Documente Academic

Documente Profesional

Documente Cultură

Variable spring supports guide

Încărcat de

golf09102518Descriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Variable spring supports guide

Încărcat de

golf09102518Drepturi de autor:

Formate disponibile

04/10

Variable Spring Supports

Pipework and/or vessels subject to temperature

change or subsidence, etc. which give rise to vertical

displacements should be supported by a resilient

device which will absorb/accommodate the

movement. For relatively small displacements (up to

about 75mm) the variable spring support is

recommended. The Carpenter & Paterson standard

range of variable spring supports are produced in four

basic travel ranges; 35mm, 70mm,140mm and

210mm. These are designated DV35, DV70, DV140

and DV210 respectively. The travels stated are the

maximum working range of the springs. This full travel

can be used providing the necessary calculations are

carried out to ensure that the connecting equipment

and pipework can withstand the large load changes

that occur during pipe movement. Most national

standards do limit the load variation to maximum of

25%. It is therefore usual to select variable spring

supports on this basis.

In keeping with generally accepted practice, we

recommend that the actual pipe load is correctly

supported when the pipe is in its normal working

position. This ensures no abnormal or excessive

forces, due to out of balance supporting effort, is

transferred to the pipework in its stressed working

condition.

Whether this or any other principle is followed for the

selection of variable spring supports, care must be

taken to ensure that sufficient travel is available in the

spring assembly to permit free movement of the pipe

within the required pipework movement range cold or

hot.

This improved range of variable spring supports has

been developed and is introduced for normal power

plant and petrochemical applications. Where severe

corrosive conditions are encountered, such as offshore installations, or complete sterility is required,

such as food process plants. The unit can be supplied

in the usual painted finishes or due to its unique

construction, can be completely coated both internally

and externally prior to assembly.

All our variable spring units are supplied with a green

synthetic resin hammer finish as standard, but our

unique design allows for other combinations of finishes

for particularly corrosive environments, etc:

Helical coil: Plastic coated. Casing and other

components; Hot dip galvanised, with threaded items

galvanised or zinc-plated. Alternatively, we are able to

manufacture all our units in a range of austenitic

stainless steel if required. With the exception of sizes

0-2 all units are supplied preset to customers design

load. Down travel hydrostatic test stop will be provided

by request.

All preset load and hydrostatic test stops must be

removed prior to operation of the equipment.

The normal hydrostatic test load is twice the rated load

of the support.

In addition to the DV range of variable spring supports

Carpenter & Paterson manufacture a range of small

compact spring supports for travels up to 150mm and

loads up to 270.N(27Kg). (See page 55 for details and

selection table).

45

46

Variable Spring Supports

Standard Design Features

Type A

Spring

Type B

Spring

Type C

Spring

Type D

Spring

1. Precompression of the spring coil into the casing

saves headroom and erection time.

2. For each series there is a reserve travel at the

upper and lower limits of the unit.

3. All steel construction that is rugged and compact.

4. Non-corrosive material used for scale plate and

name plate.

5. Load indicator clearly visible.

6. Spring Pressure plate serves as a centering

device.

7. Finish - standard green synthetic resin base

hammer finish - specialised coatings are also

available.

8. All F type floor units are inclusive of load flange

and internal load column guide.

9. Travel Stops - The Carpenter & Paterson preset

design locks the unit in the cold load position.

The lock is operable in the vertical upwards direction only.

10.No maintenance required.

Optional Design Features

1. Should the unit be subject to hydrostatic test load

then the unit should be ordered complete with

hydrostatic test stops. The strength of the preset

stops are so designed that it can withstand up to

two times the normal rated load for hydrostatic

testing.

2. Limit stops permanently installed to prevent the

movement of the pipe beyond predetermined

distance or load within the travel range of the

spring.

3. Lifting lugs - are available on large sizes to

facilitate erection and installation.

04/10

Type E

Spring

Type F

Spring

Type G

Spring

4. Corrosion resistant - the unit is galvanised,

except the spring, which is usually neoprene or

plastic coated.

5. For extreme environmental conditions we are

able to manufacture our units in a range of austenitic stainless steels.

Specification

All Carpenter & Paterson variable spring supports

meet the requirements of:British Standard 3974.

U.S. Manufacturers Standardisation Society SP58

U.S. Manufacturers Standardisation Society SP69

The ANSI Code for Power Piping ANSI B31.1

The ANSI Code for Petroleum Refinery Piping

B31.3 and others.

Ordering

When ordering please specify:1. Hanger series, type and size.

(Example: DV35 - A - 8.)

2. Operating Load.

3. Vertical movement and direction of movement,

cold to hot. (Example: 16mm up)

4. Thread details.

5. Whether hydrostatic stops are required.

6. Preset load if required sizes 0-2 inclusive.

7. Protective finish required.

8. Identification number.

9. Rod Centres and total load for Type G.

04/10

Variable Spring Supports

Type Selection

The type of spring to be used is normally determined by the

physical characteristics of the structure to which the spring

assembly will be attached, as shown by the typical

applications.

Method of Selection

In order to select the correct spring hanger size it is

necessary to know the actual load which the spring is to

support (inclusive of pipe weight, insulation, contents and

ancillary equipment). Also the magnitude and direction of

the pipe line movement from the cold to the hot position, the

actual load is the hot load. The cold load (preset load) is

calculated by adding (up movement) or subtracting (down

movement) the product of the spring rate times the

movement to the hot load, e.g.:

Cold Load (MVT.UP) = Hot Load + (MVT. x Spring Rate).

Cold Load (MVT.DN) = Hot Load - (MVT. x Spring Rate).

Using the Selection Table (either N or Kg)

1. Select the actual support load in the body of the

table.

2. Check that the support travel can be accommodated

within the recommended working range of the unit

size selected by reading the table up or down,

dependent on the pipe movement direction. It should

be noted that the chart must be read

opposite from the direction of the pipe movement.

3. If the movement can be accommodated then by

using 25% as the maximum load change cold to hot

the travel series can be established.

Variability

= Movement X Spring Rate x 100

(% Load Change)

Hot Load

EXAMPLE:Actual Load (Hot Load) = 10789 N.

Pipe Movement 20mm down cold to hot.

Maximum variation from cold to hot load = 25%.

Using N Selection Table

47

Enter table at 10789 N. This is located in size 12 column.

Since the pipe movement is down, move up the column

for a distance of 20 mm. This travel is acceptable for all

travel series, therefore unit size 12 is selected.

Check Variability

Variability

= Movement X Spring Rate x 100

(% Load Change)

Hot Load

From lower chart select spring rate for DV35 Size 12 =

157.6 N/mm

V = 20 x 157.6 x 100 = 29.2%

10789

This would not be acceptable.

Select spring rate for DV70 size 12 = 78.8 N/mm

V = 20 x 78.8 x 100 = 14.6%

10789

This is acceptable.

UNIT SELECTED WOULD BE DV70 SIZE 12

Preset Load = Actual Load - (Movement x Spring Rate)

Preset Load = 10789 - (20 x 78.8) = 9213N

Unit to be ordered would be DV70 Size 12.

Preset Load = 9213N Hot Load = 10789 N.

Calculating the Rod take out for a Hanging

Type Support

Having selected the support type, series and size, the next

step is to calculate the rod take out. Note that the rod take

out dimension listed in the various tables is given for

specific types, the dimension is always given at the

minimum load position. To calculate the rod take out for

example DV70/A/16 Preset Load = 33861 N (Refer to table

on page 60).

Firstly, refer to table on page 52.

At the intersection of a horizontal line from size

column to a vertical line down from column headed

rod take out type A - we obtain a rod take out of 376 mm.

This is at the minimum load position. To this

dimension we must add the amount of

precompression from the minimum load position to

the preset load position.

Refer now to the size selection table, (page 48).

Enter the body of the table where the load of 33861 N reads

in the size 16 column, moving horizontally to the left to read

the amount of precompression required for a series DV70

spring. In this example the precompression is

40 mm. The rod take out = 376 + 40 = 416 mm.

Other loads are treated in a similar manner.

Intermediate precompression dimensions are obtained by

linear interpolation.

To calculate loaded length X for F type

Base Mounted Support

Having selected the support type, series and size, the next

step is to calculate the loaded length. Note that the loaded

length dimension listed in the various tables is given as

minimum and maximum.

The maximum figure should be used for calculation

purposes.

EXAMPLE:Calculate the loaded length for DV140/F/10, preset load =

5414N. (Ref. to table page 53).

At the intersection of a horizontal line from hanger size

column to a vertical line down from column headed Loaded

Length X, Type F max. - we obtain a height of 778 mm. This

is at the minimum load position. From this dimension we

must subtract the amount of

precompression from the minimum load position to the

preset load position. Refer now to size selection table,

(page 48), and enter the body of the table where the load of

5414N reads in the size 10 column and moving horizontally

to the left read the amount of precompression required for

a series DV140 spring. In this example the precompression

is 60 mm. Therefore the loaded length = 778-60 = 718 mm.

Other loads are treated in a similar manner. Intermediate

precompression dimensions are obtained by linear

interpolation.

Cautionary Note Base Mounted Type

DV35 and DV70 all sizes.

Lateral loads on Base Mounted Supports shall be limited to

25% of the maximum working load. Where higher loads are

envisaged consideration shall be given to the fitting of

P.T.F.E. slider pads or rollers (Type K).

DV140 and DV210 all sizes.

Lateral loads on Base Mounted Supports shall be limited to

15% of the maximum working load. Where higher loads are

envisaged consideration shall be given to the fitting of

P.T.F.E. slider pads or rollers (Type K).

48

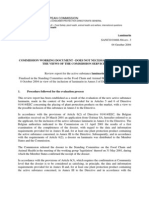

Variable Spring Supports

Loads in Newtons. Travel in mm

Variable Support Selection Table

DV

210

Over

Travel

Recommended Working Range of Springs

Min

Working

Load

DV

140

DV

70

DV

35

30

20

10

30

20

10

60

40

20

10

90

60

30

15

120

80

40

20

150

100

50

25

180

120

60

30

210

140

70

35

30

20

10

Max

Working

Load

Over

Travel

10

11

12

13

14

15

16

17

18

19

20

21

22

196

201

207

212

217

222

228

233

238

243

249

254

259

264

270

275

280

285

291

296

301

306

312

317

322

327

333

338

343

348

354

359

364

370

375

380

385

391

396

401

406

412

417

422

427

433

292

300

307

314

322

329

337

344

351

359

366

373

381

388

395

403

410

417

425

432

438

446

454

462

469

476

484

491

498

506

513

520

528

535

542

550

557

564

572

579

587

594

601

609

616

623

375

385

394

404

413

423

432

441

451

460

470

479

489

498

508

517

527

536

546

555

564

574

583

593

602

612

621

631

640

650

659

668

678

687

697

706

716

725

735

744

754

763

772

782

791

801

468

498

510

523

535

547

559

572

584

596

608

621

633

645

657

670

682

694

706

719

731

743

756

768

780

792

805

817

829

841

854

866

878

890

903

915

927

939

952

964

976

988

1001

1013

1025

1037

652

668

685

701

717

734

750

767

783

800

816

833

849

866

882

899

915

931

948

964

981

997

1014

1030

1047

1063

1080

1096

1113

1129

1146

1162

1178

1195

1211

1228

1244

1261

1277

1294

1310

1327

1343

1360

1376

1392

873

895

917

939

961

983

1005

1027

1049

1071

1093

1115

1138

1160

1182

1204

1226

1248

1270

1292

1314

1336

1358

1380

1402

1424

1446

1469

1491

1513

1535

1557

1579

1601

1623

1645

1667

1689

1711

1733

1755

1777

1799

1822

1844

1866

1161

1190

1220

1249

1287

1308

1337

1367

1396

1426

1455

1484

1514

1543

1573

1602

1631

1661

1690

1720

1749

1779

1808

1837

1867

1896

1926

1955

1984

2014

2043

2073

2102

2132

2161

2190

2220

2249

2279

2308

2338

2367

2396

2426

2455

2485

1548

1587

1626

1665

1704

1744

1783

1822

1861

1901

1940

1979

2018

2058

2097

2136

2175

2214

2254

2293

2323

2371

2411

2450

2489

2528

2567

2607

2646

2685

2724

2764

2803

2842

2881

2921

2960

3000

3039

3077

3117

3156

3195

3234

3274

3313

2073

2125

2178

2230

2283

2335

2388

2440

2493

2545

2598

2651

2703

2756

2808

2861

2913

2966

3018

3071

3123

3176

3228

3281

3334

3386

3439

3491

3544

3596

3649

3701

3754

3806

3859

3911

3964

4017

4069

4122

4174

4227

4279

4332

4384

4437

2764

2834

2904

2974

3044

3114

3184

3254

3324

3394

3464

3534

3604

3674

3744

3814

3884

3954

4024

4094

4165

4235

4305

4375

4445

4515

4585

4655

4725

4795

4865

4935

5005

5075

5145

5215

5285

5355

5425

5495

5566

5636

5706

5776

5846

5916

3593

3684

3775

3866

3957

4048

4138

4230

4321

4412

4503

4594

4685

4776

4867

4959

5050

5141

5232

5323

5414

5555

5596

5687

5778

5869

5960

6051

6142

6233

6325

6416

6507

6598

6689

6780

6871

6962

7053

7144

7235

7326

7417

7508

7599

7691

4698

4817

4936

5055

5174

5293

5412

5532

5651

5770

5889

6008

6127

6246

6365

6484

6603

6722

6842

6961

7080

7199

7318

7437

7556

7675

7794

7913

8032

8151

8271

8390

8509

8628

8747

8866

8985

9104

9223

9342

9461

9580

9700

9819

9938

10057

6218

6375

6533

6691

6848

7006

7164

7321

7479

7636

7794

7952

8109

8267

8424

8582

8740

8897

9055

9213

9370

9528

9685

9843

10001

10158

10316

10473

10631

10789

10946

11104

11262

11419

11577

11734

11892

12050

12207

12365

12522

12680

12838

13000

13153

13310

8291

8501

8711

8921

9131

9341

9551

9762

9972

10182

10392

10602

10812

11022

11233

11433

11653

11863

12073

12283

12494

12704

12914

13124

13334

13544

13754

13965

14175

14385

14595

14805

15015

15226

15436

15646

15856

16066

16276

16486

16697

16907

17117

17327

17537

17747

11054

11334

11614

11895

12175

12455

12735

13015

13296

13576

13856

14136

14416

14697

14977

15257

15537

15817

16098

16378

16658

16938

17218

17499

17779

18059

18339

18619

18900

19180

19460

19740

20020

20301

20581

20861

21141

21422

21702

21982

22262

22542

22823

23103

23383

23663

14923

15301

15679

16058

16436

16814

17193

17571

17950

18327

18706

19084

19462

19840

20219

20597

20975

21354

21732

22110

22488

22867

23245

23623

24001

24380

24758

25136

25515

25893

26271

26649

27028

27406

27784

28162

28541

28919

29297

29676

30054

30432

30810

31189

31567

31945

20726

21252

21777

22302

22828

23353

23879

24404

24929

24455

25980

26505

27031

27556

28082

28607

29132

29658

30183

30708

31234

31759

32285

32810

33335

33861

34386

34912

35437

35962

36488

37013

37538

38064

38589

39115

39640

40165

40691

41216

41741

42267

42792

43318

43843

44368

27635

28356

29036

29737

30437

31138

31838

32539

33239

33940

34640

35341

36041

36742

37442

38143

38843

39544

40244

40945

41645

42346

43046

43747

44447

45148

45848

46549

47249

47950

48650

49351

50051

50752

51452

52153

52853

53554

54254

54955

55655

56356

57056

57757

58457

59158

36799

37731

38662

39544

40526

41457

42389

43321

44252

45184

46116

47047

47979

48911

49842

50774

51706

52638

53569

54501

55433

56364

57296

58228

59159

60091

61023

61954

62886

63818

64749

65681

66613

67544

68476

69408

70339

71271

72203

73135

74066

74998

75929

76861

77793

78724

48869

50109

51349

52589

53829

55069

56309

57549

58789

60029

61268

62508

63748

64988

66228

67468

68708

69948

71188

72428

73667

74907

76147

77387

78627

79867

81107

82347

83587

84827

86066

87306

88546

89786

91026

92266

93506

94746

95986

97226

98465

99705

100945

102185

103425

104665

64978

66624

68270

69916

71563

73209

74855

76501

78147

79974

81440

83086

84372

86378

88025

89671

91317

92963

94609

96256

97902

99548

101194

102840

104486

106133

107779

109425

111071

112717

114364

116010

117656

119302

120948

122595

124241

125887

127533

129179

130826

132472

134118

135764

137410

139057

86359

88549

90738

92927

95116

97305

99494

101683

103872

106061

108250

110439

112628

114818

117007

119196

121385

123574

125763

127952

130141

132330

134519

136708

138897

141087

143276

145465

147654

149843

152032

154221

156410

158599

160788

162977

165166

167356

169545

171734

173923

176112

178301

180490

182679

184868

115171

118091

121010

123929

126849

129768

132687

135607

138526

141445

144365

147284

150204

153123

156042

158962

161881

164800

167720

170639

173558

176478

179397

182317

185236

188155

191075

193994

196913

199833

202753

205671

208591

211510

214430

217349

220268

223188

226107

229026

231946

234865

237784

240704

243623

246543

Spring Rate - N per millimetre

04/10

Figure DV35

Figure DV70

Figure DV140

Figure DV210

Size

5.3

2.6

1.3

0.87

0

7.4

3.7

1.8

1.23

1

9.4

4.7

2.4

1.57

2

12.3

6.1

3.1

2.03

3

16.5

8.3

4.2

2.77

4

22.1

11.0

5.5

3.67

5

29.4

14.7

7.4

4.9

6

39.2

19.6

9.8

6.53

7

52.5

26.3

13.1

8.77

8

70.1

35.0

17.5

11.67

9

91.1

45.5

22.8

15.17

10

119.1

59.5

29.8

19.83

11

157.6

78.8

39.4

26.27

12

210.2

105.1

52.5

35.03

13

280.2

140.1

70.1

46.7

14

378.2

189.1

94.6

63.03

15

525.4

262.7

131.3

87.57

16

700.5

350.3

175.1

116.77

17

931.7

465.3

232.9

155.1

18

1239.9

619.9

310.0

206.63

19

1646.2

823.1

411.5

274.37

20

2189.1

1094.5

547.3

364.87

21

2919.4

1459.7

729.8

486.57

22

04/10

Variable Spring Supports

Loads in kg. Travel in mm

Variable Support Selection Table

DV

210

Over

Travel

Recommended Working Range of Springs

Min

Working

Load

DV

140

DV

70

DV

35

30

20

10

30

20

10

60

40

20

10

90

60

30

15

120

80

40

20

150

100

50

25

180

120

60

30

210

140

70

35

30

20

10

Max

Working

Load

Over

Travel

10

11

12

13

14

15

16

17

18

19

20

21

22

20

20.5

21

21.5

22

22.5

23

23.5

24

24.5

25

25.5

26

27

27.5

28

28.5

29

29.5

30

30.5

31

31.5

32

32.5

33.5

34

34.5

35

35.5

36

36.5

37

37.5

38

38.5

39

39.5

40

40.5

41.5

42

42.5

43

43.5

44

29

30.5

31

32

32.5

33.5

34.5

35

36

36.5

37.5

38

39

39.5

40.5

41

42

42.5

43.5

44

45

45.5

46.5

47

48

48.5

49.5

50

51

51.5

52.5

53

54

54.5

55.5

56

57

57.5

58.5

59

60

60.5

61.5

62

63

64

38

39

40

41

42

43

44

45

46

47

48

49

50

50.5

51.5

52.5

53.5

54.5

55.5

56.5

57.5

58.5

59.5

60.5

61.5

62.5

63.5

64

65

66

67

68

69

70

71

72

73

74

75

76

77

77.5

78.5

79.5

80.5

81.5

49

51

52

53

54

56

57

58

59

61

62

63

64

66

67

68

69

71

72

73

74

76

77

78

79

81

82

83

84

86

87

88

89

91

92

93

94

96

97

98

99

101

102

103

104

106

66

68

70

71

73

75

76

78

80

81

83

85

87

88

90

92

93

95

97

98

100

102

103

105

107

108

110

112

113

115

117

118

120

122

123

125

127

128

130

132

134

135

137

139

140

142

88

91

93

95

97

100

102

104

107

109

111

113

116

118

120

122

125

127

129

131

134

136

138

140

143

145

147

149

152

154

156

158

161

163

165

167

170

172

174

176

179

181

183

185

188

190

118

121

124

127

130

133

136

139

142

145

148

151

154

157

160

163

166

169

172

175

178

181

184

187

190

193

196

199

202

205

208

211

214

217

220

223

226

229

232

235

238

241

244

247

250

253

158

162

166

170

174

178

182

186

190

194

198

202

206

210

214

218

222

226

230

234

238

242

246

250

254

258

262

266

270

274

278

282

286

290

294

298

302

306

310

314

318

322

326

330

334

338

211

216

222

227

232

238

243

248

254

259

265

270

275

281

286

291

297

302

307

313

318

323

329

334

340

345

350

356

361

366

372

377

382

388

393

398

404

409

415

420

425

431

436

441

447

452

282

289

296

303

310

317

324

332

339

346

353

360

367

374

382

389

396

403

410

417

424

432

439

446

453

460

467

474

482

489

496

503

510

517

524

532

539

546

553

560

567

574

582

589

596

603

366

376

385

394

403

413

422

431

441

450

459

468

478

487

496

506

515

524

533

543

552

561

571

580

589

598

608

617

626

636

645

654

664

673

682

691

701

710

719

729

738

747

756

766

775

784

479

491

503

515

528

540

552

564

576

588

600

613

625

637

649

661

673

685

698

710

722

734

746

758

771

783

795

807

819

831

843

856

868

880

892

904

916

928

941

953

965

977

989

1001

1013

1026

634

650

666

682

698

714

730

746

762

779

795

811

827

843

859

875

891

907

923

939

955

971

988

1004

1020

1036

1052

1068

1084

1100

1116

1132

1148

1164

1180

1196

1213

1229

1245

1261

1277

1293

1309

1325

1341

1357

845

867

888

909

931

952

974

995

1017

1038

1059

1081

1102

1124

1145

1167

1188

1209

1231

1252

1274

1295

1317

1338

1359

1381

1402

1424

1445

1467

1488

1509

1531

1552

1574

1595

1617

1638

1660

1681

1702

1724

1745

1767

1788

1810

1127

1155

1184

1213

1241

1270

1298

1327

1355

1384

1413

1441

1470

1498

1527

1556

1584

1613

1641

1670

1698

1727

1756

1784

1813

1841

1870

1898

1927

1956

1984

2013

2041

2070

2098

2127

2156

2184

2213

2241

2270

2298

2327

2356

2384

2413

1521

1560

1599

1637

1676

1714

1753

1791

1830

1869

1907

1946

1984

2023

2061

2100

2139

2177

2216

2254

2293

2331

2370

2409

2447

2486

2524

2563

2602

2640

2679

2717

2756

2794

2833

2872

2910

2949

2987

3026

3064

3103

3142

3180

3219

3257

2113

2167

2221

2274

2328

2381

2435

2488

2542

2596

2649

2703

2756

2810

2863

2917

2971

3024

3078

3131

3185

3239

3292

3346

3399

3453

3506

3560

3614

3667

3721

3774

3828

3881

3935

3989

4042

4096

4149

4203

4257

4310

4364

4417

4471

4524

2818

2889

2960

3032

3103

3175

3246

3318

3389

3461

3532

3603

3675

3746

3818

3889

3961

4032

4103

4175

4246

4318

4389

4461

4532

4604

4675

4746

4818

4889

4961

5032

5104

5175

5247

5318

5389

5461

5532

5604

5675

5747

5818

5889

5961

6032

3752

3847

3942

4037

4132

4227

4322

4417

4512

4607

4702

4797

4892

4987

5082

5177

5272

5367

5462

5557

5652

5747

5843

5938

6033

6128

6223

6318

6413

6508

6603

6698

6793

6888

6983

7078

7173

7268

7363

7458

7553

7648

7743

7838

7933

8028

4983

5109

5236

5362

5489

5615

5742

5868

5995

6121

6247

6374

6500

6627

6753

6880

7006

7133

7259

7386

7512

7638

7765

7891

8018

8144

8271

8397

8524

8650

8776

8903

9029

9156

9282

9409

9535

9662

9788

9915

10041

10167

10294

10420

10547

10673

6625

6793

6961

7129

7297

7465

7633

7801

7968

8136

8304

8472

8640

8808

8976

9144

9311

9479

9647

9815

9983

10151

10319

10487

10655

10822

10990

11158

11326

11494

11662

11830

11988

12166

12333

12501

12669

12837

13005

13173

13341

13509

13676

13844

14012

14180

8806

9029

9252

9475

9699

9922

10145

10368

10592

10815

11038

11261

11485

11708

11931

12154

12378

12601

12824

13047

13271

13494

13717

13940

14164

14387

14610

14833

15057

15280

15503

15726

15950

16173

16396

16619

16843

17066

17289

17512

17735

17959

18182

18405

18629

18852

11744

12042

12340

12637

12935

13233

13531

13828

14126

14424

14721

15019

15317

15614

15912

16210

16508

16805

17103

17400

17698

17996

18294

18591

18889

19187

19484

19782

20080

20378

20675

20973

21271

21568

21866

22164

22461

22759

23057

23354

23652

23950

24248

24545

24843

25141

0.53

0.26

0.13

0.09

0

0.75

0.37

0.18

0.12

1

0.96

0.48

0.24

0.16

2

1.25

0.62

0.31

0.21

3

1.6

0.8

0.4

0.27

4

2.2

1.1

0.5

0.37

5

3.0

1.5

0.7

0.5

6

4.0

2.0

1.0

0.67

7

5.4

2.7

1.3

0.9

8

7.1

3.6

1.8

1.2

9

9.2

4.6

2.3

1.53

10

12.1

6.0

3.0

2.0

11

16.0

8.0

4.0

2.67

12

21.4

10.7

5.3

3.57

13

28.6

14.3

7.1

4.77

14

38.6

19.3

9.6

6.43

15

53.6

26.8

13.4

8.93

16

71.4

35.7

17.8

11.9

17

Spring Rate - kg per millimetre

49

Figure DV35

Figure DV70

Figure DV140

Figure DV210

Size

95.0

47.5

23.7

15.83

18

126.4

63.2

31.6

21.07

19

168.0

84.0

42.0

28.0

20

223.2

111.6

55.8

37.2

21

297.6

148.8

74.4

49.6

22

50

Variable Spring Supports

Fig. DV35-DV70-DV140-DV210

Type A

Type B

Type C

Type D

Type E

Type H

Hole Centres Sq

Type F

Bolt Clearance

openings in casing

Type G

04/10

General Note:

Site Adjustments:

Sizes 18-22 are manufactured as a totally welded unit.

Types F, H & K

Sizes 0-17 are manufactured utilising the dimpled casing construction.

Types A, B, C & G

75mm

25mm

Support Size

0-5

6 - 14

15 - 17

18 - 20

21

22

Type K

Dimension RR

R

54

54

70

84

115

131

04/10

DV35 Table of Dimensions

Rod Case

Size Dia

Type BC

Casing

Length L

Rod Take Out

Types

Types

Thd

Depth

Type

A

Size

A, B, D, E,

C

G

M12

120

170

M12

120

M12

Type F

Type G

Loaded Length X

Type

A

Beam Section

Dimensions

Base Base Base Base Load Load Gap

W

Plt

Plt

Pad Pad

Plt

Plt

Sq Hole Bolt Thk

Thk

Sq

Crs

Sq

Type

BC

Type

D

Weight (approx) Kgs

Type

F

Type

G

Types

P

900mm

Rod

Centres

1300mm

Rod

Centres

1800mm

Rod

Centres

Min

Max

Min

Max

Min

Max

Min

Max

Min

Max

ABC

DE

12

50

12

50

12

245

280

315

350

182

217

54

182

217

224

259

2.5

11

50

12

50

12

50

12

248

283

318

353

189

224

54

188

223

224

259

2.5

11

25

50

12

50

12

50

12

269

304

339

374

205

240

54

204

239

246

281

12

20

25

76

38

76

38

76

38

254

289

324

359

192

227

54

193

228

233

268

13

20

25

76

38

76

38

76

38

266

301

336

371

202

237

54

203

238

245

280

14

130

20

25

76

38

76

38

76

38

271

306

341

376

211

246

54

212

247

250

285

15

150

10

25

51

76

38

76

38

76

38

281

316

351

386

217

252

54

223

258

255

290

14

21

M20

150

10

25

51

76

38

76

38

76

38

286

321

356

391

232

267

54

238

273

255

290

15

23

144

M20

150

10

25

51

76

38

76

38

76

38

286

321

356

391

239

274

54

245

280

262

297

10

15

24

260

190

M20

180

12

32

51

76

38

100

50

100

50

314

349

384

419

260

295

54

271

306

284

319

21

19

31

48

25

260

190

M20

180

12

32

51

76

38

100

50

100

50

297

332

367

402

273

308

54

283

318

270

305

24

22

34

53

10

25

260

190

M20

180

12

32

51

76

38

100

50

100

50

304

339

389

424

241

276

54

250

285

275

310

21

19

30

46

41

12

25

260

190

M20

180

12

38

38

100

50

125

65

125

65

321

356

406

441

251

286

54

258

293

291

326

22

20

31

51

49

46

12

25

260

190

M20

180

12

38

76

100

50

125

65

125

65

366

401

491

526

286

321

54

293

328

326

361

27

24

32

61

101

49

46

12

25

260

190

M20

180

12

38

76

100

50

125

65

125

65

375

410

500

535

292

327

54

299

334

341

376

28

25

37

63

38

101

49

51

12

25

260

190

M20

10

200

15

54

25

150

75

200

75

200

75

403

438

528

563

321

356

70

308

343

374

409

34

30

39

78

35

46

101

64

60

20

25

260

190

M20

10

200

15

54

51

150

75

200

75

200

75

433

468

573

608

353

388

70

340

375

394

429

40

35

45

92

24

35

51

111

74

67

20

25

260

190

M20

10

200

15

54

51

150

75

200

75

200

75

471

506

631

666

380

415

70

372

407

427

462

48

41

51

108

281

-27

45

60

102

80

73

20

350

283

M24

12

250

20

60

12

200

90

260

90

300

90

446

481

628

663

420

456

84

393

428

397

432

104

89

112

222

473

307

-11

50

68

114

80

79

20

350

283

M24

12

250

20

67

25

200

90

260

90

300

90

484

519

678

713

446

481

84

418

453

426

461

116

98

114

245

365

534

357

-15

55

75

114

102

86

25

350

283

M24

15

250

20

73

25

200

90

260

90

300

90

555

590

771

806

496

531

84

472

507

488

523

145

124

146

304

413

347

526

393

-58

65

84

114

102

92

25

350

283

M24

15

250

20

79

25

300

90

300

100

380

100

562

597

778

813

556

591

115

499

534

490

525

169

141

149

377

526

459

651

501

-20

65

94

127

102

98

25

350

283

M24

15

250

20

86

76

300

90

300

100

380

100

699

734

928

963

680

715

131

607

642

615

650

210

186

190

458

BC

129

128

130

200

103

25

12

18

58

32

22

20

150

113

M16

130

16

25

50

180

136

135

130

203

110

18

12

18

58

32

22

20

150

113

M16

130

16

25

120

195

152

151

142

212

126

24

12

18

58

32

22

20

150

113

M16

130

16

M12

160

180

139

138

127

197

113

24

12

18

58

32

22

20

200

139

M20

130

M12

160

190

149

148

139

209

123

26

12

18

58

32

22

20

200

139

M20

130

M12

160

200

159

158

144

214

132

21

12

18

58

32

22

20

200

139

M20

M16

180

215

167

165

151

225

138

38

16

22

58

32

27

10

20

220

144

M20

M16

180

235

182

180

156

230

158

23

16

22

58

32

27

10

20

220

144

M16

180

235

189

187

149

223

153

23

16

22

58

32

27

10

20

220

M20

240

260

203

201

162

245

166

25

20

26

63

32

32

10

25

10

M20

240

270

216

214

151

234

179

-2

20

26

63

32

32

10

11

M20

240

240

184

182

152

247

147

35

20

26

75

35

37

12

M24

240

255

198

196

152

257

157

17

30

32

75

35

13

M30

240

300

233

231

183

314

192

41

30

38

101

14

M30

240

300

239

237

192

323

198

50

30

38

15

M30

250

320

266

261

215

351

211

35

16

M36

250

360

298

293

240

376

243

16

17

M42

250

380

311

306

268

414

256

18

M48

320

360

311

303

276

423

19

M56

320

395

337

329

309

20

M64

320

460

393

388

21

M72

320

495

423

22

M80

320

620

536

51

52

DV70 Table of Dimensions

Rod Case

Size Dia

Type BC

Casing

Length L

Rod Take Out

Types

Types

Thd

Depth

Type

A

Size

A, B, D, E,

C

G

M12

120

220

M12

120

M12

Type F

Type G

Loaded Length X

Type

A

Beam Section

Dimensions

Base Base Base Base Load Load Gap

Plt

W

Plt

Pad Pad

Plt

Plt

Thk

Sq Hole Bolt Thk

Sq

Crs

Sq

900mm

Rod

Centres

Type

BC

Type

D

Weight (approx) Kgs

Type

F

Type

G

Types

04/10

1300mm

Rod

Centres

1800mm

Rod

Centres

Min

Max

Min

Max

Min

Max

Min

Max

Min

Max

ABC

DE

12

50

12

50

12

276

346

346

416

234

304

54

233

303

257

327

13

50

12

50

12

50

12

296

366

366

436

251

321

54

255

325

274

344

13

38

50

12

50

12

50

12

314

384

384

454

270

340

54

274

344

291

361

14

20

51

76

38

76

38

76

38

293

363

363

433

246

316

54

252

322

271

341

10

17

20

51

76

38

76

38

76

38

305

375

375

445

262

332

54

268

338

284

354

11

17

130

20

51

76

38

76

38

76

38

329

399

399

469

280

350

54

285

355

306

376

11

18

150

10

25

51

76

38

76

38

76

38

344

414

414

484

284

354

54

294

364

328

398

11

10

17

26

M20

150

10

25

51

76

38

76

38

76

38

367

437

437

507

308

378

54

320

390

342

412

12

12

20

29

144

M20

150

10

25

51

76

38

76

38

76

38

380

450

450

520

320

390

54

331

401

352

422

13

12

20

31

260

190

M20

180

12

32

76

76

38

100

50

100

50

395

465

465

535

337

407

54

347

417

367

437

25

23

37

56

25

260

190

M20

180

12

32

76

76

38

100

50

100

50

429

499

499

569

369

439

54

379

449

403

473

28

26

40

62

10

25

260

190

M20

180

12

32

76

76

38

100

50

100

50

402

472

487

557

313

383

54

323

393

375

445

25

28

36

57

41

12

25

260

190

M20

180

12

38

102

100

50

125

65

125

65

379

449

464

534

331

401

54

339

409

344

414

28

25

39

62

49

46

12

25

260

190

M20

180

12

38

102

100

50

125

65

125

65

470

540

595

665

396

466

54

404

474

440

510

36

33

48

80

101

49

46

12

25

260

190

M20

180

12

38

102

100

50

125

65

125

65

477

547

602

672

399

469

54

407

477

448

518

38

35

50

83

38

101

49

51

12

25

260

190

M20

10

200

15

54

102

150

75

200

75

200

75

514

584

639

709

425

495

70

417

487

476

546

44

40

53

102

35

46

101

64

60

20

25

260

190

M20

10

200

15

54

102

150

75

200

75

200

75

569

639

709

779

483

553

70

475

545

533

603

54

49

62

123

71

35

51

111

74

67

20

25

260

190

M20

10

200

15

54

102

150

75

200

75

200

75

632

702

792

862

536

606

70

528

598

583

653

67

60

72

148

395

73

45

60

102

80

73

20

350

283

M24

12

250

20

60

102

200

90

260

90

300

90

577

647

759

829

549

619

84

523

593

526

596

136

119

146

286

636

453

79

50

68

114

80

79

20

350

283

M24

12

250

20

67

102

200

90

260

90

300

90

647

717

841

911

607

677

84

580

650

590

660

157

136

163

328

561

730

535

78

55

75

114

102

86

25

350

283

M24

15

250

20

73

102

200

90

260

90

300

90

751

821

967

1037

689

759

84

663

733

686

756

204

168

204

424

648

607

786

623

39

65

84

114

102

92

25

350

283

M24

15

250

20

79

102

300

90

300

100

380

100

822

892

1038 1108

789

859

115

733

803

745

815

251

219

228

543

807

765

957

777

32

65

94

127

102

98

25

350

283

M24

15

250

20

86

102

300

90

300

100

380

100

1005 1075 1234 1304

959

1029

131

887

957

922

992

323

242

296

675

BC

181

180

149

219

150

19

12

18

58

32

22

20

150

113

M16

130

16

38

50

240

198

197

169

239

167

19

12

18

58

32

22

20

150

113

M16

130

16

38

120

260

217

216

187

257

186

17

12

18

58

32

22

20

150

113

M16

130

16

M12

160

235

193

192

166

236

162

34

12

18

58

32

22

20

200

139

M20

130

M12

160

255

209

208

178

248

178

26

12

18

58

32

22

20

200

139

M20

130

M12

160

270

227

226

202

272

196

35

12

18

58

32

22

20

200

139

M20

M16

180

280

234

232

207

281

200

36

16

22

58

32

27

10

20

220

144

M20

M16

180

305

258

256

230

304

224

34

16

22

58

32

27

10

20

220

144

M16

180

320

270

268

243

317

236

32

16

22

58

32

27

10

20

220

M20

240

330

275

273

243

326

233

61

20

26

63

32

32

10

25

10

M20

240

360

307

305

277

360

265

65

20

26

63

32

32

10

11

M20

240

305

251

249

250

345

209

93

20

26

75

35

37

12

M24

240

335

273

271

210

315

227

59

30

32

75

35

13

M30

240

395

338

336

287

418

291

76

30

38

101

14

M30

240

400

341

339

294

425

295

78

30

38

15

M30

250

415

360

355

326

462

300

98

35

16

M36

250

480

419

414

376

512

359

83

17

M42

250

545

471

466

429

575

411

18

M48

320

480

430

422

406

554

19

M56

320

545

488

480

472

20

M64

320

640

575

570

21

M72

302

735

658

22

M80

320

900

817

04/10

DV140 Table of Dimensions

Rod Case

Size Dia

Casing

Length L

Rod Take Out

Types

Types

Type BC

Thrd

Depth

Type

A

Size

Type F

Type G

Loaded Length X

Type

A

Beam Section

Dimensions

Base Base Base Base Load Load Gap

W

Plt

Plt

Pad Pad

Plt

Plt

Sq

Thk

Sq Hole Bolt Thk

Crs

Sq

Type

D

Type

F

Type

G

Types

1800mm

Rod

Centres

Min

Max

Min

Max

Min

Max

Min

Max

Min

Max

ABC

DE

50

12

421

561

491

631

387

527

54

380

520

400

540

16

12

50

12

465

605

535

675

422

562

54

423

563

443

583

18

50

12

50

12

494

634

582

722

460

600

54

461

601

470

610

10

20

38

76

38

76

38

449

589

519

659

413

553

54

415

555

423

563

15

23

76

38

76

38

76

38

491

631

561

701

445

585

54

447

587

467

607

11

10

17

26

51

76

38

76

38

76

38

524

664

594

734

480

620

54

482

622

500

640

12

11

18

26

25

51

76

38

76

38

76

38

536

676

606

746

480

620

54

489

629

512

652

18

17

27

40

10

25

51

76

38

76

38

76

38

596

736

666

806

528

668

54

538

678

570

710

22

21

32

47

150

10

25

51

76

38

76

38

76

38

602

742

672

812

552

692

54

562

702

580

720

27

22

33

58

180

12

32

76

76

38

100

50

100

50

619

759

689

829

571

711

54

576

716

589

729

40

38

57

85

M20

180

12

32

76

76

38

100

50

100

50

683

823

753

893

634

774

54

638

778

657

797

47

45

64

100

190

M20

180

12

32

76

76

38

100

50

100

50

580

720

665

805

523

663

54

527

667

552

692

40

39

56

86

260

190

M20

180

12

38

102

100

50

125

65

125

65

582

722

667

807

556

696

54

559

699

552

692

45

43

61

97

25

260

190

M20

180

12

38

102

100

50

125

65

125

65

755

895

880

1020

687

827

54

689

829

725

865

61

59

78

130

12

25

260

190

M20

180

12

38

102

100

50

125

65

125

65

768

908

893

1033

693

833

54

696

836

734

874

65

62

81

138

51

12

25

260

190

M20

10

200

15

54

102

150

75

200

75

200

75

783

923

908

1048

721

861

70

702

842

753

893

72

68

86

155

64

60

20

25

260

190

M20

10

200

15

54

102

150

75

200

75

200

75

908

1048 1048 1188

838

978

70

819

959

873

1013

93

86

103

217

111

74

67

20

25

260

190

M20

10

200

15

54

102

150

75

200

75

200

75

1033 1173 1193 1333

943

1083

70

924

1064

990

1130

118

106

124

247

60

102

80

73

20

350

283

M24

12

250

20

60

102

200

90

260

90

300

90

961

925

1065

84

897

1037

905

1045

219

203

241

452

50

68

114

80

79

20

350

283

M24

12

250

20

67

102

200

90

260

90

300

90

1098 1238 1292 1432 1040 1180

84

1011 1151 1044 1184

259

235

274

531

89

55

75

114

102

86

25

350

283

M24

15

250

20

73

102

200

90

260

90

300

90

1267 1407 1483 1623 1205 1345

84

1177 1317 1202 1347

351

315

357

714

1315 1241 1231 1178 1357 1196

30

65

84

114

102

92

25

350

283

M24

15

250

20

79

102

300

90

300

100

380

100

1393 1533 1609 1749 1386 1526

115

1310 1450 1319 1459

413

370

382

864

1640 1550 1540 1481 1673 1504

65

94

127

102

98

25

350

283

M24

15

250

20

86

102

300

90

300

100

380

100

1721 1861 1950 2090 1710 1850

131

1620 1760 1631 1771

549

504

524

1137

A, B, D, E,

C

G

M12

120

370

M12

120

M12

900mm

Rod

Centres

1300mm

Rod

Centres

Type

BC

Weight (approx) Kgs

BC

329

328

294

364

294

14

12

18

58

32

22

20

150

113

M16

130

16

38

50

12

50

12

405

363

362

338

408

328

23

12

18

58

32

22

20

150

113

M16

130

16

38

50

12

50

120

445

401

400

367

455

366

12

12

18

58

32

22

20

150

113

M16

130

16

38

50

12

M12

160

400

354

353

322

392

318

25

12

18

58

32

22

20

200

139

M20

130

20

51

76

M12

160

430

386

385

364

434

350

37

12

18

58

32

22

20

200

139

M20

130

20

51

M12

160

465

421

420

397

467

385

35

12

18

58

32

22

20

200

139

M20

130

20

M16

180

470

424

422

399

473

386

38

16

22

58

32

27

10

20

220

144

M20

150

10

M16

180

520

472

470

459

533

434

48

16

22

58

32

27

10

20

220

144

M20

150

M16

180

540

496

494

465

539

458

34

16

22

58

32

27

10

20

220

144

M20

M20

240

555

494

496

467

550

452

60

20

26

63

32

32

10

25

260

190

M20

10

M20

240

615

562

560

531

614

516

64

20

26

63

32

32

10

25

260

190

11

M20

240

505

450

448

428

523

404

71

20

26

75

35

37

10

25

260

12

M24

240

545

488

486

413

518

438

52

30

32

75

35

41

12

25

13

M30

240

675

618

616

572

703

568

81

30

38

101

49

46

12

14

M30

240

685

624

622

585

716

574

84

30

38

101

49

46

15

M30

250

695

640

635

595

731

580

87

35

38

101

49

16

M36

250

815

757

752

715

851

698

87

35

46

101

17

M42

250

930

862

857

830

976

802

87

35

51

18

M48

320

850

795

787

790

938

750

87

45

19

M56

320

965

911

903

923

1087

866

110

20

M64

320

1145 1080 1075 1077 1246 1031

21

M72

320

22

M80

320

1101 1143 1283

53

54

DV 210 Table of Dimensions

Rod Case

Size Dia

Size

Casing

Length L

Rod Take Out

Types

Types

Type BC

Thrd

Depth

Type

A

Type F

Type G

Dimensions

Loaded Length X

Type

A

Beam Section

Base Base Base Base Load Load Gap

Plt

Plt

Plt

Plt

Pad Pad

W

Sq Hole Bolt Thk

Sq

Thk

Crs

Sq

Type

BC

Type

D

Weight (approx) Kgs

Type

F

Type

G

Types

04/10

900mm

Rod

Centres

1300mm

Rod

Centres

1800mm

Rod

Centres

Min

Max

Min

Max

Min

Max

Min

Max

Min

Max

ABC

DE

40

50

12

50

12

50

12

592

802

662

872

550

760

54

560

770

571

781

12

19

16

40

50

12

50

12

50

12

652

862

722

932

605

815

54

620

830

640

850

12

23

16

40

50

12

50

12

50

12

697

907

767

977

660

870

54

680

890

699

909

10

10

13

26

130

20

50

76

38

76

38

76

38

627

837

697

907

590

800

54

610

820

622

832

12

13

20

29

130

20

50

76

38

76

38

76

38

687

897

757

967

640

850

54

655

865

677

887

16

13

23

35

M20

130

20

50

76

38

76

38

76

38

737

947

807

1017

695

905

54

710

920

729

939

17

15

25

35

144

M20

150

10

25

50

76

38

76

38

76

38

742

952

813

1023

690

900

54

710

920

733

943

25

22

37

54

220

144

M20

150

10

25

50

76

38

76

38

76

38

827

1037

898

1108

760

970

54

785

995

813

1023

32

30

44

65

20

220

144

M20

150

10

25

50

76

38

76

38

76

38

847

1057

918

1128

795