Documente Academic

Documente Profesional

Documente Cultură

Nano Fibers Applications

Încărcat de

Olga IevtushenkoDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Nano Fibers Applications

Încărcat de

Olga IevtushenkoDrepturi de autor:

Formate disponibile

TECHNICAL UNIVERSITY OF LIBEREC

FACULTY OF TEXTILE ENGINEERING

ELECTROSTATIC SPINNING OF NANOFIBERS

David Luk

4/4

TECHNICAL UNIVERSITY OF LIBEREC

FACULTY OF TEXTILE ENGINEERING

Applications: Composites Filtration Separation membranes Biomedicine artificial organs tissue engineering blood vessels drug delivery systems wound dressing breathing masks

TECHNICAL UNIVERSITY OF LIBEREC

FACULTY OF TEXTILE ENGINEERING

Applications: Protective clothing Solar sails, light sails, and mirrors for use in space Application of pesticides to plants Nanoconductors, nanoelectric applications as field effect transistors and ultra-small antennas Chemical catalytic apparatus Hydrogen storage tank for fuel cell

TECHNICAL UNIVERSITY OF LIBEREC

FACULTY OF TEXTILE ENGINEERING

Composite applications Composites may be reinforced by fibers. With these reinforcements, the composite materials can provide superior structural properties such as high modulus and strength to weight ratios, which generally cannot be achieved by other engineered monolithic materials alone. Nanofibers can have even better mechanical properties than micro fibers of the same materials, and hence the superior structural properties of nanocomposites can be anticipated.

TECHNICAL UNIVERSITY OF LIBEREC

FACULTY OF TEXTILE ENGINEERING

Composite applications

Carbon nanofibers may be created of polymer precursors, such as PAN or PVA.

TECHNICAL UNIVERSITY OF LIBEREC

FACULTY OF TEXTILE ENGINEERING

Composite applications

The advantage of nanofibrous composites is that they are transparent. If there is a difference in refractive indices between fiber and matrix, the resulting composite becomes opaque or nontransparent due to light scattering. This limitation, however, can be circumvented when the fiber diameters become significantly smaller than the wavelength of visible light

TECHNICAL UNIVERSITY OF LIBEREC

FACULTY OF TEXTILE ENGINEERING

Filtration applications

Filtration is essential for many industries. Fiber materials used for filtration media offer an advantage of high filtration efficiency and low air resistance. Currently, nonwovens created by Meltblown and Spunbond or their combinations are used for filters.

Spunbond meltblown spunbond composite nonwoven

TECHNICAL UNIVERSITY OF LIBEREC

FACULTY OF TEXTILE ENGINEERING

Filtration applications

Filtration efficiency is closely related to the fiber diameter. Electrospinning technology is able to produce fibers with diameter in submicron range and created materials can filter off dangerous bacterias and viruses but also the tobacco smoke and their size is noted in table below.

EXAMPLES OF BIOLOGICAL STRUCTURES Leukocytes Bacteria Virus Protein DNA (width) Atom DIMENSION IN NANOMETERS (nm) 10,000 nm 1,000 - 10,000 nm 75 - 100 nm 5-50 nm 2 nm 0.1 nm

Examples of biological structures and their size

TECHNICAL UNIVERSITY OF LIBEREC

FACULTY OF TEXTILE ENGINEERING

Filtration applications

Nanofibers on a wetlaid cellulose substrate for air filtration

Cross section view of nanofiber web on spunbond substrate

TECHNICAL UNIVERSITY OF LIBEREC

FACULTY OF TEXTILE ENGINEERING

Filtration applications

Filtration effectivity for different area density of nanofibers layer in the spunbond or meltblown textile basis.

100 90 80 70 60 50 40 30 20 10 0 0 0,5 1 1,5 2 2,5 3 meltblow n w ith nanofibers spunbond w ith nanofibers meltblow n only spunbond only Area density (gsm)

Efficiency (%)

Pressure drop for different area density of nanofibers layer in the spunbond or meltblown textile basis.

1600 1400 1200 1000 800 600 400 200 0 0 1 2 3

meltblown with nanofibers spunbond with nanofibers meltblown only

Area density (gsm)

Pressure drop (Pa)

TECHNICAL UNIVERSITY OF LIBEREC

FACULTY OF TEXTILE ENGINEERING

Filtration applications

Picture shows a composite media sample that has been exposed to a submicron sodium chloride contaminant, with particles in the size range of 0.01 to 0.5 microns. By replacing the salt crystals with functional materials, such as pharmaceuticals for drug delivery applications, or antimicrobial chemistry for wipes and clothing applications, new uses for nanofiber webs as a high surface area functional chemistry delivery structures can be imagined

TECHNICAL UNIVERSITY OF LIBEREC

FACULTY OF TEXTILE ENGINEERING

Filtration applications

Filtration properties of nanofibers may be also evaluated visually by the help of scanning electron microscopy of nanofiber media exposed to contamination

Cellulose filter media with ISO Fine Test dust loading (left). Nanofiber filter media with ISO Fine Test Dust loading (right)

TECHNICAL UNIVERSITY OF LIBEREC

FACULTY OF TEXTILE ENGINEERING

Filtration applications

Donaldson Company Inc. developed filters containing nanofiber layers for air filtration

Commercial air filtration cartridge using nanofiber filter media

TECHNICAL UNIVERSITY OF LIBEREC

FACULTY OF TEXTILE ENGINEERING

Filtration applications

Polymer nanofibers can also be electrostatically charged to modify the ability of electrostatic attraction of particles without increase in pressure drop to further improve filtration efficiency. In this regard, the electrospinning process has been shown to integrate the spinning and charging of polymer into nanofibers in one step. In addition to fulfilling the more traditional purpose in filtration, the nanofiber membranes fabricated from some specific polymers or coated with some selective agents can also be used as, for example, molecular filters. For instance, such filters can be applied to the detection and filtration of chemical and biological weapon agents.

TECHNICAL UNIVERSITY OF LIBEREC

FACULTY OF TEXTILE ENGINEERING

Biomedical applications

To this area belongs the tissue engineering, templates for cell growth and medical prostheses especially vascular grafts. From a biological viewpoint, almost all of the human tissues and organs are deposited in nanofibrous forms or structures. Examples include: bone, dentin, collagen, cartilage, and skin. All of them are characterized by well organized hierarchical fibrous structures realigning in nanometer scale.

TECHNICAL UNIVERSITY OF LIBEREC

FACULTY OF TEXTILE ENGINEERING

Biomedical applications - prostheses

Polymer nanofibers fabricated via electrospinning have been proposed for a number of soft tissue prostheses applications such as blood vessel, vascular, breast, etc. In addition, electrospun biocompatible polymer nanofibers can also be deposited as a thin porous film onto a hard tissue prosthetic device designed to be implanted into the human body. This coating film with gradient fibrous structure works as an interphase between the prosthetic device and the host tissues, and is expected to efficiently reduce the stiffness mismatch at the tissue/device interphase and hence prevent the device failure after the implantation.

TECHNICAL UNIVERSITY OF LIBEREC

FACULTY OF TEXTILE ENGINEERING

Biomedical applications prostheses bones

Bone is a composite made when proteins in collagen fibers coax calcium, phosphate, and hydroxide ions in solution to condense atop the fibers and grow into a rigid structure of tiny crystallites of hydroxyapatite all aligned in the same direction. Hydroxyapatite gives bone its toughness. Although research teams have induced hydroxyapatite crystallites to grow atop other materials such as polymers and they can assume the same structure as in the real bone.

TECHNICAL UNIVERSITY OF LIBEREC

FACULTY OF TEXTILE ENGINEERING

Biomedical applications prostheses blood vessels

Traditional heart bypass surgeries require using veins from the leg to replace damaged blood vessels. Using a nanotechnology it would be possible to use artificial blood vessels grown in a laboratory. After the scaffold is spun, smooth muscle cells are seeded or placed on its surface in a laboratory. The cells grow and within three-to-six weeks the tissue-engineered blood vessel is ready to implant.

Artificial blood vessel

TECHNICAL UNIVERSITY OF LIBEREC

FACULTY OF TEXTILE ENGINEERING

Biomedical applications tissue template

Human cells can attach and organize well around fibers with diameters smaller than those of the cells. In this regard, nanoscale fibrous scaffolds can provide an optimal template for cells to seed, migrate, and grow. A successful regeneration of biological tissues and organs calls for the development of fibrous structures with fiber architectures beneficial for cell deposition and cell proliferation. Of particular interest in tissue engineering is the creation of reproducible and biocompatible three-dimensional scaffolds for cell ingrowth resulting in bio-matrix composites for various tissue repair and replacement procedures.

TECHNICAL UNIVERSITY OF LIBEREC

FACULTY OF TEXTILE ENGINEERING

Biomedical applications antiadhesive membranes

There was created a nanofiber membrane that serves for prevention of sticking of a tissue during the healing process. It degrades in the body such as biodegradable sutures in the course of time. This anti-adhesive material is prepared by electrospinning. The experimental team in its previous work found that surgical adhesion of the scar tissue formed in the abdominal cavity or pelvis in the healing process after surgery was significant medical problem causing for example infertility or viscera impaction.

TECHNICAL UNIVERSITY OF LIBEREC

FACULTY OF TEXTILE ENGINEERING

Biomedical applications drug delivery systems

The smaller the dimensions of the drug and the coating material required to encapsulate the drug, the better the drug to be absorbed by human being. Drug delivery with polymer nanofibers is based on the principle that dissolution rate of a particulate drug increases with increasing surface area of both the drug and the corresponding carrier if needed.

(1) drug as particles attached to the surface of the carrier which is in the form of nanofibers, (2) both drug and carrier are nanofiber-form, hence the end product will be the two kinds of nanofibers interlaced together, (3) the blend of drug and carrier materials integrated into one kind of fibers containing both components, and (4) the carrier material is electrospun into a tubular form in which the drug particles are encapsulated.

TECHNICAL UNIVERSITY OF LIBEREC

FACULTY OF TEXTILE ENGINEERING

Biomedical applications wound dressing

Polymer nanofibers can also be used for the treatment of wounds or burns of a human skin, as well as designed for haemostatic devices with some unique characteristics. With the aid of electric field, fine fibers of biodegradable polymers can be directly sprayed/spun onto the injured location of skin to form a fibrous mat dressing which can let wounds heal by encouraging the formation of normal skin growth and eliminate the formation of scar tissue which would occur in a traditional treatment. Nonwoven nanofibrous membrane mats for wound dressing usually have pore sizes ranging from 500 nm to 1m, small enough to protect the wound from bacterial penetration via aerosol particle capturing mechanisms. High surface area of 5100 m2/g is extremely efficient for fluid absorption and dermal delivery.

TECHNICAL UNIVERSITY OF LIBEREC

FACULTY OF TEXTILE ENGINEERING

Biomedical applications wound dressing

Formation of wound dressing on the skin

TECHNICAL UNIVERSITY OF LIBEREC

FACULTY OF TEXTILE ENGINEERING

Biomedical applications respirators

In age of SARS, one of the most important things the world needs is better respirators.

TECHNICAL UNIVERSITY OF LIBEREC

FACULTY OF TEXTILE ENGINEERING

Biomedical applications respirators

Typical respirators are uncomfortable when worn for long periods. But nanofiber material for a mask that would be comprised of just less than 2 percent material, more than 98 percent air making for a more comfortable and efficient fit. Current respirators are composed of 90% of glass microfibers with average diameter around 500 nanometers, but nanofibrous respirators are made of polymer nanofibers with diameter in range of 20 to 30 nanometers. Small size of fiber material is important because the size of bacterias is in order of micrometers. Viruses are even smaller, most of them are in nanometer range.

TECHNICAL UNIVERSITY OF LIBEREC

FACULTY OF TEXTILE ENGINEERING

Biomedical applications protective clothing

The protective clothing in military is mostly expected to help maximize the survivability, sustainability and combat effectiveness of the individual soldier system against extreme weather conditions, ballistics and NBC (nuclear, biological, and chemical) warfare. In peace ages, breathing apparatus and protective clothing with the particular function of against chemical warfare agents such as sarin, soman, tabun and mustard gas from inhalation and absorption through the skin become special concern for combatants in conflicts and civilian populations in terrorist attacks.

TECHNICAL UNIVERSITY OF LIBEREC

FACULTY OF TEXTILE ENGINEERING

Biomedical applications protective clothing

Electrospinning results in nanofibers laid down in a layer that has high porosity but very small pore size, providing good resistance to the penetration of chemical harm agents in aerosol form. Preliminary investigations have indicated that compared to conventional textiles the electrospun nanofibers present both minimal impedance to moisture vapor diffusion and extremely efficiency in trapping aerosol particles as well as show strong promises as ideal protective clothing.

TECHNICAL UNIVERSITY OF LIBEREC

FACULTY OF TEXTILE ENGINEERING

Biomedical applications cosmetics

The current skin care masks applied as topical creams, lotions or ointments may include dusts or liquid sprays which may be more likely than fibrous materials to migrate into sensitive areas of the body such as the nose and eyes where the skin mask is being applied to the face. Electrospun polymer nanofibers have been attempted as a cosmetic skin care mask for the treatment of skin healing, skin cleansing, or other therapeutical or medical properties.

TECHNICAL UNIVERSITY OF LIBEREC

FACULTY OF TEXTILE ENGINEERING

Electrical a optical applications

Conductive nanofibers are expected to be used in the fabrication of tiny electronic devices or machines such as Schottky junctions, sensors and actuators. The rate of electrochemical reactions is proportional to the surface area of the electrode, conductive nanofibrous membranes are also quite suitable for using as porous electrode in developing high performance battery. Conductive (in terms of electrical, ionic and photoelectric) membranes also have potential for applications including electrostatic dissipation, corrosion protection, electromagnetic interference shielding, photovoltaic device and for LCD devices where the fiber size is used for determining sensitivities of the refractive index differences between the liquid crystal material and the fibers and consequently governs the transmisivity of the device.

TECHNICAL UNIVERSITY OF LIBEREC

FACULTY OF TEXTILE ENGINEERING

Solar sails

A solar sail is a spacecraft with a large, lightweight mirror attached to it that moves by being pushed by light reflecting off of the mirror instead of rockets. Nanofiber layers have a very low area weight and that is the reason why they are interesting in that area of research. Solar sails work off of the principal that light has momentum. When light strikes an object (incident light), it transfers its momentum to that object. When light is reflected, there is a second momentum exchange with the object. The total force on the object is the vector sum of the forces from the incident and reflected light.

TECHNICAL UNIVERSITY OF LIBEREC

FACULTY OF TEXTILE ENGINEERING

Solar sails

Solar sail

TECHNICAL UNIVERSITY OF LIBEREC

FACULTY OF TEXTILE ENGINEERING

Other applications

Nanofibers from polymers with piezoelectric effect such as polyvinyliden fluoride will make the resultant nanofibrous devices piezoelectric. Electrospun polymer nanofibers could also be used in developing functional sensors with the high surface area of nanofibers facilitating the sensitivity. Highly sensitive optical sensors based on fluorescent electrospun polymer nanofiber films were also recently reported .

TECHNICAL UNIVERSITY OF LIBEREC

FACULTY OF TEXTILE ENGINEERING

Other applications

Nanoscale tubes made from various materials including carbon, ceramics, metals, and polymers are important in many industry fields. Ultrafine fibers prepared from electrospinning can be used as templates to develop the various nanotubes. Another possible applications include device for electro-magnetic shielding, material preventing composite delamination, device with liquid crystals, carriers of chemical catalyzer and application of pesticides to plants.

S-ar putea să vă placă și

- Electro-Static Spinning: HistoryDocument6 paginiElectro-Static Spinning: Historyila03Încă nu există evaluări

- Antimicrobial Finishing of Textiles For Protective ClothingDocument3 paginiAntimicrobial Finishing of Textiles For Protective ClothingFatema QutbiÎncă nu există evaluări

- Nanofibers The Novel TechnologyDocument9 paginiNanofibers The Novel TechnologyIJRASETPublicationsÎncă nu există evaluări

- Ampicilne PDFDocument10 paginiAmpicilne PDFamatoryfictionliteraÎncă nu există evaluări

- A Technical Seminar Report ON "Implantable Electronics"Document24 paginiA Technical Seminar Report ON "Implantable Electronics"Seshu GuttapalliÎncă nu există evaluări

- Technical Seminar Final ReportDocument11 paginiTechnical Seminar Final ReportPradeep B RÎncă nu există evaluări

- Pplications OF Anofibers: by - Pranshul Jain 2009TT10814Document18 paginiPplications OF Anofibers: by - Pranshul Jain 2009TT10814Arpit AwasthiÎncă nu există evaluări

- Nanotechnology in Vascular Tissue Engineering FromDocument7 paginiNanotechnology in Vascular Tissue Engineering FromMadalina CalcanÎncă nu există evaluări

- Application of Nanotechnology in TextileDocument34 paginiApplication of Nanotechnology in Textileparthjoshi91Încă nu există evaluări

- Development and Characterization of Novel Electrospun Meshes For Hernia RepairDocument10 paginiDevelopment and Characterization of Novel Electrospun Meshes For Hernia Repairanon_883477356Încă nu există evaluări

- Non WovenDocument7 paginiNon WovenCarlos Ernesto Aguilar LópezÎncă nu există evaluări

- Agra WalDocument11 paginiAgra WalRODHIANSYAH DJAYASINGAÎncă nu există evaluări

- G STS - Lesson 3.2Document5 paginiG STS - Lesson 3.2IkeeÎncă nu există evaluări

- Nonotechnology in TextilesDocument45 paginiNonotechnology in TextilesjayantverÎncă nu există evaluări

- Slide 3Document9 paginiSlide 3AL SathvikaÎncă nu există evaluări

- Paper 8679Document14 paginiPaper 8679IJARSCT JournalÎncă nu există evaluări

- Nano TechnologyDocument26 paginiNano TechnologyanilÎncă nu există evaluări

- Nano 0101 15Document17 paginiNano 0101 15Muhammad Ilyas ArdiansyahÎncă nu există evaluări

- Bio NanotechnologyDocument9 paginiBio Nanotechnologybarakota366Încă nu există evaluări

- Mid Term Report - 2Document13 paginiMid Term Report - 2vermashivam679Încă nu există evaluări

- Use of Nanotechnology in Technical TextilesDocument12 paginiUse of Nanotechnology in Technical TextilesNaimul HasanÎncă nu există evaluări

- IJN 2006 1 (1) VasitaDocument16 paginiIJN 2006 1 (1) VasitarvcmlaÎncă nu există evaluări

- Nano TechnologyDocument21 paginiNano TechnologyheroÎncă nu există evaluări

- New Orthopaedic BiomaterialDocument2 paginiNew Orthopaedic BiomaterialArmen MalawaniÎncă nu există evaluări

- Nanobionics Lect 2Document15 paginiNanobionics Lect 2Muhammad Sadiq NaseerÎncă nu există evaluări

- Material Science and Metallurgy SeminarDocument28 paginiMaterial Science and Metallurgy SeminarRatan Sadanandan O MÎncă nu există evaluări

- 0040517520932230Document18 pagini0040517520932230engrkskÎncă nu există evaluări

- The Nano World A. DefinitionDocument6 paginiThe Nano World A. DefinitionSavy CruzÎncă nu există evaluări

- Use of Electrospinning Technique For Biomedical ApplicationsDocument19 paginiUse of Electrospinning Technique For Biomedical ApplicationsAnne FernandezÎncă nu există evaluări

- Nanofiber Nonwovens: Raghavendra R Hegde, Atul Dahiya, M. G. KamathDocument9 paginiNanofiber Nonwovens: Raghavendra R Hegde, Atul Dahiya, M. G. KamathMuhammad YusofÎncă nu există evaluări

- Nanofibers and Their Applications in Tissue Engineering: Rajesh Vasita Dhirendra S KattiDocument16 paginiNanofibers and Their Applications in Tissue Engineering: Rajesh Vasita Dhirendra S KattiAlex John Denoga AbandoÎncă nu există evaluări

- Project Proposal For For Masters Thesis in Wound Care ProductsDocument3 paginiProject Proposal For For Masters Thesis in Wound Care Productssins1984100% (2)

- New Sensors and Processing ChainDe la EverandNew Sensors and Processing ChainJean-Hugh ThomasÎncă nu există evaluări

- Effect of Collector On Electrospinning To Fabricate Aligned NanofiberDocument40 paginiEffect of Collector On Electrospinning To Fabricate Aligned Nanofiberen_samaraÎncă nu există evaluări

- Materials Today Communications: Judith Vergara-Figueroa, Serguei Alejandro-Martin, Fabiola Cerda-Leal, William GacitúaDocument12 paginiMaterials Today Communications: Judith Vergara-Figueroa, Serguei Alejandro-Martin, Fabiola Cerda-Leal, William GacitúaWalter Ricardo BritoÎncă nu există evaluări

- Nano World ModuleDocument6 paginiNano World Modulecarabacanmaryjane9Încă nu există evaluări

- Tencelcotton Blends On Knitted FabricDocument9 paginiTencelcotton Blends On Knitted FabriclfomlfomÎncă nu există evaluări

- Prototypes of Textile Sensors Made by Printing TechniqueDocument5 paginiPrototypes of Textile Sensors Made by Printing TechniqueEwa SÎncă nu există evaluări

- 2005 - CS PEO Cellular CompatibilityDocument9 pagini2005 - CS PEO Cellular CompatibilityTiÎncă nu există evaluări

- Biofabrication One-StopmicrofiberspinningDocument9 paginiBiofabrication One-StopmicrofiberspinningSujon mollaÎncă nu există evaluări

- Nanotechnology: Prepared By: Pathan Mohsin M 0643 Purohit Jigar Patel SanjayDocument22 paginiNanotechnology: Prepared By: Pathan Mohsin M 0643 Purohit Jigar Patel Sanjay816623Încă nu există evaluări

- Nano Technology in Textiles A ReviewDocument6 paginiNano Technology in Textiles A ReviewMohammed Atiqul Hoque Chowdhury100% (1)

- Nanotechnology: Presented By, Faizal.I Guided By, Nisha.K.JDocument30 paginiNanotechnology: Presented By, Faizal.I Guided By, Nisha.K.JRaseem ShaÎncă nu există evaluări

- Nanopatterning and Bioprinting in Orthopedic Surgery: Felasfa M. Wodajo,, Adam E. JakusDocument13 paginiNanopatterning and Bioprinting in Orthopedic Surgery: Felasfa M. Wodajo,, Adam E. JakusJavier Andres Munoz ChavesÎncă nu există evaluări

- Nikita Seth IT3 SEM (439/08Document14 paginiNikita Seth IT3 SEM (439/08Nikita SethÎncă nu există evaluări

- Method 2Document12 paginiMethod 2JaisonÎncă nu există evaluări

- Materials Science and Engineering C: Stephen R. Baker, Soham Banerjee, Keith Bonin, Martin GutholdDocument10 paginiMaterials Science and Engineering C: Stephen R. Baker, Soham Banerjee, Keith Bonin, Martin GutholdJabid LoteroÎncă nu există evaluări

- Synthesis and Applications of Electrospun NanofibersDe la EverandSynthesis and Applications of Electrospun NanofibersÎncă nu există evaluări

- H ProgramDocument18 paginiH ProgramRawa OmarÎncă nu există evaluări

- Optical Fibers For Smart Clothing & Technical Textile ApplicationsDocument14 paginiOptical Fibers For Smart Clothing & Technical Textile Applicationsm.v.naidu.Încă nu există evaluări

- Biomedical TextileDocument19 paginiBiomedical TextileBetemariam limenewuÎncă nu există evaluări

- Antibacterial Effect of Nanosized Silver Colloidal Solution On Textile FabricsDocument6 paginiAntibacterial Effect of Nanosized Silver Colloidal Solution On Textile Fabricsapi-3733260Încă nu există evaluări

- 006 Na NotecDocument25 pagini006 Na NotecsanthiyaperemelÎncă nu există evaluări

- tmp597F TMPDocument6 paginitmp597F TMPFrontiersÎncă nu există evaluări

- Nanofibers in Drug Delivery An OverviewDocument19 paginiNanofibers in Drug Delivery An Overviewnitesh vyasÎncă nu există evaluări

- Tissue MaterialDocument10 paginiTissue MaterialMelis Nur YılmazÎncă nu există evaluări

- Research Article: Design and Fabrication of Smart Diapers With Antibacterial YarnDocument10 paginiResearch Article: Design and Fabrication of Smart Diapers With Antibacterial Yarnelvis bellidoÎncă nu există evaluări

- NanomaterialsDocument11 paginiNanomaterialsFatmaÎncă nu există evaluări

- Szczesna-Antczak Et Al 2013Document5 paginiSzczesna-Antczak Et Al 2013rafacpereiraÎncă nu există evaluări

- CHE 425 Ch5 PDFDocument52 paginiCHE 425 Ch5 PDFTaniadi SuriaÎncă nu există evaluări

- Cost Estimation TT508Document16 paginiCost Estimation TT508Olga IevtushenkoÎncă nu există evaluări

- Chapter3 CropDocument43 paginiChapter3 CropOlga IevtushenkoÎncă nu există evaluări

- Cost Model MMADocument312 paginiCost Model MMAOlga Ievtushenko100% (1)

- Nurses Guide To Family Assessment and InterventionDocument9 paginiNurses Guide To Family Assessment and InterventionKaye CorÎncă nu există evaluări

- Claudia Maienborn, Semantics, 381Document34 paginiClaudia Maienborn, Semantics, 381robert guimaraesÎncă nu există evaluări

- Hydraulic Excavator: Engine WeightsDocument28 paginiHydraulic Excavator: Engine WeightsFelipe Pisklevits LaubeÎncă nu există evaluări

- MVC Training Course Prerequisite: WWW - Focustech.InDocument2 paginiMVC Training Course Prerequisite: WWW - Focustech.InLakshman Samanth ReddyÎncă nu există evaluări

- Sullivan's Interpersonal TheoryDocument27 paginiSullivan's Interpersonal TheoryJezalen GonestoÎncă nu există evaluări

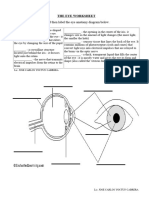

- The Eye WorksheetDocument3 paginiThe Eye WorksheetCally ChewÎncă nu există evaluări

- Notes 3 Mineral Dressing Notes by Prof. SBS Tekam PDFDocument3 paginiNotes 3 Mineral Dressing Notes by Prof. SBS Tekam PDFNikhil SinghÎncă nu există evaluări

- NRNP PRAC 6665 and 6675 Focused SOAP Note ExemplarDocument6 paginiNRNP PRAC 6665 and 6675 Focused SOAP Note ExemplarLogan ZaraÎncă nu există evaluări

- Syllabus: Cambridge IGCSE (9-1) Art & Design 0989Document27 paginiSyllabus: Cambridge IGCSE (9-1) Art & Design 0989Jashan LoombaÎncă nu există evaluări

- Quiz EditedDocument6 paginiQuiz EditedAbigail LeronÎncă nu există evaluări

- Chapter 5: Current and Resistance: 5.1 The Motion of Electric ChargeDocument11 paginiChapter 5: Current and Resistance: 5.1 The Motion of Electric Chargeayunna ayunniÎncă nu există evaluări

- Reaffirmed 1998Document13 paginiReaffirmed 1998builconsÎncă nu există evaluări

- Second Quarter Lesson 4Document7 paginiSecond Quarter Lesson 4Jomarie PauleÎncă nu există evaluări

- Elad Shapira - Shall We Play A Game - Lessons Learned While Playing CoreWars8086Document61 paginiElad Shapira - Shall We Play A Game - Lessons Learned While Playing CoreWars8086james wrightÎncă nu există evaluări

- EDL E-Catalogue 2021-22 With ApticoDocument78 paginiEDL E-Catalogue 2021-22 With Apticotkteetopoi1Încă nu există evaluări

- Addpac AP1000 DSDocument2 paginiAddpac AP1000 DSEnrique RamosÎncă nu există evaluări

- Zanussi Parts & Accessories - Search Results3 - 91189203300Document4 paginiZanussi Parts & Accessories - Search Results3 - 91189203300Melissa WilliamsÎncă nu există evaluări

- School Form 8 Grade 3Document20 paginiSchool Form 8 Grade 3Mimi Ng PinasÎncă nu există evaluări

- Visvesvaraya Technological University: Jnana Sangama, Belgavi-590018, Karnataka, INDIADocument7 paginiVisvesvaraya Technological University: Jnana Sangama, Belgavi-590018, Karnataka, INDIAShashi KaranÎncă nu există evaluări

- Adolescence Problems PPT 1Document25 paginiAdolescence Problems PPT 1akhila appukuttanÎncă nu există evaluări

- Case StarbucksDocument3 paginiCase StarbucksAbilu Bin AkbarÎncă nu există evaluări

- VDA Volume Assessment of Quality Management Methods Guideline 1st Edition November 2017 Online-DocumentDocument36 paginiVDA Volume Assessment of Quality Management Methods Guideline 1st Edition November 2017 Online-DocumentR JÎncă nu există evaluări

- Project 2 Analysis of Florida WaterDocument8 paginiProject 2 Analysis of Florida WaterBeau Beauchamp100% (1)

- Enterprise GRC Solutions 2012 Executive SummaryDocument5 paginiEnterprise GRC Solutions 2012 Executive SummarySanath FernandoÎncă nu există evaluări

- Psyche Finals: Trans 2: Psychotic Disorder: SchizophreniaDocument4 paginiPsyche Finals: Trans 2: Psychotic Disorder: SchizophreniajisooÎncă nu există evaluări

- Interventional Studies 2Document28 paginiInterventional Studies 2Abdul RazzakÎncă nu există evaluări

- Tugas Bahasa Inggris: ButterflyDocument4 paginiTugas Bahasa Inggris: ButterflyRiyadi TeguhÎncă nu există evaluări

- TVL-SMAW 12 - Week 4 - Lesson 1 - Concept of Welding Codes and StandardsDocument9 paginiTVL-SMAW 12 - Week 4 - Lesson 1 - Concept of Welding Codes and StandardsNelPalalonÎncă nu există evaluări

- Centric WhitepaperDocument25 paginiCentric WhitepaperFadhil ArsadÎncă nu există evaluări

- Assignment # 1 POMDocument10 paginiAssignment # 1 POMnaeemÎncă nu există evaluări