offer other

advantages in lattice girders. Due to the torsional and

bending stiffness of the members in combination with

joint stiffness, the effective buckling length of

compression members in lattice girders can be

reduced (Fig. 2.5). Eurocode 3 (EN 1993-1-1)

recommends an effective buckling length for hollow

section brace members in welded lattice girders equal

to or less than 0,75, in which represents the system

length, see also Rondal et al. (1992).

For chords, 0,9 times the system length for in-plane

buckling or 0,9 times the length between the supports

for out-of-plane buckling, is taken as the effective

buckling length.

These reductions are also based on the fact that the

chord and brace members are generally not fully

optimised. If for example the chord would be fully

utilized with different members for every panel then

these reductions would not be allowed.

Laterally unsupported compression chords of lattice

girders (see Fig. 2.6) have a reduced buckling length

due to the improved torsional and bending stiffness of

the tubular members (Baar, 1968; Mouty, 1981).

These factors make the use of hollow sections in

girders or trusses even more favourable.

2.3.3 Bending

In general, I and H sections are more economical

under bending about the major axis (I

max

larger than

for hollow sections). Only in those cases in which the

design resistance in open sections is largely reduced

by lateral buckling, hollow sections offer an

advantage.

It can be shown by calculations that lateral instability

is not critical for circular hollow sections, square

hollow sections and for the most commonly used

rectangular hollow sections with bending about the

strong axis. Table 2.8 shows allowable span-to-depth

ratios for the most commonly used sections (EN

1993-1-1, 2005). According to a study of Kaim (2006)

these limits can be taken considerably larger.

It is apparent that hollow sections are especially

favourable compared to other sections if bending

about both axes is present.

Hollow sections used for elements subjected to

bending can be more economically designed by using

plastic design. However, then the sections have to

satisfy more restricted conditions to avoid premature

local buckling. Like other steel sections loaded in

bending, different moment-rotation behaviour can be

observed.

Fig. 2.7 shows various moment-rotation diagrams for

a member loaded by bending moments.

The moment-rotation curve "1" shows a moment

exceeding the plastic moment M

pl

and a considerable

rotation capacity. Moment-rotation curve "2" shows a

moment exceeding the plastic moment capacity M

pl

,

but after the maximum, the moment drops

immediately, so that little moment-rotation capacity

exists. Moment-rotation curve "3" represents a

capacity lower than the plastic moment capacity,

which, however, exceeds the yield moment capacity

M

el

. In the moment-rotation curve "4" the capacity is

even lower than the yield moment capacity M

el

and

failure is by elastic buckling. The effect of the

moment-rotation behaviour is reflected in the

classification of cross sections as shown in Fig. 2.8

and Table 2.7. The cross section classification is

given in limits for the diameter- or flat

width-to-thickness ratio.

The limits are based on experiments and can be

expressed as:

yd

f

235

c

t

d

= for CHS (2.9)

f

235

c 3

t

b

yd

= for RHS (2.10a)

yd

f

235

c 3

t

h

= for RHS (2.10b)

with f

yd

in N/mm

2

and c depending on the section

class, the cross section and the loading. For RHS, it is

conservatively assumed that the width of the "flat" is

equal to the external width b or depth h of the RHS

minus 3t.

12

The cross section classes 1 and 2 can develop the

plastic moment capacity up to the given b/t or d/t limits

with bi-linear stress blocks, whereas the moment

capacity of the cross section classes 3 and 4 is based

on an elastic stress distribution (see Fig. 2.8). The

difference between the cross section classes 1 and 2

is reflected in the rotation capacity. After reaching the

plastic moment capacity, the cross section class 1 can

keep this capacity after further rotation, whereas the

capacity of the cross section class 2 drops after

reaching this capacity. As a consequence, the

moment distribution in the structure or structural

component should be determined by elastic analysis

for structures made of sections with cross section

classes 2, 3 or 4. For structures made of sections with

cross sections in class 1 a plastic moment distribution

can be adopted, but an elastic moment distribution is

still permissible (and in some countries more

common).

For a class 1 beam fully clamped at both ends and

subjected to a uniformly distributed loading q, the

plastic moment distribution implies that after reaching

the plastic moment capacity at the ends, the beam

can be loaded until a further plastic hinge occurs at

mid span (see Fig. 2.9).

For the class 4 cross section, the maximum stress is

determined by local buckling and the stress in the

outer fibre is lower than the yield strength f

y

.

Alternatively, an effective cross sectional area based

on the yield strength may be determined.

Detailed information about the cross sectional

classification is given by Rondal et al. (1992).

Research by Wilkinson & Hancock (1998) showed

that especially the limits for the side wall slenderness

of RHS need to be reduced considerably. E.g. for

class 1 sections, they suggest reducing the Eurocode

3 limits (EN 1993-1-1) for the side wall slenderness to:

6t

) 2r 2t 5(b

70

t

2r) 2t (h

s

(2.11)

with 30

t

r 2 t 2 b

s

For r = t, this can be simplified to:

t

b

83 , 0 77

t

h

s with 34

t

b

s (2.11a)

In the absence of shear forces or if the shear forces

do not exceed 50% of the shear capacity V

pl,Rd

, the

effect of shear may be neglected and the bending

moment capacity about one axis is given by:

yd pl Rd , c

f W M = for cross section classes 1 or 2 (2.12)

yd el Rd , c

f W M = for cross section class 3 (2.13)

yd eff Rd , c

f W M = for cross section class 4 (2.14)

When the shear force exceeds 50% of the shear

capacity, combined loading has to be considered, see

Eurocode 3 (EN 1993-1-1).

2.3.4 Shear

The elastic shear stress in circular and rectangular

hollow sections can be determined with simple

mechanics by:

3

f

t I 2

S V

yd

Ed

s = t (2.15)

Fig. 2.10 shows the elastic stress distribution. The

design capacity based on plastic design can be easily

determined based on the Huber-Hencky-Von Mises

criterion by assuming the shear yield strength in those

parts of the cross section active for shear.

3

f

A V

yd

v Rd , pl

= (2.16)

where:

h b

h

A A

v

+

= for RHS (2.17)

(or just 2

h

t) with V in the direction of h.

A

2

A

v

t

= for CHS (2.18)

2.3.5 Torsion

Hollow sections, especially CHS, have the most

effective cross section for resisting torsional moments,

because the material is uniformly distributed about the

polar axis. A comparison of open and hollow sections

of nearly identical mass in Table 2.9 shows that the

torsional constant of hollow sections is about 200

times that of open sections.

13

The design capacity for torsional moments is

described by:

3

f

W M

yd

t Rd , t

= (2.19)

or circular hollow sections: F

t ) t d (

2 t d

I 2

W

t

t

t

=

= (2.20)

here: w

( ) t t d

4

I

3

t

t

~ (2.21)

or rectangular hollow sections (Marshall, 1971): F

A

m

t

t

A

2 t

I

W

+

= (2.22)

here: w

A

A

3

t

t A 4

3

t

I

2

m

+ ~ (2.23)

) (2.24)

(2.25)

or thin walled rectangular hollow sections, eq. (2.22)

(2.26)

he first term in eq. (2.23) is generally only used for

he exact, more complicated equations for the cross

.3.6 Internal pressure

he design capacity per unit length, shown in Fig.

( ) ( t + = 4 r 2 b h 2

m m m A

( ) t = 4 r h b A

2

m m m m

F

can be approximated by:

t b h 2 W

m m t

=

T

open sections. However, research by Marshall (1971)

showed that the given formula provides the best fit

with the test results.

T

sectional properties are given in EN 10210-2 (2006)

and EN 10219-2 (2006).

2

he circular hollow section is most suitable to resist T

an internal pressure p.

T

2.11, is given by:

t 2 d

t 2

f p

yd

= (2.27)

M0

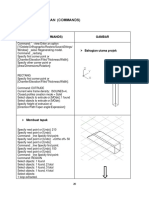

ectional classification,

.4 DRAG COEFFICIENTS

hollow sections,

.5 CORROSION PROTECTION

tructures designed in hollow sections have a 20 to

eq. (2.27), = 1,0, but for transport pipelines, the In

M0

value may be considerably larger than for other

cases, depending on the hazard of the product, the

effect of failure on the environment and inspectability.

The design capacities for RHS sections subjected to

internal pressure are much more complicated;

reference can be made to the Deutscher

Dampfkesselausschu (1975).

2.3.7 Combined loadings

arious combinations of loadings are possible, e.g. V

tension, compression, bending, shear and torsion.

Depending on the cross s

various interaction formulae should be applied.

Reference can be made to Eurocode 3 (EN 1993-1-1).

It is beyond the scope of this book to deal with all

possible formulae; however, the interaction between

the various loads in the cross section can be based on

the Huber-Hencky-Von Mises stress criterion (Roik &

Wagenknecht, 1977). For the member checks, other

interaction formulae apply, see e.g. EN1993-1-1.

2

ially circular Hollow sections, espec

have a striking advantage for use in structures

exposed to fluid currents, i.e. air or water. The drag

coefficients are much lower than those of open

sections with sharp edges, see Fig. 2.12 (Schulz,

1970; CIDECT, 1984; Dutta, 2002).

2

tructures made of hollow sections offer advantages S

with regard to corrosion protection. Hollow sections

have rounded corners (Fig. 2.13) resulting in a better

protection than that for sections with sharp corners.

This is especially true for the joints in circular hollow

sections where there is a smooth transition from one

section to another. This better protection increases

the protection period of coatings against corrosion.

S

50% smaller surface to be protected than comparable

structures made of open sections. Many

14

investigations, summarized by Tissier (1978), have

been conducted to assess the likelihood of internal

corrosion. These investigations, carried out in various

countries, show that internal corrosion does not occur

in sealed hollow sections.

Even in hollow sections which are not perfectly

.6 USE OF INTERNAL VOID

he possibilities of using the internal space are briefly

.6.1 Concrete filling

wall thicknesses are not

very important reason for using concrete filled

oncrete filling of hollow sections contributes not only

.6.2 Fire protection by water circulation

nother method for fire protection of buildings is to

he columns are interconnected with a water storage

order to prevent freezing, potassium carbonate

.6.3 Heating and ventilation

he inner voids of hollow sections are sometimes

.6.4 Other possibilities

ometimes hollow section chords of lattice girder

.7 AESTHETICS

rational use of hollow sections leads in general to

sealed, internal corrosion is limited. If there is concern

about condensation in an imperfectly sealed hollow

section, a drainage hole can be made at a point where

water can drain by gravity.

2

he internal void in hollow sections can be used in T

various ways, e.g. to increase the compressive

resistance by filling with concrete, or to provide fire

protection. In addition, heating or ventilation systems

are sometimes incorporated into hollow section

columns.

T

described below.

2

the commonly-available If

sufficient to meet the required load bearing resistance,

the hollow section can be filled with concrete. For

example, it may be preferable in buildings to have the

same external dimensions for the columns on every

floor. At the top floor, the smallest wall thickness can

be chosen, and the wall thickness can be increased

with increasing load for lower floors. If the hollow

section with the largest available wall thickness is not

sufficient for the ground floor, the hollow section can

be filled with concrete to increase the load bearing

resistance.

A

hollow sections is that the columns can be relatively

slender. Design rules are given in e.g. Eurocode 4

(EN 1994-1-1, 2004).

C

to an increase in load bearing resistance, but it also

improves the fire resistance duration. Extensive test

projects carried out by CIDECT and the European

Coal and Steel Community (ECSC) showed that

reinforced concrete filled hollow section columns

without any external fire protection like plaster,

vermiculite panels or intumescent paint, can attain a

fire life of even 2 hours depending on the cross

section ratio of the steel and concrete, reinforcement

percentage of the concrete and the applied load, see

Fig. 2.14 (Twilt et al., 1994).

2

A

use water filled hollow section columns.

T

tank. Under fire conditions, the water circulates by

convection, keeping the steel temperature below the

critical value of 450 C. This system has economical

advantages when applied to buildings with more than

about 8 storeys. If the water flow is adequate, the

resulting fire resistance time is virtually unlimited.

In

(K

2

CO

3

) is added to the water. Potassium nitrate is

used as an inhibitor against corrosion.

2

T

used for air and water circulation for heating and

ventilation of buildings. Many examples in offices and

schools show the excellent combination of the

strength function of hollow section columns with the

integration of heating or ventilation systems. This

system offers maximization of floor area through

elimination of heat exchangers, a uniform provision of

warmth and a combined protection against fire.

2

S

bridges are used for conveying fluids (pipe bridge). In

buildings, the rain water downpipes may go through

the hollow section columns or in other cases electrical

wiring is located in the columns. The internal space

can also be used for prestressing a hollow section.

2

A

structures which are cleaner and more spacious.

Hollow sections can provide slender aesthetic

columns, with variable section properties but flush

external dimensions. Due to their torsional rigidity,

hollow sections have specific advantages in folded

structures, V-type girders, etc.

15

16

often made of hollow

sections directly connected to one another without any

stiffener or gusset plate, is often preferred by

architects for structures with visible steel elements.

However, it is difficult to express aesthetic features in

economic comparisons. Sometimes hollow sections

are used only because of aesthetic appeal, see e.g.

Fig. 2.15, whilst at other times appearance is less

important.

Lattice construction, which is

Table 2.1a Hot finished structural hollow sections Non-alloy steel properties (EN 10210-1, 2006)

Minimum yield strength

(1)

(N/mm

2

)

Minimum tensile

strength

(N/mm

2

)

Longitudinal

(2)

minimum elongation (%)

on gauge

o o

S 65 , 5 L =

Charpy impact

strength

(10 x 10 mm)

Steel

designation

t s 16

mm

16 < t s 40

mm

40< t s 63

mm

t < 3

mm

3 s t s 100

mm

3 < t s 40

mm

40 < t s 63

mm

Temp.

C

J

S235JRH 235 225 215 360-510 360-510 26 25 20 27

S275J0H

S275J2H

275 265 255 430-580 410-560 23 22

0

-20

27

27

S355J0H

S355J2H

S355K2H

355 345 335 510-680 470-630 22 21

0

-20

-20

27

27

40

(3)

(1)

For thicknesses above 63 mm, these values are further reduced.

(2)

In transverse direction 2% lower.

(3)

Corresponds to 27 J at -30 C.

Table 2.1b Cold formed welded structural hollow sections Non-alloy steel (EN 10219-1, 2006) Steel

properties different from EN 10210-1 (2006)

Steel designation

Minimum longitudinal elongation (%),

all thicknesses, t

max

= 40 mm

S235JRH 24

(1)

S275J0H

S275J2H

20

(2)

S355J0H

S355J2H

S355K2H

20

(2)

(1)

For t > 3 mm and d/t < 15 or 5 , 12

t 2

h b

<

+

the minimum elongation is reduced by 2 to 22%; for t s 3 mm the minimum

elongation is 17%.

(2)

For d/t < 15 or 5 , 12

t 2

h b

<

+

the minimum elongation is reduced by 2 to 18%.

17

Table 2.2a Hot finished structural hollow sections Fine grain steel properties (EN 10210-1, 2006)

Minimum yield strength

(N/mm

2

)

Minimum

tensile strength

(N/mm

2

)

Minimum elongation (%)

on gauge

o o

S 65 , 5 L =

t s 65 mm

Charpy impact

strength

(10 x 10 mm)

Steel

designation

t s 16

mm

16 < t s 40

mm

40 < t s 65

mm

t s 65

mm

Long. Trans.

Temp.

C

J

S275NH

S275NLH

275 265 255 370-510 24 22

-20

-50

40

(1)

27

S355NH

S355NLH

355 345 335 470-630 22 20

-20

-50

40

(1)

27

S420NH

S420NLH

420 400 390 520-680 19 17

-20

-50

40

(1)

27

S460NH

S460NLH

460 440 430 540-720 17 15

-20

-50

40

(1)

27

(1)

Corresponds to 27 J at -30 C.

Table 2.2b Cold formed welded structural hollow sections Fine grain steel (EN 10219-1, 2006) Steel

properties different from EN 10210-1 (2006)

Feed stock condition M

(1)

Steel designation

Minimum tensile strength

(N/mm

2

)

Minimum longitudinal

elongation (%)

(2)

S275MH

S275MLH

360 - 510 24

S355MH

S355MLH

450 - 610 22

S420NH

S420NLH

520 - 660 19

S460NH

S460NLH

530 - 720 17

(1)

M refers to thermal mechanical rolled steels.

(2)

For d/t < 15 or

5 , 12

t 2

h b

<

+

the minimum elongation is reduced by 2, e.g. from 24% to 22% for S275MH and S275MLH.

Table 2.3 Minimum inner corner radii of cold formed RHS according to EN 1993-1-8 (2005)

Maximum wall thickness t (mm)

General

r/t

Strain due to cold

forming (%)

Predominantly static

loading

Fatigue dominating

Aluminium-killed steel

(Al > 0,02%)

> 25

> 10

> 3,0

> 2,0

> 1,5

> 1,0

s 2

s 5

s 14

s 20

s 25

s 33

any

any

24

12

8

4

any

16

12

10

8

4

any

any

24

12

10

6

18

Table 2.4a Hot finished structural hollow sections Tolerances (EN 10210-2, 2006)

Section type Square/rectangular Circular

Outside dimension the greater of 0,5 mm and 1%

(1)

the greater of 0,5 mm and 1% but not

more than 10 mm

Welded -10%

Thickness

Seamless -10% and -12,5% at maximum 25% cross section

Welded 6% on individual lengths

Mass

Seamless -6%; +8%

Straightness 0,2% of the total length and 3 mm over any 1 m length

Length (exact) +10 mm, -0 mm, but only for exact lengths of 2000 to 6000 mm

Out of roundness - 2% for d/t s 100

Squareness of sides 90 1 -

Corner radii Outside 3,0t maximum -

Concavity/convexity 1% of the side -

Twist 2 mm + 0,5 mm/m

(1)

-

(1)

For elliptical hollow sections with h s 250 mm, the tolerances are twice the values given in this table.

Table 2.4b Cold formed welded structural hollow sections (EN 10219-2, 2006) Tolerances different

from EN 10210-2 (2006)

Section type Square/rectangular Circular

Outside dimension

b < 100 mm: the greater of 0,5 mm and 1%

100 mm s h, b s 200 mm: 0,8%

b > 200 mm: 0,6%

1%, minimum 0,5 mm

maximum 10 mm

Thickness Welded

t s 5 mm: 10%

t > 5 mm: 0,5 mm

for d s 406,4 mm:

t s 5 mm: 10%

t > 5 mm: 0,5 mm

for d > 406,4 mm:

10% with maximum 2,0 mm

Mass 6% 6%

Straightness

0,15% of the total length and 3 mm over any 1 m

length

Outside corner radii

(profile)

t s 6 mm: 1,6 to 2,4t

6 mm < t s 10 mm: 2,0 to 3,0t

t > 10 mm: 2,4 to 3,6t

-

Concavity/convexity maximum 0,8% with a minimum of 0,5 mm -

Table 2.5 Special shapes available

Triangular Hexagonal Octagonal Flat - oval Elliptical Half-elliptical

Shape

19

Table 2.6 European buckling curves according to manufacturing processes (EN 1993-1-1, 2005)

Cross section Manufacturing process Buckling curves

Hot finished

420 N/mm

2

< f

y

s 460 N/mm

2

a

0

Hot finished

f

y

s 420 N/mm

2

a

Cold formed c

h

b

Flange

Web

t

h

b

Flange

Web

h

b

h

b

Flange

Web

t

h

b

Flange

Web

t

h

b

Flange

Web

h

b

h

b

Flange

Web

t

b

t

d

t

d

t

d

t

h

b

Flange

Web

t

h

b

Flange

Web

h

b

h

b

Flange

Web

t

h

b

Flange

Web

t

h

b

Flange

Web

h

b

h

b

Flange

Web

t

b

t

d

t

d

t

d

t

hh

Table 2.7 Limits for b/t, h/t and d/t for cross section classes 1, 2 and 3 (EN 1993-1-1, 2005)

Class 1 2 3

f

yd

(N/mm

2

) f

yd

(N/mm

2

) f

yd

(N/mm

2

)

Cross

section

Load type

Considered

element

235 275 355 460 235 275 355 460 235 275 355 460

3

f

235

c

t

b

yd

+ s

c = 33 c = 38 c = 42

RHS

b/t

(1)

Compression Top face

36,0 33,5 29,8 26,6 41,0 38,1 33,9 30,2 45,0 41,8 37,2 33,0

3

f

235

c

t

h

yd

+ s

c = 72 c = 83 c = 124

RHS

h/t

(1)

Bending Side wall

(2)

75,0 69,6 61,6 51,8 86,0 79,7 70,5 62,3 127,0 117,6 103,9 91,6

yd

f

235

c

t

d

s

c = 50 c = 70 c = 90

CHS

d/t

Compression

and/or

bending

t

t

t

t

50,0 42,7 33,1 25,5 70,0 59,8 46,3 35,8 90,0 76,9 59,6 46,0

(1)

For all hot finished and cold formed RHS, it is conservative to assume that the width-to-thickness ratio of the "flat" is

3

t

b

t

2r - 2t - b

= or 3

t

h

t

2r - 2t - h

= .

(2)

Wilkinson & Hancock (1998) suggested reducing the Eurocode limits (EN 1993-1-1) for the side wall slenderness of RHS

considerably, e.g. for class 1 in a simplified form to:

t

b

83 , 0 77

t

h

s with 34

t

b

s .

20

Table 2.8 Allowable span-to-depth ratios L/(h-t) to avoid lateral buckling based on EN 1993-1-1 (2005)

s

t h

L

t h

t b

S235 S275 S355 S460

0,5 73,7 63,0 48,8 37,7

0,6 93,1 79,5 61,6 47,5

0,7 112,5 96,2 74,5 57,5

0,8 132,0 112,8 87,4 67,4

0,9 151,3 129,3 100,2 77,3

1,0 170,6 145,8 112,9 87,2

h

b

Flange

b

t

h

b

Flange

b

h

b

h

b

Flange

b

t

h

b

Flange

b

t

h

b

Flange

b

h

b

h

b

Flange

b

t

b

h

t

h

b

Flange

b

t

h

b

Flange

b

h

b

h

b

Flange

b

t

h

b

Flange

b

t

h

b

Flange

b

h

b

h

b

Flange

b

t

b

h

t

Table 2.9 Torsional strength of various sections

Section

Mass

(kg/m)

Torsion constant I

t

(10

4

mm

4

) or (cm

4

)

UPN 200 25,3 11,9

INP 200 26,2 13,5

HEB 120 26,7 13,8

HEA 140 24,7 8,1

140 x 140 x 6 24,9 1475

168.3 x 6 24,0 2017

21

Fig. 2.1 Lamellar tearing

Actual f

y

mean

after cold forming

Actual f

y

mean

after cold forming

Actual f

y

mean

after cold forming

Fig. 2.2 Influence of cold forming on the yield strength for a square hollow section of 100 x 100 x 4 mm

0

1,00

0,75

0,50

0,25

0

0 0,5 1,0 1,5 2,0

00

1,00

0,75

0,50

0,25

0

0 0,5 1,0 1,5 2,0

Fig. 2.3 Eurocode 3 buckling curves (EN 1993-1-1, 2005)

22

B

u

c

k

l

i

n

g

s

t

r

e

s

s

(

N

/

m

m

2

)

B

u

c

k

l

i

n

g

s

t

r

e

s

s

(

N

/

m

m

2

)

Fig. 2.4 Comparison of the masses of hollow and open sections under compression in relation to the loading

Fig. 2.5 Restraints for the buckling of a brace member

Fig. 2.6 Bottom chord laterally spring supported by the stiffness of the members, joints and purlins

23

M

pl

M

el

M

e

M

pl

M

el

M

e

Fig. 2.7 Moment-rotation curves

Fig. 2.8 Stress distribution for bending

Fig. 2.9 Moment distribution in relation to the cross section classification

24

Fig. 2.10 Elastic shear stress distribution

tf

yd

t f

yd

t f

yd

t

d - 2t

Fig. 2.11 Internal pressure

Fig. 2.12 Wind flow for open and circular hollow sections

25

paint layers

steel

steel

corner protection for RHS

and open sections

paint layers

steel

steel

corner protection for RHS

and open sections

paint layers

steel

steel

corner protection for RHS

and open sections

paint layers

steel

steel

corner protection for RHS

and open sections

Fig. 2.13 Painted corners of RHS vs. open sections

Fig. 2.14 Fire resistance of concrete filled hollow sections

RHS 304,8x304,8x9,5

111 min.

14 min.

only

RHS

non-

reinforced

concrete

filling

50min.

steel fibre

reinforced

concrete

filling

working load (kN)

f

i

r

e

l

i

f

e

(

m

i

n

.

)

1650. 3150. 3150.

120.

60.

RHS 304,8x304,8x9,5

111 min.

14 min.

only

RHS

non-

reinforced

concrete

filling

50min.

steel fibre

reinforced

concrete

filling

working load (kN)

f

i

r

e

l

i

f

e

(

m

i

n

.

)

1650. 3150. 3150.

120.

60.

RHS 304,8x304,8x9,5

111 min.

14 min.

only

RHS

non-

reinforced

concrete

filling

50min.

steel fibre

reinforced

concrete

filling

working load (kN)

f

i

r

e

l

i

f

e

(

m

i

n

.

)

1650. 3150. 3150.

120.

60.

26

Fig. 2.15 Aesthetically appealing structures

27

28

3. APPLICATIONS

The applications of structural hollow sections nearly

cover all fields. Hollow sections may be used because

of the beauty of their shape or to express lightness,

while in other cases their geometrical properties

determine their application. In this chapter, examples

are given for the various fields and to show the

possibilities of constructing with hollow sections.

3.1 BUILDINGS AND HALLS

In buildings and halls, hollow sections are mainly used

for columns and lattice girders or space frames for

roofs. In modern architecture, they are also used for

other structural or architectural reasons, e.g. facades.

Fig. 3.1 shows a 10-storey building in Karlsruhe,

Germany with rectangular hollow section columns

180 x 100. Special aspects are that the columns are

made of weathering steel and are water filled to

ensure the required fire protection. The columns are

connected with water reservoirs to ensure circulation.

Besides the fire protection, a further advantage is that

due to the water circulation in the columns, the

deformation of the building due to temperature

differences by sunshine is limited.

Fig. 3.2 shows an example of lattice girder trusses

used in a roof of an industrial building. For an optimal

cost effective design, it is essential that the truss joints

are made without any stiffening plates.

An especially appealing application is given in Fig.

3.3, showing a tree-type support of the airport

departure hall in Stuttgart, Germany. For the joints,

streamlined steel castings are used.

Fig. 3.4 shows the roof of the terminal of Kansai

International Airport in Osaka, Japan with curved

triangular girders of circular hollow sections.

Fig. 3.5 shows a dome under construction, whereas

Fig. 3.6 illustrates a special application using columns

and beams in the faade for ventilation assuring clean

windows in the swimming pool.

Fig. 3.7 shows a very nice architectural application in

Bush Lane House in the city of London, UK. The

external circular hollow section lattice transfers the

faade loads and the loads on the floors to the main

columns. The hollow sections are filled with water for

fire protection.

Very attractive applications can be found in the halls

and buildings for the Olympic Games in Athens, e.g.

Fig. 3.8.

Elliptical hollow sections are becoming more and

more popular among architects and already several

examples exist, see for example Fig. 3.9, the airport

building in Madrid.

Nowadays, many examples of tubular structures are

found in railway stations (Figs. 3.10 and 3.11) and

roofs of stadia and halls (Figs. 3.12 to 3.14).

Indeed, as stated by one of the former CIDECT vice

presidents, Jim Cran, at the Tubular Structures

Symposium in Delft (1977) "The sky is the limit", whilst

presenting beautiful applications of structural hollow

sections.

3.2 BRIDGES

As mentioned in the introduction, the Firth of Forth

Bridge is an excellent example of using the hollow

section shape for structural applications in bridges.

Nowadays, many modern examples exist (IISI, 1997).

Figs. 1.4, 3.15 to 3.17 and 3.20 show various

examples of pedestrian bridges; some of these are

movable bridges.

Circular hollow sections can also be used as a flange

for plate girders, as shown in Fig. 3.17 for a triangular

box girder.

A very nice example of a road-pedestrian bridge is

illustrated in Fig. 3.18, being a composite

steel-concrete bridge with hollow sections for the arch

and braces and a concrete deck.

Fig. 3.19 shows a railway bridge near Rotterdam, The

Netherlands with circular hollow section arches.

3.3 BARRIERS

There are a few aspects which make hollow sections

increasingly suitable for hydraulic structures, such as

barriers. Due to environmental restrictions, the

maintenance of hydraulic structures requires severe

precautions, making durability an important issue.

Structures of hollow sections are less susceptible to

corrosion due to the rounded corners. Furthermore,

especially circular hollow sections have lower drag

coefficients, leading to lower forces due to wave

loading. Fig. 3.21 shows a barrier with a support

29

structure of circular hollow sections. Fig. 3.22 shows

the storm surge barrier near Hook of Holland with

triangular arms made of circular hollow sections and a

length (250 m) equal to the height of the Eiffel Tower

in Paris.

3.4 OFFSHORE STRUCTURES

Offshore, many application examples are available;

most of them in circular hollow sections. For the

support structure, the jacket or tower, not only is the

wave loading important, but also other aspects are

leading to the use of circular hollow sections. E.g. in

jackets, the circular hollow section piles are often

driven through the circular hollow section legs of the

jacket, thus the pile is guided through the leg.

Sometimes the internal void is used for buoyancy.

Further, the durability and easy maintenance in

severe environments are extremely important.

Hollow section members are used in jackets, towers,

the legs and diagonals in topside structures, cranes,

microwave towers, flare supports, bridges, support

structures of helicopter decks and further in various

secondary structures, such as staircases, ladders, etc.

Figs. 3.23 and 3.24 show two examples.

3.5 TOWERS AND MASTS

Considering wind loading, corrosion protection and

architectural appearance, there is no doubt that hollow

sections are to be preferred. However, in many

countries, electric power transmission towers are

made of angle sections with simple bolted joints.

Nowadays, architectural appearance becomes more

important, while stringent environmental restrictions

make protection and maintenance increasingly

expensive. These factors stimulate designs made of

hollow sections (Figs. 3.25 and 3.26).

3.6 SPECIAL APPLICATIONS

The field of special applications is large, e.g. along the

roads, petrol stations (Fig. 3.27), sound barriers (Fig.

3.28), traffic information gantries (Fig. 3.29), guard

rails, parapets and sign posts.

Further, excellent application examples are found in

radio telescopes (Fig. 3.30), in mechanical

engineering, cranes (Fig. 3.31) and roller coasters

(Fig. 3.32).

In the agricultural field, glass houses (Fig. 3.33) and

agricultural machinery are typical examples. Also in

transport, many examples exist but these are outside

the scope of this book. Indeed, the sky is the limit.

30

Fig. 3.2 Roof with lattice girders

Fig. 3.1 Faade of the Institute for Environment in

Karlsruhe, Germany

Fig. 3.3 Airport departure hall in Stuttgart, Germany

31

Fig. 3.4 Roof of Kansai International Airport in Osaka,

Japan

Fig. 3.6 Faade with ventilation through the RHS

columns and beams, Borkum, Germany

Fig. 3.8 Hall for the 2004 Olympic Games, Athens,

Greece

Fig. 3.5 Dome structure in Gothenburg, Sweden

Fig. 3.7 Bush Lane House in London, UK

Fig. 3.9 Airport Madrid with EHS sections, Spain

32

Fig. 3.10 Railway station in Rotterdam, The

Netherlands

Fig. 3.12 Barrel dome grid for the Trade Fair building

in Leipzig, Germany

Fig. 3.13 Retractable roof for the Rogers Centre in

Toronto, Canada

Fig. 3.11 TGV railway station at Charles de Gaulle

Airport, France

Fig. 3.14 Stadium Australia for the 2000 Olympic

Games, Sydney, Australia

33

Fig. 3.15 Movable pedestrian bridge in RHS, The

Netherlands

Fig. 3.17 Pedestrian bridge in Houdan, France

Fig. 3.19 Railway bridge with CHS arches, The

Netherlands

Fig. 3.21 Eastern Scheldt barrier, The Netherlands

Fig. 3.16 Movable pedestrian bridge in RHS near

Delft, The Netherlands

Fig. 3.18 Composite road bridge in Marvejols, France

Fig. 3.20 Movable pedestrian bridge in CHS near

Delft, The Netherlands

Fig. 3.22 Storm surge barrier, The Netherlands

34

Fig. 3.23 Bullwinkle offshore structure, Gulf of Mexico

Fig. 3.25 Electric power transmission tower

Fig. 3.27 Petrol station, The Netherlands

Fig. 3.24 Amoco P15 offshore platform with jack-up,

North Sea

Fig. 3.26 Mast, The Netherlands

Fig. 3.28 Sound barrier, Delft, The Netherlands

35

Fig. 3.29 Traffic information gantry, The Netherlands

Fig. 3.30 Radio telescope

Fig. 3.31 Cranes

Fig. 3.33 Green house, The Netherlands Fig. 3.32 Roller coaster

36

4. COMPOSITE STRUCTURES

4.1 INTRODUCTION

Concrete filled hollow sections (Fig. 4.1) are mainly